U-shaped bone nail having muscle/bone induction activity and realizing flexible connection after degradation

A flexible connection and osteoinduction technology, applied in the direction of manufacturing tools, internal bone synthesis, furnace type, etc., can solve the problems of corrosion degradation, loss of mechanical support of materials, pain of patients, etc., and achieve the effect of promoting growth and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

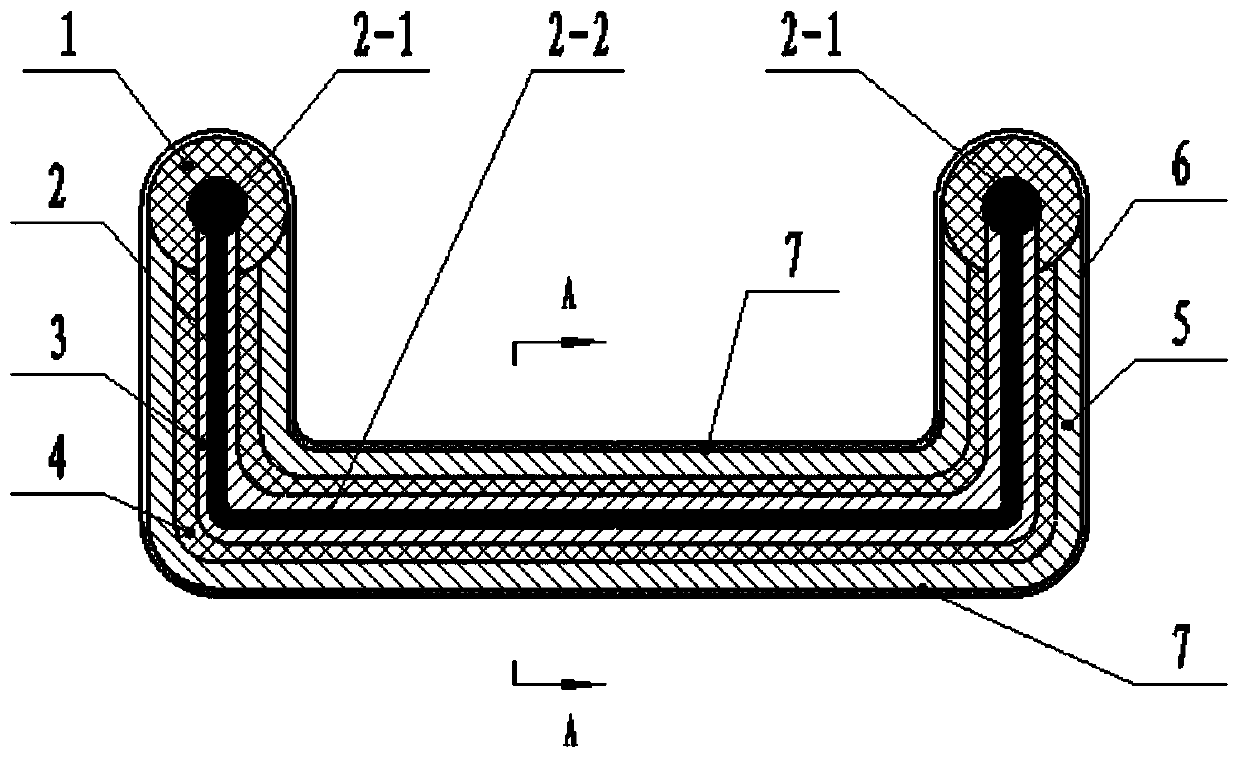

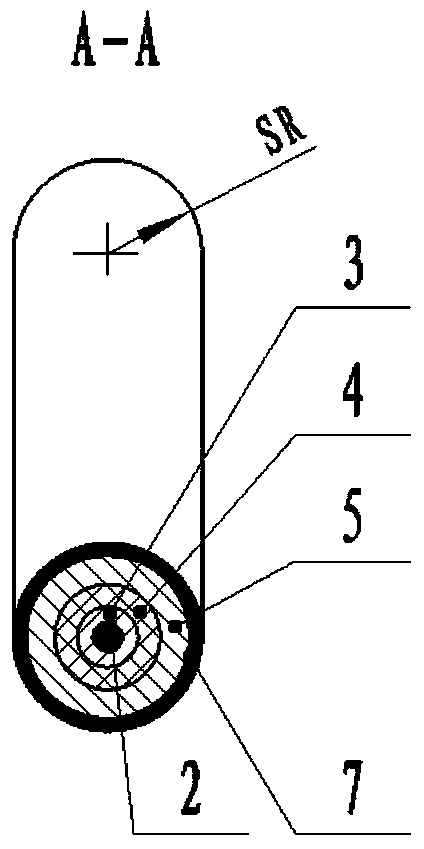

[0049] Such as figure 1 and 2 Shown: U-shaped bone nail with muscle / osteoinductive activity after degradation and flexible connection. U-shaped bone nail is composed of two nail feet made of composite rod and a nail-foot connector connecting the two nail feet. Composite rod It includes titanium alloy sphere 1, carbon fiber bundle 2, niobium wire layer 3, magnesium alloy layer 4, zinc alloy layer 5, nail foot coating 6 and nail foot connector coating 7.

[0050] The carbon fiber bundle 2 is located at the center of the U-shaped bone nail, including a knot 2-1 and a U-shaped bundle 2-2. Preferably, the carbon fiber bundle 2 is composed of 30-100 carbon fiber monofilaments, and the diameter of the carbon fiber monofilament is 6.8 μm- 7.0μm, the carbon fiber monofilament is made of any one of polyacrylonitrile-based carbon fiber, pitch-based carbon fiber, and viscose-based carbon fiber, and has high tensile strength. The knot 2-1 is located at the two ends of the U-shaped bundle...

Embodiment 2

[0057] The preparation method of the flexible-connected U-shaped bone nail after degradation with muscle / bone induction activity comprises the following steps:

[0058] (1) Preparation of niobium alloy wire:

