Pressure cleaning method and system of candle type demister

A technology for cleaning systems and demisters, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as single washing points, damage to demisters, corrosion of demisters, etc. Achieve the effect of improving the quality of defogging, increasing the service life and reducing the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

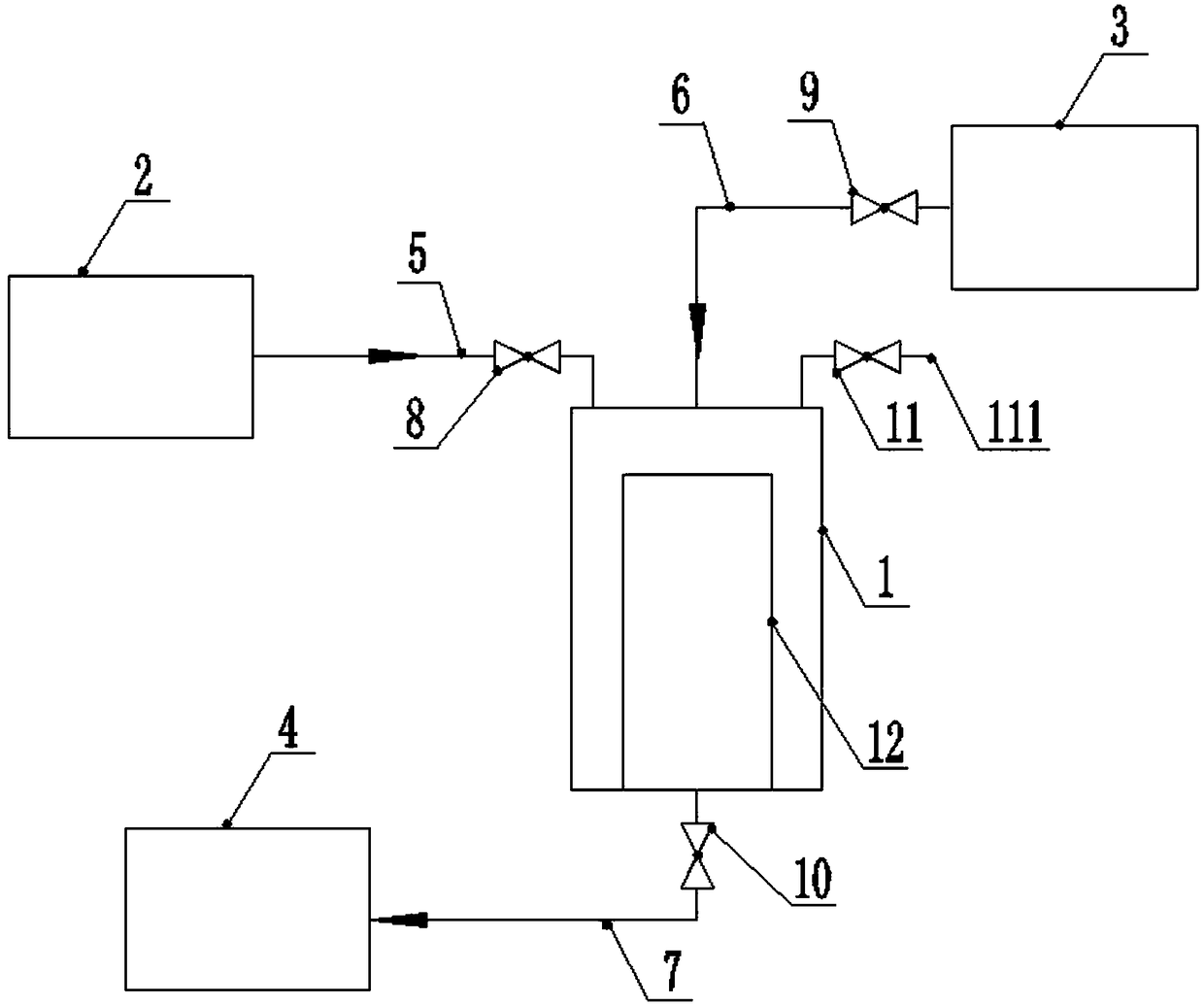

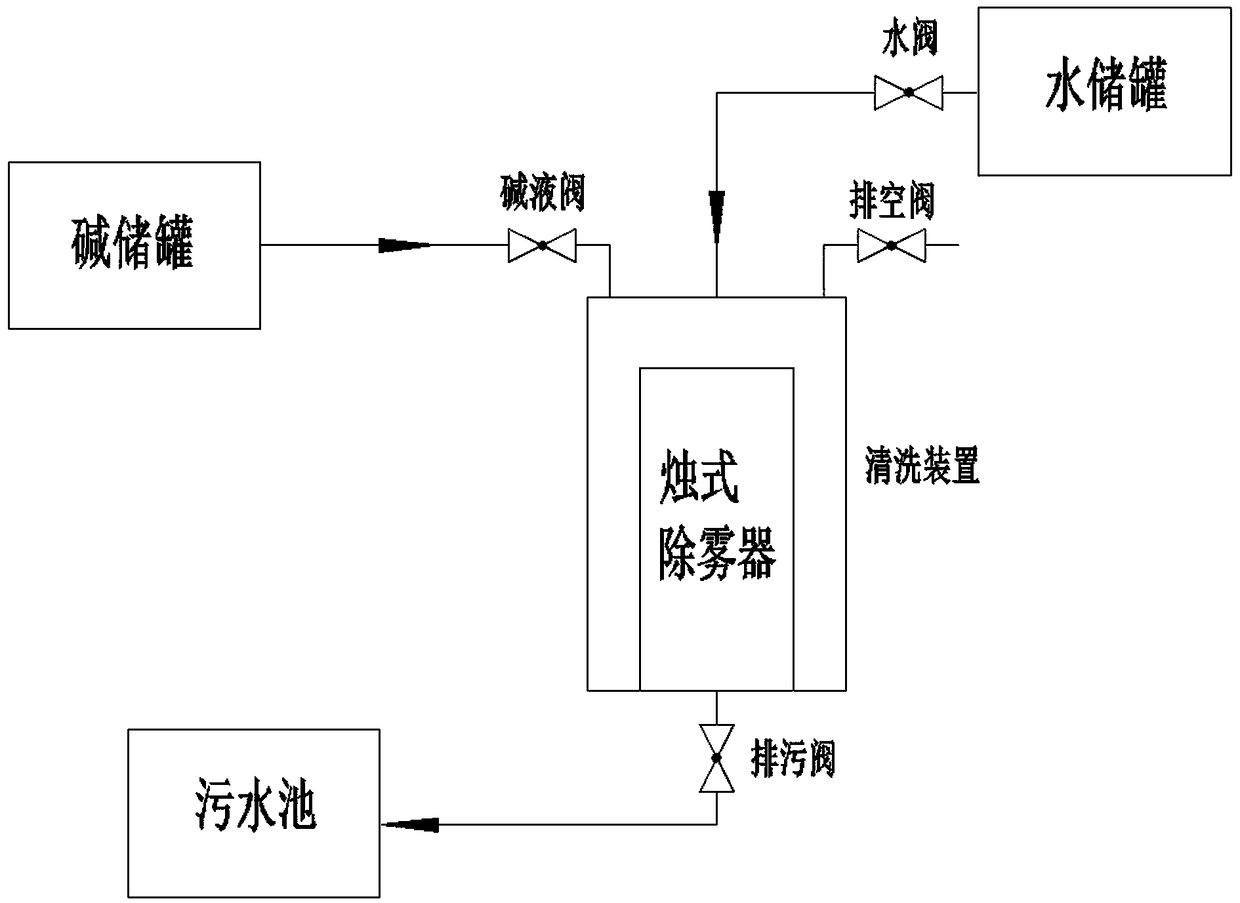

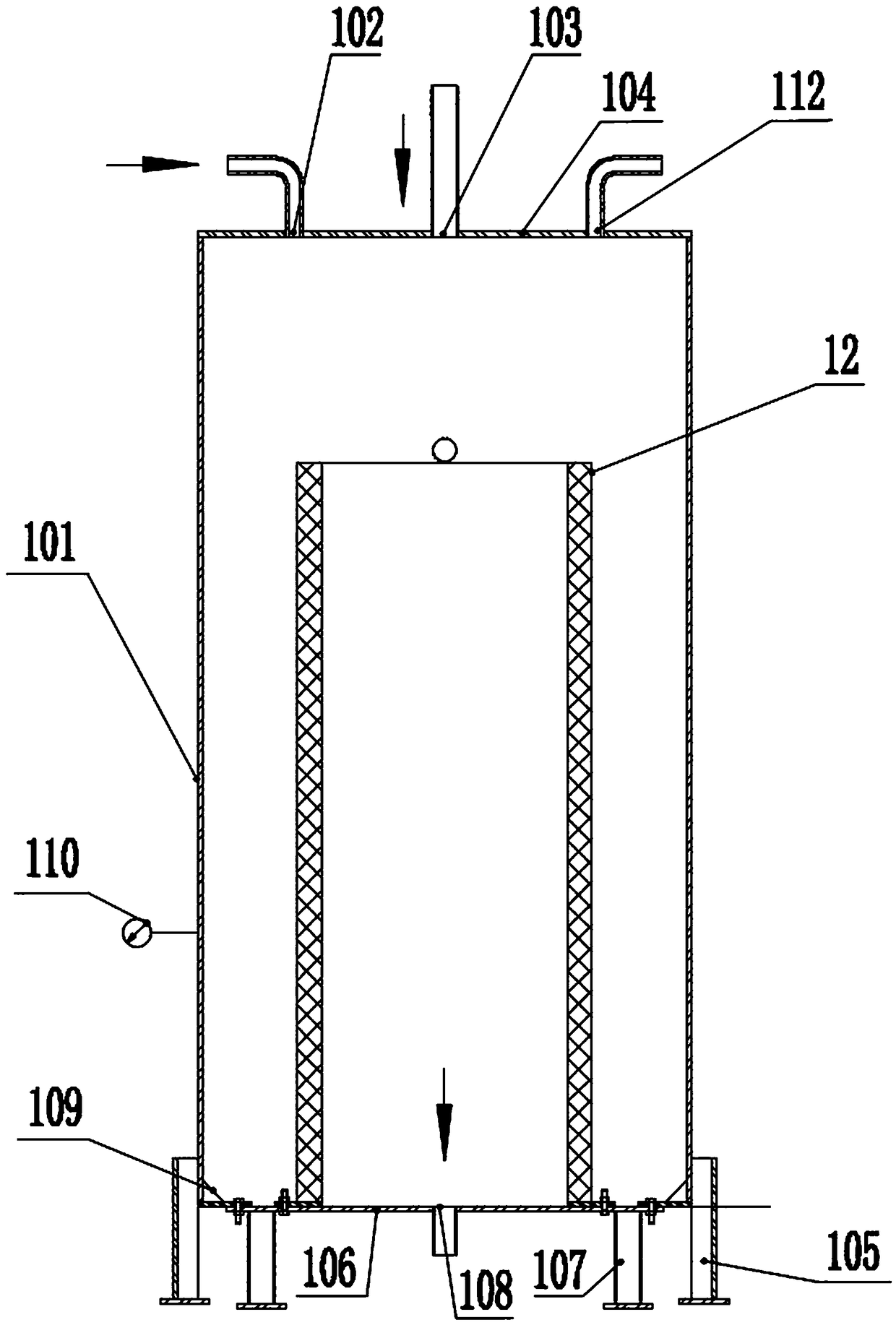

[0043] Such as Figure 1-3 Shown: a pressure cleaning system for a candle type mist eliminator, including a cleaning device 1, and an alkali storage tank 2 and a water storage tank 3 connected to the cleaning device 1; The top cover 104 at the top of the body 