Preparation method of water-soluble antimony-carbon quantum dots, prepared antimony-carbon quantum dots, application thereof and corrosion-resistant composite material

An antimony carbon quantum, water-soluble technology, applied in the fields of nanotechnology, luminescent materials, chemical instruments and methods for materials and surface science, can solve the problems of poor water solubility of antimony quantum dots, low antimonene yield, etc. Obviously, the effect of shortening the reaction time and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix 0.5mol / L sodium sulfate solution with ethylene glycol, and the volume ratio of ethylene glycol and sodium sulfate solution is 1:10 to obtain a mixed electrolyte. Put the antimony block (cathode) and platinum sheet (positive electrode) into the mixed electrolyte for electrolysis, 1 / 2 of the cathode antimony block is placed in the electrolyte, and the electrolysis is carried out at a voltage of 5V, and the current density ranges from 0.1 to 0.8A / cm 2 , After 12 hours of electrolysis, add sodium hydroxide, the mass volume ratio of sodium hydroxide and ethylene glycol is 10g:20mL, stir for 2 hours, and let stand for 24 hours. Take the red liquid in the upper layer and centrifuge at 11000rpm for 25min to remove large particles and then dialyze for 3 days, changing deionized water every 3h. The solution after dialysis is as follows: figure 1 shown, and then dried at 70° C. for 24 h to obtain water-soluble antimony carbon quantum dots with a calculated yield of 90%. fi...

