Novel micro powder intelligent multi-pipe distribution full-body ceramic tile and preparation method thereof

A technology of ceramic tiles and fabrics, which is applied in the field of architectural ceramics, can solve the problems of non-renewable natural stone resources, non-wearable glazed surfaces, single patterns, etc., and achieve excellent physical and chemical properties, restrain front and rear displacement, and smooth patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

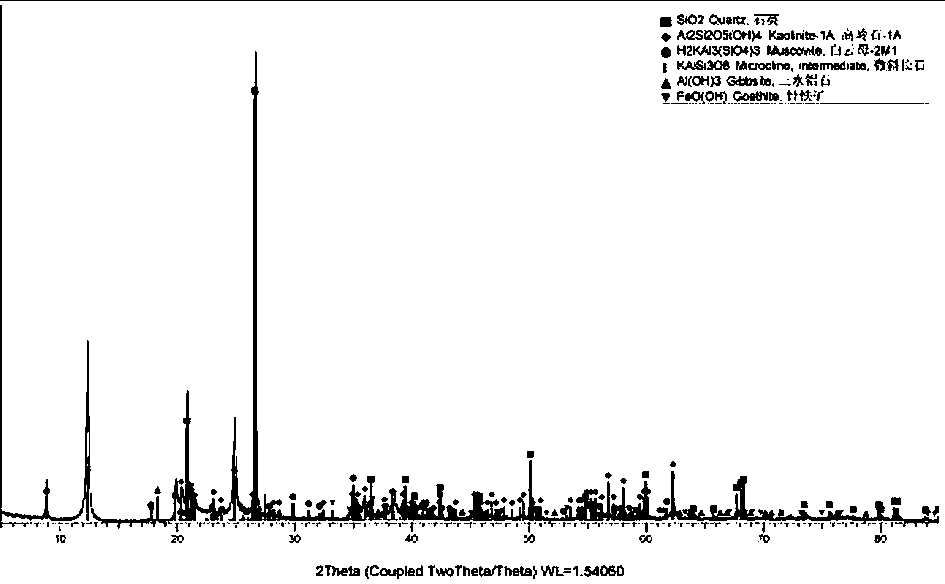

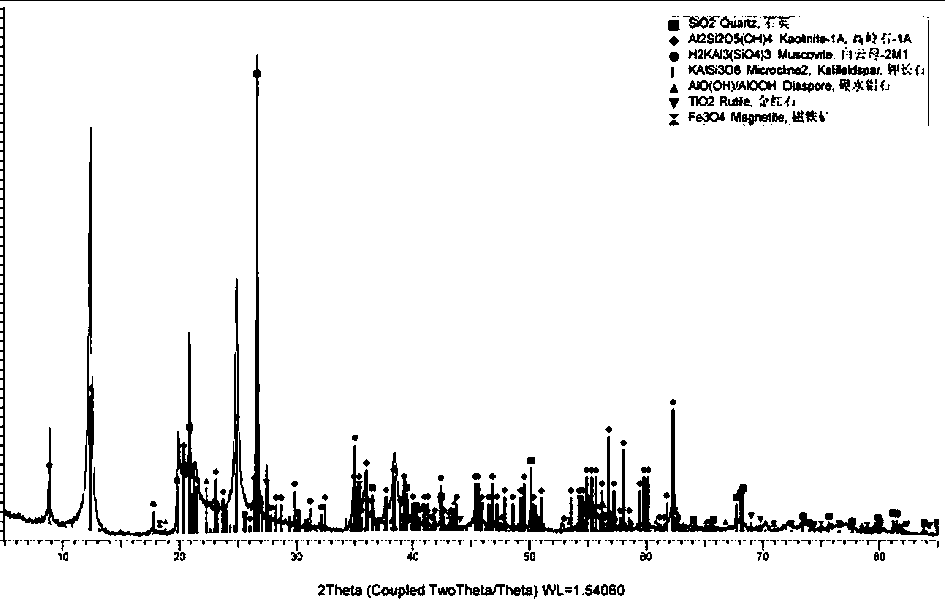

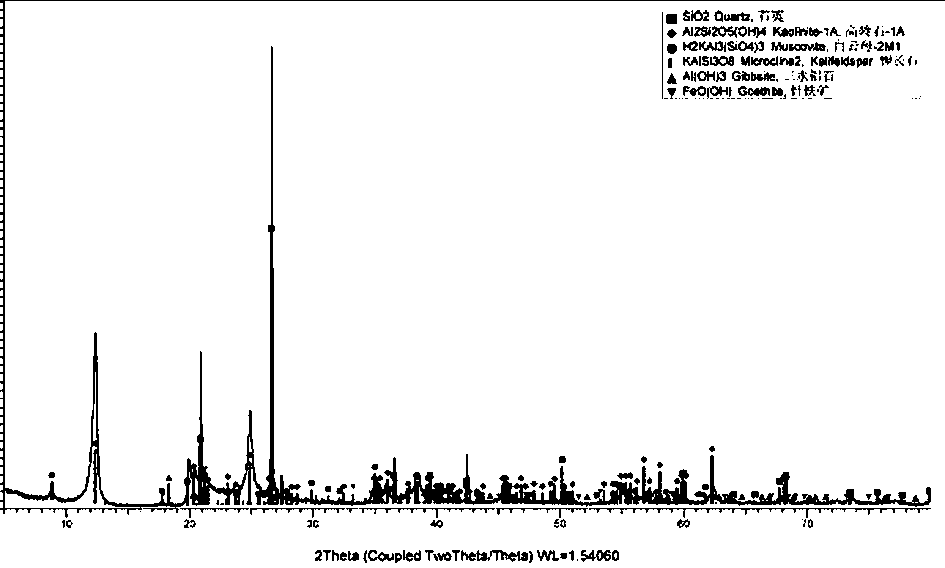

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention, but not to limit the present invention.

[0064] The main process flow of the existing ceramic tiles, such as micro-powder polished tiles, includes: raw materials-ball milling-sieving to remove iron-color matching-spray drying-storage-powder crushing-cloth-pressing-drying-firing-polishing-grading Packaging-storage, etc. However, the present invention addresses the problem that the existing micro-powder bricks are difficult to form, and the secondary cloth method must be adopted, which causes the problem that the surface layer micro-powder and the bottom layer powder pattern cannot be completely consistent; at the same time, the roller grid cloth technology used in the technology causes Simple and hard patterns, poor decorative effects, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com