[0059] 1) Ingredients, the chemical composition of the niobium alloy is calculated by mass percentage: Cu 12.0%, La 0.5%, and the balance is Nb.

[0060] 2) Vacuum smelting niobium alloy, put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and vacuum the furnace to 8×10 -4 Pa, pass in argon gas with a purity of 99.99% for 3 times of repeated gas scrubbing, and smelt with electricity under an argon atmosphere at a temperature of 2510°C ± 5°C and hold for 60 minutes;

[0061] 3) Casting into a niobium alloy ingot;

[0062] 4) Heat the ingot at 880°C for 45 minutes, then carry out high-temperature plastic deformation at 850°C, and then air-cool to room temperature to obtain a heat-deformed alloy. The high-tem...

Embodiment 3

[0085] The preparation method of the flexible-connected U-shaped bone nail after degradation with muscle / bone induction activity comprises the following steps:

[0086] (1) Preparation of niobium alloy wire:

[0087] 1) Ingredients, the chemical composition of the niobium alloy is calculated by mass percentage: Cu 13.5%, La 0.9%, and the balance is Nb.

[0088] 2) Vacuum smelting niobium alloy, put the prepared raw materials into the non-consumable electrode water-cooled copper crucible electric arc furnace, and vacuum the furnace to 8×10 -4 Pa, pass in argon gas with a purity of 99.99% for 3 times of repeated gas scrubbing, and smelt with electricity under an argon atmosphere at a temperature of 2510°C ± 5°C and hold for 60 minutes;

[0089] 3) Casting into a niobium alloy ingot;

[0090] 4) Heat the ingot at 880°C for 45 minutes, then carry out high-temperature plastic deformation at 850°C, and then air-cool to room temperature to obtain a heat-deformed alloy. The high-tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com