Patents

Literature

49 results about "Thermal optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

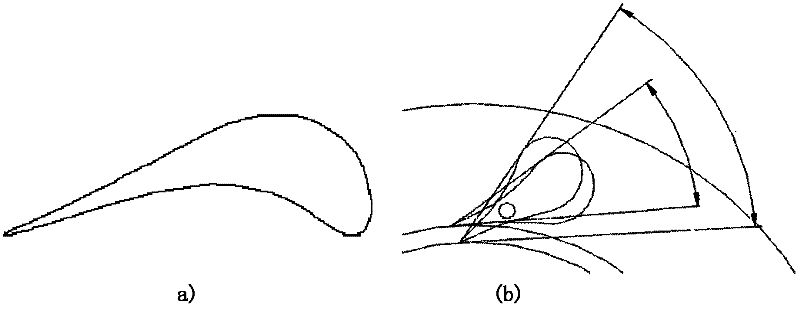

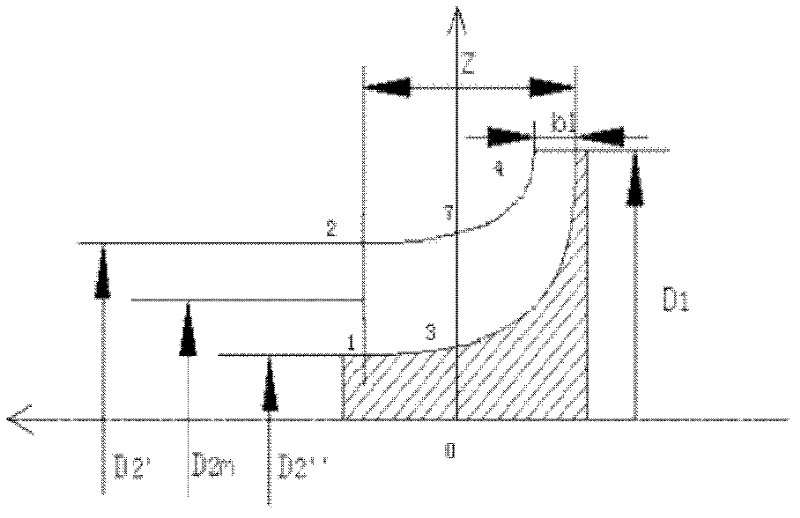

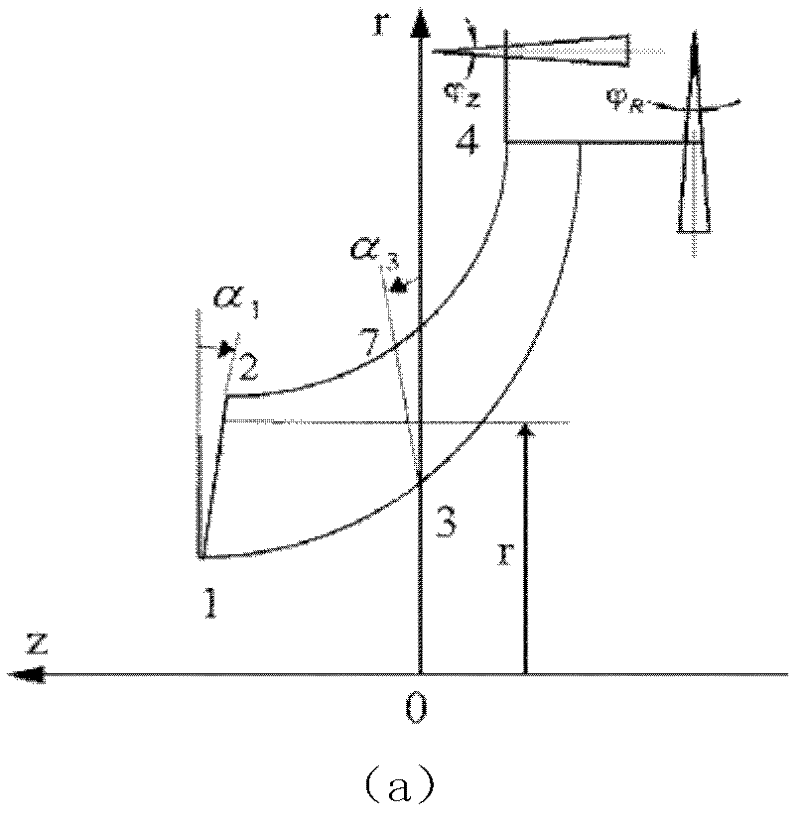

Optimization design method of radial-flow-type hydraulic turbine

ActiveCN102608914ASmall amount of calculationHigh precisionAdaptive controlImpellerMultivariable optimization

Owner:开山(西安)透平机械有限公司

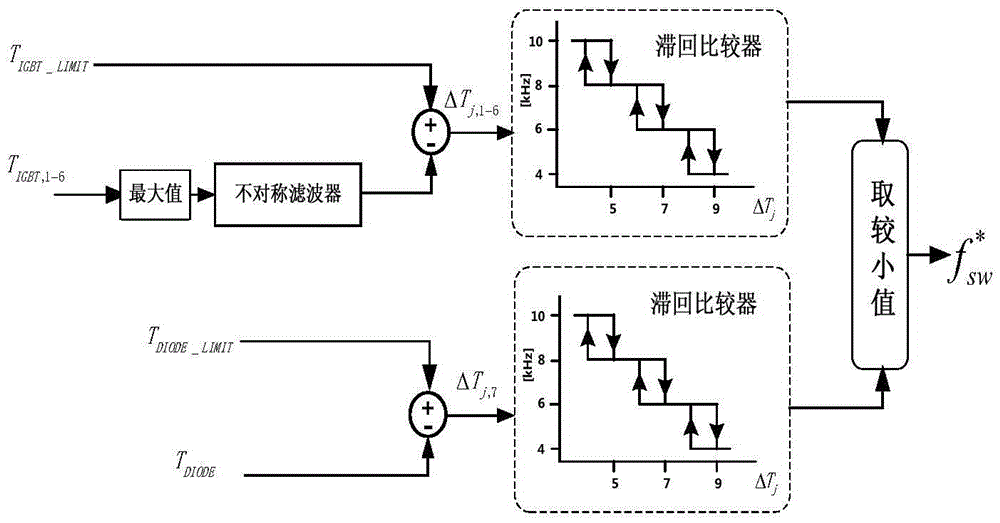

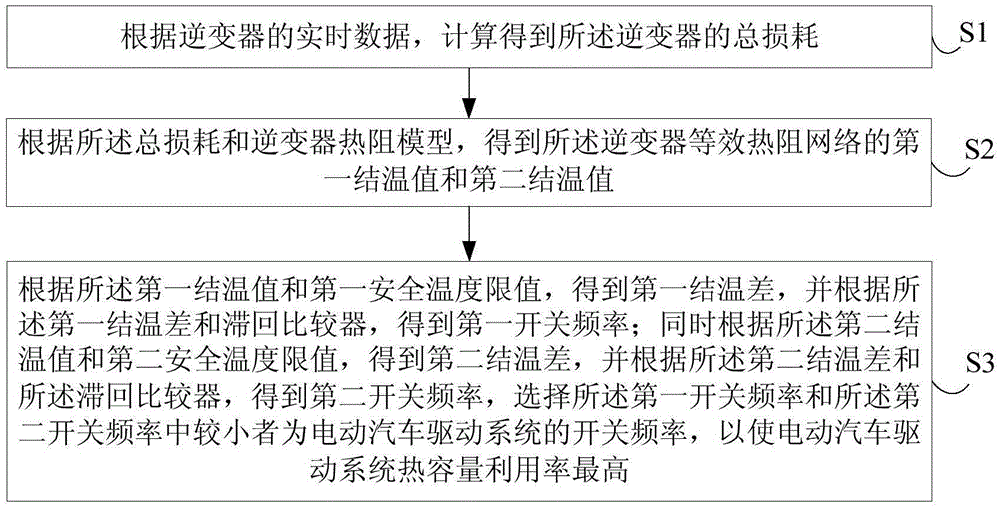

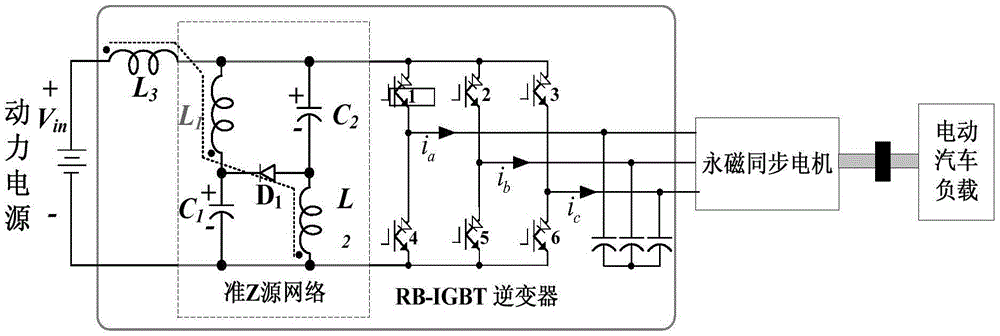

Active thermal optimization control method and device of electromobile driving system

ActiveCN105577069ASolving Control Problems for Active Thermal OptimizationImprove efficiencyAC motor controlElectric machinesZ-source inverterReal-time data

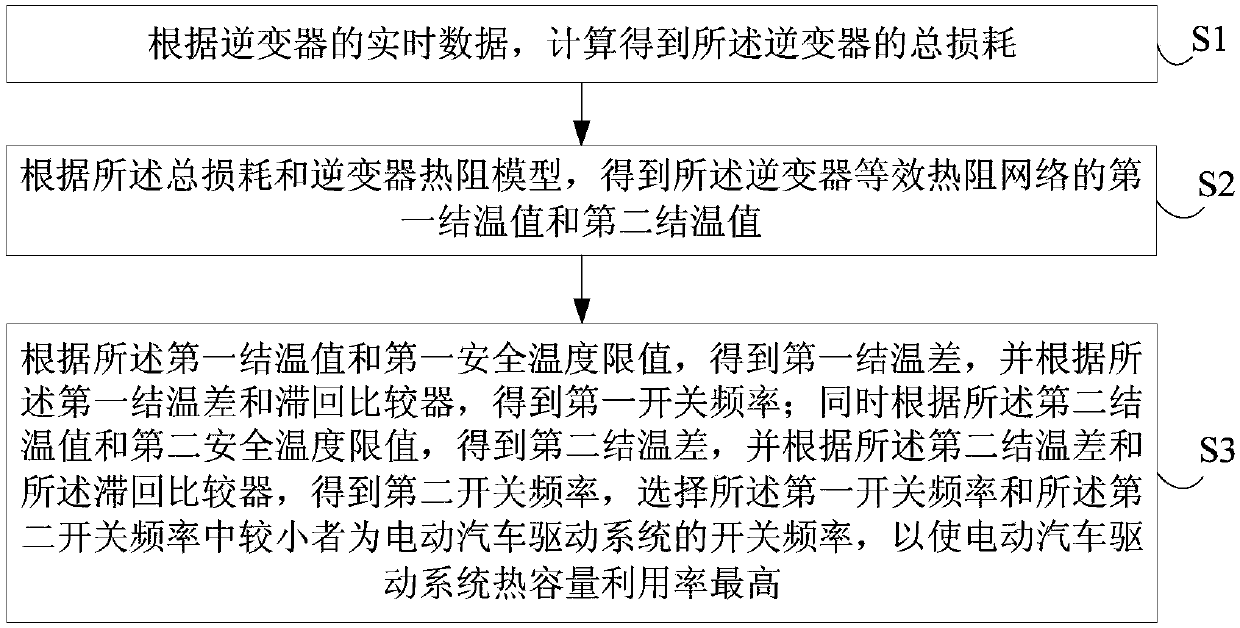

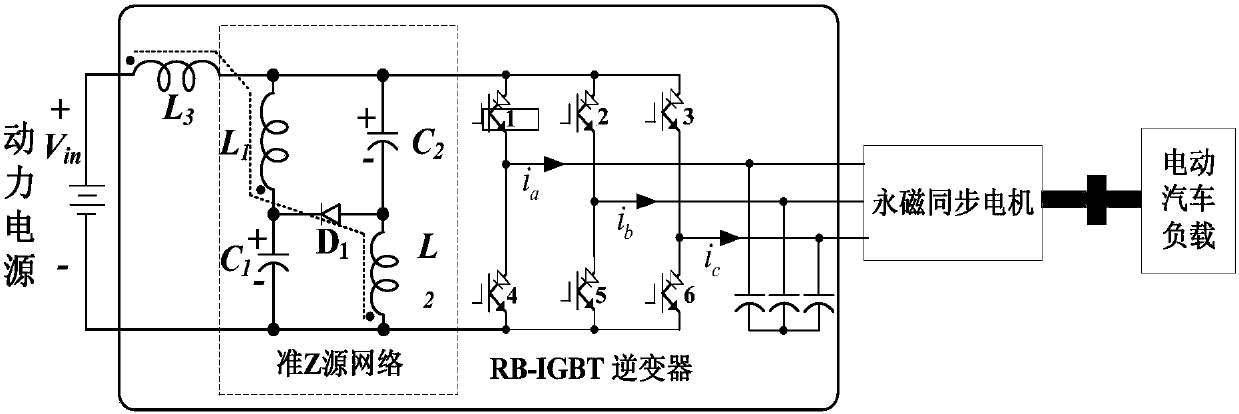

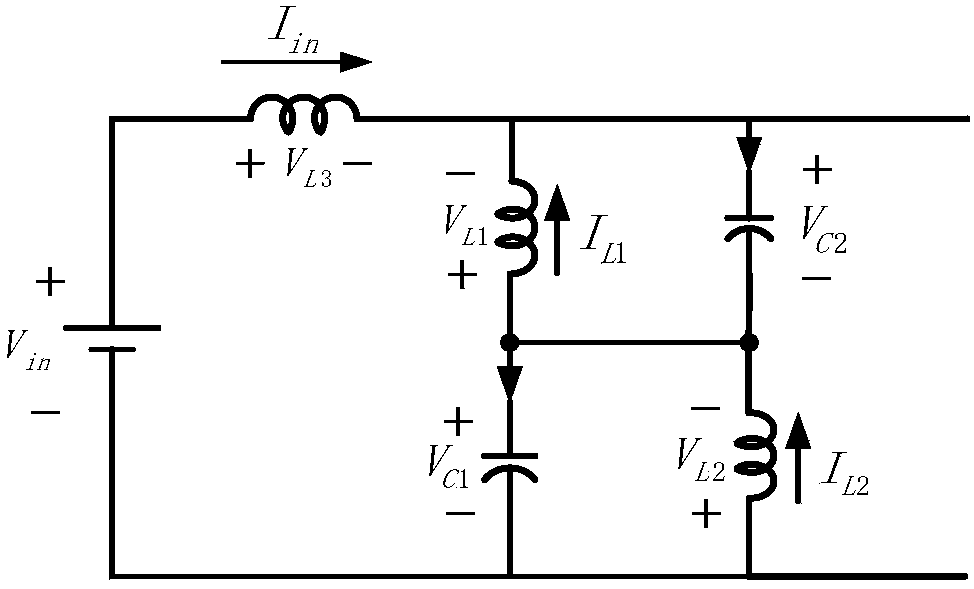

The invention discloses an active thermal optimization control method and device of an electromobile driving system. The method comprises the following steps of calculating total loss of an inverter according to real-time data of the inverter; obtaining a first junction temperature value and a second junction temperature value of an inverter equivalent thermal resistance network according to the total loss and an inverter thermal resistance model; obtaining a first switching frequency according to the first junction temperature value, a first safe temperature limit value and a hysteresis comparator; simultaneously obtaining a second switching frequency according to the second junction temperature value, a second safe temperature limit value and the hysteresis comparator; and selecting the smaller one of the first switching frequency and the second switching frequency as the switching frequency of the electromobile driving system. According to the method, a current-type quasi-Z source inverter is adopted, and the problem of active thermal optimization control of the inverter on an actual heat constraint condition is solved by adjusting the shoot-through duty ratio of the inverter, the switching frequency and a control signal output from a space vector pulse width modulator.