Embodiment 2

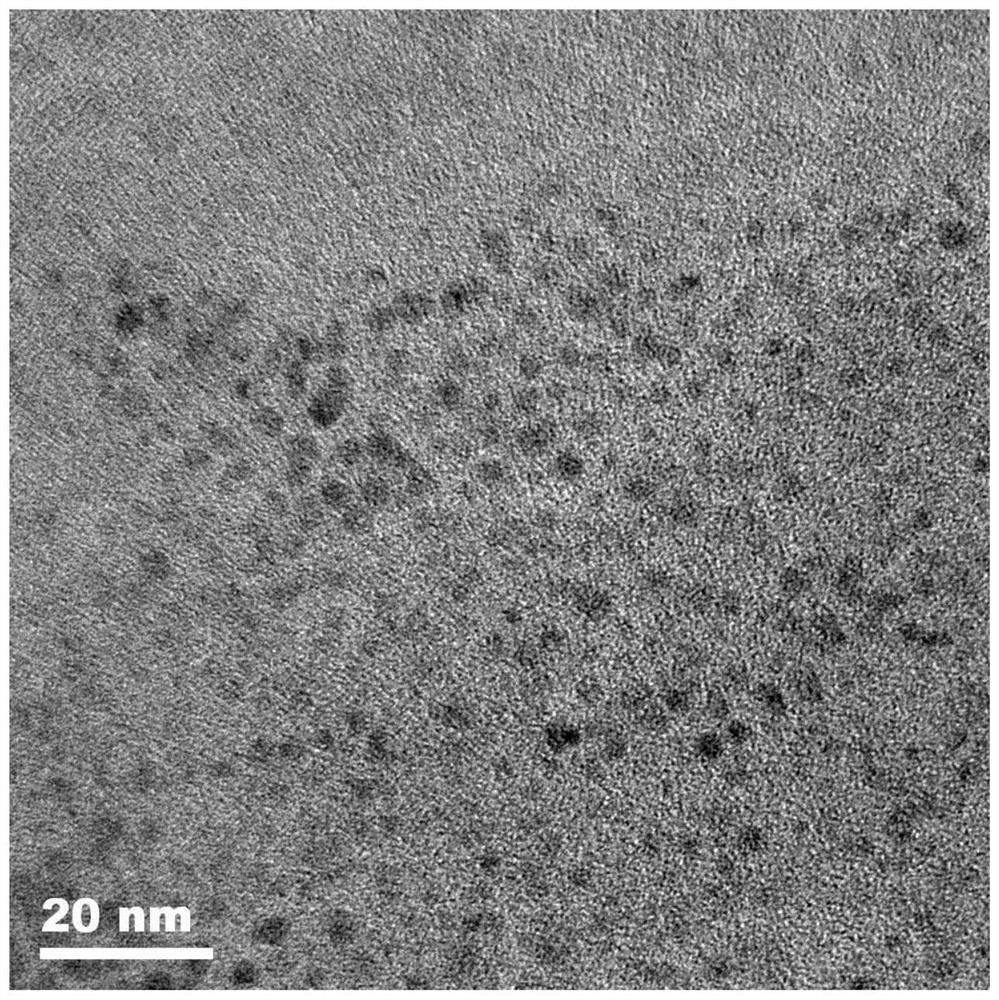

[0039] Mix 0.4mol / L sodium sulfate solution with ethylene glycol, and the volume ratio of ethylene glycol and sodium sulfate solution is 1:15 to obtain a mixed electrolyte. Put the antimony rod (cathode) and platinum wire (positive electrode) into the mixed electrolyte for electrolysis, 1 / 2 of the cathode antimony rod is placed in the electrolyte, and the electrolysis is carried out at a voltage of 10V, and the current density ranges from 0.5 to 1.2A / cm 2 , after 6 hours of electrolysis, add potassium hydroxide, the mass volume ratio of potassium hydroxide and ethylene glycol is 15g:20mL, stir for 4 hours, and let stand for 6 hours. The red liquid in the upper layer was centrifuged at 10,000rpm for 30 minutes to remove large particles and then dialyzed for 3 days. The deionized water was changed every 3 hours, and then dried at 60°C for 36 hours to obtain water-soluble antimony carbon quantum dots with a calculated yield of 95%. Figure 5 It shows that the particle size of t...

Embodiment 3

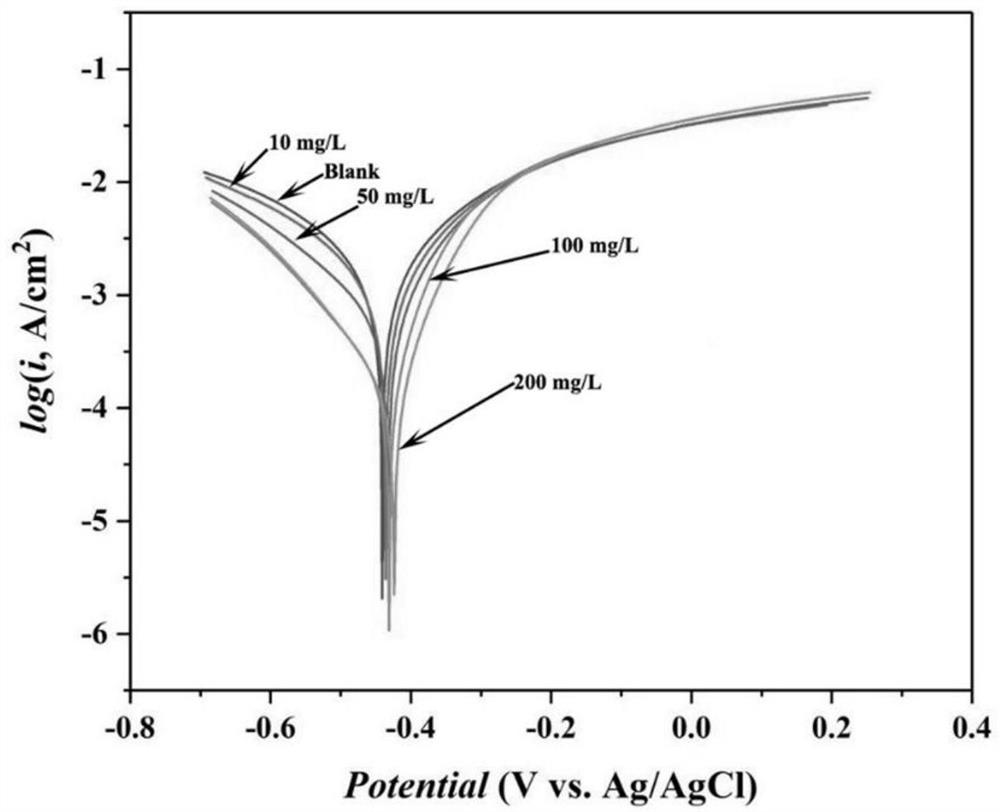

[0041] Mix 0.6mol / L sodium chloride solution with ethylene glycol, and the volume ratio of ethylene glycol to sodium chloride solution is 1:20 to obtain a mixed electrolyte. Put the antimony plate (cathode) and platinum wire (positive electrode) into the mixed electrolyte for electrolysis, 1 / 4 of the cathode antimony plate is placed in the electrolyte, and the electrolysis is performed at a voltage of 20V, and the current density ranges from 0.5 to 1.2A / cm 2 , After 24 hours of electrolysis, add sodium hydroxide and potassium hydroxide, the mass volume ratio of sodium hydroxide and potassium hydroxide to ethylene glycol is 20g:20mL, stir for 6 hours, and let stand for 12 hours. The red liquid in the upper layer was centrifuged at 12000rpm for 20min to remove large particles and then dialyzed for 3 days, changing deionized water every 3h, and then drying at 80°C for 12h to obtain water-soluble antimony carbon quantum dots with a calculated yield of 92%. The synthesized water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com