Split drilling and milling pipe cutting machine

A split type, pipe cutting machine technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high work intensity of operators, small wall thickness of cutting pipelines, and complicated procedures, etc. The effect of fast cutting speed and improved groove quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

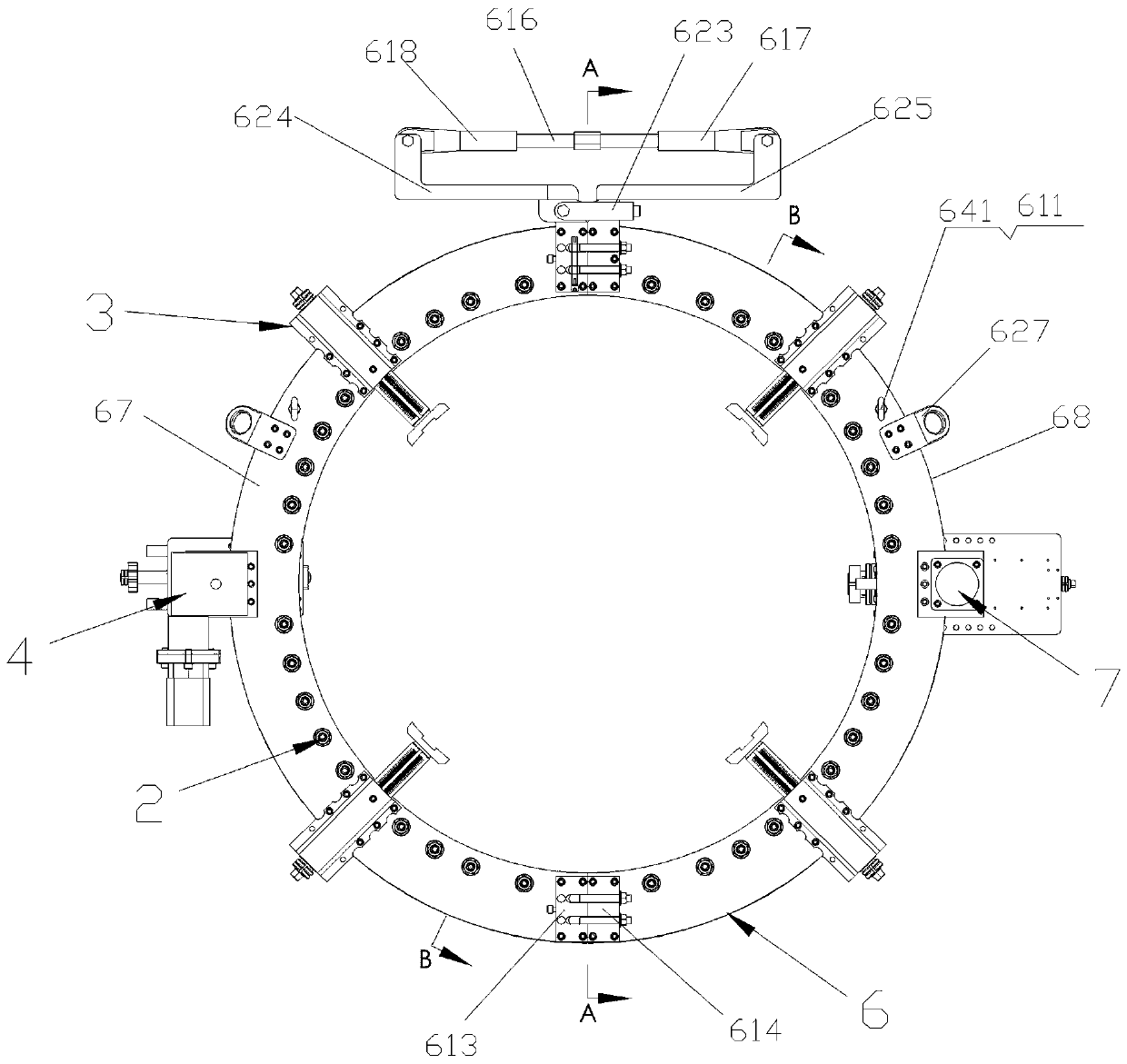

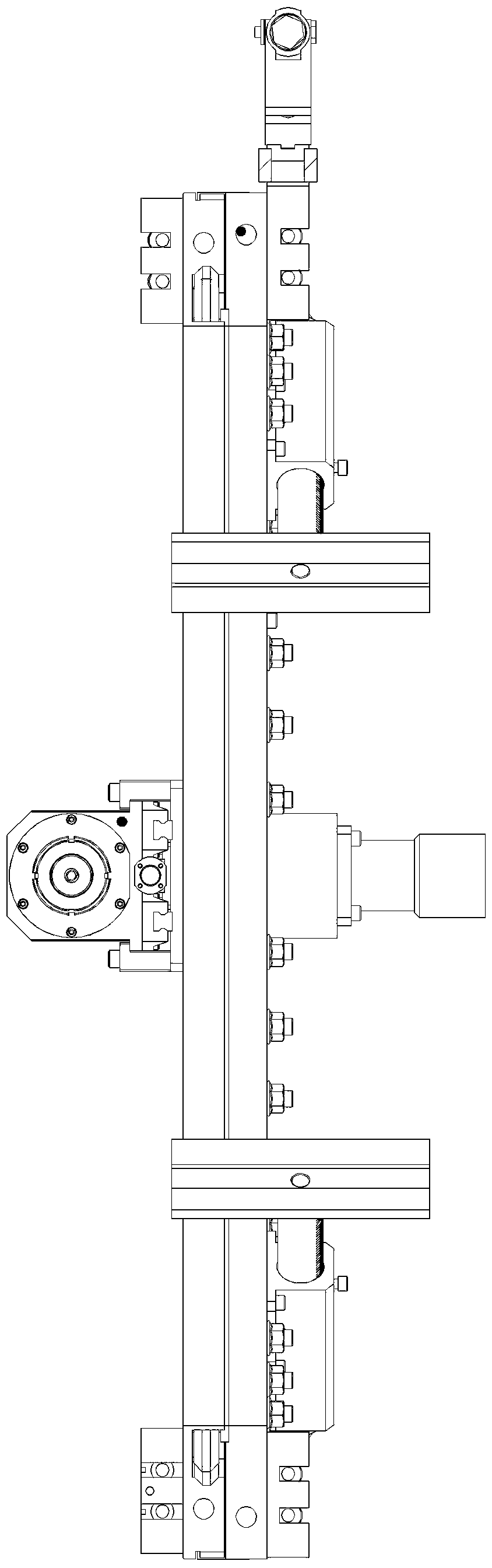

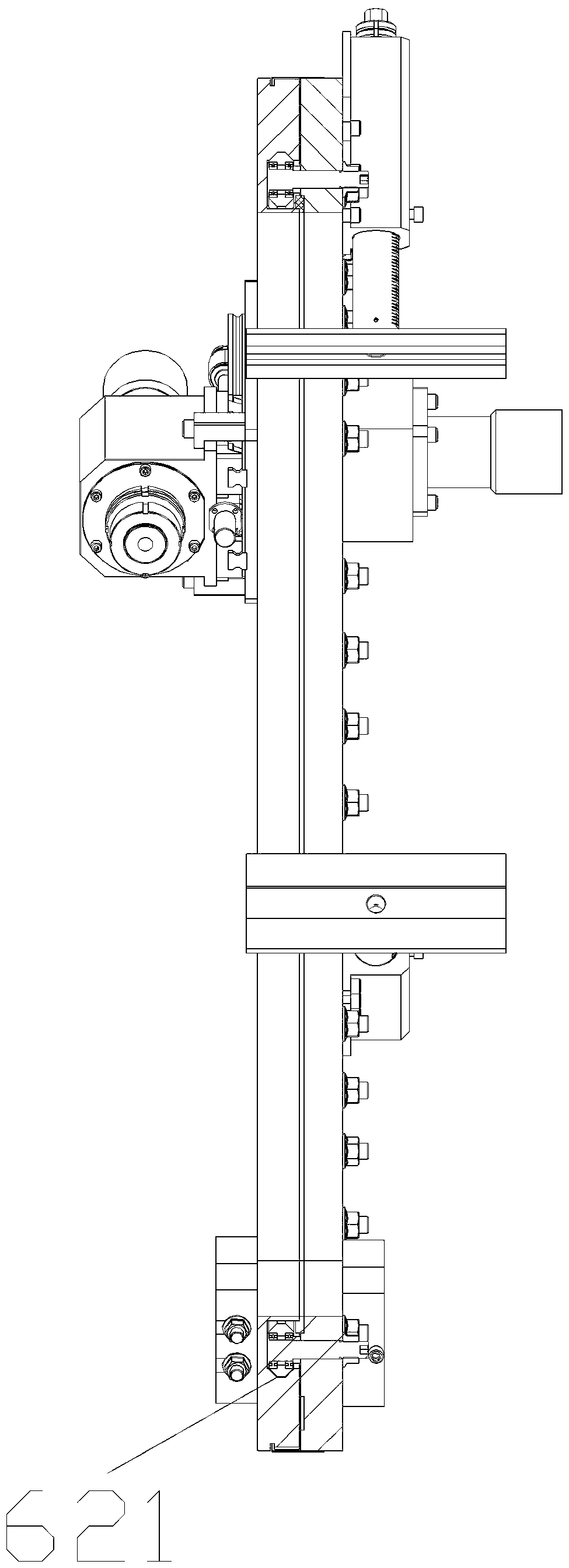

[0036] The split drilling and milling pipe cutting machine includes a drilling and milling assembly 1 , a main driving assembly 4 , a plurality of roller assemblies 2 , a plurality of support assemblies 3 , a turning tool assembly 5 , a turning tool main driving assembly 7 and a fixing assembly 6 . The drilling and milling assembly 1 includes a drilling and milling screw 19, a first hydraulic motor 126, a drilling and milling base plate 128, a drilling and milling main shaft 12, a drilling and milling nut 17 and a drilling and milling box 11, and the shell of the first hydraulic motor 126 is fixed on On the rear end face of the drilling and milling box body 11, the power output shaft of the first hydraulic motor 126 passes through the rear end face of the drilling and milling box body 11 and is fixedly connected with the rear end of the drilling and milling main shaft 12, and the front and rear ends of the drilling and milling main shaft 12 The first bearing 122 is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com