Scraper Squeegee with Variable Vertical Flexibility

A scraper and scraper technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of no gasket damage, scraper damage, windshield damage, etc., and achieve low implementation cost and simple industrial implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

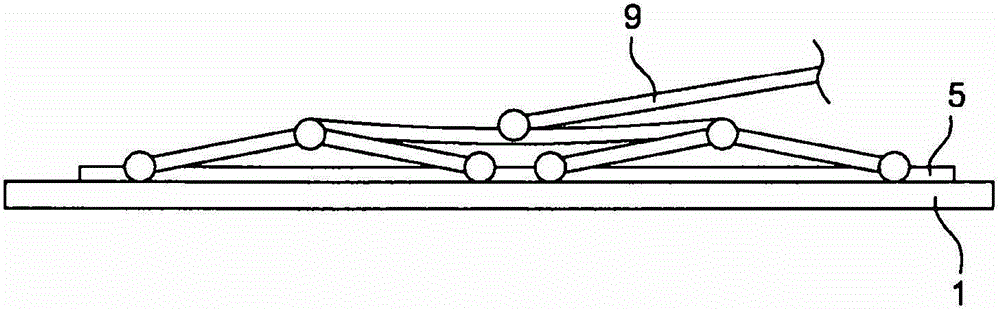

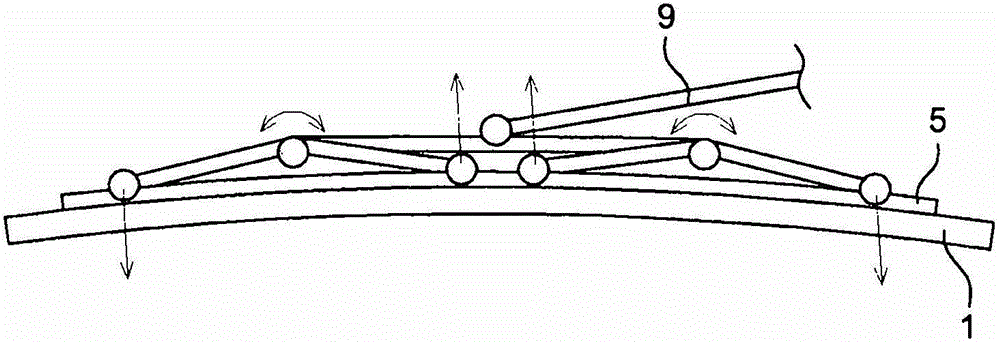

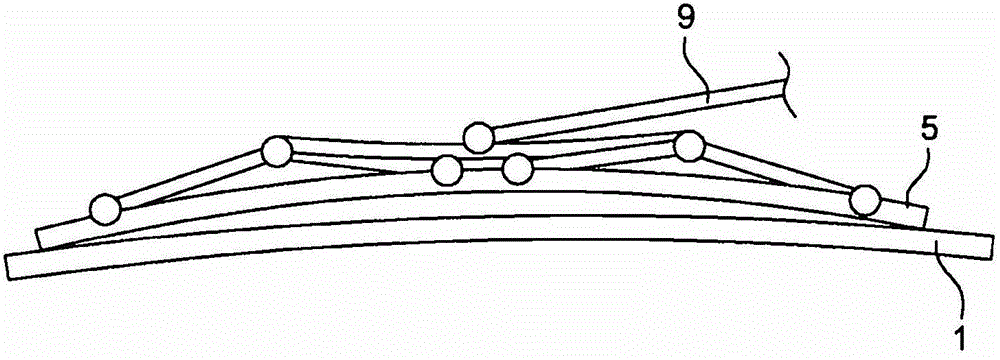

Method used

Image

Examples

Embodiment Construction

[0047] The invention is applied in the front part of the aircraft fuselage, at the windshield of the cockpit.

[0048] Such as image 3As can be seen above, in this non-limiting example, the windshield comprises two front panes 1 connected to the fuselage 2 by means of hoops and sealing gaskets 3 . exist figure 2 In the example shown, two front panes 1 are separated by a vertical strut 15 .

[0049] image 3 Mounted towards each of the front glass 1 is a wiper 4 shown above, while its function is to wipe the surface of said glass 1 by cyclic scraping, said wiper being driven by a motor of a type known to those skilled in the art and manipulation. For the two front panes forming the windshield, the two wipers 4 are arranged in a symmetrical manner, and as image 3 As seen above, the two wipers are stored in a rest position, which in this example is a vertical position next to the vertical support 15 .

[0050] For the following description, define: a longitudinal axis X,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com