Owner:HUNAN UNIV

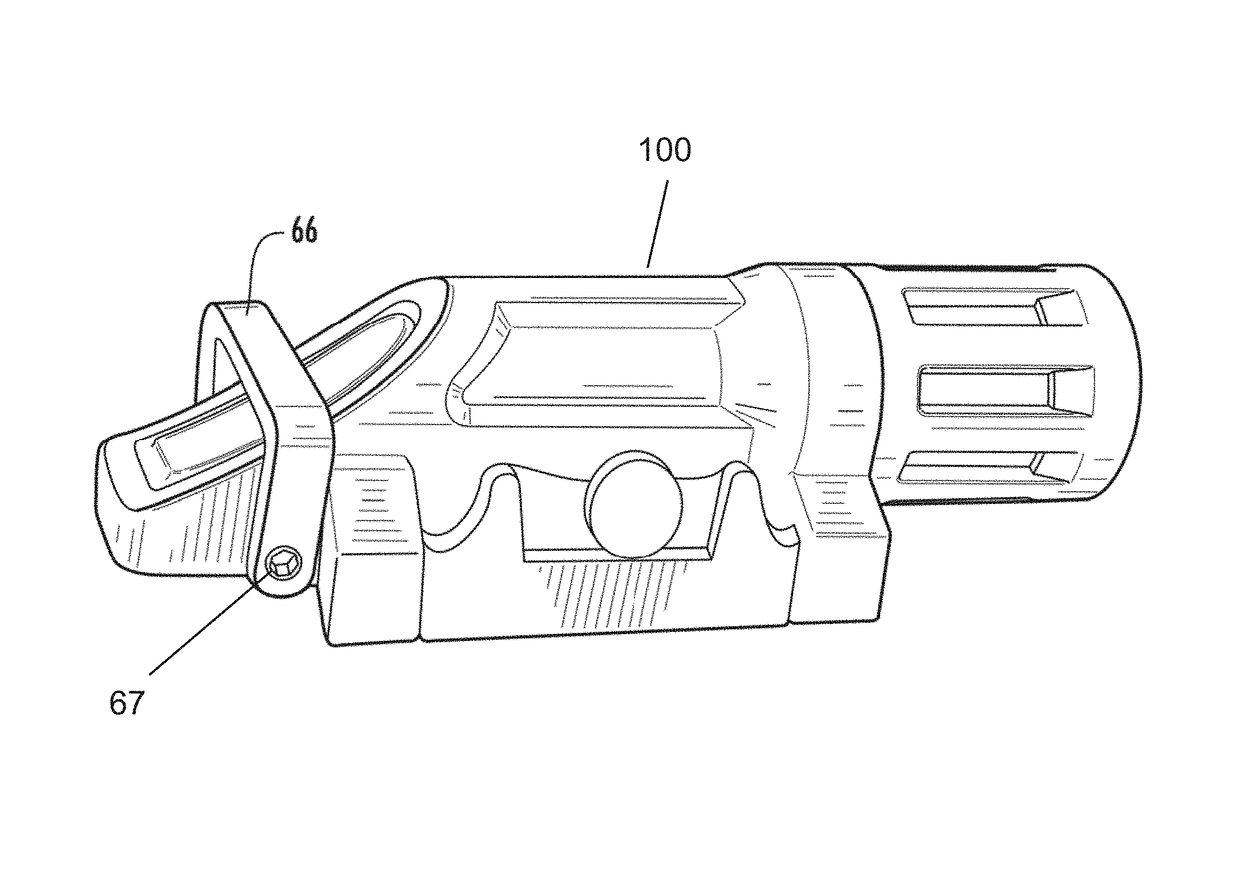

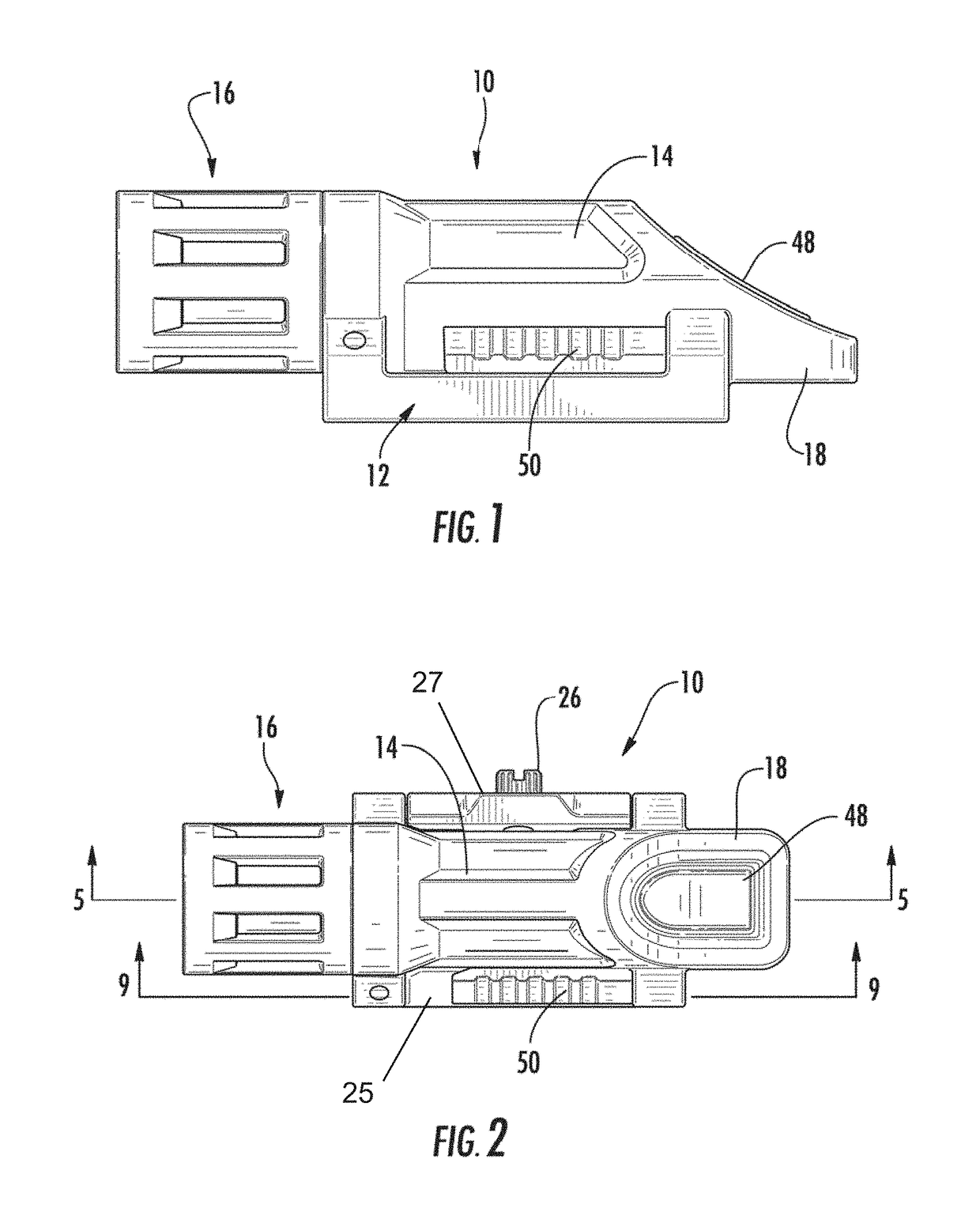

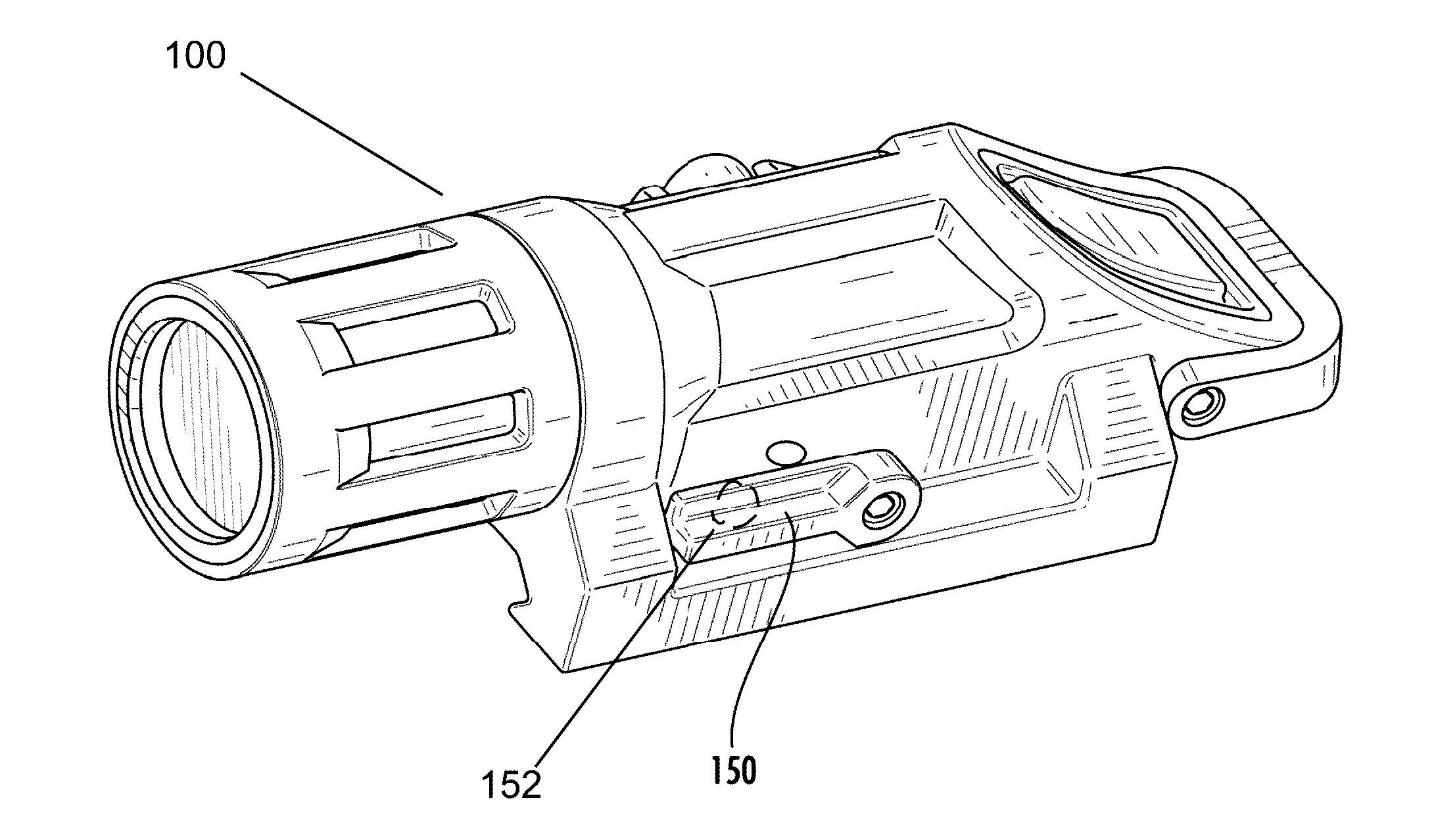

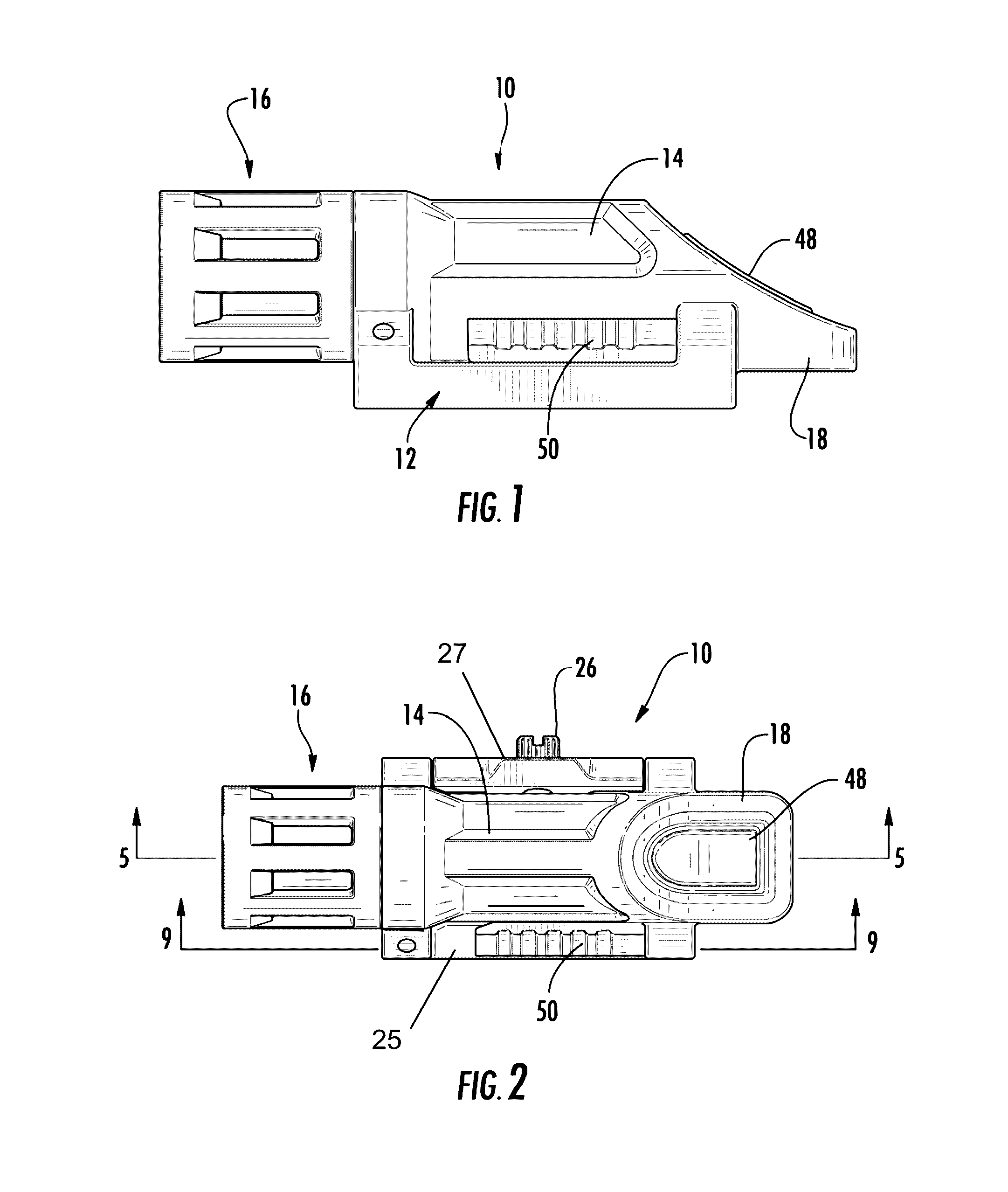

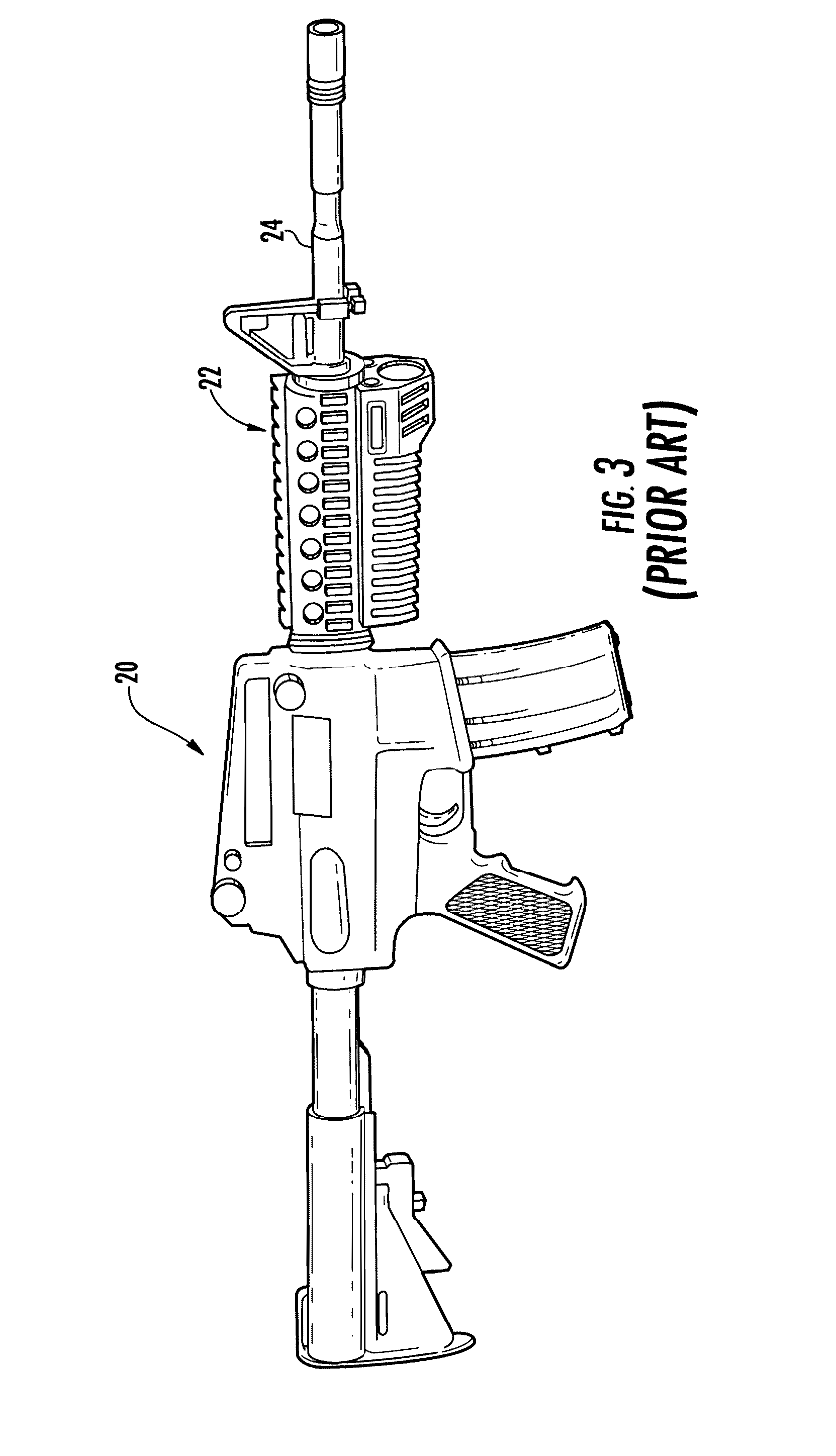

Weapon mounted light and operation thereof

ActiveUS9958143B2Conducive to compact designReduce the temperatureElectrical apparatusLighting support devicesEngineeringOperation mode

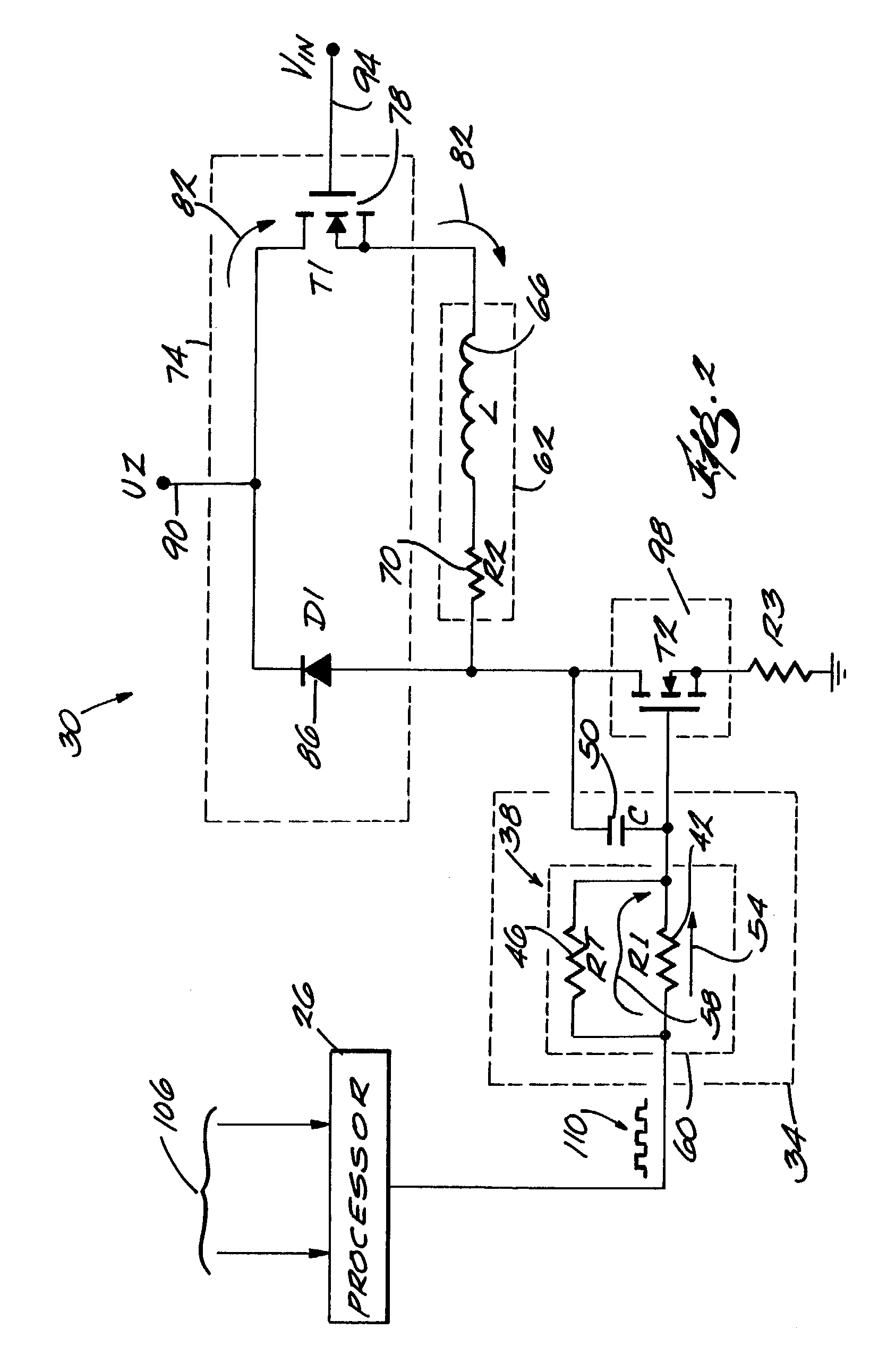

A flashlight assembly includes a bistable safety bail to prevent inadvertent depression of an operational push button switch. The flashlight assembly further includes a bistable pivoting mode selection lever which controls operational modes of the flashlight. Further, the flashlight operates with a thermal optimization circuit which automatically, over time, reduces the duty cycle of the control circuit to reduce the temperature of the LED junction, improve LED performance and increase battery life.

