Automatic beancurd sheet production machine with blowing pipes

A technology for automatic production and air blowing, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of hindering the development of the company, difficult to unify the quality, and insufficient guarantee of product quality, so as to make up for training and artificial factors, improve production efficiency, and ensure the effect of consistent texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

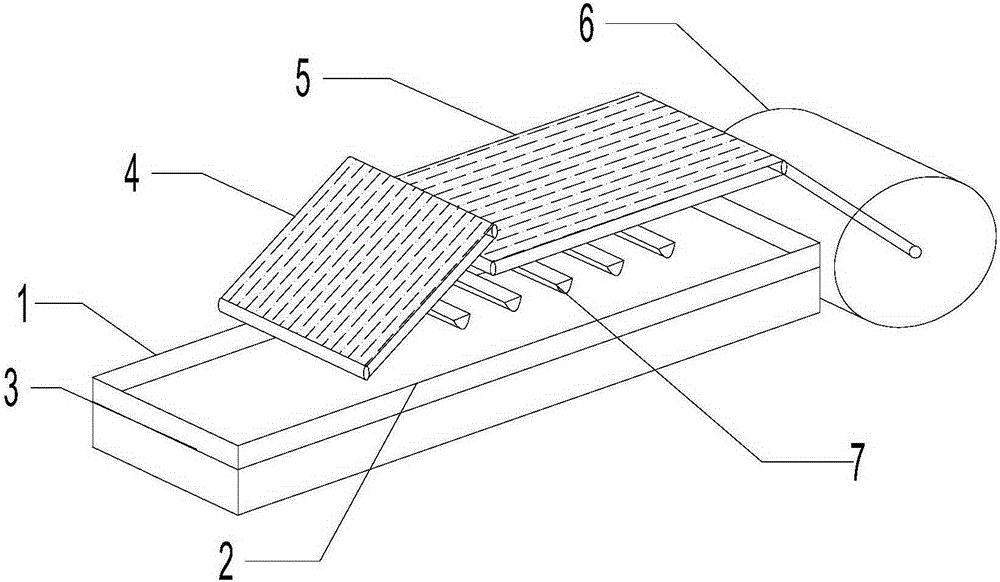

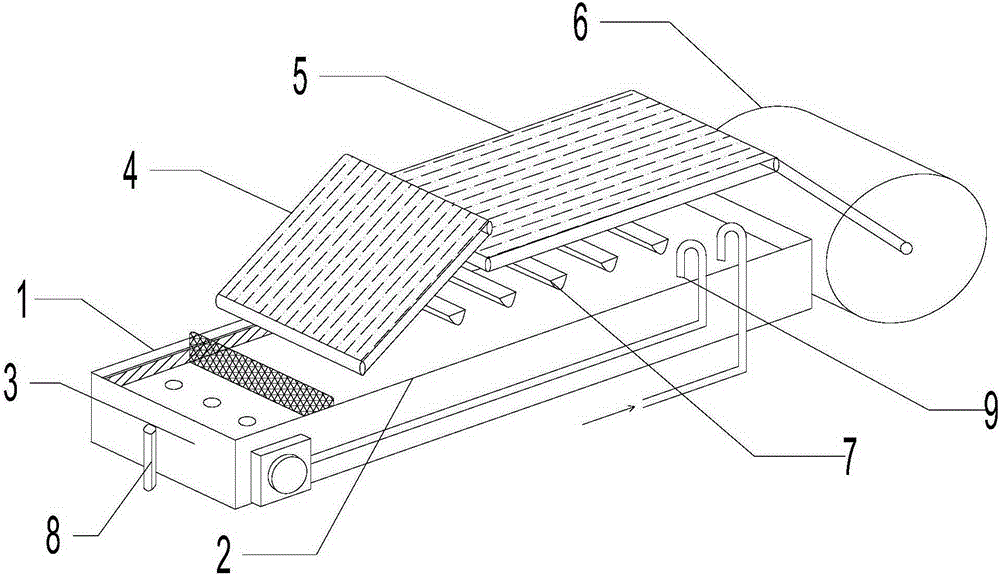

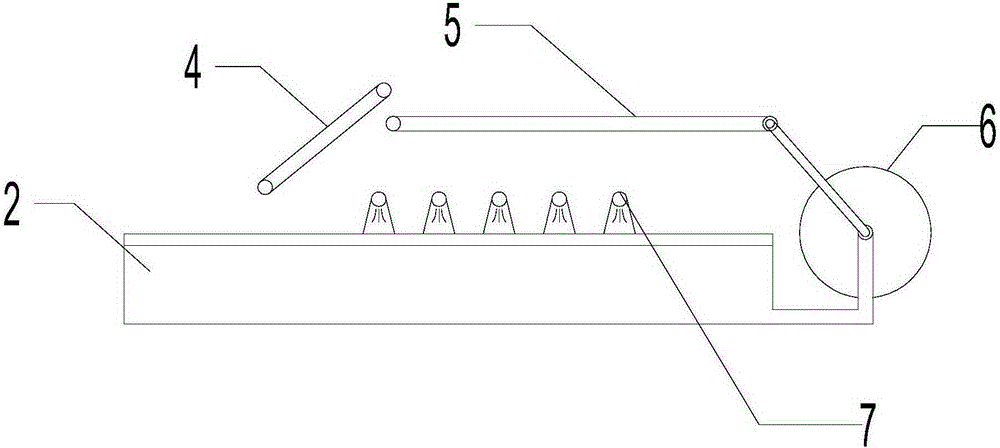

[0018] The bean curd skin automatic production machine that is provided with cooling tank described in the embodiment of the present invention, comprises frame and is arranged on the water tank 1 on the frame, and water tank 1 top seal is equipped with slurry tank 2, and water tank 1 inner chamber is provided with steam pipe; One end of the slurry tank is connected with a soybean milk circulation pump 3, and the upper part is provided with an inclined conveyor belt 4; the soybean milk circulation pump 3 continuously sends the soybean milk from the front slurry tank to the tail end slurry tank to prevent the flow of soybean milk during production. The protein structure of soya-bean milk withers in the slurry tank and the smooth flow of bean curd skin in the slurry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com