Decorative line covered by metallic film and producing method thereof

A metal film and decorative line technology, which is applied in special decorative structures, surface pretreatment bonding methods, decorative arts, etc., can solve the problems of unsatisfactory bonding effect and curing effect of adhesives, aesthetics, decoration, and luxury costs. , the consistency of texture can not be ideal, etc., to achieve the effect of maintaining product color stability, rich metal texture, and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

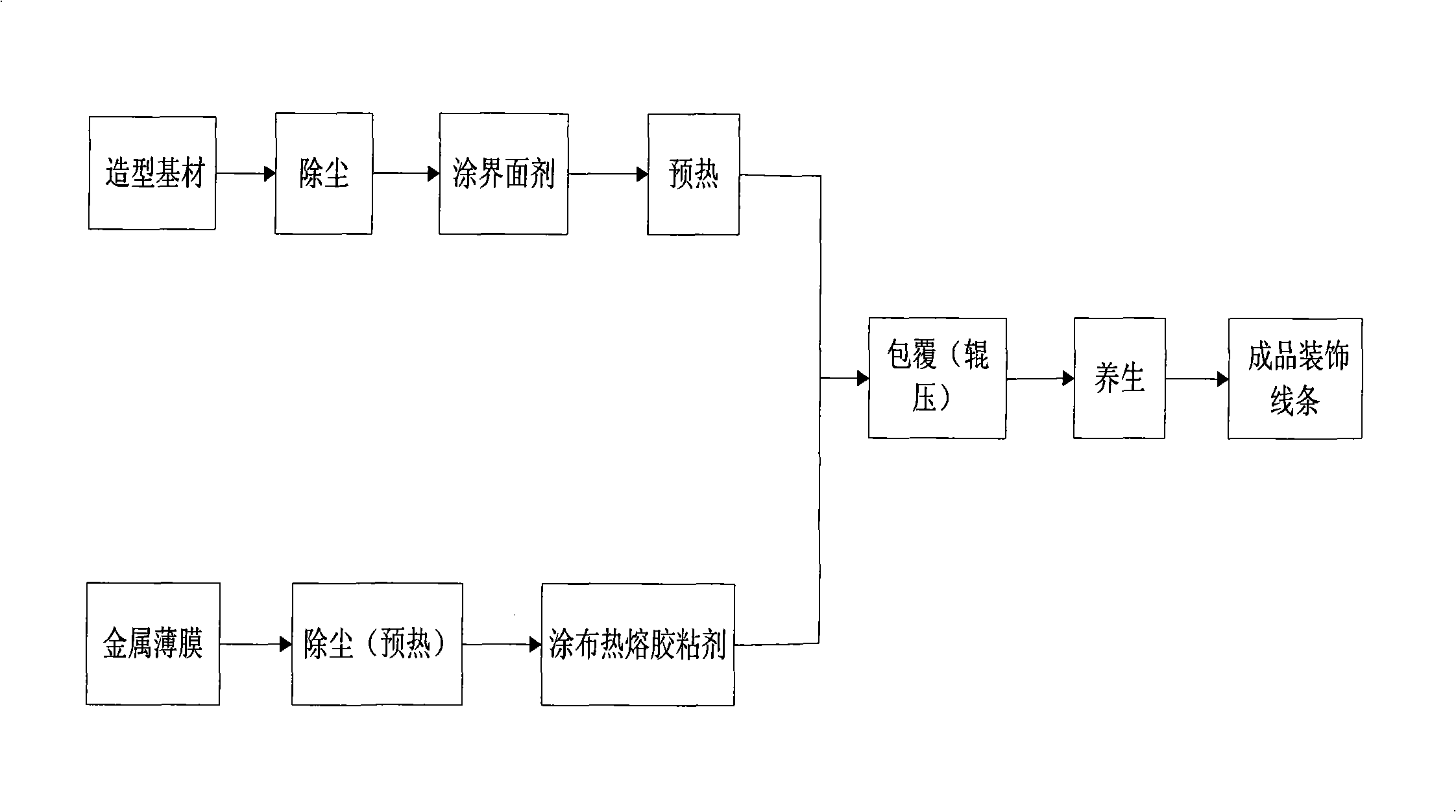

Method used

Image

Examples

Embodiment 1

[0027] (1) The solid wood is processed into various shapes of molding lines according to the customer's requirements, and then transported to the feed port of the wrapping machine. The wrapping machine is an open wrapping machine, which is convenient for people to operate on the wrapping machine.

[0028] (2) Decontaminate and dedust the solid wood lines on the coating machine, and use the dust removal system to remove dust by air adsorption.

[0029] (3) Coat the surface of solid wood to be coated with an interface affinity agent, the main components of which are polycondensation resin and chlorinated hydrocarbons.

[0030] (4) Convey the aluminum foil with a thickness of 0.5 mm to another feeding port of the coating machine.

[0031] (5) The aluminum foil is decontaminated and dedusted on the coating machine, and the dedusting system is used for air adsorption.

[0032](6) Apply PUR adhesive on one side of the aluminum foil. The PUR polyurethane adhesive is in the form of ...

Embodiment 2

[0035] (1) Process PVC into various shapes of molding lines according to customer requirements, and then transport them to the feed port of the coating machine.

[0036] (2) Decontaminate and dedust the PVC lines on the coating machine, and use the dust removal system to remove dust by air adsorption.

[0037] (3) Coat the PVC surface to be covered with an interface affinity agent, the main components of which are polycondensation resin and chlorinated hydrocarbons.

[0038] (4) After the PVC is coated with the interface affinity agent, it is preheated until the surface temperature of the PVC reaches 28°C. The preheating method adopts the electric heating wire method.

[0039] (5) Transport the aluminum alloy film with a thickness of 0.1 mm to another feed port of the cladding machine.

[0040] (6) The aluminum alloy film is decontaminated and dedusted on the coating machine, and the dedusting system is used for air adsorption.

[0041] (7) Coating PO adhesive on one side of...

Embodiment 3

[0045] (1) Process the wood fiber board into various shapes of molding lines according to the customer's requirements, and then transport it to the feeding port of the cladding machine.

[0046] (2) Carry out decontamination and dust removal on the wood fiber board on the cladding machine, and use the dust removal system to remove dust by air adsorption.

[0047] (3) Coat the surface of the wood fiberboard to be coated with an interfacial affinity agent, the main components of which are polycondensation resin and chlorinated hydrocarbons.

[0048] (4) Preheat the wood fiberboard coated with the interfacial affinity agent until the surface temperature of the wood fiberboard reaches 55°C, and use infrared rays for preheating.

[0049] (5) The zinc alloy film with a thickness of 0.15mm is transported to another feed port of the cladding machine.

[0050] (6) The zinc alloy film is decontaminated and dedusted on the coating machine, and the dedusting system is used for air adsorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com