Heat supply optimization method for coupling absorption heat pump of thermal power plant

A technology of absorption heat pump, optimization method, applied in the direction of domestic heating, heating system, space heating and ventilation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

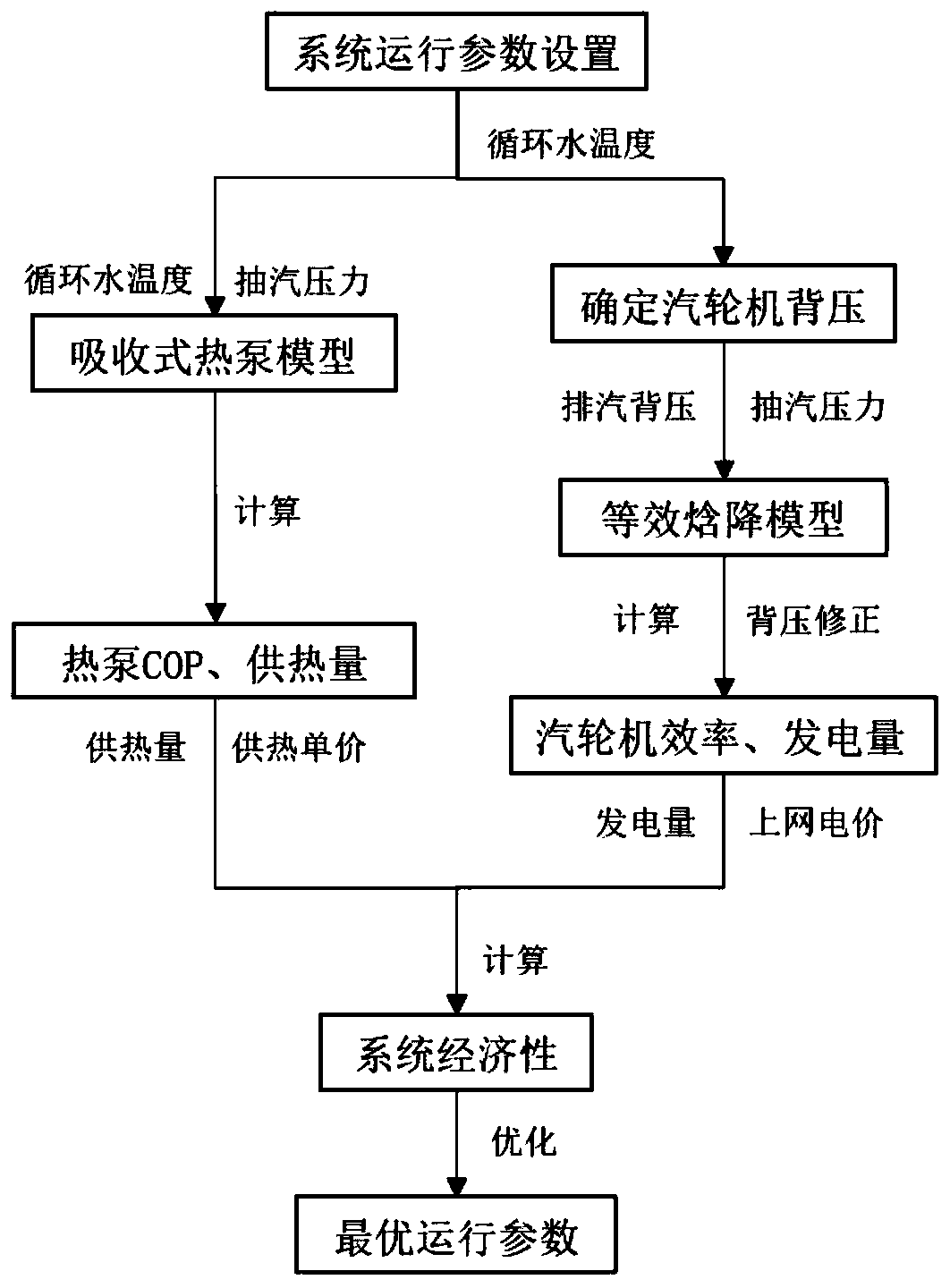

[0056] figure 1 It is a flow chart of a heat supply optimization method for a thermal power plant coupled with an absorption heat pump in Embodiment 1 of the present invention.

