Optimization design method of radial-flow-type hydraulic turbine

An optimized design, hydraulic turbine technology, applied in the direction of instrument, adaptive control, control/regulation system, etc., can solve the problem of limited theoretical data for the design of radial hydraulic turbine through-flow components, etc., to improve the optimization efficiency , improve the accuracy and ensure the effect of calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] In order to facilitate the implementation of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and equations.

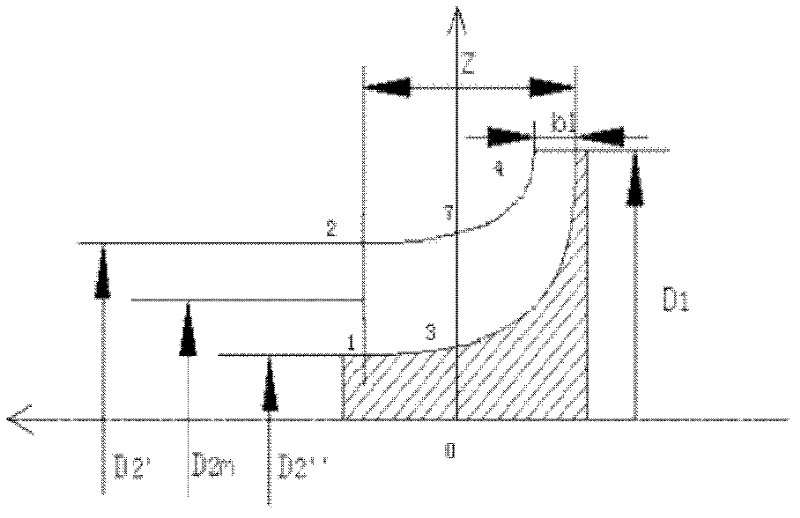

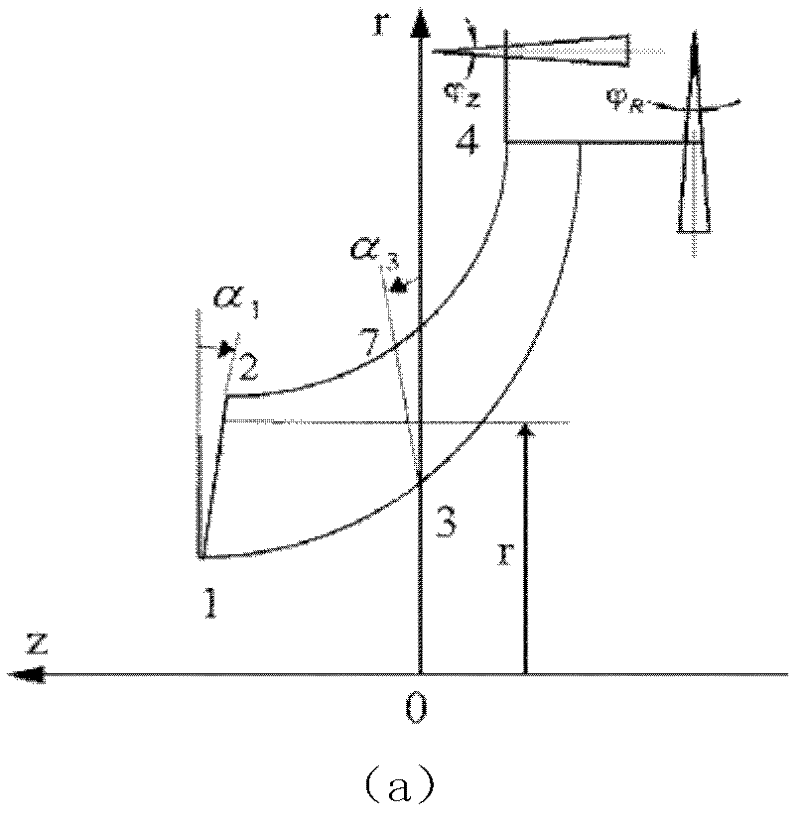

[0111] First, combining the unary optimization model described by equation (1) with the optimization algorithm, considering various constraints, solving the optimization problem through programming, and determining the impeller inlet and outlet diameters, velocity triangle, etc., are the basis for the three-dimensional design of flow components.

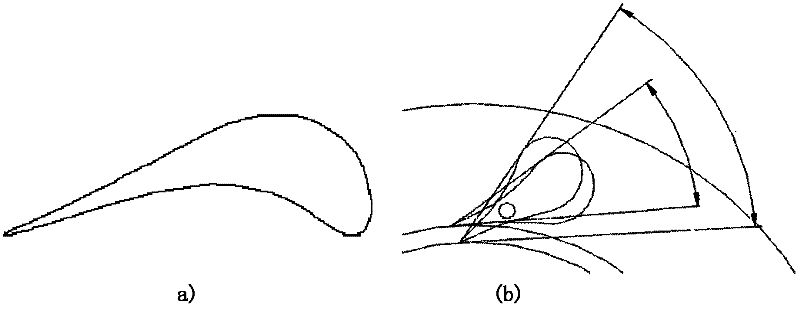

[0112] Second, based on the unary optimization design results, the initial shape of the flow-through components is designed, including the nozzle guide vane shape, impeller meter, and volute design. For hydraulic turbines operating at a fixed flow rate, it is recommended to use a fixed-installation angle nozzle structure, and the guide vane adopts an aerodynamic blade shape to reduce flow loss, such as figure 1 (a) shown. For the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com