A processing method for making imitation cypress material from Chinese fir

A processing method and technology of imitating cypress, which is applied in the direction of wood processing equipment, manufacturing tools, wood treatment, etc., can solve the problems of slow growth, scarce materials and high hardness of natural cypress, and achieve the effect of hard wood, low price and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A processing method for manufacturing imitation cypress wood material by using fir includes the following steps:

[0054] Step 1: Cut fresh fir, remove the bark and other debris on the outer surface of the fir, and cut the fir into a certain length of wood;

[0055] Step 2: Put the Chinese fir wood section into a wood drying kiln for drying at a drying temperature of 80°C and a drying time of 24 hours. After drying, the moisture content of the Chinese fir wood section is 8%;

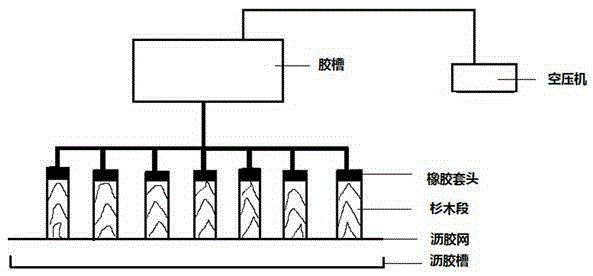

[0056] Step 3: Put one end of the dried cedar wood section with a rubber sleeve, fix and lock it with a lock throat, then place the other end of the cedar wood section facing down in the drain net on the drain tank to complete this The multiple cedar wood sections of the step are arranged in parallel in the drain net and fixed with ropes to prevent lodging during the pressurizing process and affecting the pouring effect;

[0057] Step 4: Connect the glue outlet at the lower end of the glue tank with a sea...

Embodiment 2

[0069] A processing method for manufacturing imitation cypress wood material by using fir includes the following steps:

[0070] Step 1: Cut fresh fir, remove the bark and other debris on the outer surface of the fir, and cut the fir into a certain length of wood;

[0071] Step 2: Put the fir wood section into a wood drying kiln for drying at a drying temperature of 100°C and a drying time of 60 hours. After drying, the moisture content of the fir wood section is 10%;

[0072] Step 3: Put one end of the dried cedar wood section with a rubber sleeve, fix and lock it with a lock throat, then place the other end of the cedar wood section facing down in the drain net on the drain tank to complete this The multiple cedar wood sections of the step are arranged in parallel in the drain net and fixed with ropes to prevent lodging during the pressurizing process and affecting the pouring effect;

[0073] Step 4: Connect the glue outlet at the lower end of the glue tank with a seamless steel tu...

Embodiment 3

[0085] A processing method for manufacturing imitation cypress wood material by using fir includes the following steps:

[0086] Step 1: Cut fresh fir, remove the bark and other debris on the outer surface of the fir, and cut the fir into a certain length of wood;

[0087] Step 2: Put the Chinese fir wood section into a wood drying kiln for drying at a drying temperature of 90°C and a drying time of 40 hours. The moisture content of the dried Chinese fir wood section is 9%;

[0088] Step 3: Put one end of the dried cedar wood section with a rubber sleeve, fix and lock it with a lock throat, then place the other end of the cedar wood section facing down in the drain net on the drain tank to complete this The multiple cedar wood sections of the step are arranged in parallel in the drain net and fixed with ropes to prevent lodging during the pressurizing process and affecting the pouring effect;

[0089] Step 4: Connect the glue outlet at the lower end of the glue tank with a seamless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com