Owner:EMISSIVE ENERGY A DELAWARE

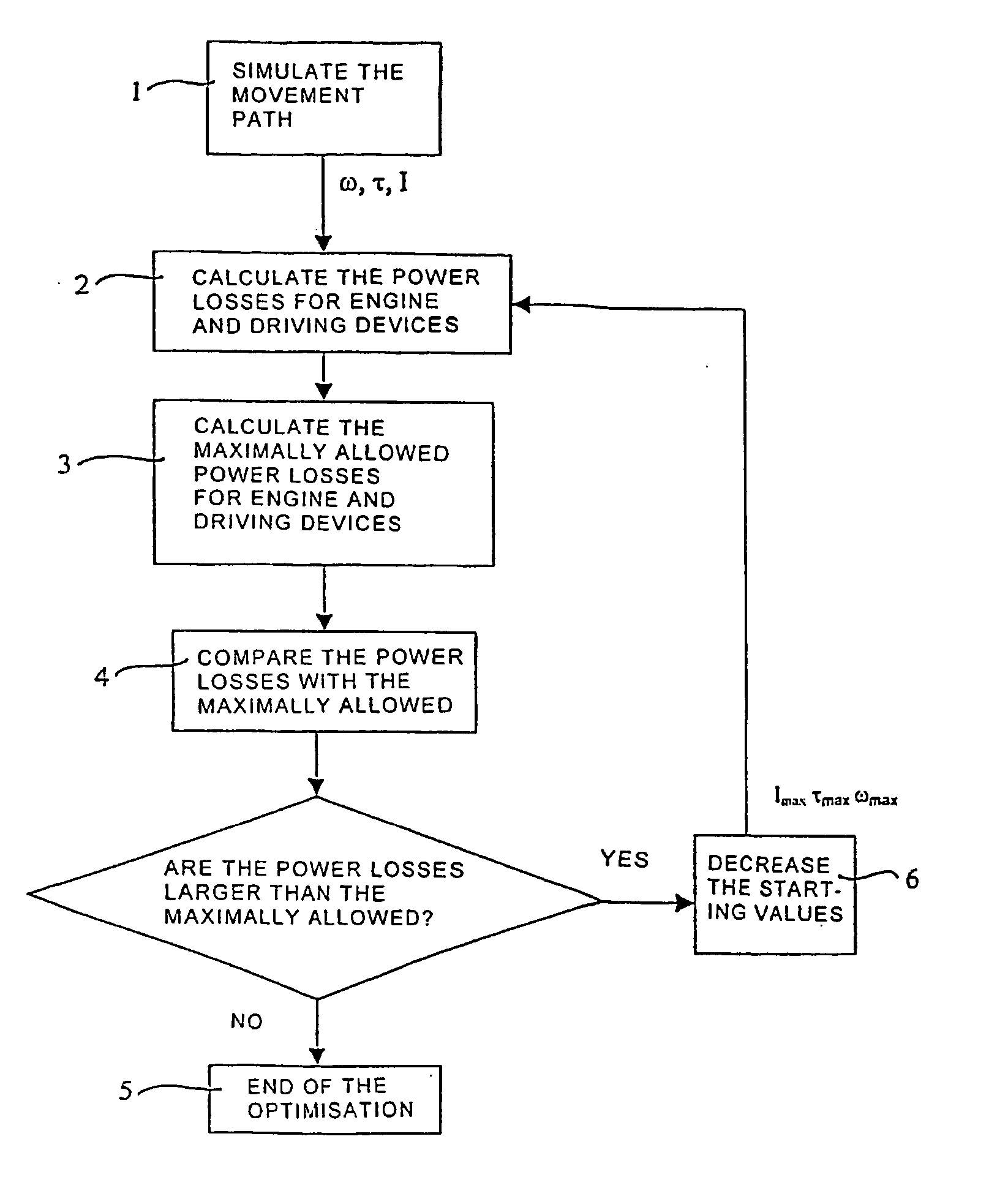

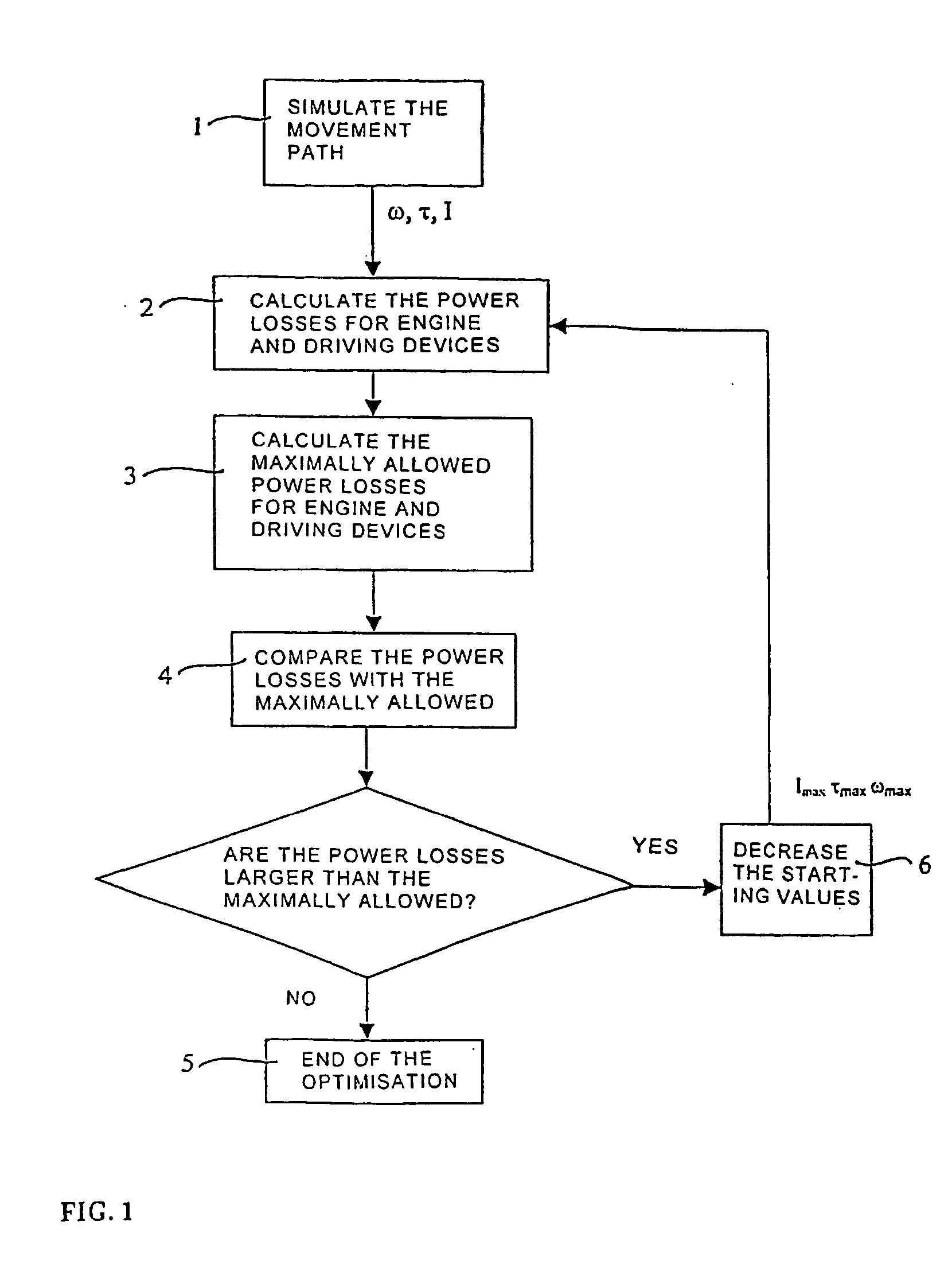

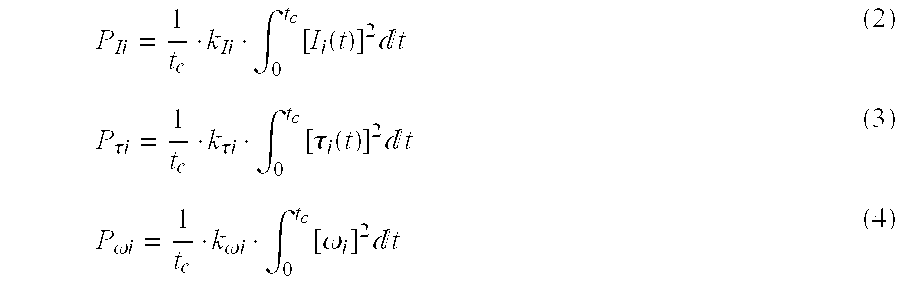

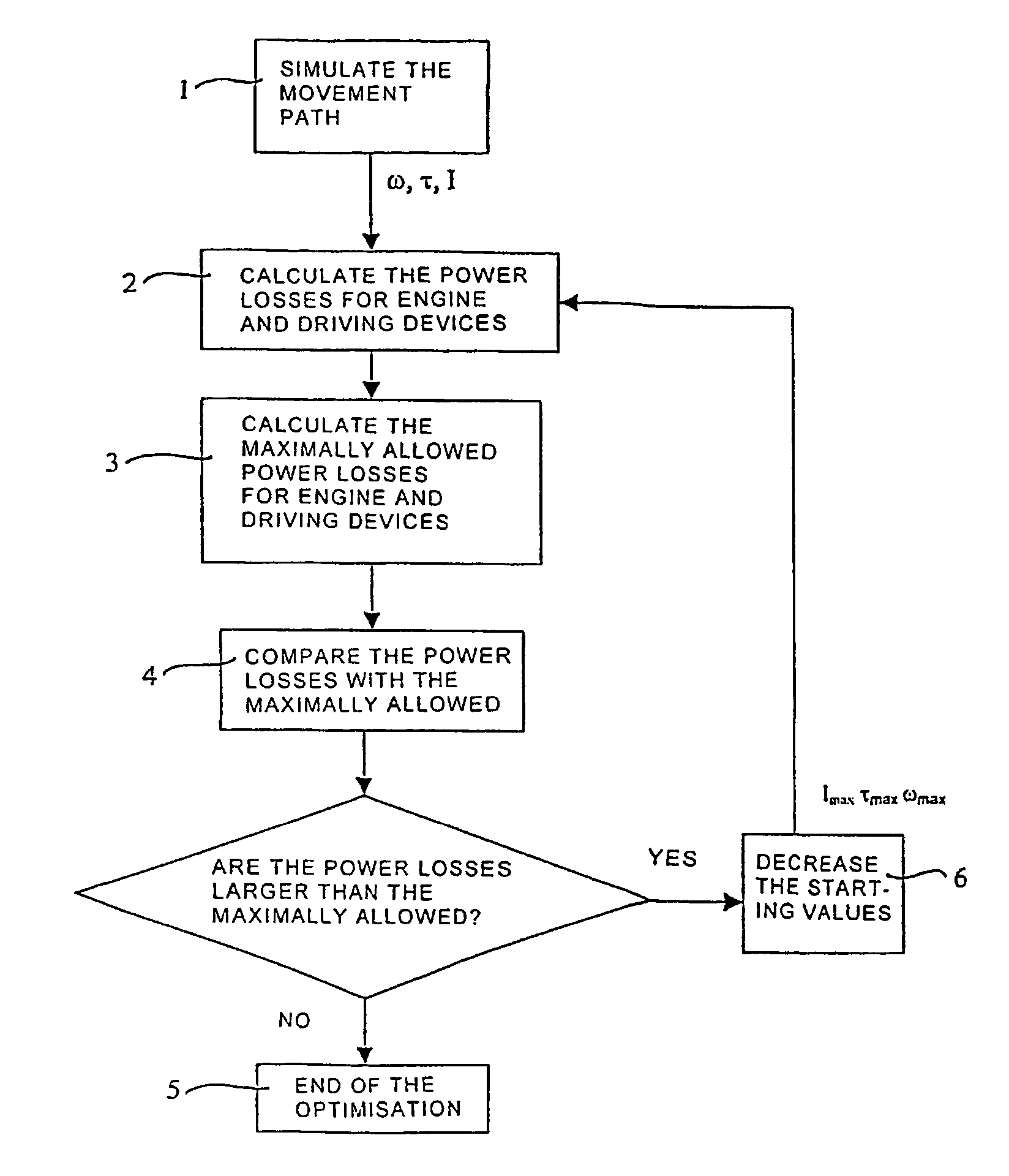

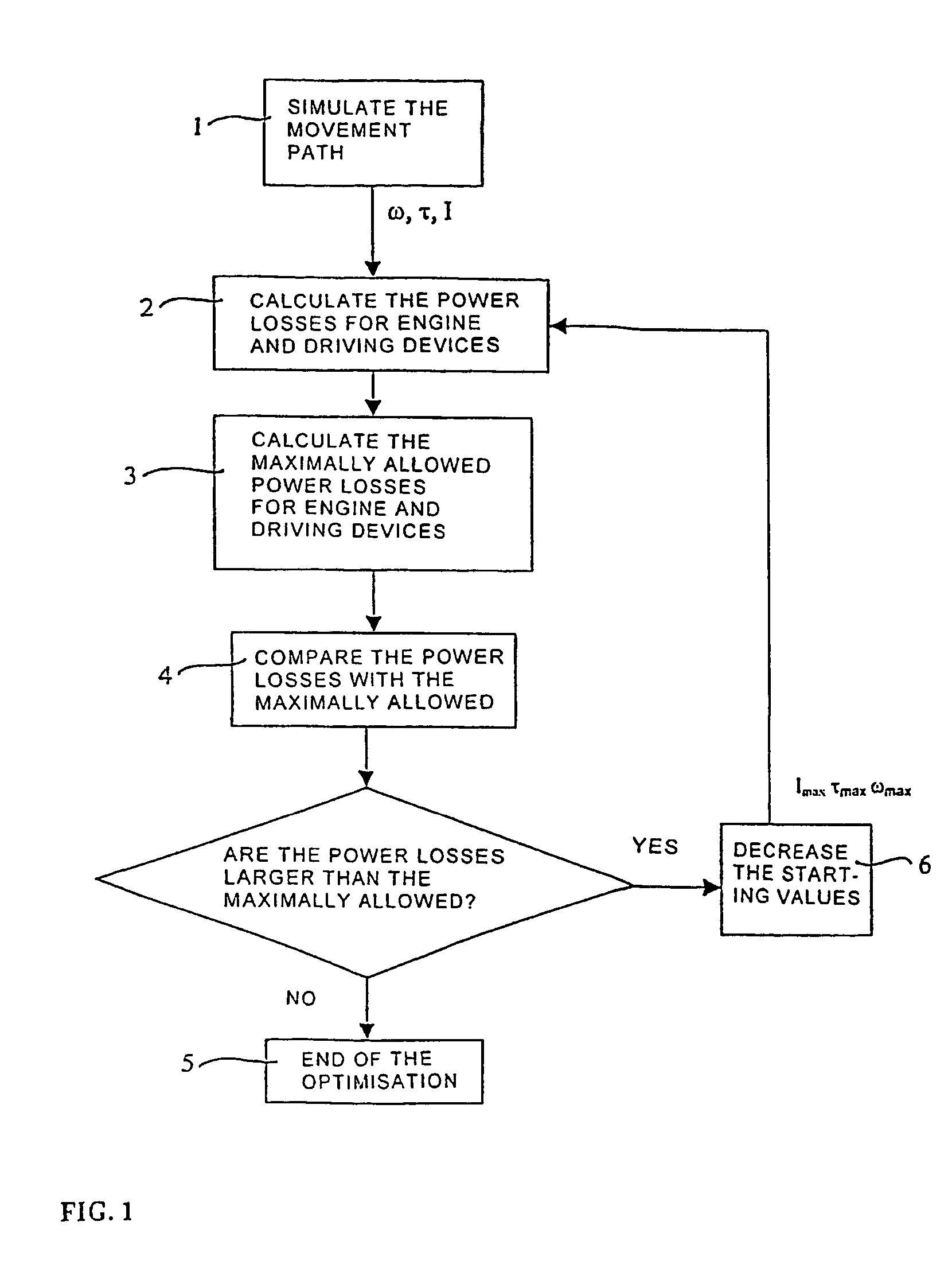

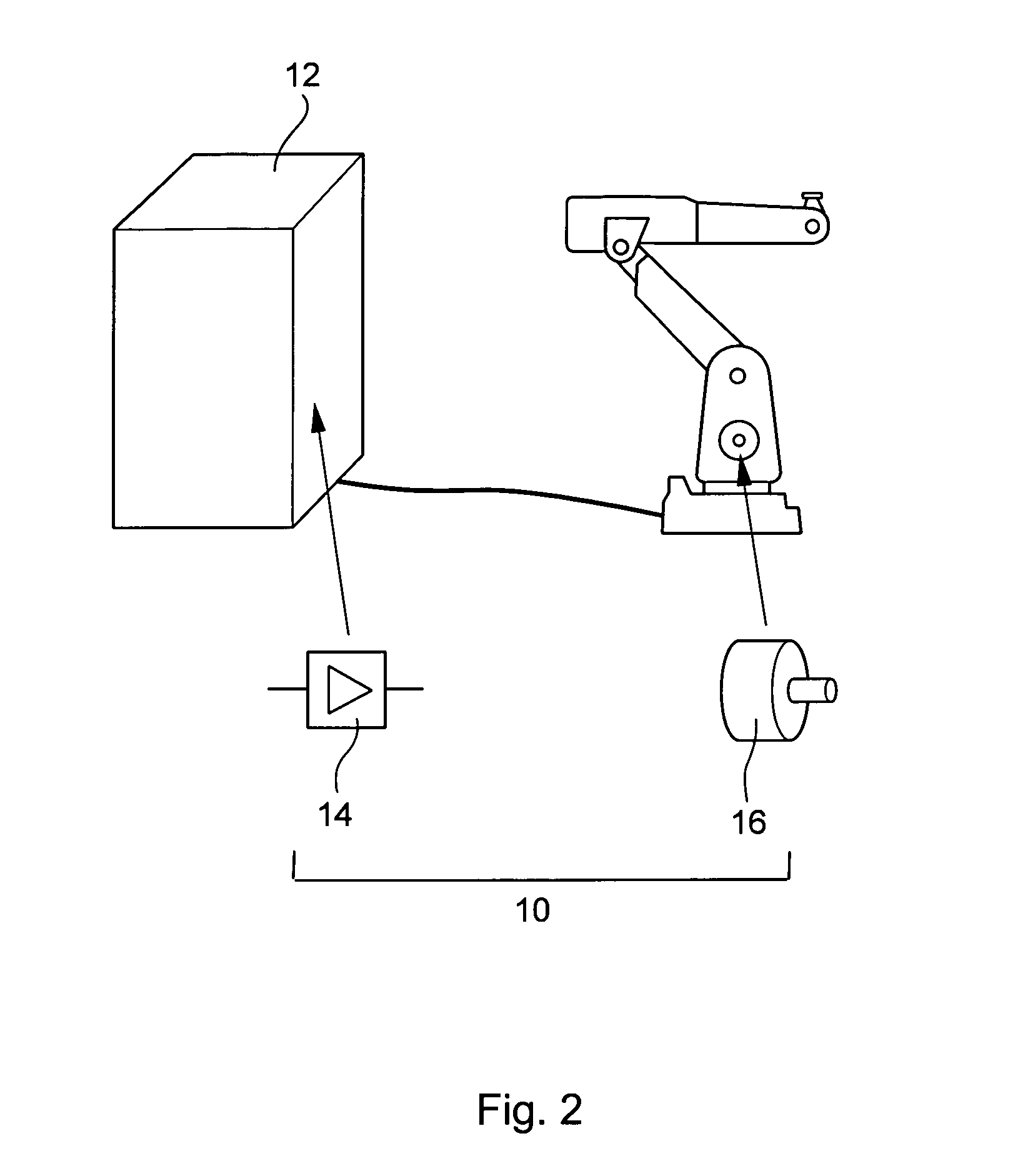

Method for thermal optimization

InactiveUS20040124802A1Not possibleImprove performanceProgramme-controlled manipulatorComputer controlSimulationAcceleration Unit

Method for optimising the movement performance of an industrial robot for a current movement path with respect to thermal load on the driving system of the robot, wherein the method comprises the following steps: for at least one component in the driving system, the thermal load is calculated for the whole or parts of the movement path if the calculated thermal load is compared with a maximally allowed load for the component; and dependent on said comparison, a course of accelerations and velocities for the current movement path are adjusted.

Owner:ABB (SCHWEIZ) AG

Weapon mounted light and operation thereof

ActiveUS20160348880A1Conducive to compact designImproving LED performanceLighting support devicesElectrical apparatusOperation modePush switch

A flashlight assembly includes a bistable safety bail to prevent inadvertent depression of an operational push button switch. The flashlight assembly further includes a bistable pivoting mode selection lever which controls operational modes of the flashlight. Further, the flashlight operates with a thermal optimization circuit which automatically, over time, reduces the duty cycle of the control circuit to reduce the temperature of the LED junction, improve LED performance and increase battery life.

Owner:EMISSIVE ENERGY A DELAWARE

Method for thermal optimization

InactiveUS7084595B2Improve performanceMaximum performanceProgramme-controlled manipulatorComputer controlSimulationThermal load

Method for optimizing the movement performance of an industrial robot for a current movement path with respect to thermal load on the driving system of the robot, wherein the method comprises the following steps: for at least one component in the driving system, the thermal load is calculated for the whole or parts of the movement path if the calculated thermal load is compared with a maximally allowed load for the component; and dependent on said comparison, a course of accelerations and velocities for the current movement path are adjusted.

Owner:ABB (SCHWEIZ) AG

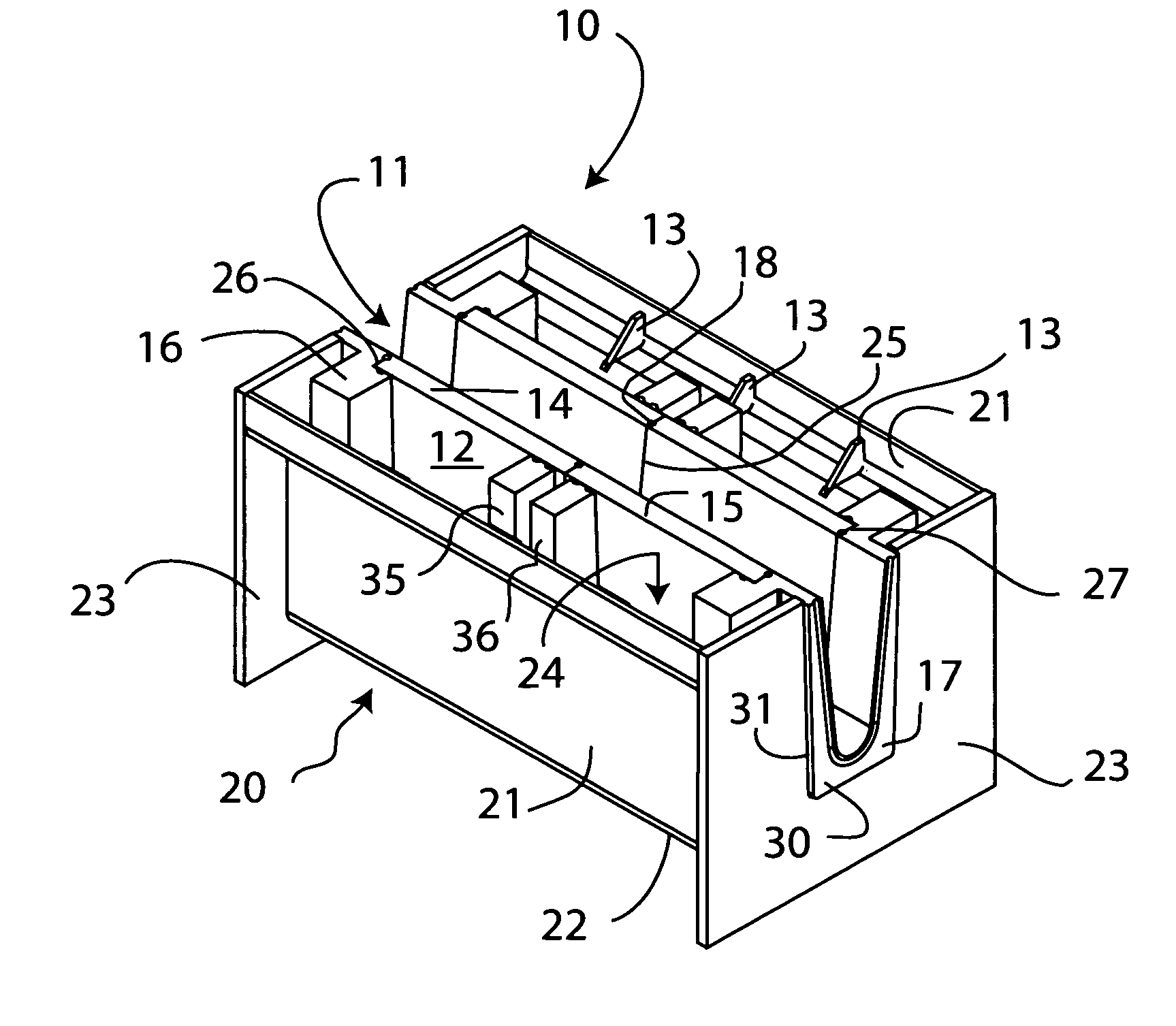

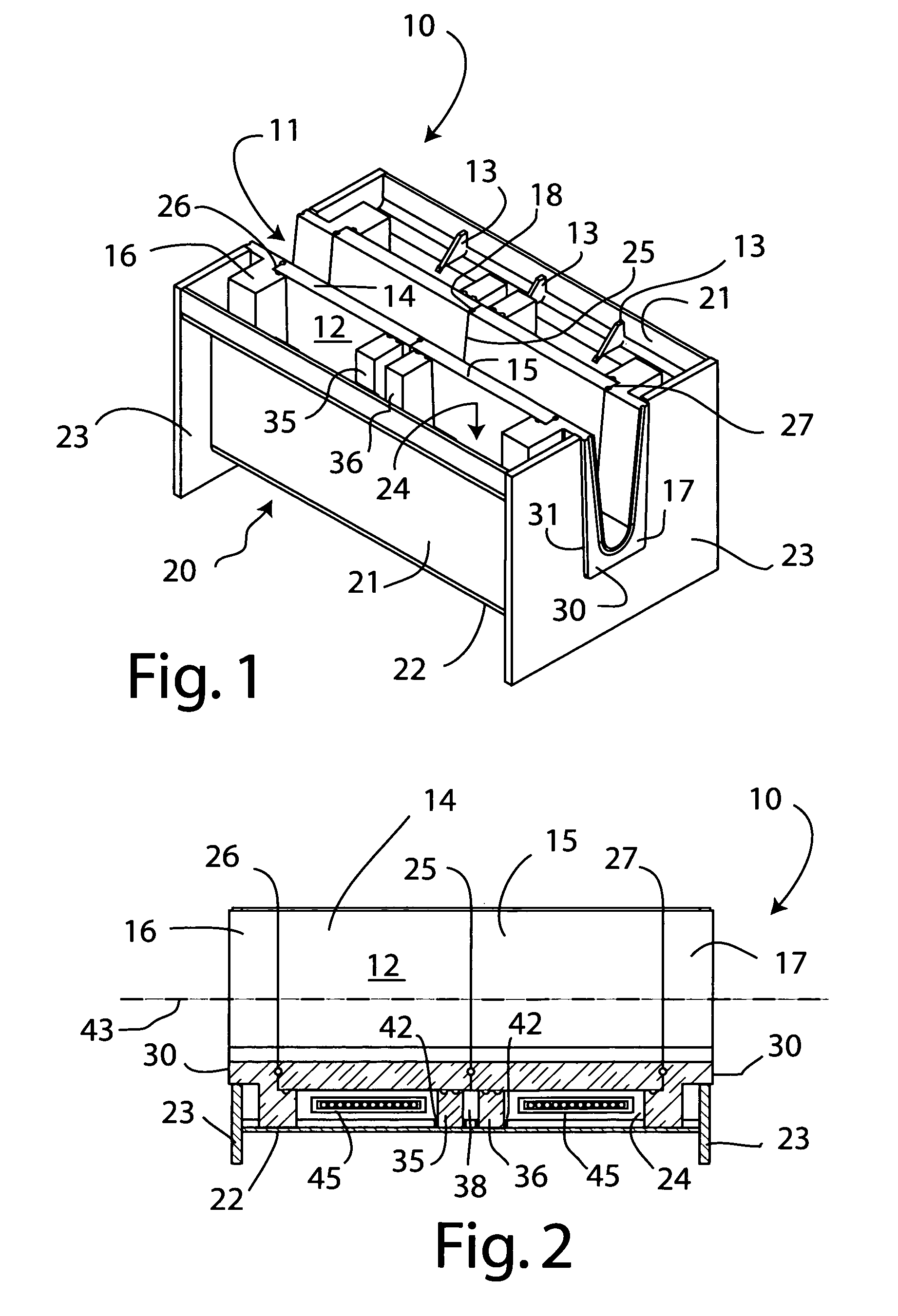

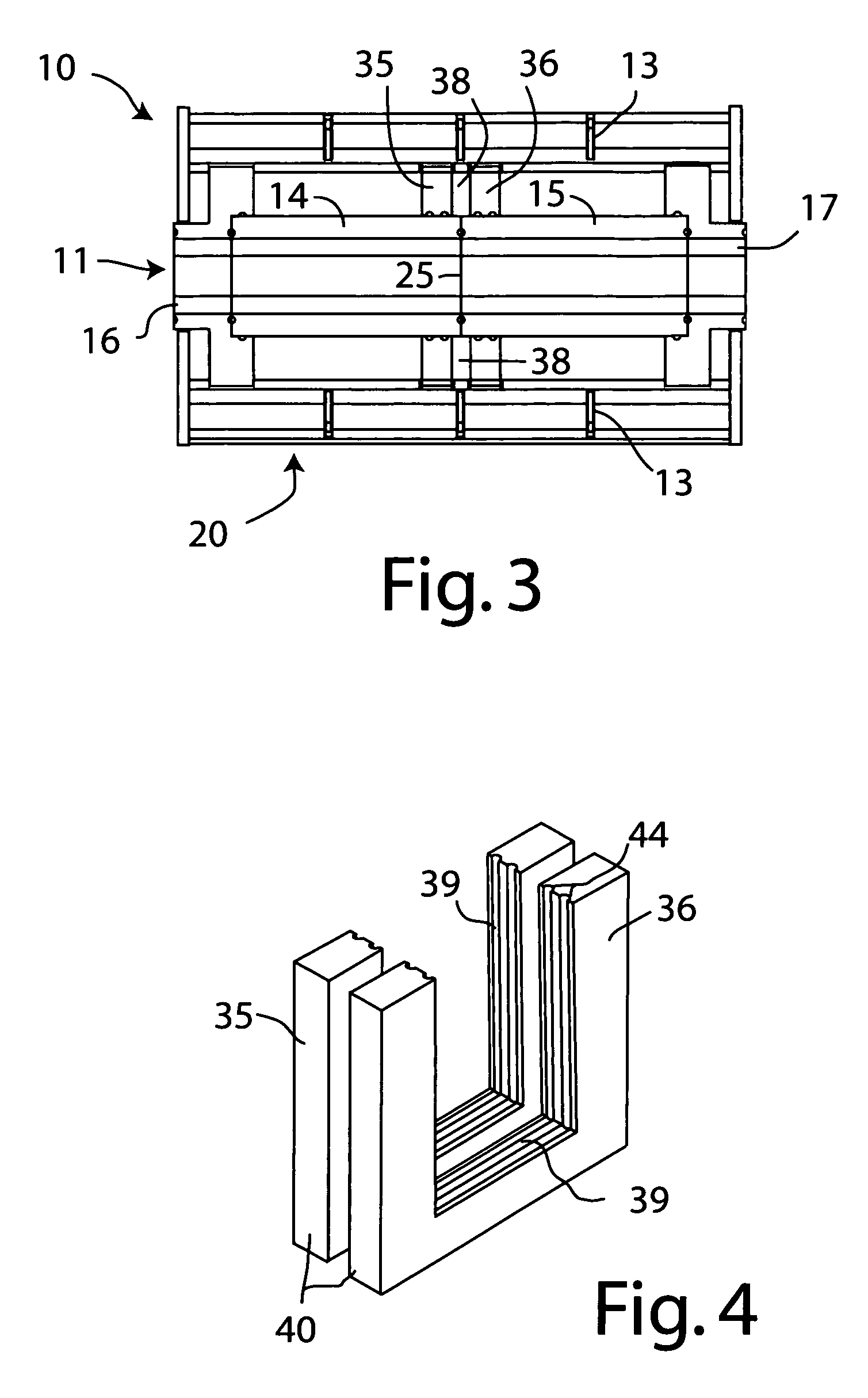

Molten metal leakage confinement and thermal optimization in vessels used for containing molten metal

ActiveUS8657164B2Prevent penetrationLow thermal conductivityMelt-holding vesselsBlast furnace detailsMetallurgyHeat losses

A vessel used for containing molten metal, e.g. a trough section for conveying molten metal from one location to another. The vessel has a refractory liner made of at least two refractory liner units positioned end to end, with a joint between the units, the units each having an exterior surface and a metal-contacting interior surface. A housing at least partially surrounds the exterior surfaces of the refractory liner units with a gap present between the exterior surfaces and the housing. Molten metal confinement elements, impenetrable by molten metal, are positioned on opposite sides of the joint within the gap, at least below a horizontal level corresponding to a predetermined maximum working height of molten metal held within the vessel in use, to partition the gap into a molten metal confinement region between the elements and at least one other region that may be used to hold equipment such as electrical heaters that may be damaged by contact with molten metal. Another embodiment employs refractory liner units of different thermal conductivity to maximize heat penetration into the molten metal from heaters in the gap, but to minimize heat loss at the inlet and outlet of the vessel where the end units contact the housing.

