Manufacture equipment of rainbow tube

A manufacturing equipment, rainbow technology, applied in the field of rainbow tube manufacturing equipment, can solve problems such as reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

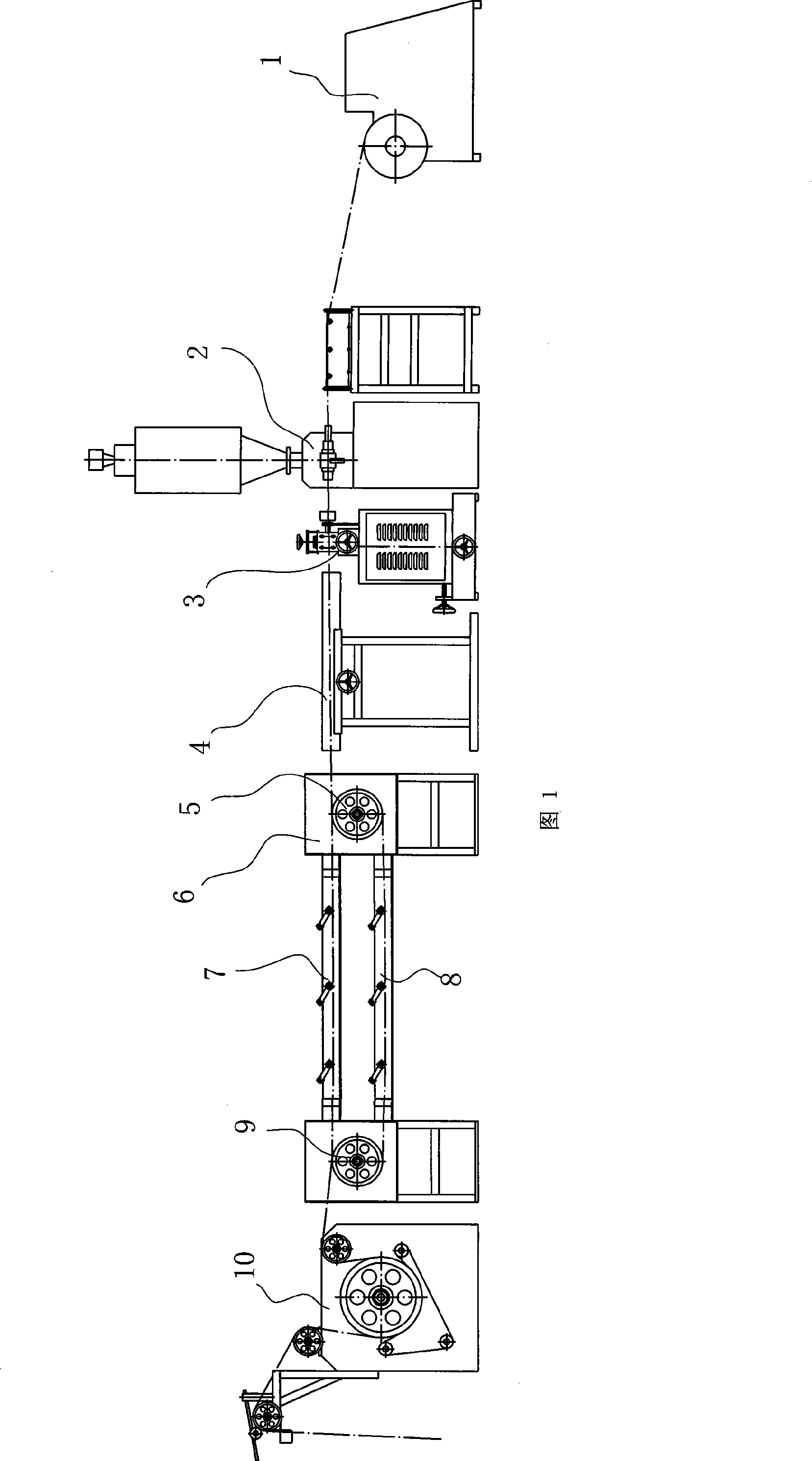

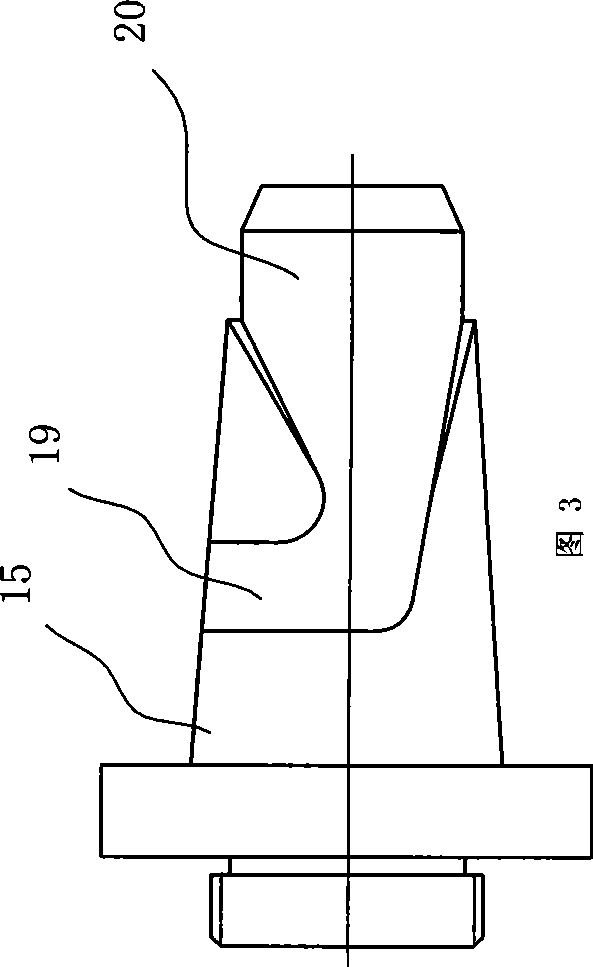

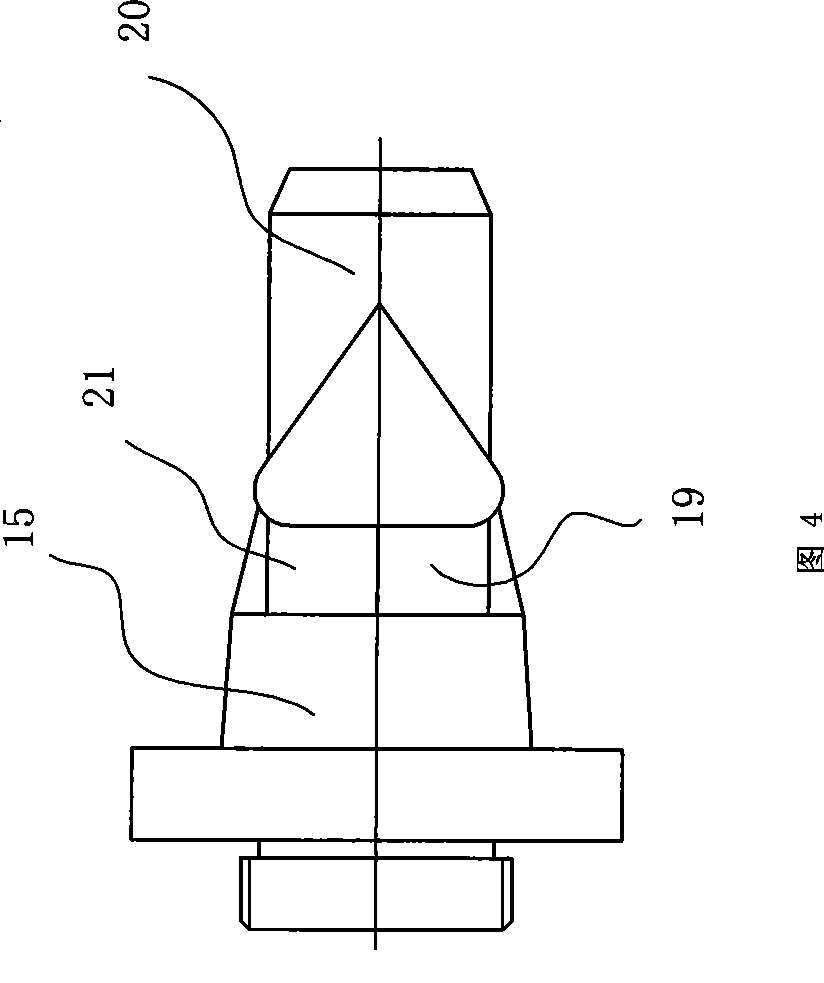

[0014] With reference to the accompanying drawings, the manufacturing equipment of this rainbow tube includes a discharge mechanism 1, an extrusion mechanism 2, a knurl mechanism 3, a cutting mechanism (not shown in the figure), two cooling mechanisms 4, 6 and a traction mechanism 10 , the cutting mechanism is installed on the traction mechanism 10. After the cutting mechanism of the present invention is installed on the traction mechanism 10, its cutting knife can be lifted or lowered according to the needs, depending on the needs of the work, which belongs to the prior art. In this paper No longer. Wherein, the discharge mechanism 1, extrusion mechanism 2, knurling mechanism 3, cooling mechanism 4, 6 and traction mechanism 10 are placed in sequence, and the extrusion mechanism 2 is composed of a barrel (not shown in the figure), a screw 25 and a die head, the die head includes an aligning shaft 12, a mold core 15, a mold barrel 16, an inner core positioning die 17 and a die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com