[0057] Such as figure 1 As shown, this embodiment provides a thermal power plant coupling absorption heat pump heat supply optimization method, which is used to realize the optimal heat supply system (thermal power plant coupling absorption heat pump system) after the thermal power plant and the absorption heat pump are coupled. The determination of economical operation parameters, the method includes the following steps:

[0058] Step 1. According to the data and operating conditions of the steam turbine in the thermal power plant, an equivalent enthalpy drop model is established. The equivalent enthalpy drop model determines the exhaust steam back pressure of the corresponding steam turbine according to different circulating water temperatures, and then uses the extraction pressure and Based on ...

Embodiment 2

[0115] In this embodiment, a 300MW subcritical unit is taken as an example, and optimization processing (calculation) is carried out on it according to the heat supply optimization method of a thermal power plant coupled with an absorption heat pump in Embodiment 1.

[0116] In the 300MW subcritical unit of this example, under the THA working condition, the main steam pressure temperature is 16.7Mpa, 537°C, the reheat steam pressure temperature is 3.123Mpa, 537°C, the main steam flow rate is 882690kg / h, and the exhaust pressure flow rate is 4.9 kPa, 535490kg / h. The steam extraction parameters at all levels under specific THA working conditions are shown in Table 4:

[0117] Table 4. Extraction parameter table of each stage under THA working condition of 300MW unit

[0118]

[0119]

[0120] The optimization process includes:

[0121] Step 1 and 2:

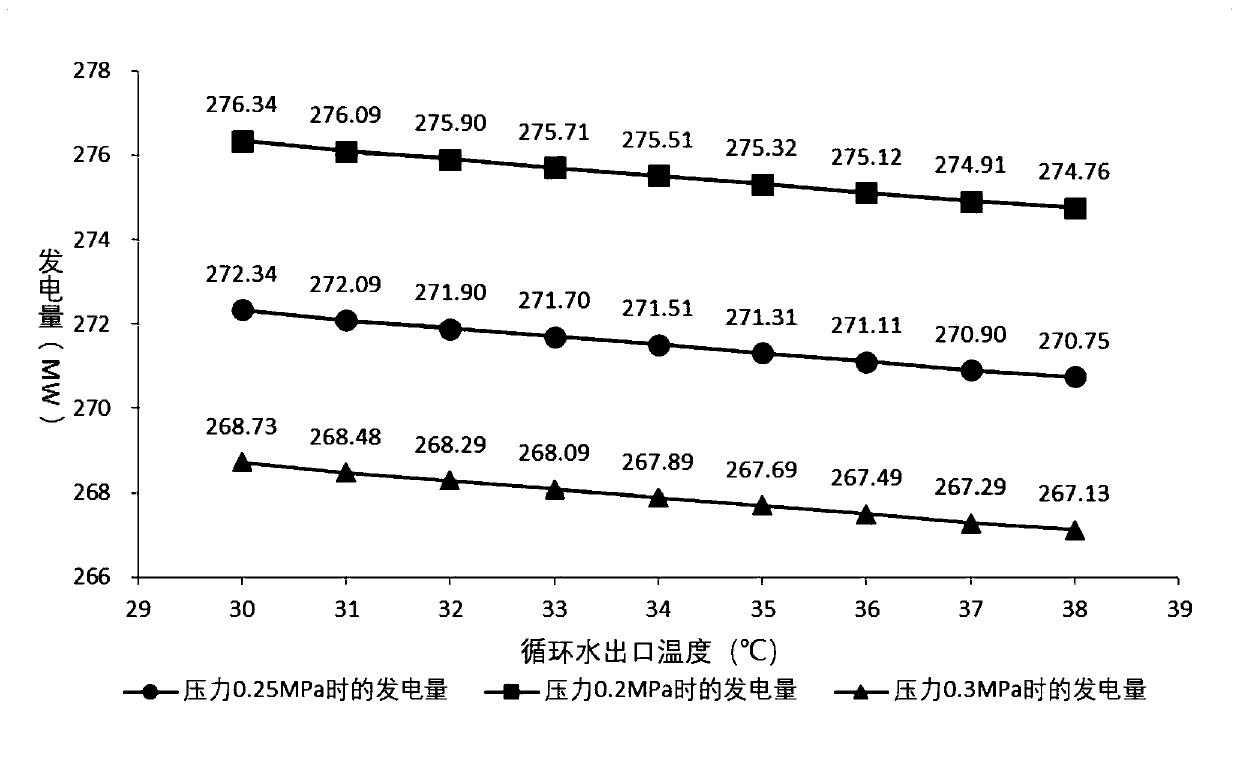

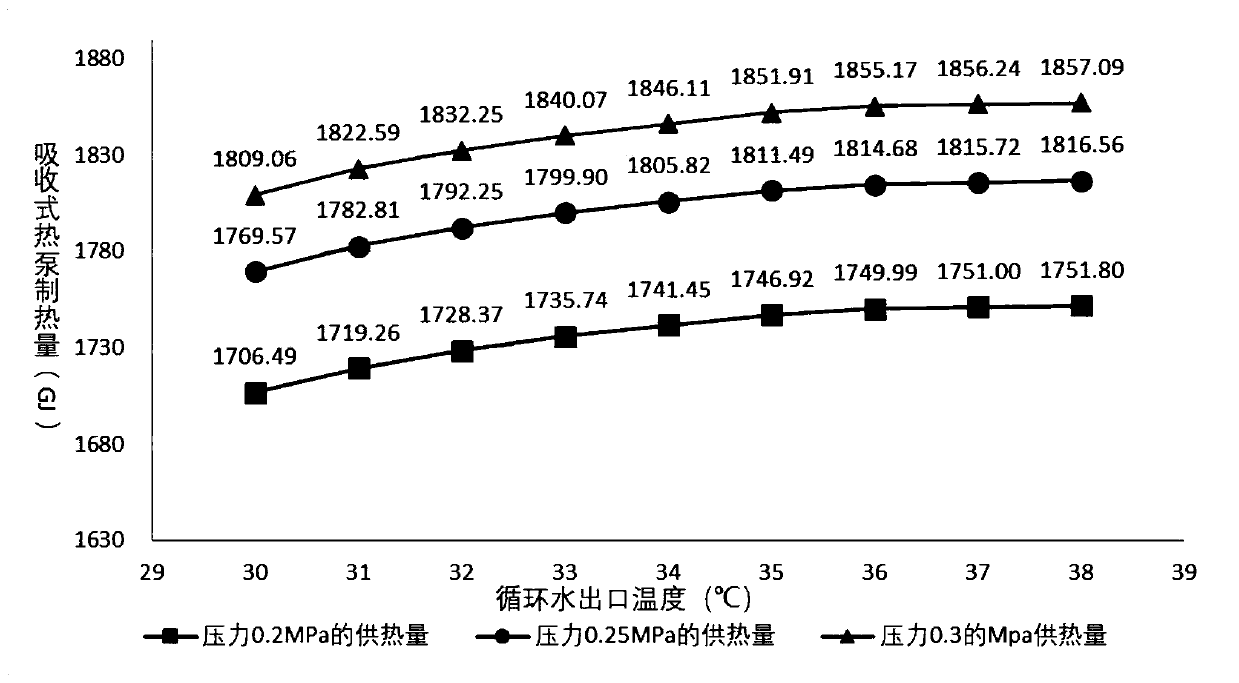

[0122] According to the operating parameters of the steam turbine under the THA working condition, the fifth-stage extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com