Owner:NOVELIS INC

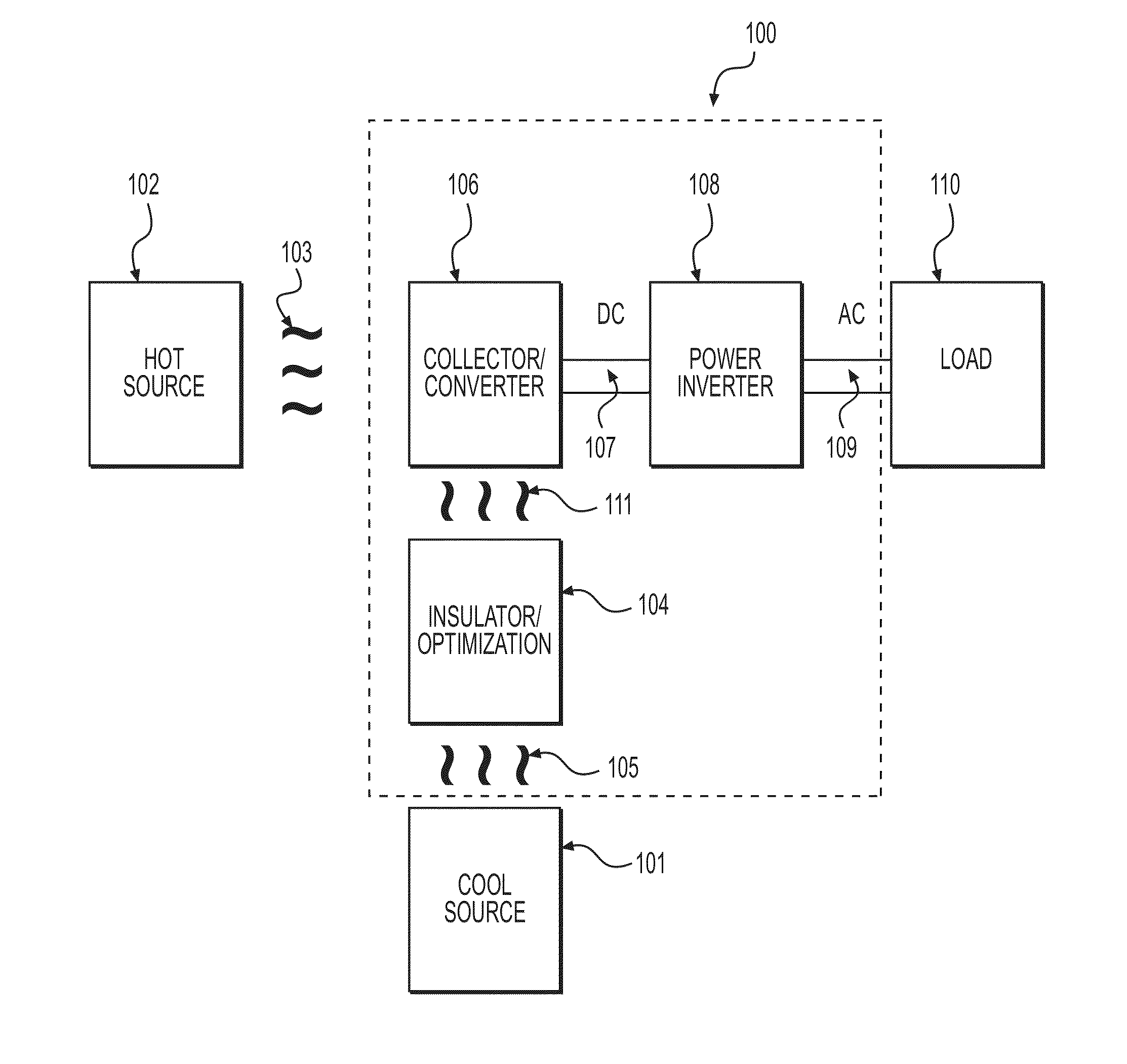

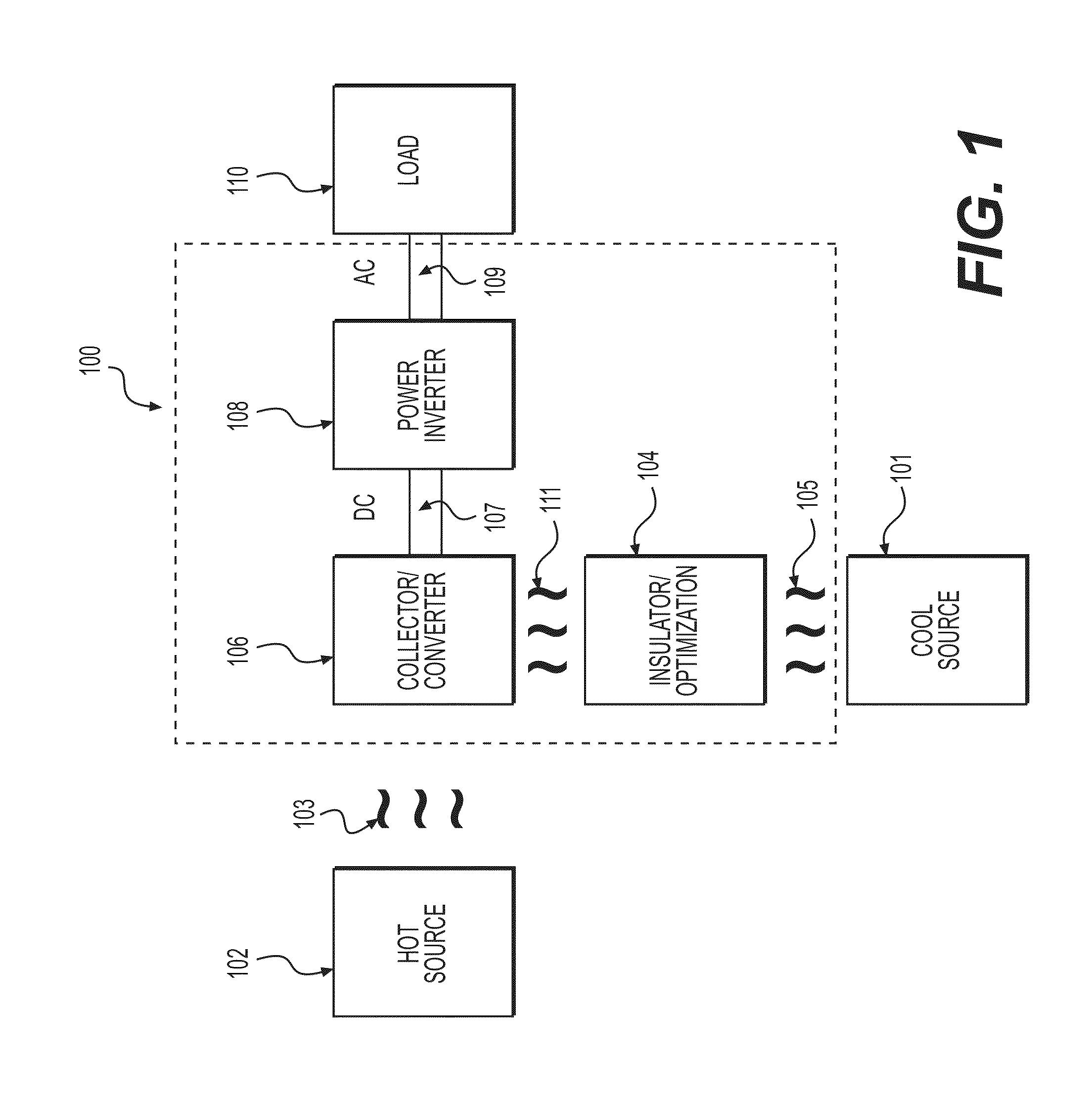

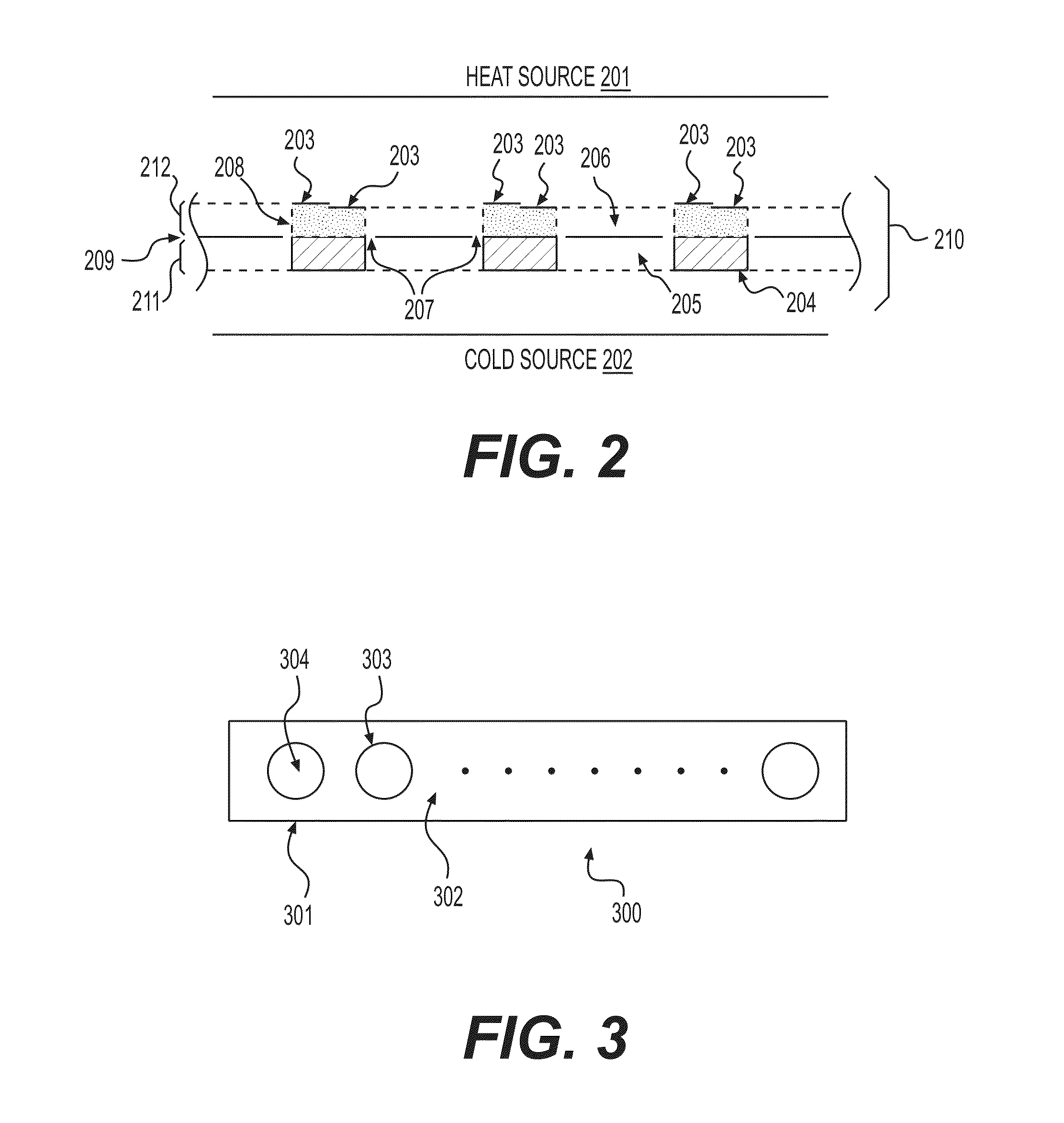

Structures, System and Method for Converting Electromagnetic Radiation to Electrical Energy

ActiveUS20160126441A1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEnergy transferEngineering

A substrate, resonant structures, a ground plane, a thermal optimization layer and energy transfer structures are combined to receive and convert incoming electromagnetic radiation into electrical energy. This combination of materials may be housed in various configurations near heat sources to maximize surface area for heat contact as well as cooling. All structures are designed so as to be manufactured in low cost processes such as roll to roll.

Owner:REDWAVE ENERGY

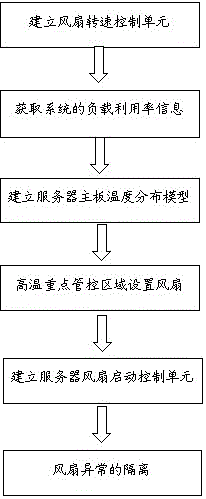

Rotating speed control system and method of server fan

InactiveCN106837838AConvergent stabilityAchieve thermal optimizationPump componentsPump controlSpeed control systemControl system

The invention discloses a rotating speed control system and a method of a server fan. The system comprises a fan rotating speed control unit for obtaining load utilization rate information of the system and adjusting the rotating speed of the fan according to the change tendency of the total load utilization rate of the system. The system is provided with the fan rotating speed control unit for realizing slow switching of the rotating speed transition of the fan and quick and stable cnvergence of the rotating speed of the fan based on the temperature prediction control. Meanwhile, a temperature distribution model of a server main board is built; different important heat dissipating areas are divided in a main board area; the different fan rotating speed control is adopted to realize overall heat dissipating optimization of the server main board; and the reliability of the system is guaranteed.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

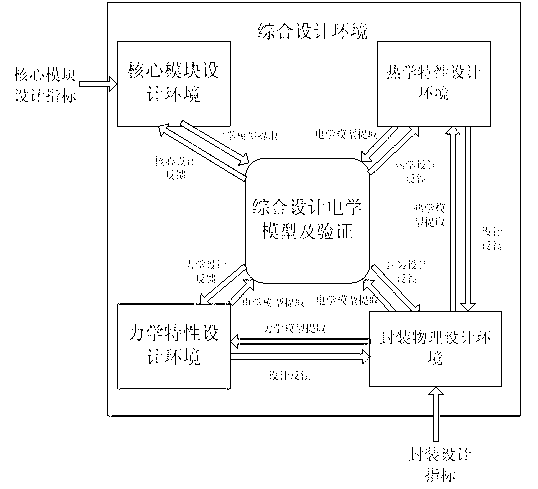

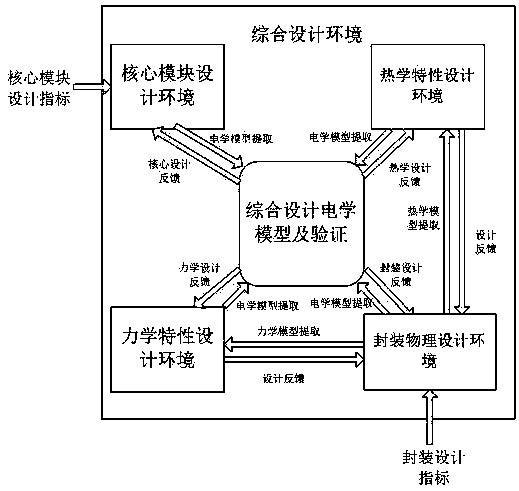

Electric, thermal and mechanical integrated design environment applicable to electronic product packaging design

InactiveCN103186682AReduce complexityReduce design iterationsSpecial data processing applicationsIntegrated designMechanical design

The invention discloses a novel collaborative environment which contains electric, thermal and mechanical characteristics related to electronic product packaging. Compared with a conventional electronic product design, the design is greatly reduced in complexity on the aspects of a packaging method and a process, a product design period is shortened, and the success rate of a one-time design is increased. The environment is characterized in that the comprehensive, accurate and reconfigurable design parameters and performances and function prediction of the electronic product packaging are provided on an integrated design platform. By collaboratively considering the functions of packaging and thermal and mechanical characteristics on product performances, the product performance can be optimized through product core design optimization, packaging optimization, thermal optimization and mechanical design optimization according to the design cost and implementation complexity in a product design stage. On the one hand, the product performances are realized through low cost, and on the other hand, the freedom of a plurality of designs is provided, so that the performance implementation complexity is lowered; and most important of all, the expectation of the product performances can be accurately estimated in a product design stage, so that design iteration is reduced.

Owner:SHANGHAI RES INST OF MICROELECTRONICS SHRIME PEKING UNIV

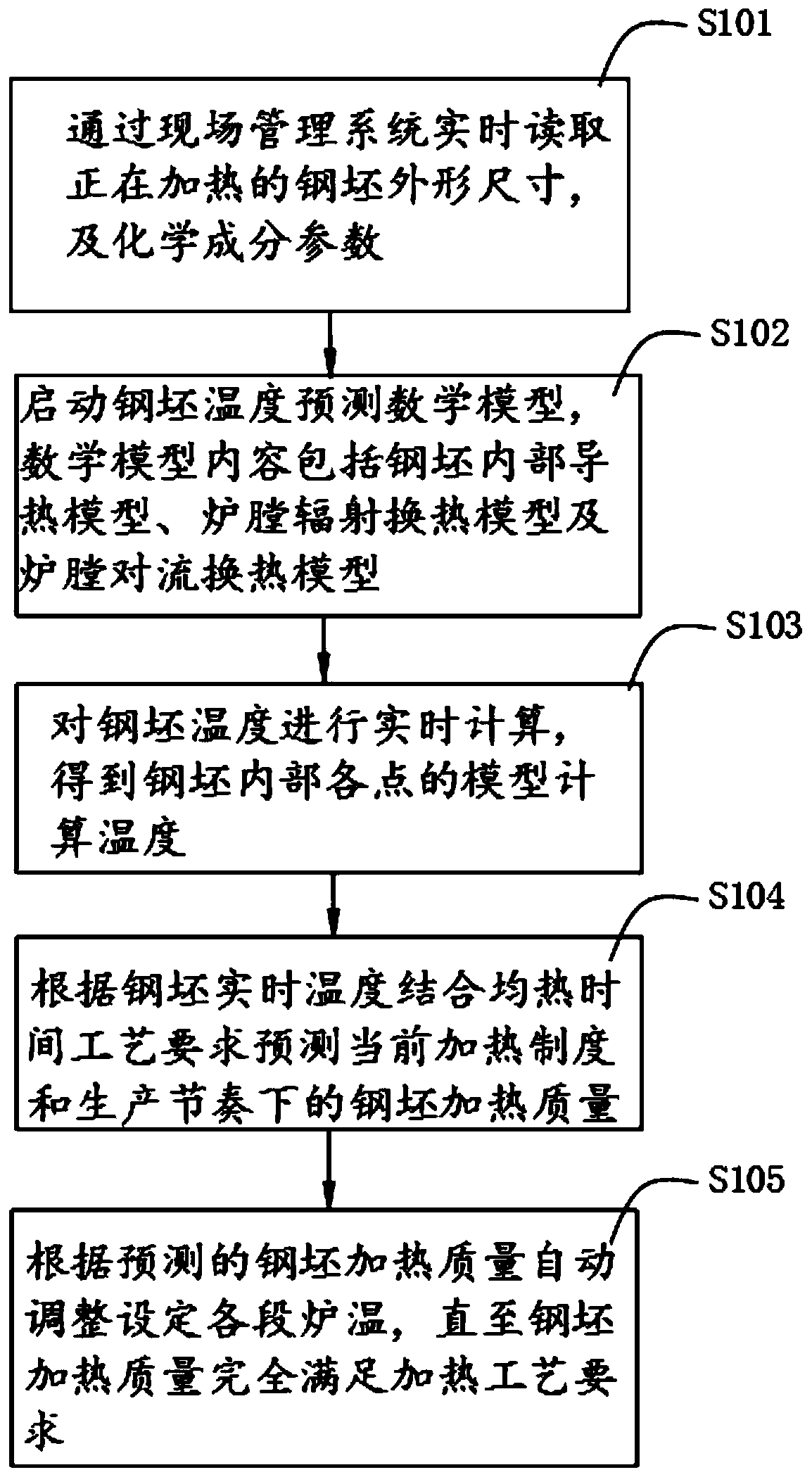

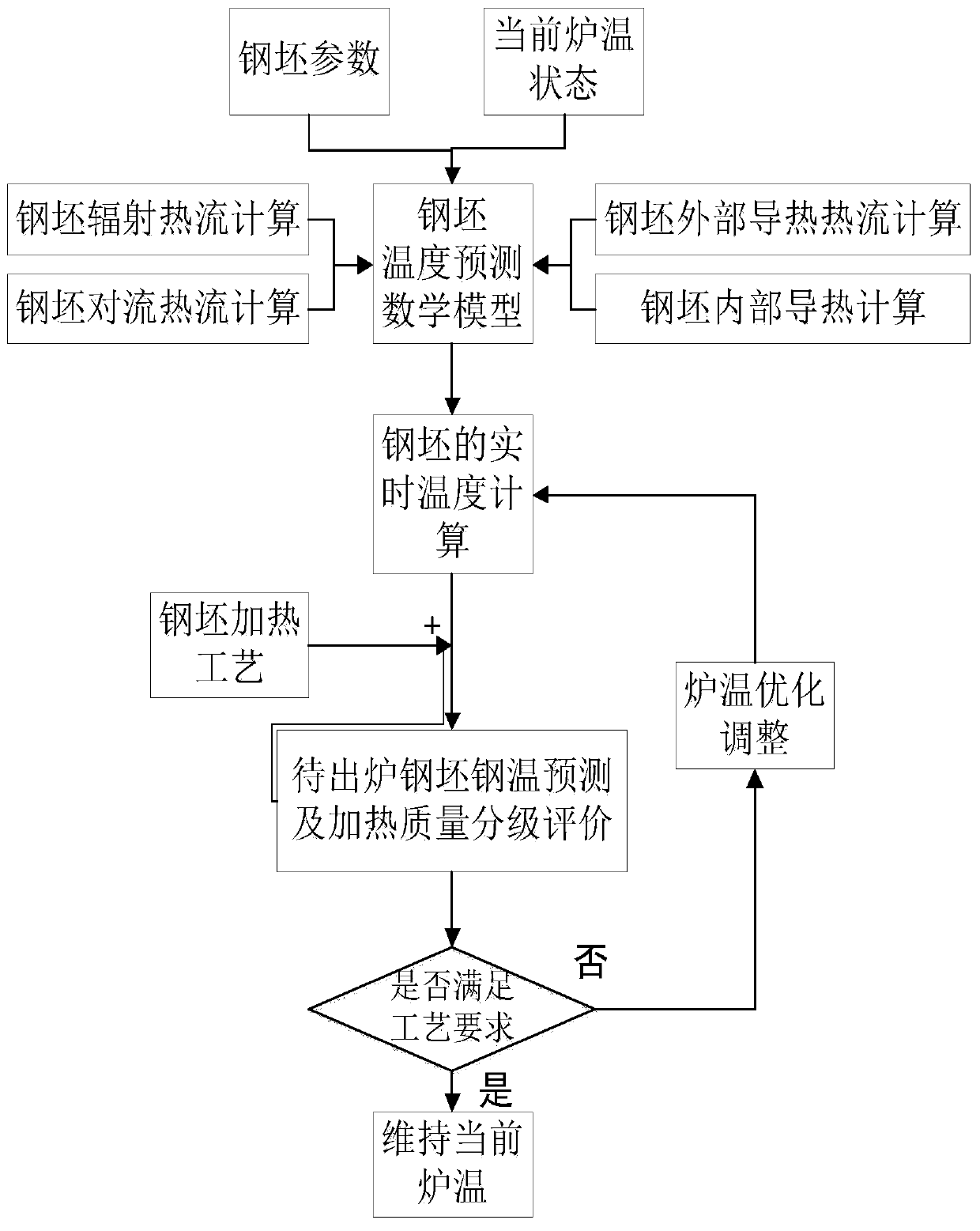

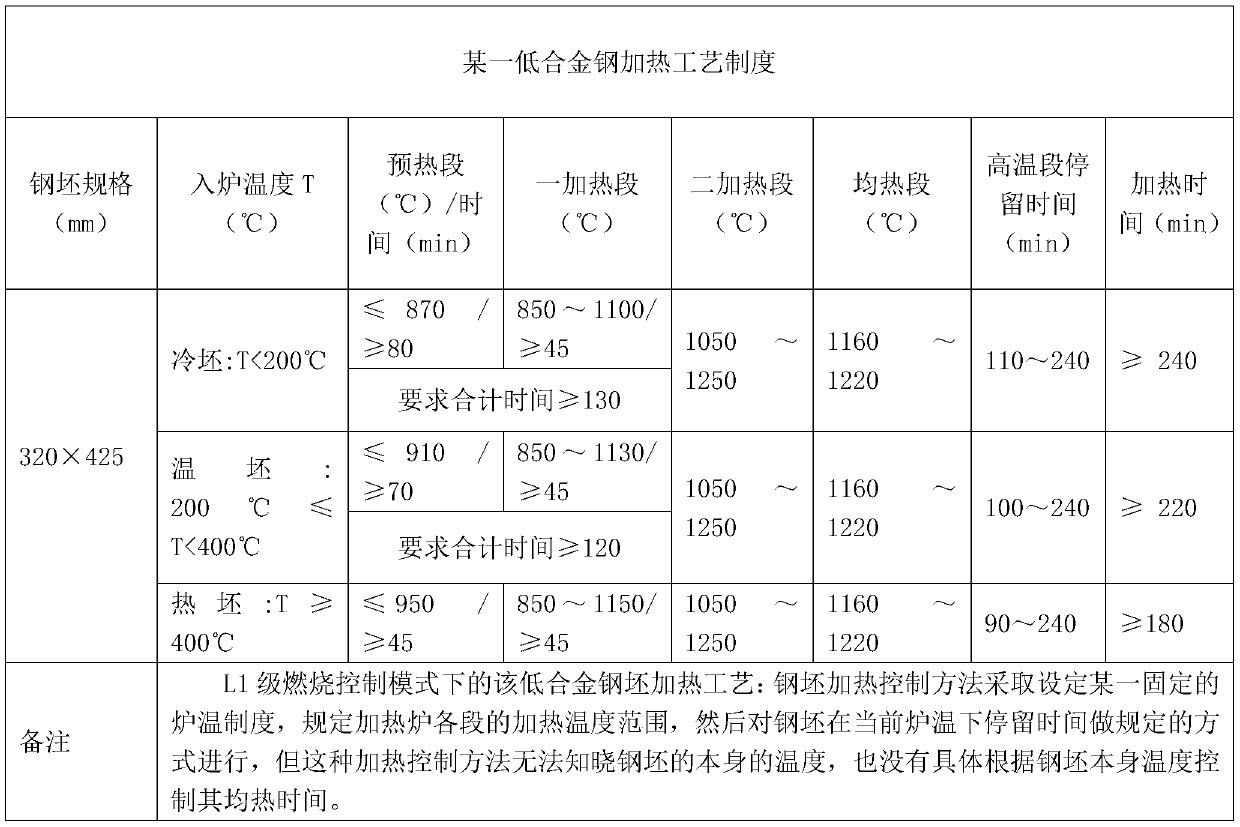

Refined heating control method

InactiveCN110918655AAvoid the phenomenon that the heating quality is not enoughImprove heating qualityTemperature control deviceFurnace temperatureChemical composition

The invention relates to the field of metal heating optimization control methods, in particular to a refined heating control method. According to the technical scheme, the method is characterized by comprising the following steps that the dimension data and chemical composition parameters of steel billet being heated are acquired through a field management system; a steel billet temperature prediction mathematical model is started, the steel billet temperature prediction mathematical model comprises a steel billet internal heat conduction model, a hearth radiation heat exchange model and a hearth convection heat exchange model, and the steel billet temperature is calculated in real time to obtain a model calculation temperature of each point inside the steel billet; according to the real-time temperature of the steel billet in combination with the soaking time process requirements, the heating quality of the steel billet at the current heating system and production rhythm is predicted;and the furnace temperature of each section is automatically adjusted and set according to the predicted heating quality of the steel billet until the heating quality of the steel billet meets the heating process requirement. The method has the advantages that the heating process of the steel billet is finely controlled, and the heating quality of the steel billet and the steel rolling productionefficiency are improved to the maximum extent.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

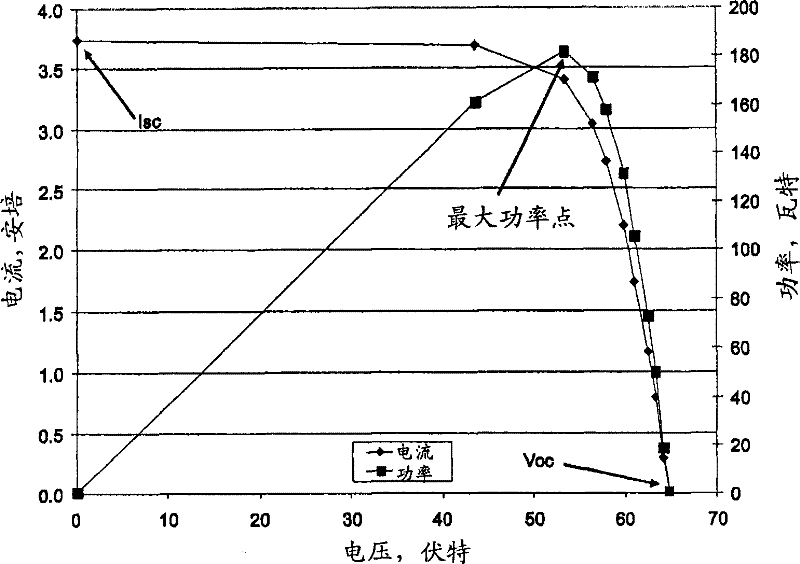

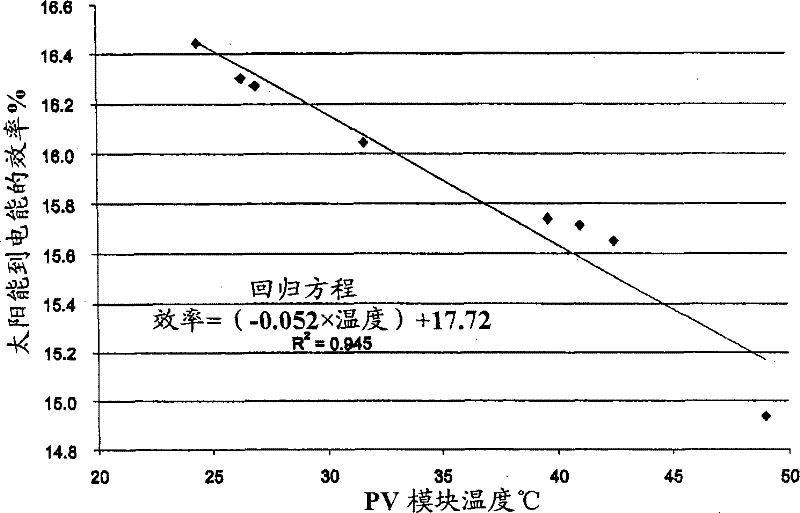

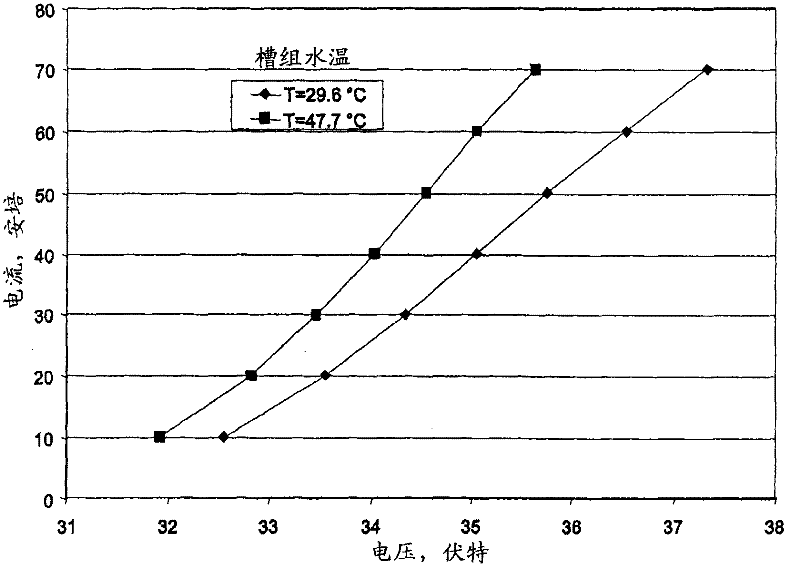

Thermal optimization of a solar photovoltaic powered electrolyzer system

One embodiment of the invention includes a process comprising transmitting electrical power produced by a PV array to an electrolyzer and transferring heat from the PV array to the electrolyzer. The resulting process produces renewable hydrogen from solar energy at a lower cost per kg.

