Method for preparing titanium metal coating on ceramic surface

A technology for ceramic surface and titanium metal, which is applied in the field of ceramic treatment to metallize its surface, which can solve the problems of troublesome maintenance, adjustment and regeneration, poor wettability between metal and ceramic, single Ti coating, etc., and achieves low cost and environmental pollution. Small, simple device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

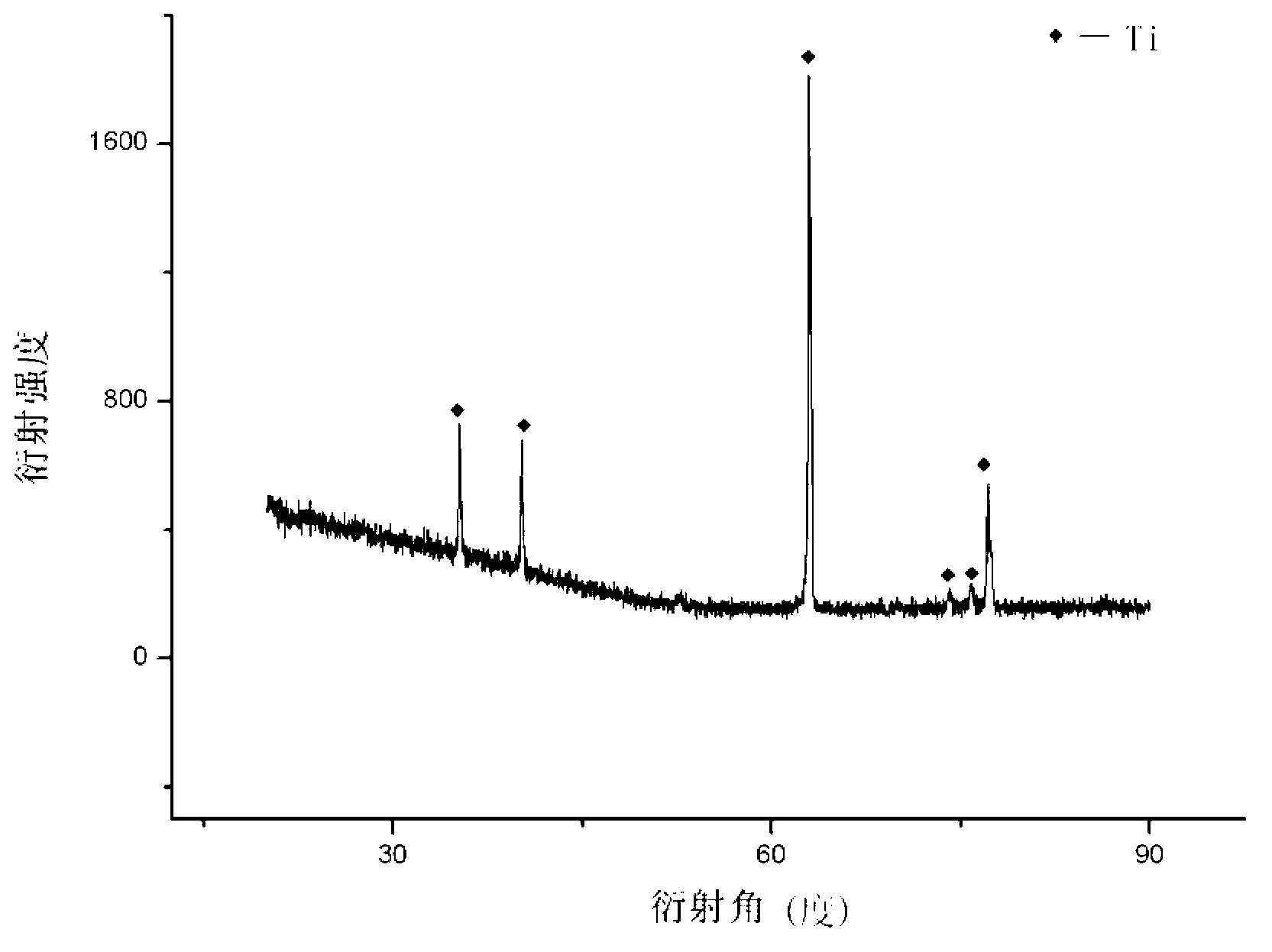

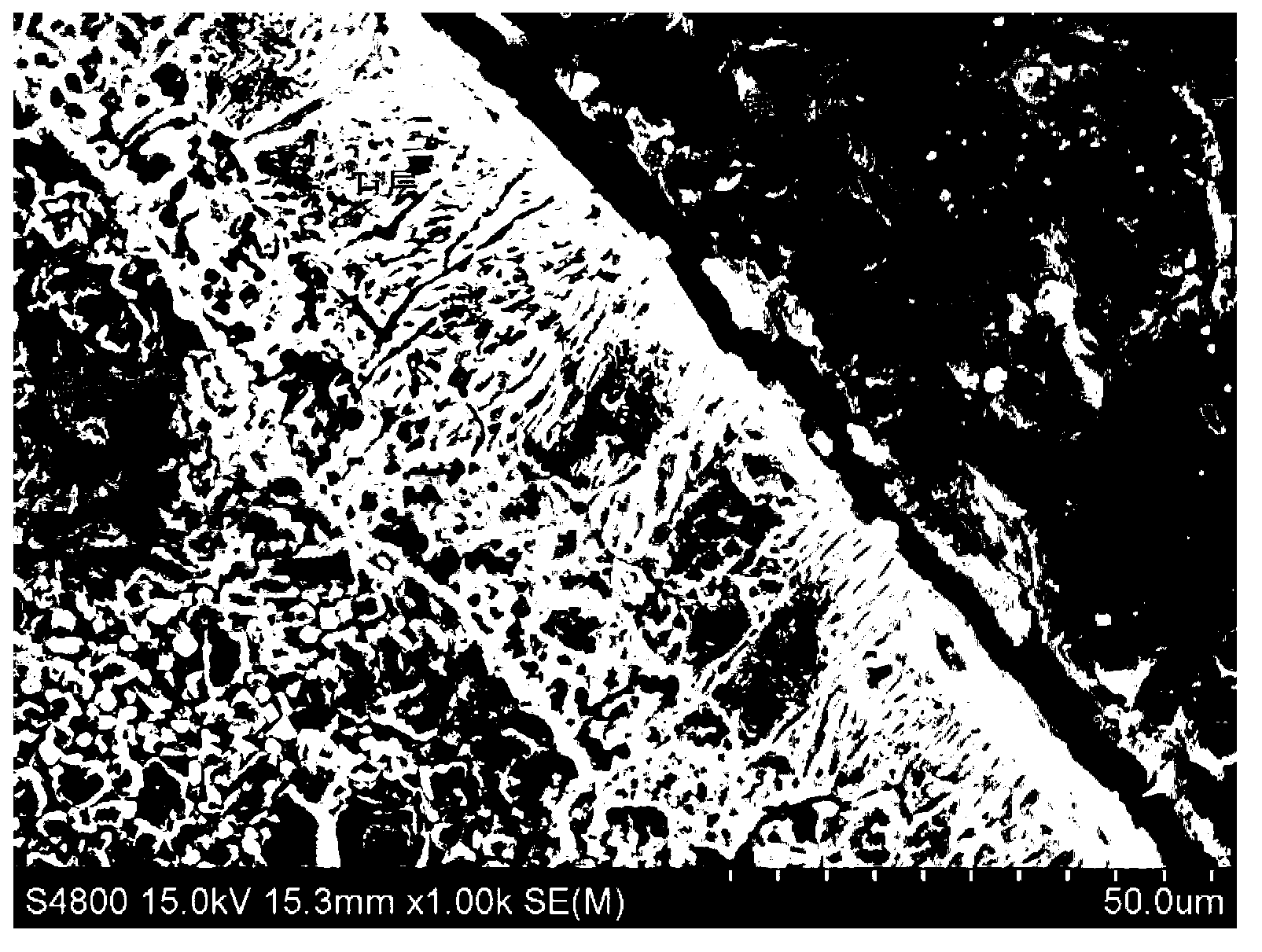

[0025] Use 600-mesh sandpaper to repeatedly grind the ceramics to obtain ceramics with a smooth surface and uniform roughness, then place the ceramics in water for repeated cleaning, and then use ethanol for ultrasonic cleaning for 10 minutes, then put the surface-treated ceramics into the bottom of the quartz tube, Then put the mixture of titanium powder and iodine powder in the quartz material boat, put the quartz material boat into the middle of the quartz tube; then put the quartz tube into the program-controlled furnace, evacuate the program-controlled furnace with argon, and then repeat vacuuming In the operation of argon flow, the temperature of the program-controlled furnace was raised to 1030°C at a heating rate of 15°C / min for 60 minutes, and then cooled with the furnace; the ceramics were taken out and washed repeatedly, and then dried to obtain ceramics coated with titanium metal coating on the surface. The thickness of the layer is about 8.2um, wherein the titanium...

Embodiment 2

