Infrared gas sensing system

A gas sensing and infrared technology, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems that the temperature of the detector module cannot be kept consistent, reduce environmental impact factors, and have large differences in heat loss, etc., to achieve Improve anti-interference, wide detection range, and reduce the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings.

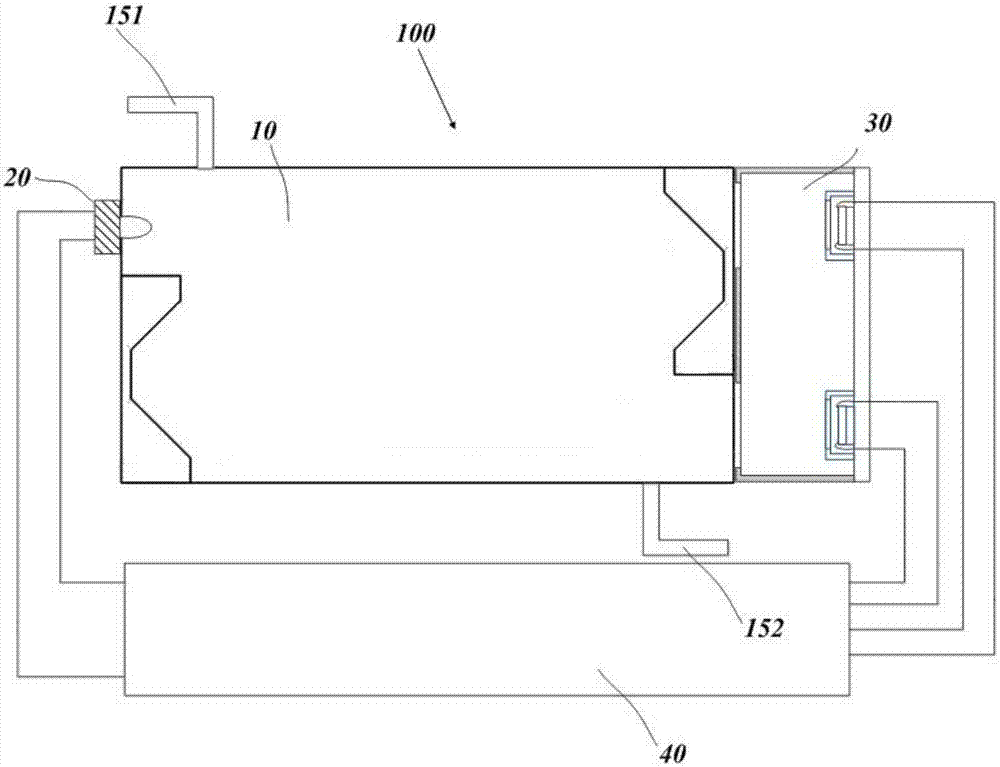

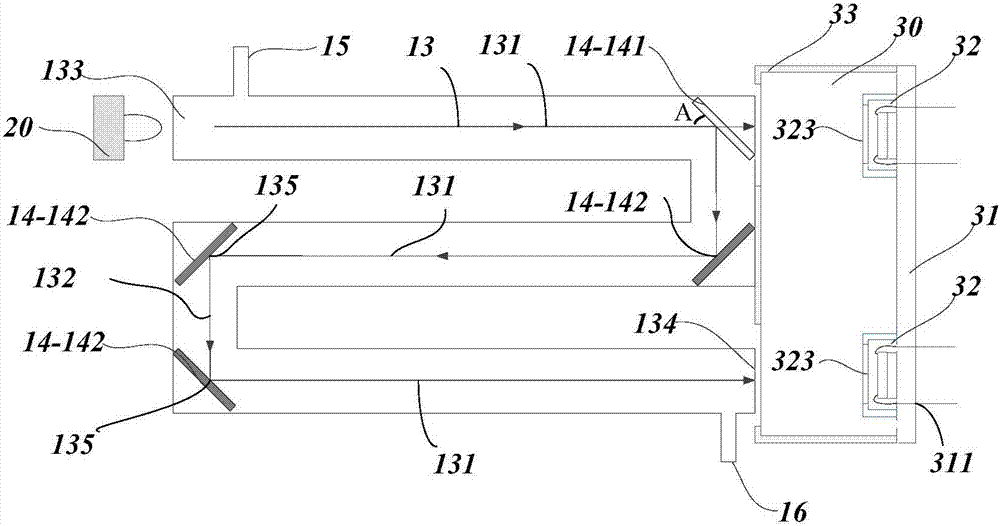

[0030] See Figure 1 to Figure 6 As shown, the present invention relates to an infrared gas sensing system 100 comprising a base 10 having a broken line channel 13, an infrared light source 20 disposed adjacent to the base 10, and a detection module disposed adjacent to the base 10 30, and a control module 40 electrically connected to the infrared light source 20 and the detection module 30.

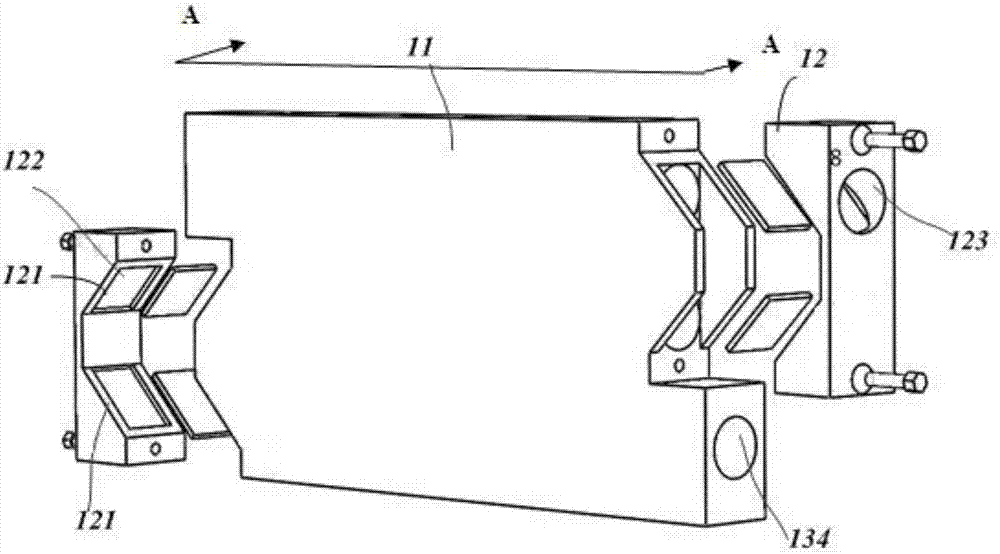

[0031] The base 10 includes a substrate 11, at least two mounts 12 matched with the substrate 11, a mirror 14 arranged between the substrate 11 and the mounts 12, and a mirror 14 arranged on the substrate 11. The air inlet 15 and the air outlet 16 on the top, in this embodiment, the number of the mounting base 12 is two, and they are respectively located on both sides of the base plate 11 .

[0032] The two side walls of the base plate 11 are provided with two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com