Owner:GM GLOBAL TECH OPERATIONS LLC

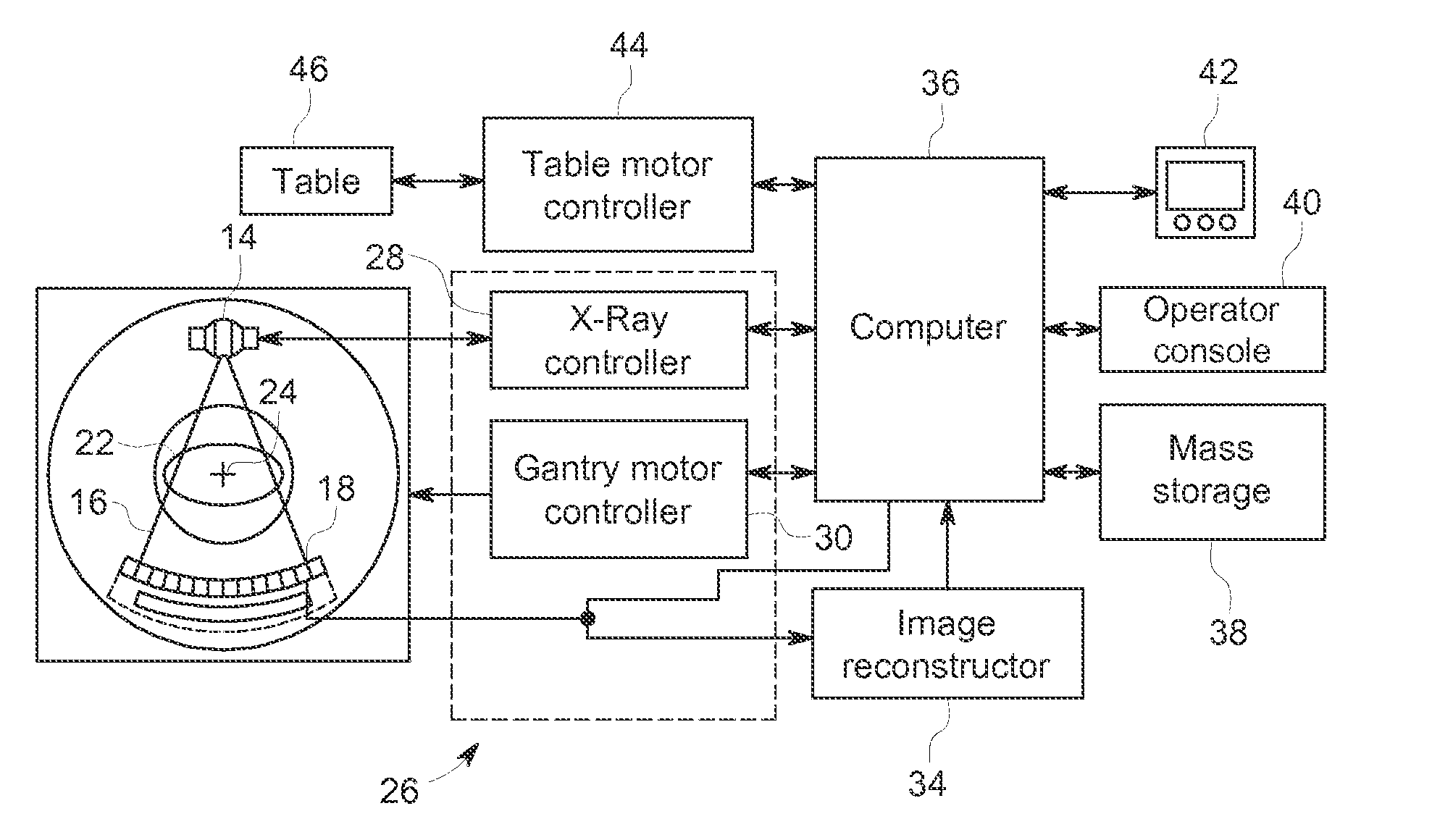

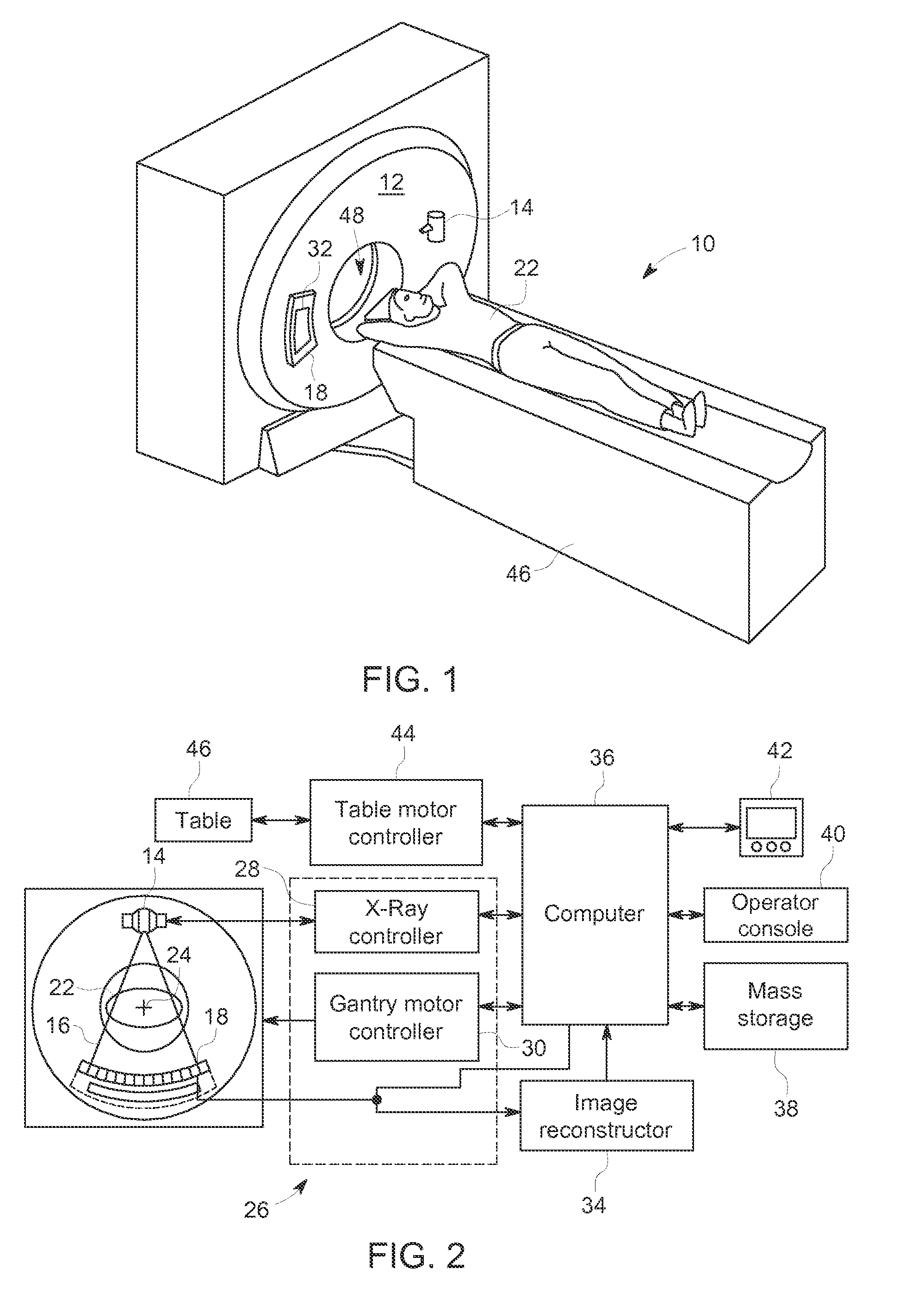

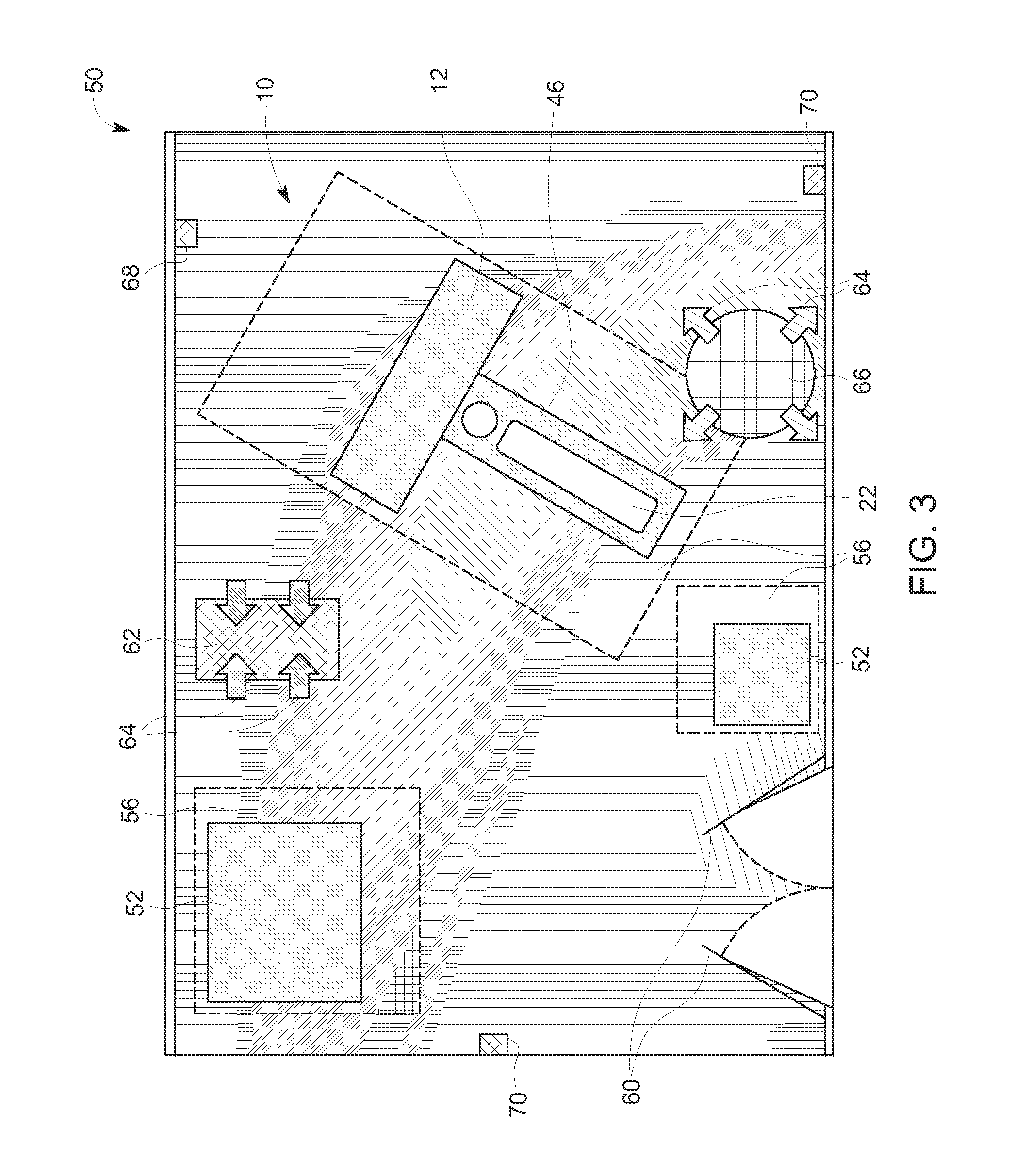

Thermal optimization of an imaging scan room

In accordance with the present disclosure, a tool for evaluating the thermal layout of a scan room is discussed. In practice, the tool may be used to quickly generate and test different room and imaging system layouts to identify a suitable layout. A scan room and imaging system may then be placed and oriented in accordance with the layout that has been tested and found acceptable using the tool.

Owner:GENERAL ELECTRIC CO

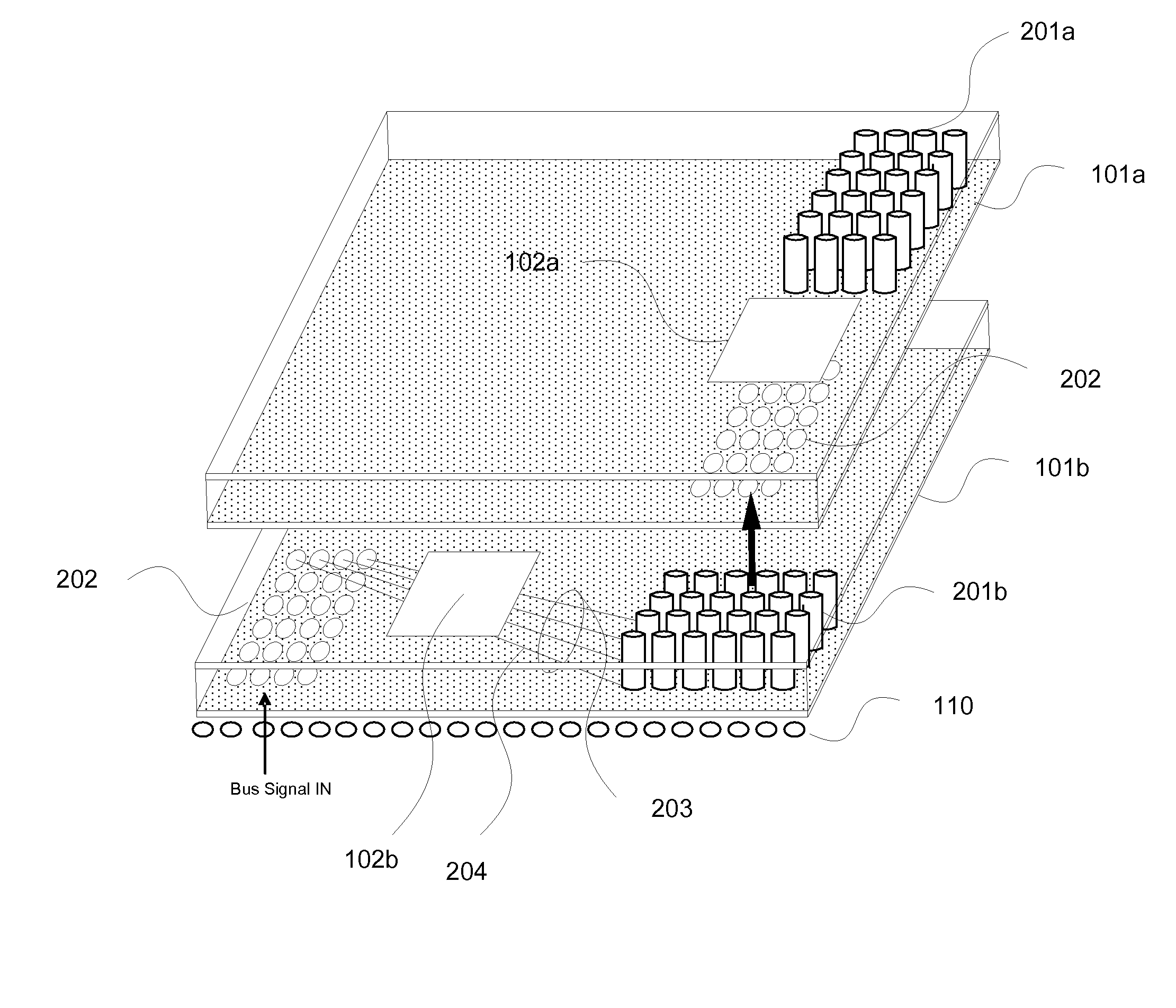

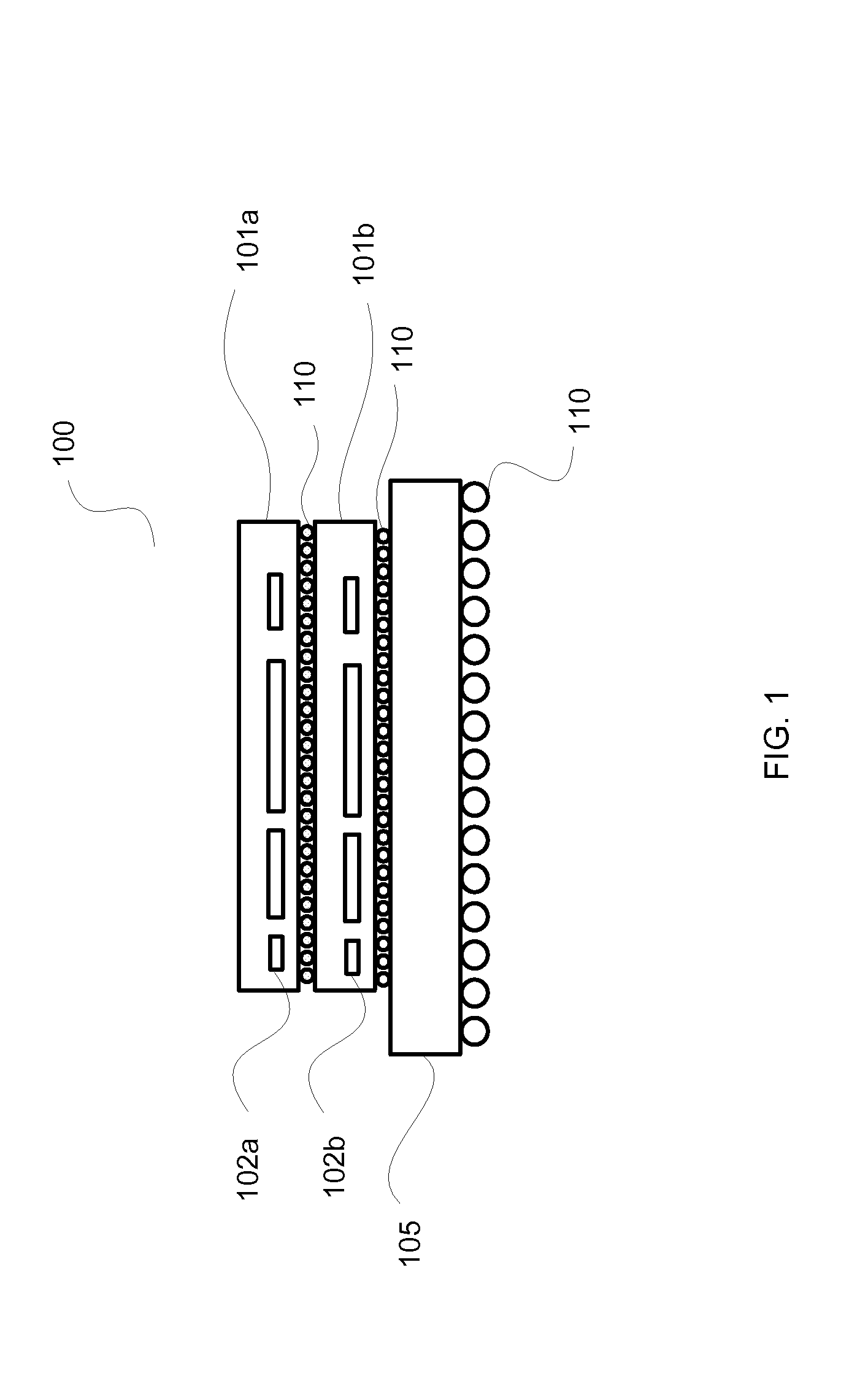

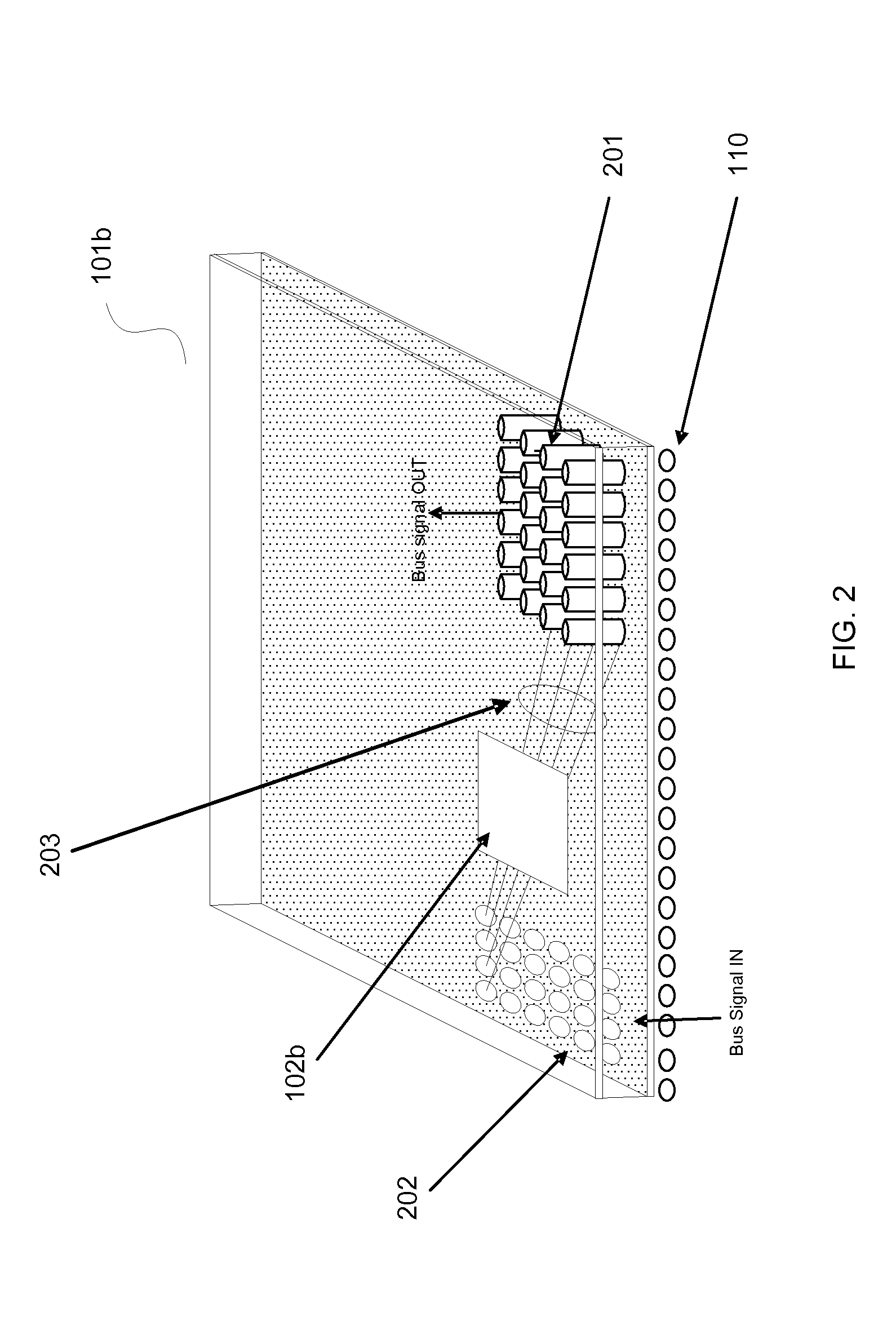

System and Method for Thermal Optimized Chip Stacking

InactiveUS20090305463A1Reduce the impactUniform power densitySemiconductor/solid-state device detailsSolid-state devicesEngineeringChip stacking

A method for thermal optimization comprising the steps of stacking a first chip layer and a second chip layer wherein the second chip layer is rotated in relation to the first chip layer wherein a first hot spot on the first chip layer and a second hot spot on the second chip layer are not spatially aligned; routing a signal input through the first chip layer from a first chip pad on the first chip layer to a first silicon via so as to form a physical input to output twist and a first signal output; and routing the first signal output from the first chip layer through a second chip layer from a second chip pad on the second chip layer to a second silicon via so as to form a second signal output.

Owner:IBM CORP

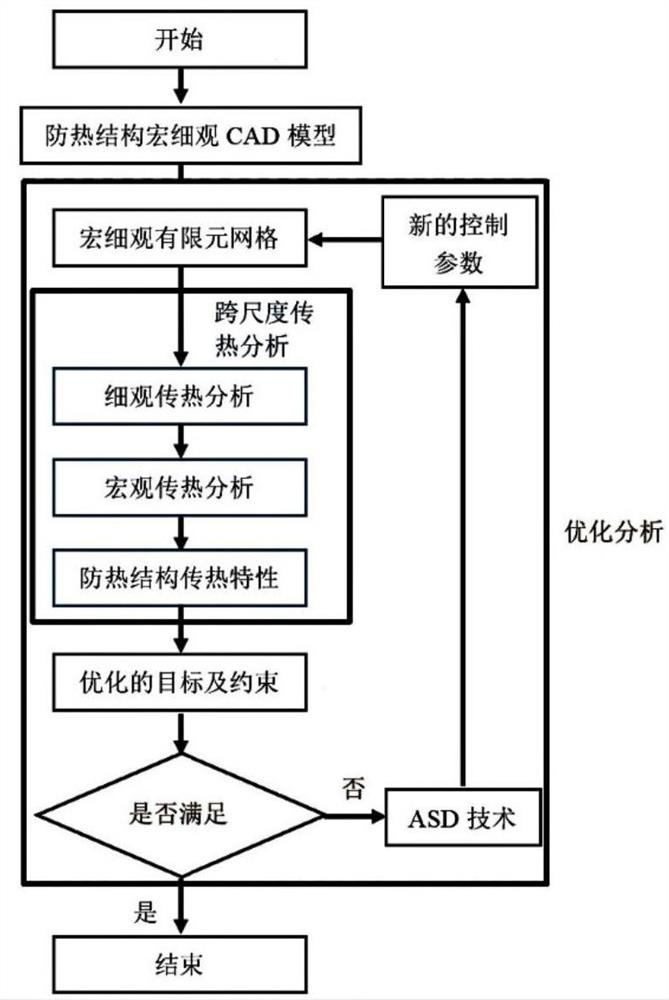

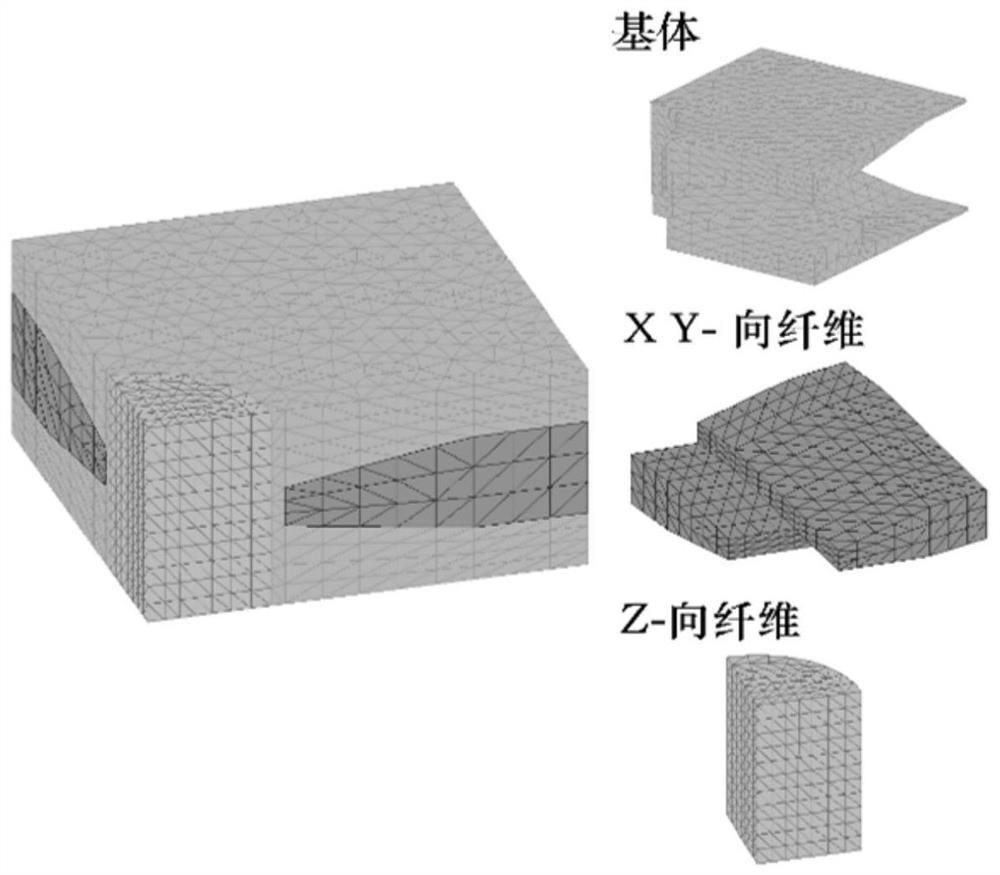

Multi-scale heat-proof optimization method for composite material

ActiveCN112668113AReduce the temperatureImprove computing efficiencyGeometric CADDesign optimisation/simulationElement modelMacroscopic scale

The invention provides a multi-scale heat-proof optimization method for a composite material. The multi-scale heat-proof optimization method comprises the following steps: step 1, establishing finite element models of the composite material to be optimized according to design variables, wherein the finite element models comprise a mesoscopic finite element heat transfer analysis model, a macroscopic finite element heat transfer analysis model and a cell body expansion model; step 2, performing mesoscopic heat transfer analysis on the established mesoscopic finite element heat transfer analysis model to obtain equivalent thermophysical parameters; transmitting equivalent thermophysical property parameters obtained through mesoscopic heat transfer analysis into a macroscopic finite element heat transfer analysis model through a cell body expansion model for macroscopic heat transfer analysis; in the heat transfer analysis, optimizing the mesoscopic heat transfer analysis model and the macroscopic heat transfer analysis model by adjusting design variables, ending the optimization if the optimized target meets constraint conditions, and outputting a heat transfer analysis result; and if the constraint condition is not met, readjusting the design variable of the finite element model, and repeatedly iterating until a heat transfer analysis result is output. By adopting the scheme of the invention, the optimization algorithm and the grid free deformation technology can be introduced while the temperature is reduced more effectively, so that the calculation efficiency is effectively improved.