[0027] Use 600-mesh sandpaper to repeatedly grind the ceramics to obtain ceramics with a smooth surface and uniform roughness, then place the ceramics in water for repeated cleaning, and then use ethanol for ultrasonic cleaning for 15 minutes, then put the surface-treated ceramics into the bottom of the quartz tube, Then put the mixture of titanium powder and iodine powder in the quartz material boat, put the quartz material boat into the middle of the quartz tube; then put the quartz tube into the program-controlled furnace, evacuate the program-controlled furnace and pass inert gas, and then repeat the vacuuming After the argon gas operation, the program-controlled furnace was heated to 1100°C at a heating rate of 15°C / min and kept for 60 minutes, and then cooled with the furnace; the ceramics were taken out and washed repeatedly, and then dried to obtain ceramics coated with titanium metal coating on the surface. The thickness of the coating is about 28.9um, among which, the...

Embodiment 3

[0029] Use 600-mesh sandpaper to repeatedly grind the ceramics to obtain ceramics with a smooth surface and uniform roughness, then place the ceramics in water for repeated cleaning, and then use ethanol for ultrasonic cleaning for 15 minutes, then put the surface-treated ceramics into the bottom of the quartz tube, Then put the mixture of titanium powder and iodine powder in the quartz material boat, put the quartz material boat into the middle of the quartz tube; then put the quartz tube into the program-controlled furnace, evacuate the program-controlled furnace with inert gas, and then repeat the vacuuming process In the operation of argon flow, the temperature of the program-controlled furnace was raised to 1200°C at a heating rate of 15°C / min for 60 minutes, and then cooled with the furnace; the ceramics were taken out and washed repeatedly, and then dried to obtain ceramics coated with titanium metal coating on the surface. The thickness of the layer is about 29.5um, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com