Production method of close-joint grain-connection super-wear-resistant diamond glaze marble ceramic tile and ceramic tile

A production method and super wear-resistant technology, applied in the field of ceramic tiles, can solve the problems of uneven gaps in the joints, affecting the decorative effect, poor pattern correspondence, etc., to ensure uniformity, consistent texture, and control deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

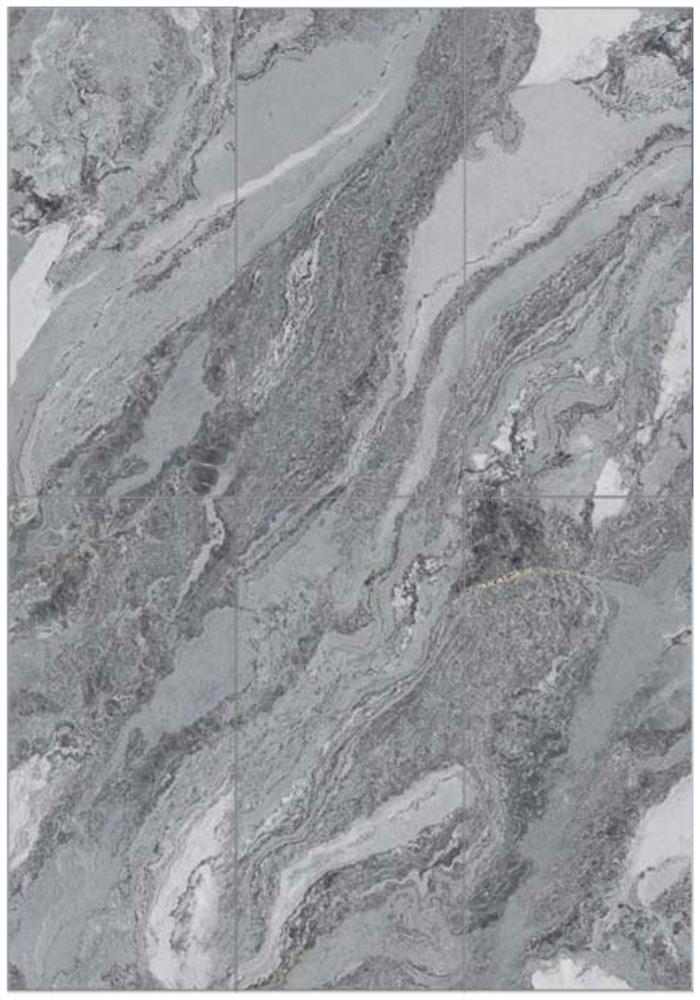

[0069] The present embodiment provides a production method of continuous grain ceramic tiles, which specifically includes:

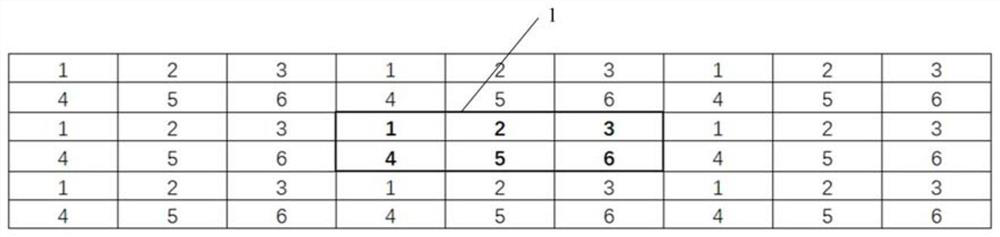

[0070] (1) Obtain the pattern image on the stone, and divide the pattern image into 6 design drawings;

[0071] (2) Layer each of the design drawings according to different colors to obtain 5 printed drawings;

[0072] (3) prepare ceramic tile green body, adopt ink-jet printing machine to print the first design drawing on ceramic tile green body;

[0073] (4) adopting screen printing machine to print 5 described first printing drawings successively on the surface of the ceramic tile green body of step (3) gained;

[0074] (5) applying glaze on the ceramic tile green body gained in step (4), to obtain the ceramic tile body;

[0075] Specifically, the glaze includes by weight:

[0076] SiO 2 48.95 parts, Al 2 o 3 26.4 parts, Fe 2 o 3 0.25 parts, CaO 7.92 parts, MgO 4.66 parts, K 2 O 3.9 parts, Na 2 O 1.4 parts, BaO 2.6 parts, ZnO 2.3 parts; ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com