Owner:AERODYNAMICS NAT KEY LAB

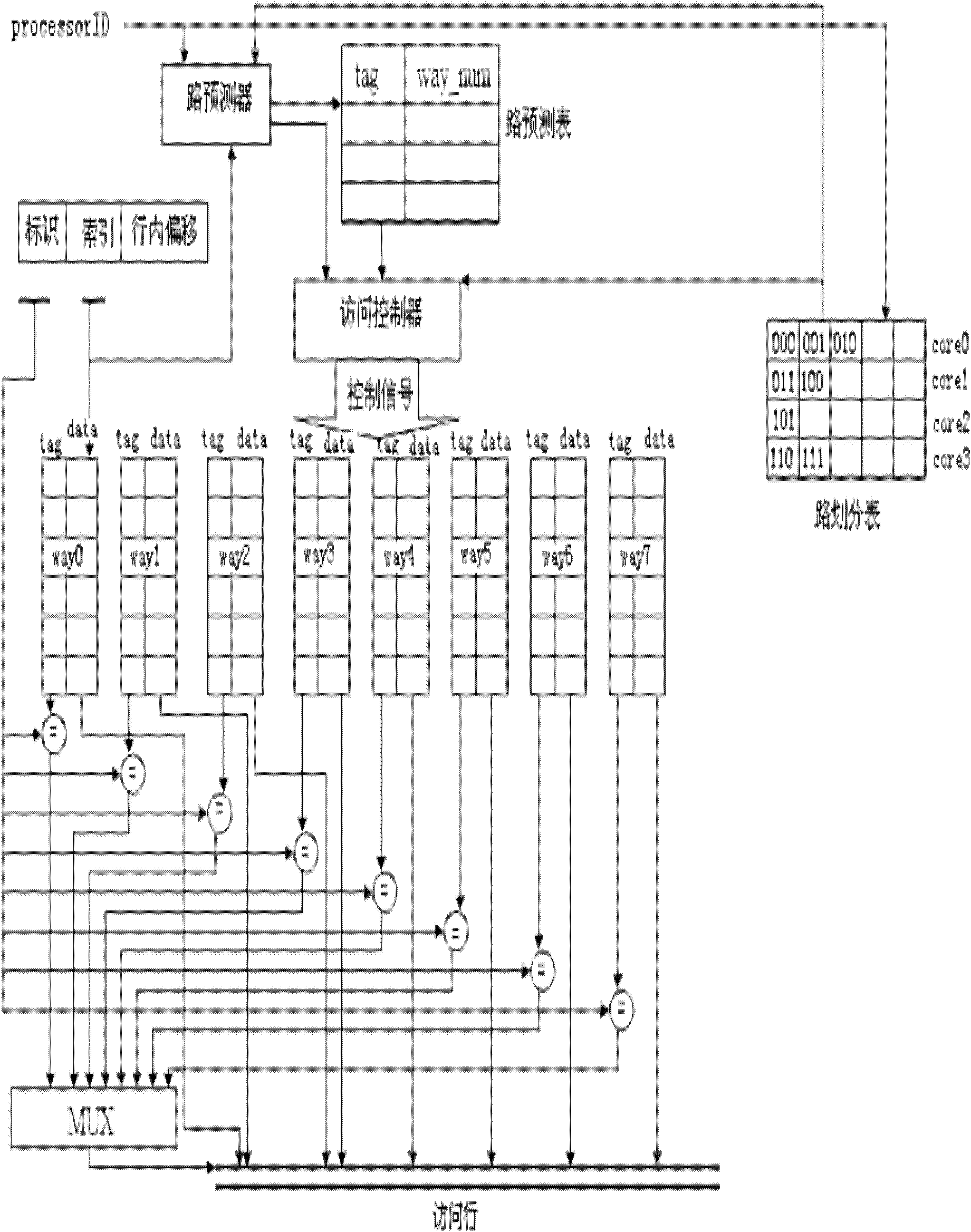

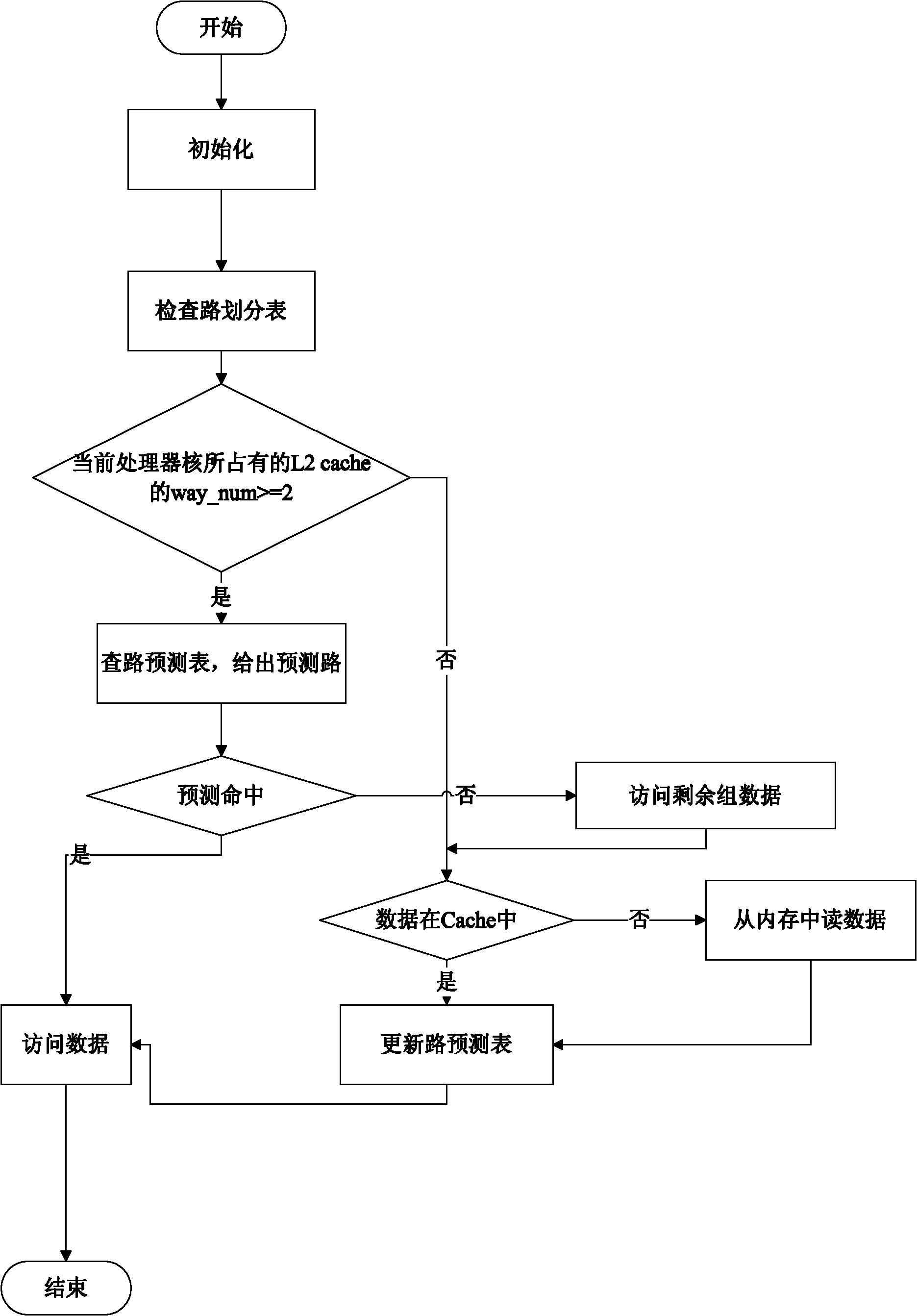

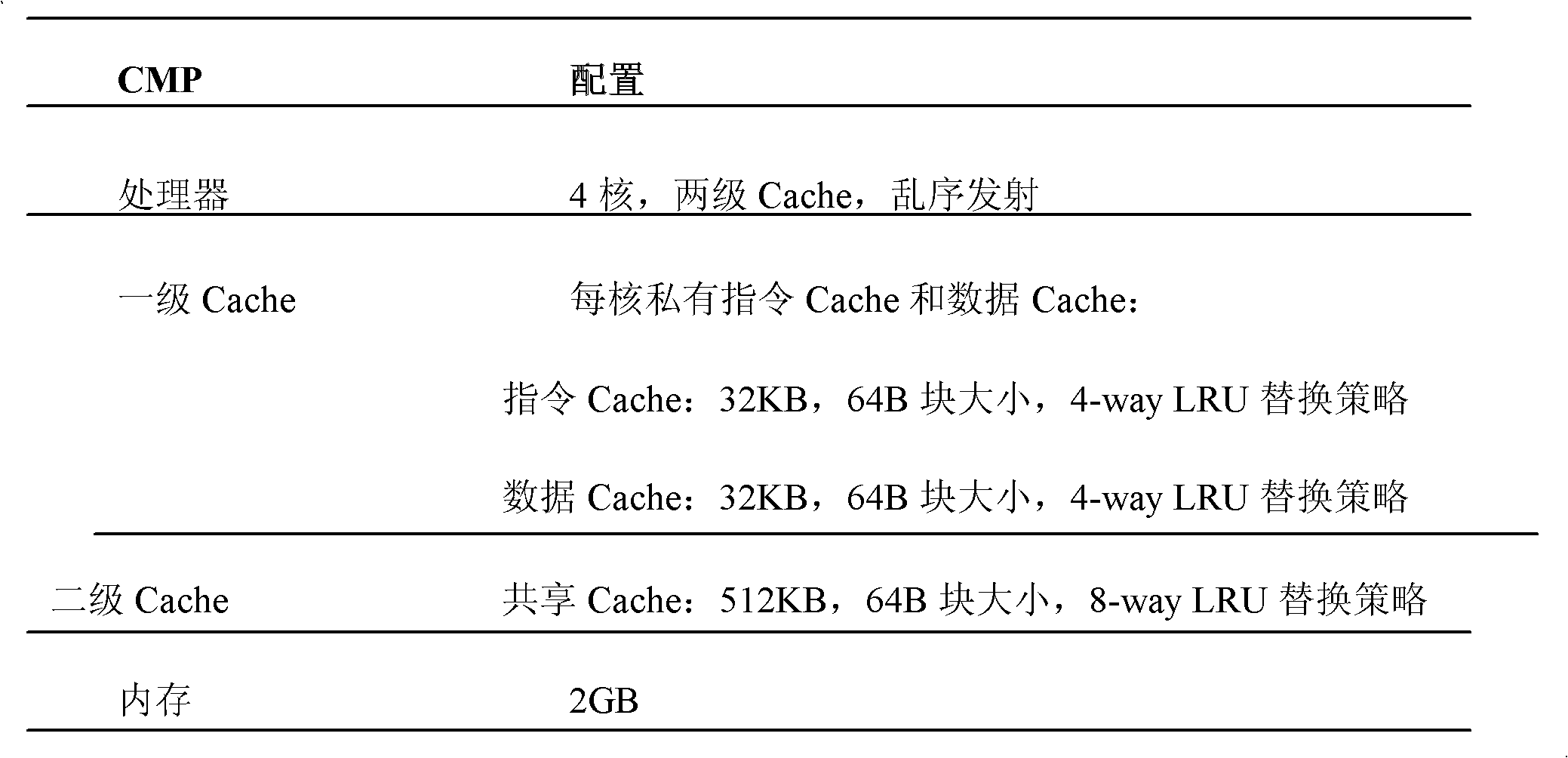

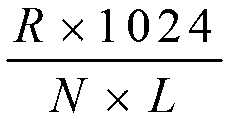

Multi-core adaptive way prediction algorithm based on Cache division

InactiveCN102193875AReduce access power consumptionReduce power consumptionEnergy efficient ICTMemory adressing/allocation/relocationPrediction algorithmsSystem structure

The invention relates to a multi-core adaptive way prediction algorithm based on Cache division and belongs to the field of computer system structures. At present, a low-power-consumption and thermal optimization design becomes a core problem of the micro processor research. By a multi-core structure of a multi-core processor, a relevant power-consumption research is a rather important subject. By using a partial theory of program running and aiming at a multi-core processor environment, the Cache division is combined with way prediction of Cache; and by the adoption of the adaptive way prediction algorithm on a result of the Cache division, the aim of reducing the Cache power consumption is fulfilled on the premise of keeping the conventional system performance balanced.

Owner:BEIJING UNIV OF TECH

Heat supply optimization method for coupling absorption heat pump of thermal power plant

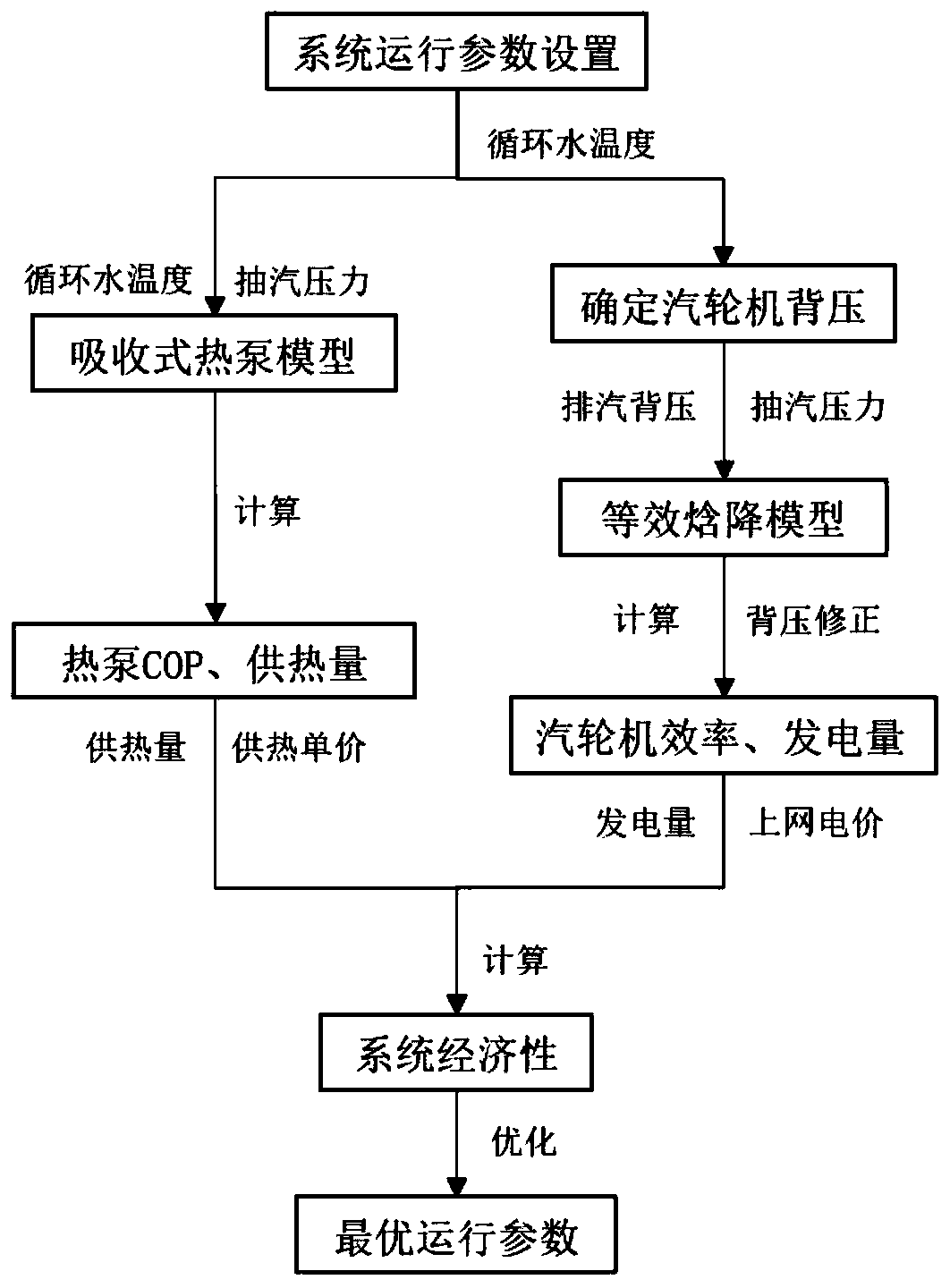

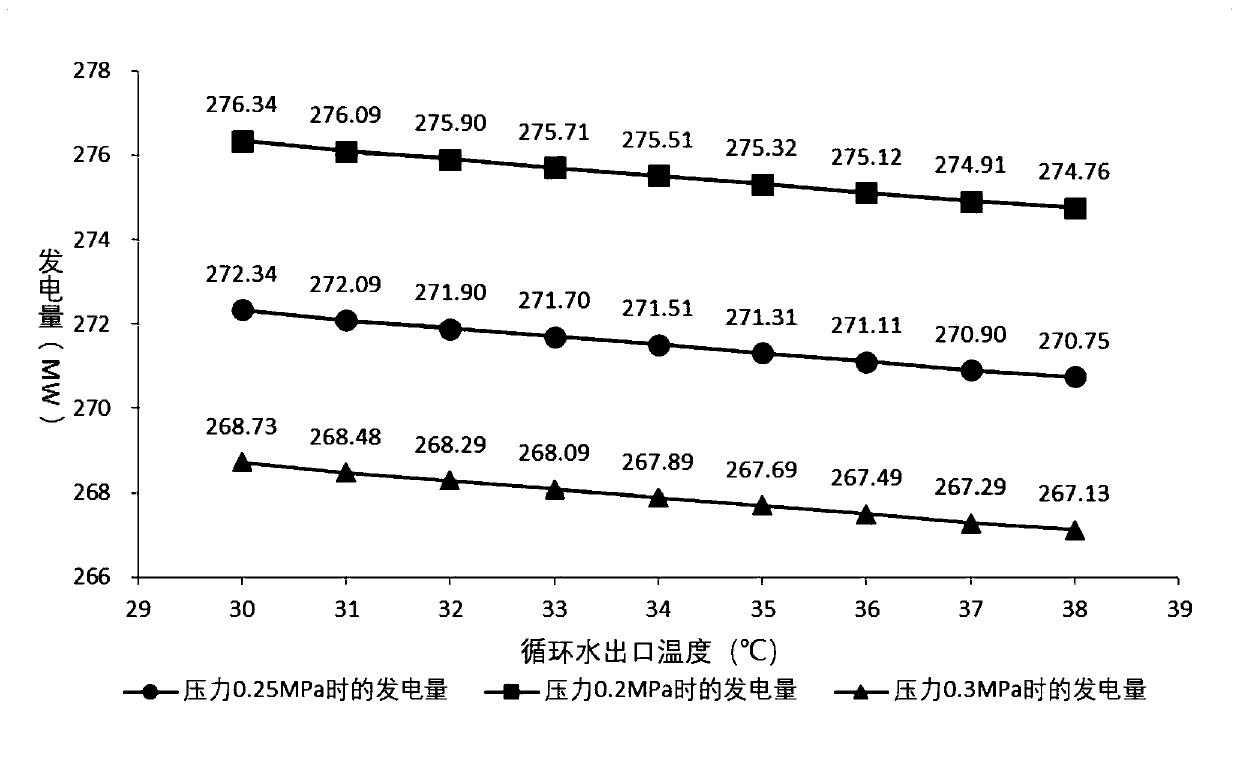

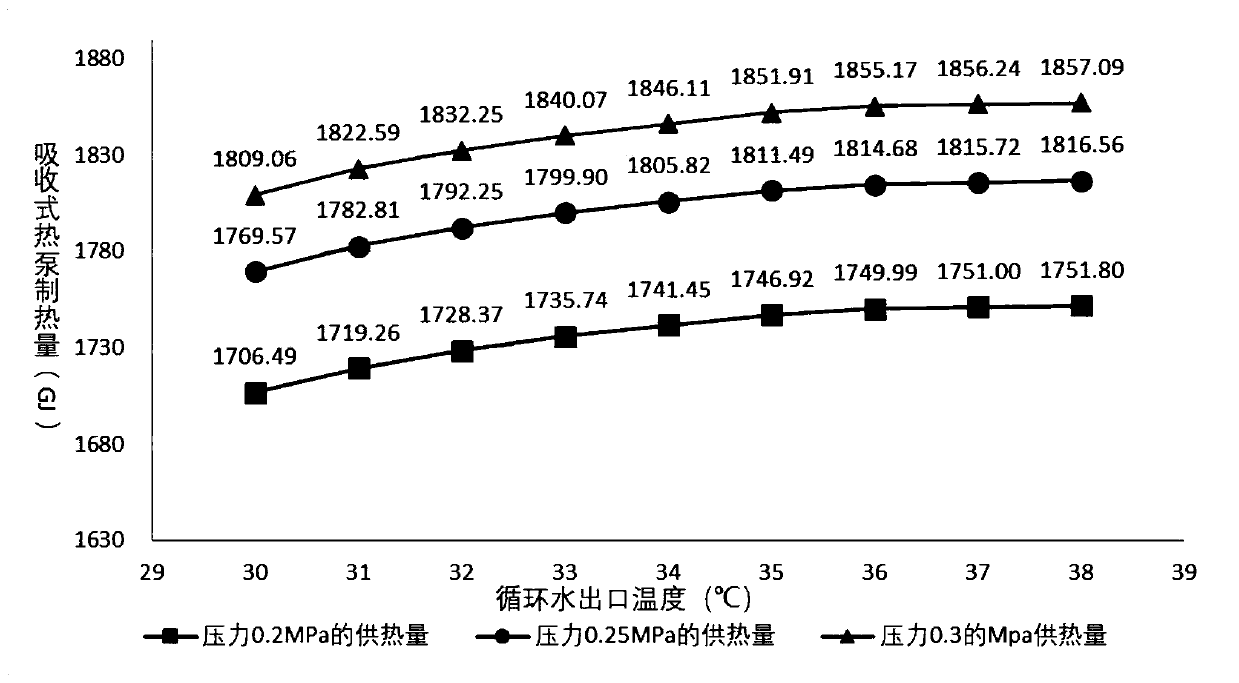

ActiveCN111256204AOptimal operating parametersImprove economyLighting and heating apparatusSpace heating and ventilation detailsLithium bromideAbsorption heat pump

The invention provides a heat supply optimization method for a coupling absorption heat pump of a thermal power plant. The method comprises the following steps of 1, establishing an equivalent enthalpy drop model according to data and operation conditions of a steam turbine in the thermal power plant, determining corresponding steam exhaust back pressure of the steam turbine according to differentcirculating water temperatures by the model, and calculating the heat supply of the coupling absorption heat pump based on the steam extraction pressure and the steam exhaust back pressure, and calculating turbine efficiency and generating capacity; 2, establishing a thermal power plant cold end optimization model according to the characteristics of the steam turbine, and correcting the efficiency and the generating capacity of the steam turbine; 3, establishing an absorption heat pump model according to the property of the absorption lithium bromide heat pump, and calculating COP and heat supply after the absorption heat pump is coupled with the heat supply of the thermal power plant; and 4, setting different operating parameters (circulating water temperature and steam extraction pressure) according to the absorption heat pump waste heat recovery heat supply system, performing joint calculation through the models in the steps 1-3, and calculating the operating economy of the systemaccording to the local on-grid electricity price and the heat supply price to obtain the optimal operating parameters.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

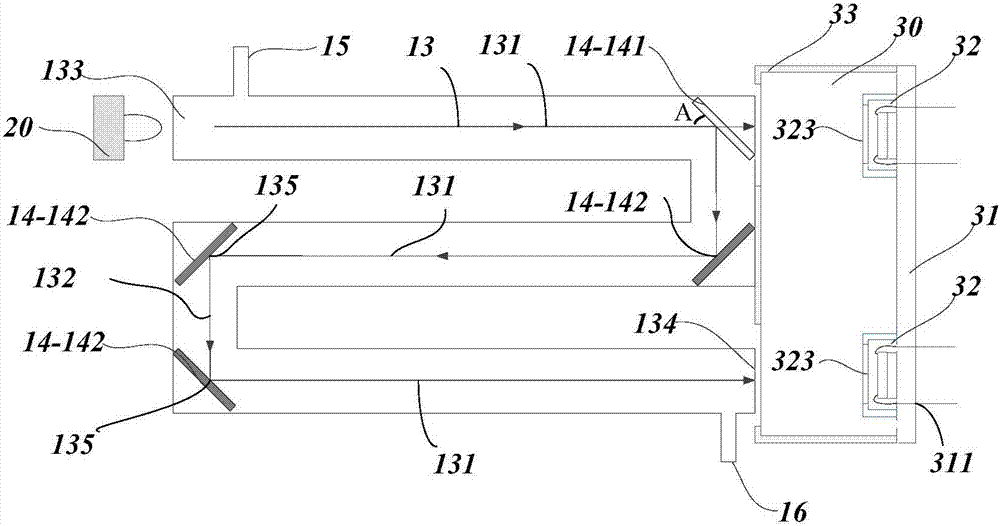

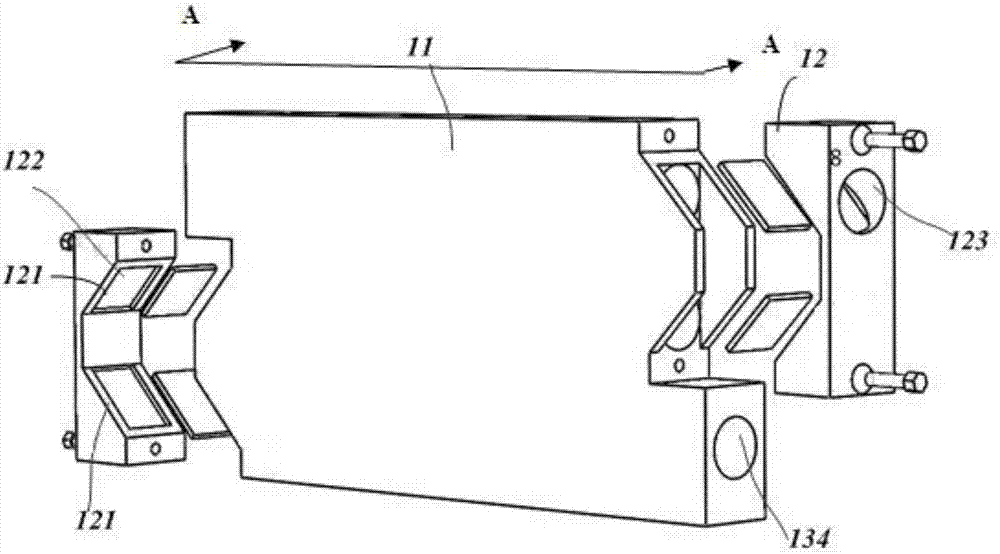

Infrared gas sensing system

InactiveCN107192669AImprove anti-interference abilityConsistent temperatureMaterial analysis by optical meansHeat conductingEngineering

The invention provides an infrared gas sensing system. The infrared gas sensing system comprises an infrared light source, a base and a probing module, the base is provided with a zigzag channel arranged inside and a reflecting mirror arranged in the zigzag channel, the zigzag channel is provided with several channel corners, and the reflecting mirror comprises a half-transmitting-half-reflecting mirror arranged at one of the channel corners and a full-reflecting mirror arranged at other channel corners; the probing module comprises a heat conducting baseboard and two probe modules which are arranged at the same side of the heat conducting baseboard and have the same specification. Through the structure, the influence caused by light intensities which are measured by the two probe module represents the linear relation due to external environment changes, and is conveniently eliminated through computation, therefore the anti-jamming performance of the system to the external environment changes is improved; by conducting thermal optimization on the two probe sensor modules, the temperatures of the two probe modules are identical, and the influence of the temperature on the measurement result of the probe modules is reduced.