101 and the bottom plate 106 arranged at the bottom of the casing 101, the casing 101, the top cover 104 and the bottom plate 106 form a closed space, and the casing 101 is provided with a pressure gauge 110; There are an alkali inlet 102, a water inlet 103 and an emptying outlet 112. The inner casing of the alkali inlet 102 is provided with an alkali delivery pipe 5 for transporting lye, and the alkali delivery pipe 5 is connected with the alkali storage tank 2; the inner casing of the water inlet 103 is provided with The water pipe 6 for transporting clean water is connected to the water storage tank 3; the emptying port 112 is set with an emptying pipe 111 for discharging air, and the emptying pipe 111 is provided with...

Embodiment 2

[0045] On the basis of embodiment 1, further,

[0046] The cleaning device 1 is connected with a sewage pool 4 through a sewage pipe 7 .

[0047] Said alkali delivery pipe 5 is provided with lye valve 8 , water delivery pipe 6 is provided with water valve 9 , and sewage discharge pipe 7 is provided with blowdown valve 10 .

Embodiment 3

[0049] On the basis of embodiment 2, further,

[0050] The bottom plate 106 is arranged on the bottom plate support 107 , and the fastening device II for fixing the housing 101 is also provided on the bottom plate 106 , and the housing 101 is buckled and arranged on the bottom plate 106 .

[0051] The bottom of the housing 101 is provided with a housing bracket 105 and ribs 109 .

[0052] The housing 101 is cylindrical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com