Owner:PROMISENSE ELECTRONICS TECH CO LTD

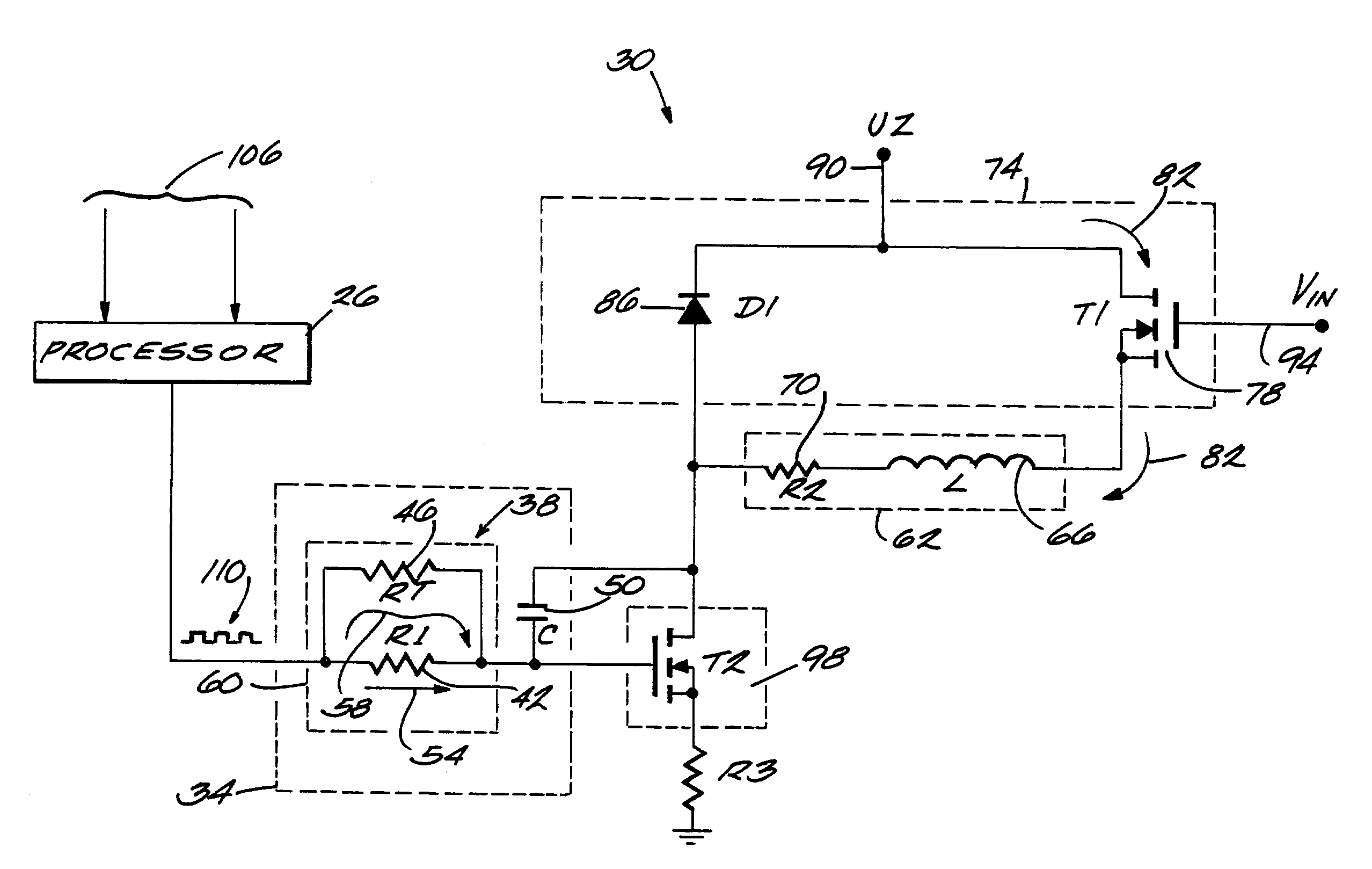

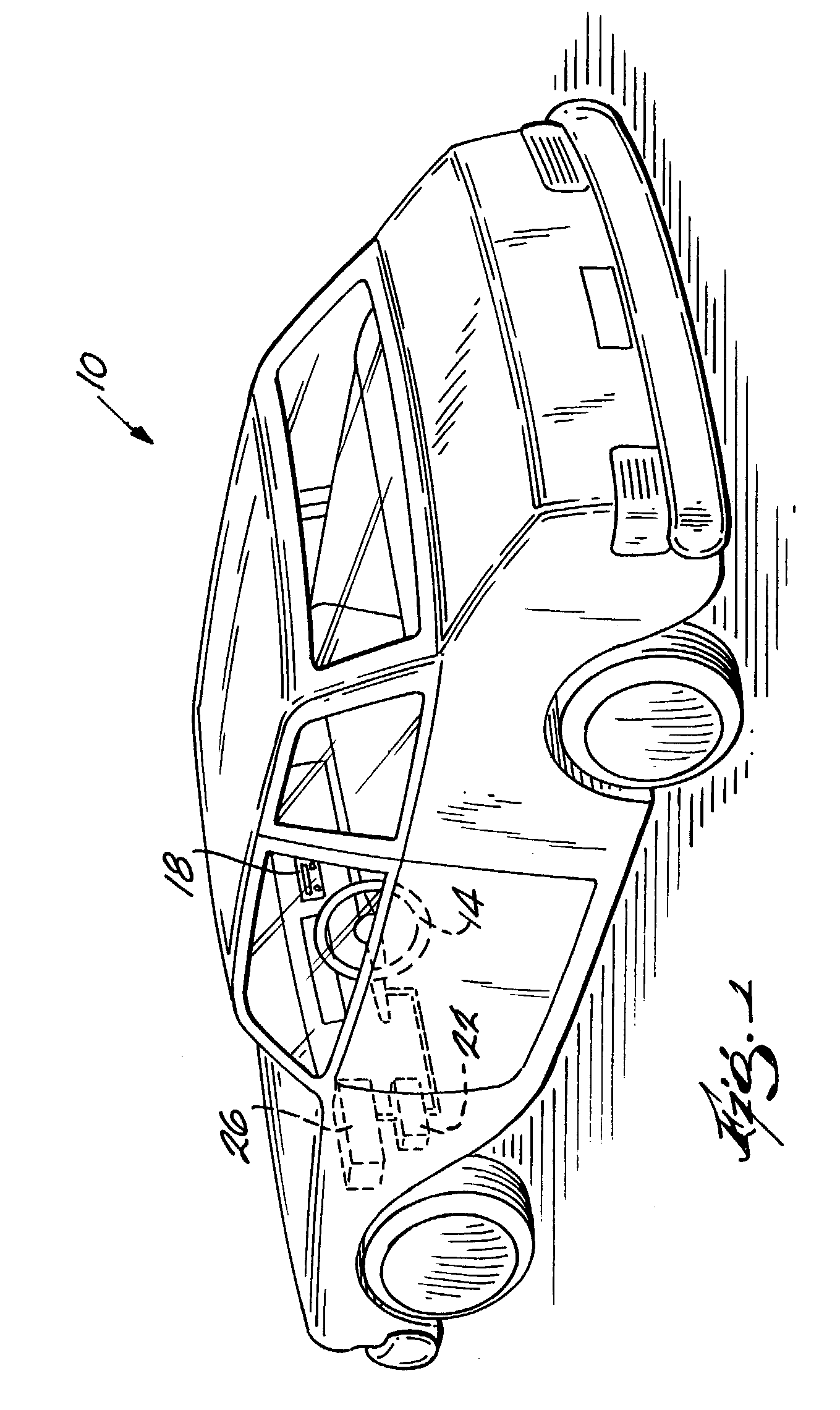

Thermal optimization of EMI countermeasures

InactiveUS7251553B2Improve efficiencyReduced effectivenessSparking plugsAnalogue computers for vehiclesCountermeasureNormal conditions

The present invention provides an electronic circuit and EMI countermeasure for an automotive electronic control unit that provides a maximum amount of EMI protection under normal operating conditions, i.e., ambient temperatures. The effectiveness of the EMI countermeasure is limited at extremely high temperatures. The electronic circuit and EMI countermeasure optimizes the effectiveness of EMI countermeasures as a function of temperature to improve performance under normal conditions.

Owner:ROBERT BOSCH CORP

Active thermal optimization control method and device for electric vehicle drive system

ActiveCN105577069BSolving Control Problems for Active Thermal OptimizationImprove efficiencyAC motor controlElectric machinesZ-source inverterControl signal

Owner:HUNAN UNIV

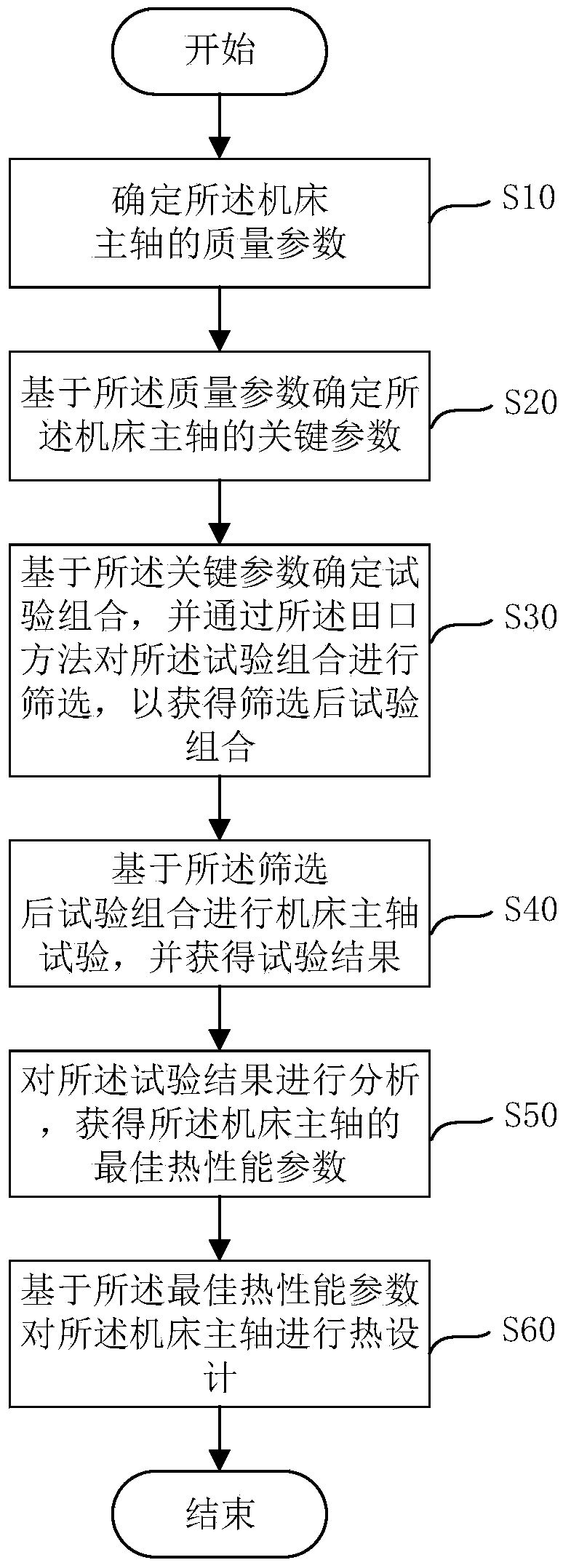

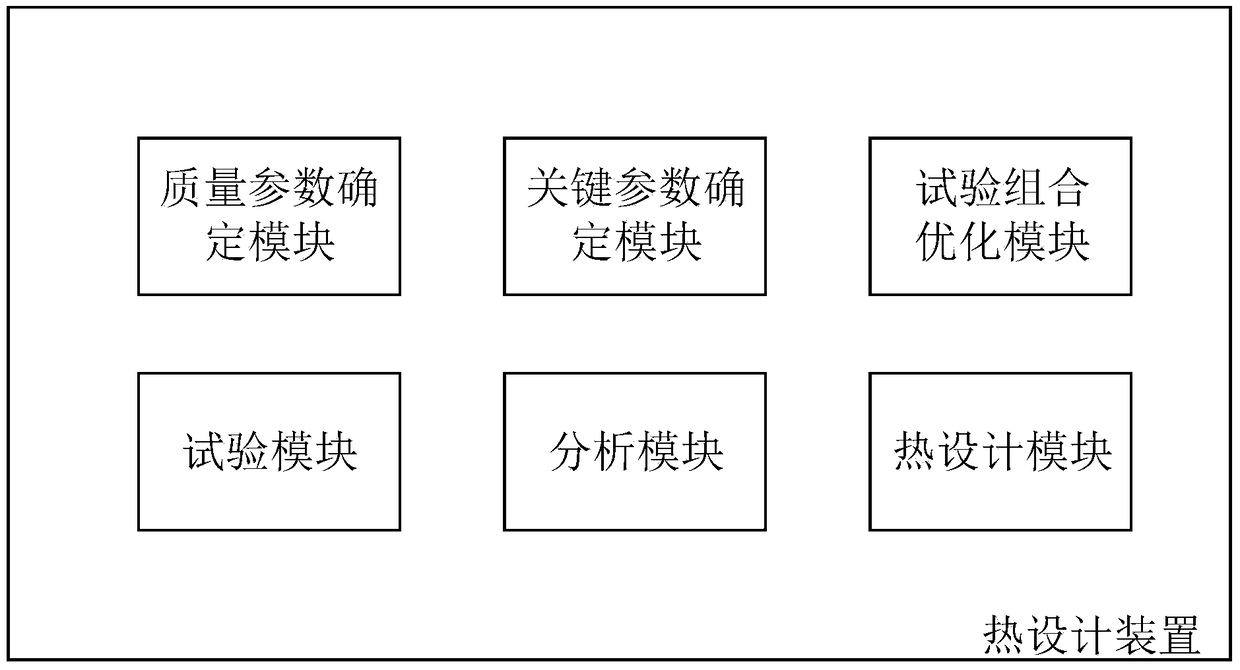

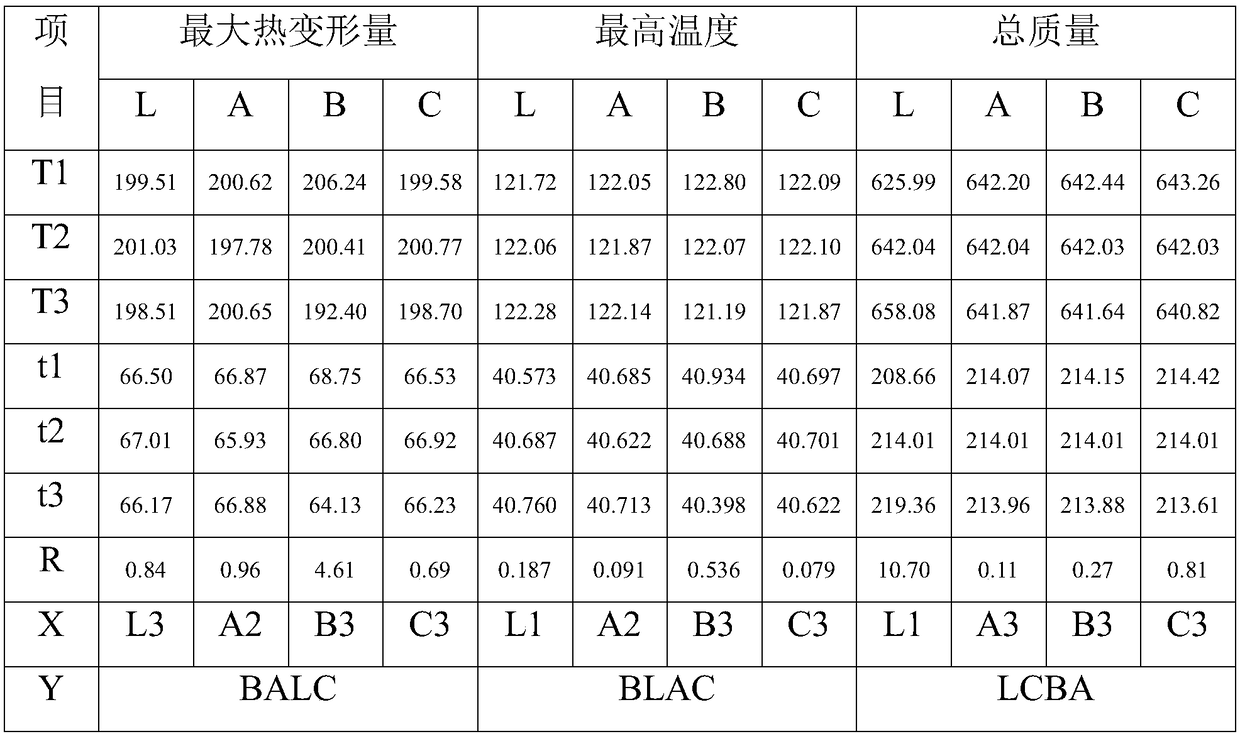

Taguchi method-based thermal-optimization method of machine tool spindle

ActiveCN108763682AEasy accessFull accessGeometric CADDesign optimisation/simulationEngineeringMachine tool

The invention discloses a Taguchi method-based thermal-optimization method of a machine tool spindle. The method includes: determining quality parameters of the machine tool spindle; determining key parameters of the machine tool spindle on the basis of the quality parameters; determining test combinations on the basis of the key parameters, and screening the test combinations through a Taguchi method to obtain a test combination after screening; carrying out a machine tool spindle test on the basis of the test combination after screening, and obtaining a test result; analyzing the test resultto obtain optimal thermal performance parameters of the machine tool spindle; and carrying out thermal optimization on the machine tool spindle on the basis of the optimal thermal performance parameters. The invention also discloses a thermal-optimization device of the machine tool spindle on the basis of the Taguchi method. Through using the Taguchi method to screen the test combinations in an optimization process, the better test combination is selected for a test, computational complexity in the optimization process is reduced, and thus the machine tool spindle is more quickly, more comprehensively and more accurately optimized.

Owner:QUZHOU UNIV

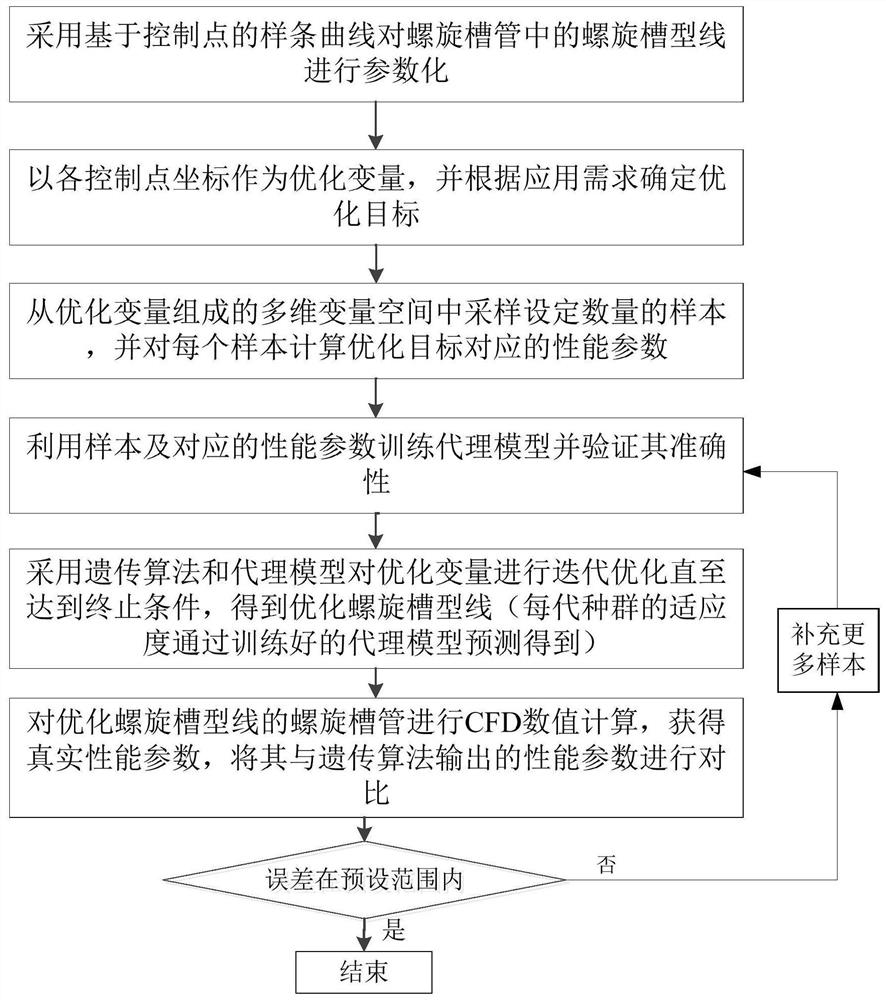

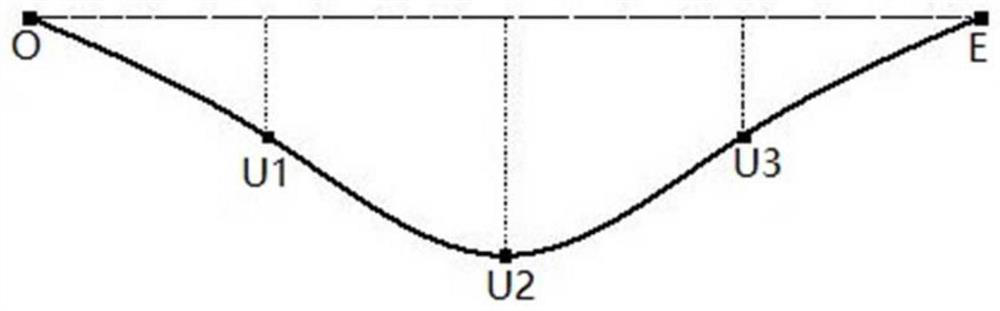

Spiral groove pipe optimization method

ActiveCN113435133AImprove performanceControl point coordinates are sensitive to changesGeometric CADDesign optimisation/simulationGenetic algorithmEngineering

The invention discloses a spiral grooved tube optimization method, and belongs to the field of spiral grooved tube heat exchange optimization. Through overall optimization of the shape of the spiral groove, the optimized spiral groove pipe with the performance improved greatly can be obtained, specifically, parameterized description is conducted on the spiral groove molded line through the spline curve, the molded line more sensitive to coordinate changes of the control points can be obtained, and then the requirement for fine adjustment and optimization of the molded line is met. According to the method, the genetic algorithm is adopted to screen the optimal spiral groove profile in the optimization target value, so that the coordinates corresponding to the screened spiral groove profile can be selected, crossed and / or mutated to obtain the optimized spiral groove profile, and the optimized spiral groove profile can be iteratively calculated again to obtain the optimization target so that a more excellent spiral groove tube type line can be obtained; and meanwhile, the performance parameters of each generation of population are predicted through the agent model, a large number of CFD calculation processes are replaced, calculation resources are saved, the optimization period is shortened, and the efficiency of the optimization process is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

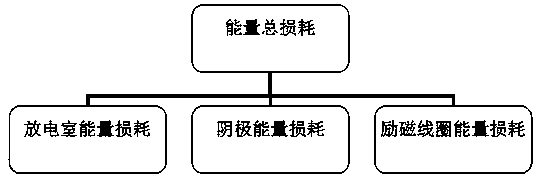

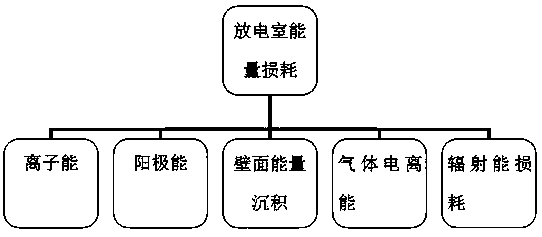

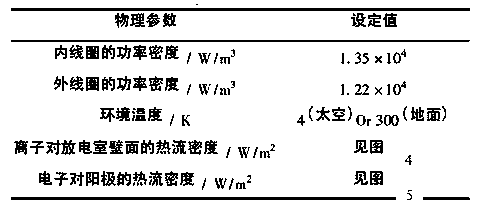

A Method of Reducing Heat Load of Hall Thruster

ActiveCN108799033BIncrease temperatureReduce heat loadMachines/enginesDesign optimisation/simulationHeat flowEngineering

The invention belongs to the technical field of Hall thrusters, and in particular relates to a method for reducing the thermal load of the Hall thruster. The method for reducing the thermal load of the Hall thruster mainly comprises the following steps of: establishing a thermal balance model; solving the energy loss of a discharge chamber of the Hall thruster; determining the boundary conditionsof heat conduction; determining the size of the inner diameter of a radiating fin; and evaluating the performance of a magnetic field based on the influence of temperature on the magnetic field. A magnetic shield thermal optimization method of the invention can reduce the thermal load of the Hall thruster and optimize the temperature distribution and heat flow direction of a magnetic shield on thebasis of the magnetic field strength reaching a certain value, and lays a certain theoretical and practical foundation for the thermomagnetic correlation analysis of the Hall thruster in related research.

Owner:山东连辰机械设备有限公司

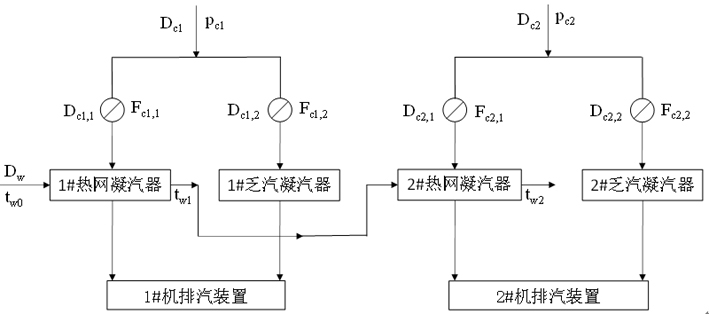

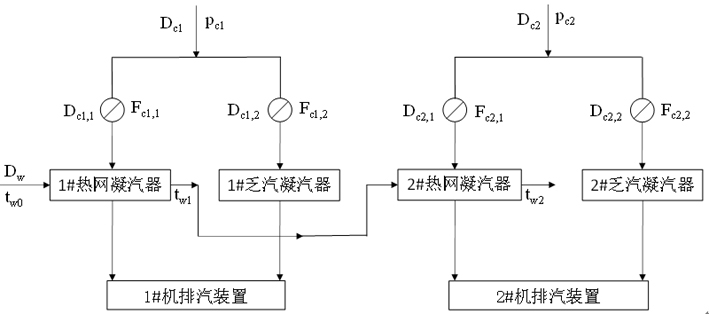

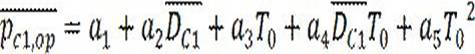

Optimization method of high back pressure heat supply for thermal power units

ActiveCN113074402BGuaranteed heat load demandIncrease power generationHeating fuelLighting and heating apparatusProcess engineeringGenerating capacity

The invention discloses a high-back pressure heating optimization method for a thermal power unit. The method is: when two units in a thermal power plant are connected in series with high back pressure for heating, the current 1# unit exhaust volume, 2# unit exhaust volume, cycle Under the condition of water volume and return water temperature, the back pressure of 1# and 2# units is optimized collaboratively to ensure the water supply temperature. Specifically, first optimize the operation of the 1# unit under the best back pressure, and adjust the back pressure of the 2# unit to the most economical back pressure to ensure the water supply temperature; if the back pressure of the 2# unit is p c2 has been adjusted to the highest back pressure p c2max If it still cannot meet the water supply temperature requirements, the 2# unit maintains the highest back pressure operation, and adjusts the 1# unit back pressure to the most economical back pressure to ensure the water supply temperature; the invention provides two units of the high back pressure series heat supply optimization method, Under the condition of maintaining heat supply, the power generation is maximized and the energy consumption for heating is minimized.

Owner:TAIYUAN UNIV OF TECH +1

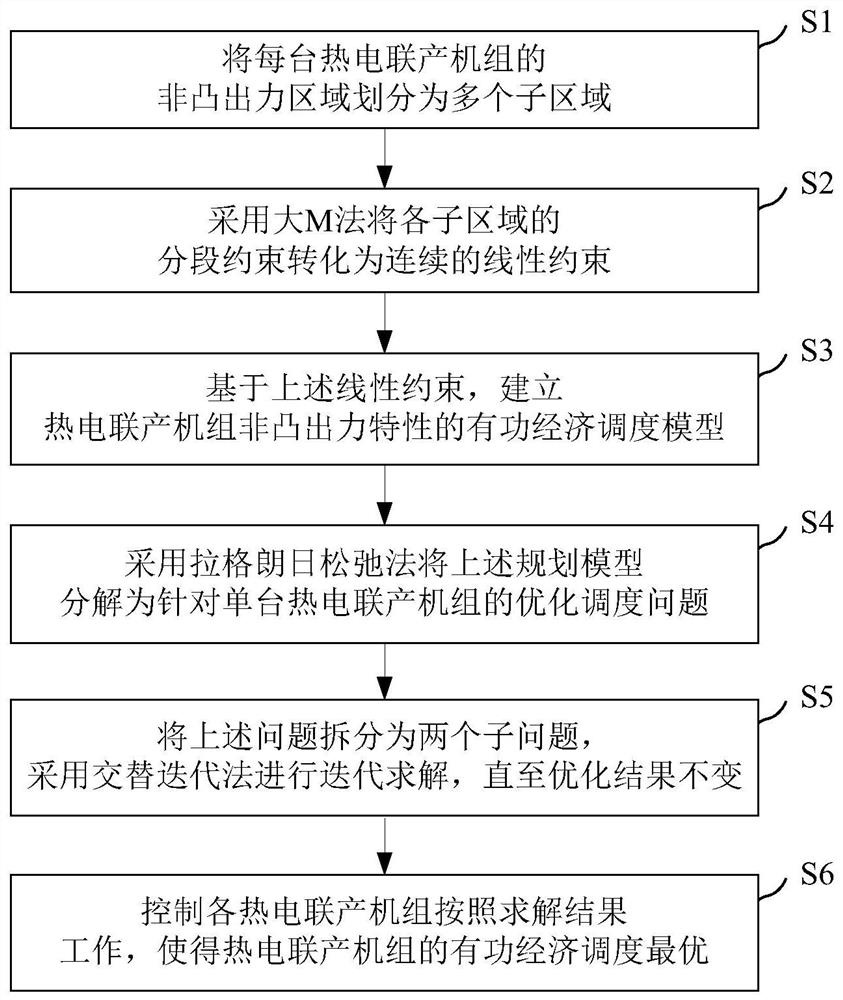

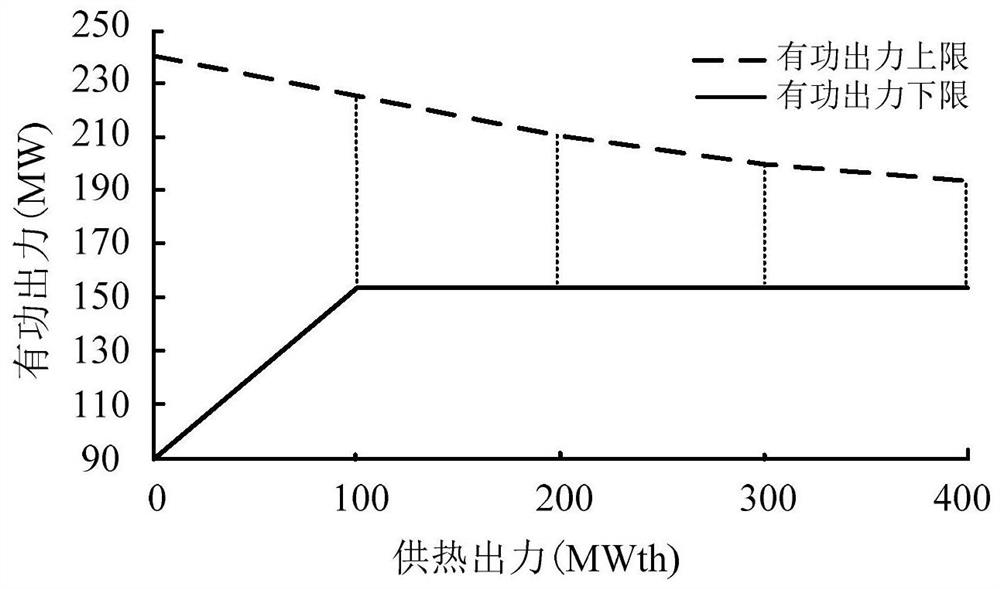

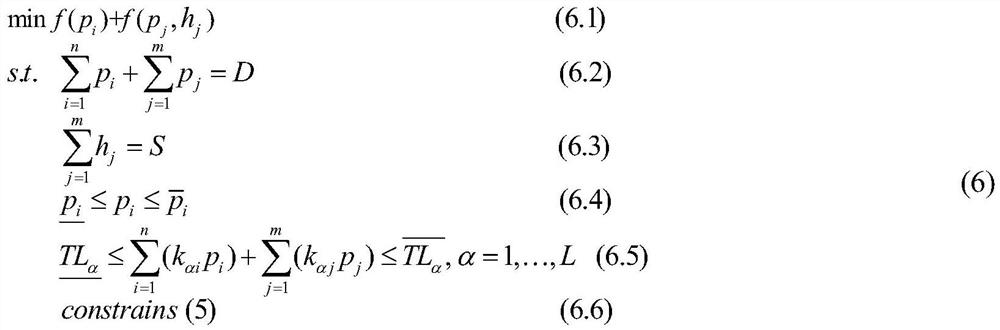

Alternative Iterative Optimal Scheduling Method Based on Non-Protruding Force Characteristics of Combined Heat and Power Units

ActiveCN108876196BImprove solution efficiencyThe best results can be verifiedResourcesOptimal schedulingPower optimization

The invention discloses an alternate iterative optimization scheduling method based on the characteristics of non-protruding force of cogeneration units. The above method divides the non-protruding force area of each cogeneration unit into a plurality of sub-regions, and divides the segmental constraints of each sub-region Convert it into a continuous linear constraint, and then establish the active power economic dispatch model of the non-salient force characteristics of the cogeneration unit, simplify the above model into an optimal dispatch model for a single cogeneration unit, and further decompose it into optimal dispatch of heat supply and optimization of active power The two sub-models of scheduling are solved by mixed integer quadratic programming algorithm and quadratic programming algorithm respectively, and at the same time, alternate iteration method is used for iterative optimization, and the work of combined heat and power units is controlled according to the optimization results to make the active economic scheduling optimal. This application It is suitable for the non-convex operating characteristic area of cogeneration units, and can realize real-time online scheduling of cogeneration units.

Owner:STATE GRID JIBEI ELECTRIC POWER COMPANY +2

Synergistic Environment of Electrical, Thermal and Mechanical Properties of Electronic Product Packaging

InactiveCN109145332AReduce complexityReduce design iterationsDesign optimisation/simulationSpecial data processing applicationsDegrees of freedomDesign stage

The invention discloses a novel synergistic environment including electrical, thermal and mechanical characteristics considering electronic product packaging. The invention is characterized in that alumped design platform provides comprehensive, accurate and reconfigurable design parameters, performance and function prediction for the electrical, thermal and mechanical characteristics of the electronic product package. By considering the effect of packaging, thermal and mechanical properties on product performance, the product performance can be optimized from the aspects of core design optimization, packaging optimization, thermal optimization, and mechanical design optimization according to the design cost and complexity of realization in the design stage of product. On the one hand, itguarantees the low cost realization of product performance; on the other hand, it provides multiple design degrees of freedom, reduces the complexity of performance realization, and most importantly,it can accurately evaluate the expectation of product performance in the product design stage, and reduces the design iteration.

Owner:上海卓弘微系统科技有限公司

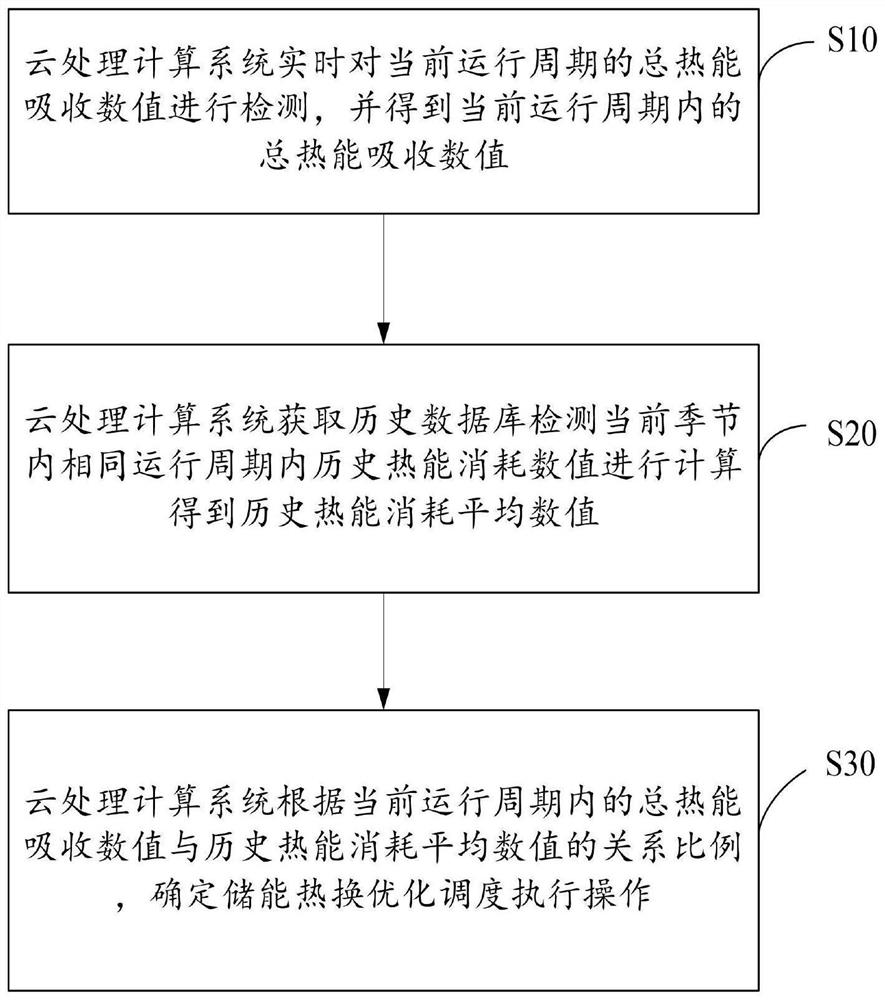

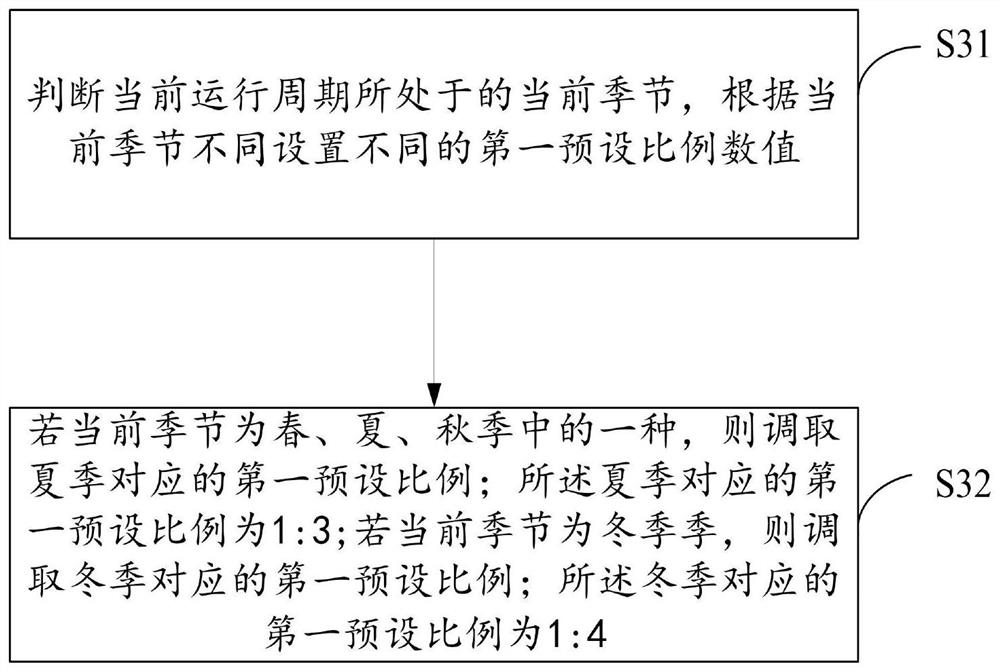

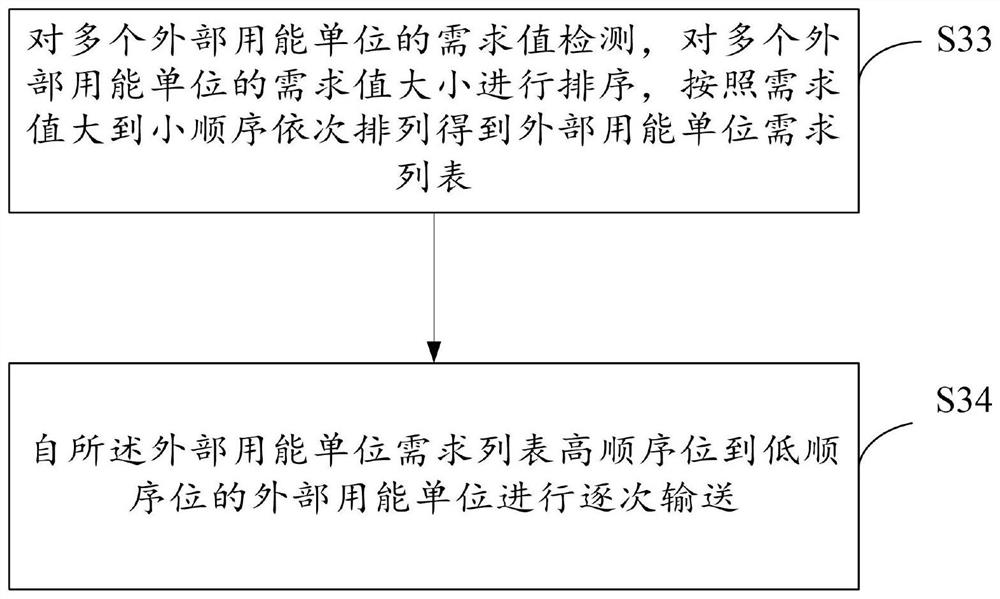

Energy storage and heat exchange optimization scheduling method

PendingCN113867291ATotal factory controlProgramme total factory controlThermodynamicsCloud processing

The invention discloses an energy storage heat exchange optimization scheduling method, which comprises the following steps that: a cloud processing computing system detects a total heat energy absorption value in a current operation period in real time, and obtains the total heat energy absorption value in the current operation period; historical heat energy consumption values in the same operation period in the current season are detected, and calculating is conducted to obtain a historical heat energy consumption average value; the cloud processing computing system determines energy storage heat exchange optimization scheduling execution operation according to the relation proportion of the total heat energy absorption value and the historical heat energy consumption average value in the current operation period. According to the scheduling method, the relationship between the actual total heat energy absorption numerical value and the historical heat energy consumption average numerical value of the energy storage system is fully considered, intelligent management and control are achieved, and the long-term use reliability and safety of the system are guaranteed.

Owner:NEIMENGGU RUNTAI NEW ENERGY TECH CO LTD

Multi-core adaptive way prediction algorithm based on Cache division

InactiveCN102193875BGuaranteed to workReduce energy consumptionEnergy efficient ICTMemory adressing/allocation/relocationPrediction algorithmsSystem structure

The invention relates to a multi-core adaptive way prediction algorithm based on Cache division and belongs to the field of computer system structures. At present, a low-power-consumption and thermal optimization design becomes a core problem of the micro processor research. By a multi-core structure of a multi-core processor, a relevant power-consumption research is a rather important subject. By using a partial theory of program running and aiming at a multi-core processor environment, the Cache division is combined with way prediction of Cache; and by the adoption of the adaptive way prediction algorithm on a result of the Cache division, the aim of reducing the Cache power consumption is fulfilled on the premise of keeping the conventional system performance balanced.

Owner:BEIJING UNIV OF TECH

Thermoelectric unit high-back-pressure heat supply optimization method

ActiveCN113074402AGuaranteed heat load demandIncrease power generationHeating fuelLighting and heating apparatusEngineeringProcess engineering

The invention discloses a thermoelectric unit high-back-pressure heat supply optimization method. The method is characterized in that when two units of a thermal power plant are connected in series for heat supply under high back pressure, the back pressure of a first unit and the back pressure of a second unit are collaboratively optimized under the current steam exhaust amount of the first unit, the current steam exhaust amount of the second unit, the current circulating water amount and the current water return temperature, and the water supply temperature is guaranteed. The method comprises the steps that firstly, the first unit is optimized to operate under the optimal back pressure, and the back pressure of the second unit is adjusted to the most economical back pressure for guaranteeing the water supply temperature; and if the water supply temperature requirement still cannot be met when the back pressure pc2 of the second unit is adjusted to the highest back pressure pc2max, the second unit maintains the highest back pressure operation, and the back pressure of the first unit is adjusted to the most economical back pressure for guaranteeing the water supply temperature. According to the two-unit high-back-pressure series heat supply optimization method, under the condition of heat supply guaranteeing, the generating capacity is maximized, and heat supply energy consumption is minimized.

Owner:TAIYUAN UNIV OF TECH +1

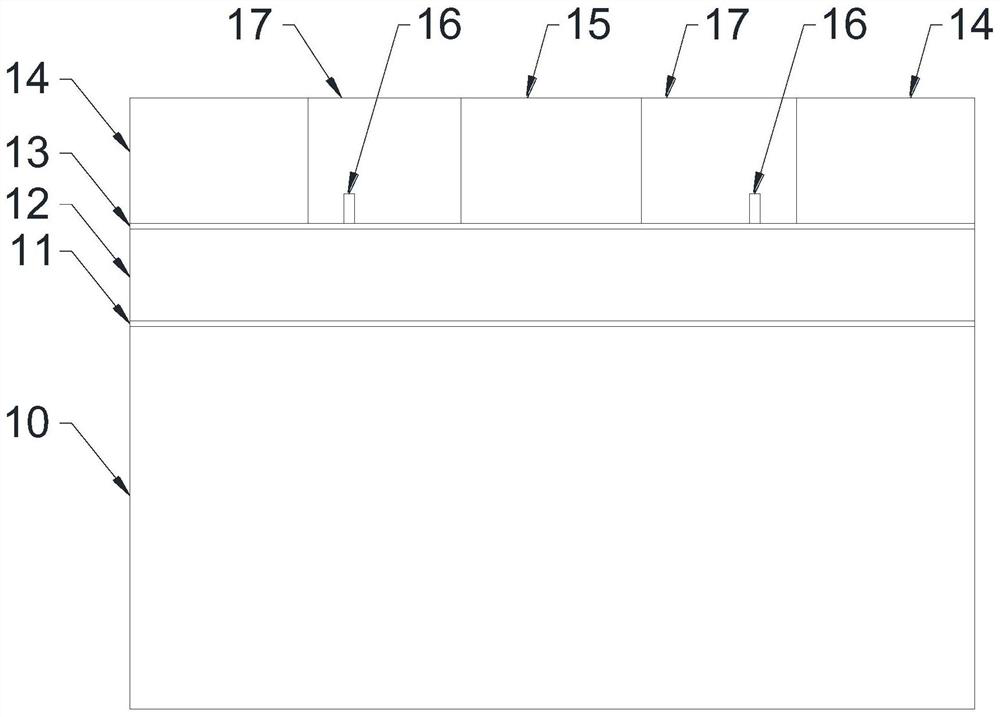

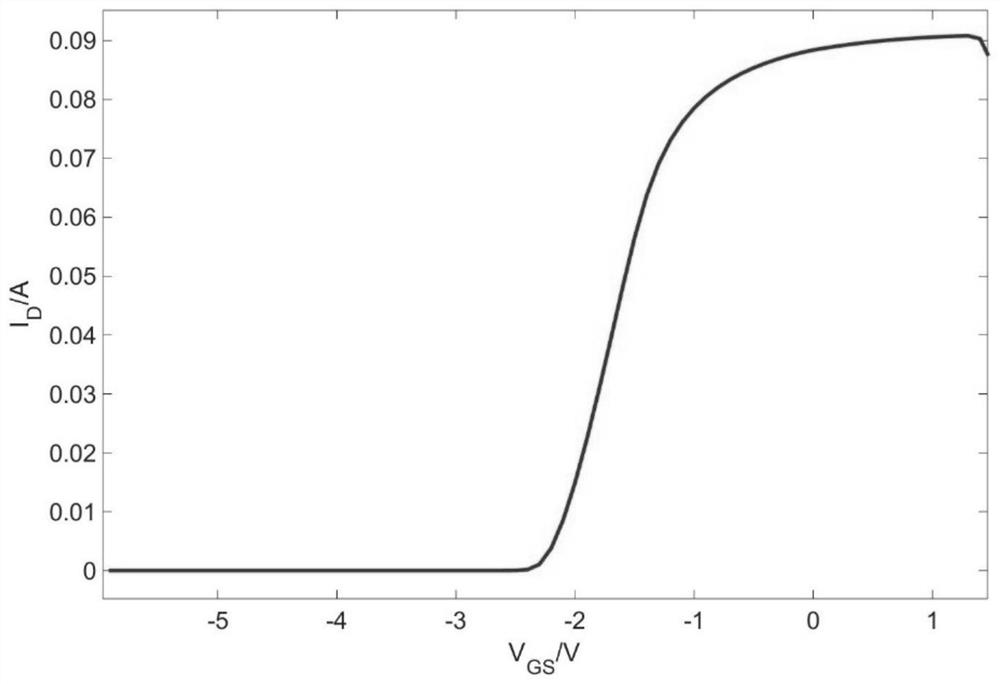

Simulation method for multi-gate-finger gallium nitride device electric heating joint modeling

InactiveCN112183018AImprove output efficiencyComputer aided designSpecial data processing applicationsHemt circuitsEngineering

The invention discloses a simulation method for multi-gate-finger gallium nitride device electro-thermal joint modeling, and belongs to a new generation of information technology. The scheme is provided for solving the problem that in the prior art, the mutual influence between multiple grids and multiple heat sources cannot be predicted. According to the invention, electro-thermal joint simulation of a device is realized by means of sequential two-dimensional model structure setting, doping setting, superposition of a physical field and a physical effect, boundary condition setting, mesh generation and the like; and the method has the advantages that the mutual influence among multiple heat sources after the self-heating effect of the device occurs can be more accurately predicted on theelectrical level of the device, the method is used for thermal management and thermal optimization occasions of the device on a chip and a circuit, and the output efficiency of the circuit can be improved.

Owner:SOUTH CHINA UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com