Refined heating control method

A heating control and billet heating technology, applied in temperature control and other directions, can solve the problems of uneven section temperature of billet, affecting steel rolling production, unable to know whether the billet temperature and section temperature difference meet the requirements of the rolling process, etc., so as to improve the heating quality and The effect of rolling production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

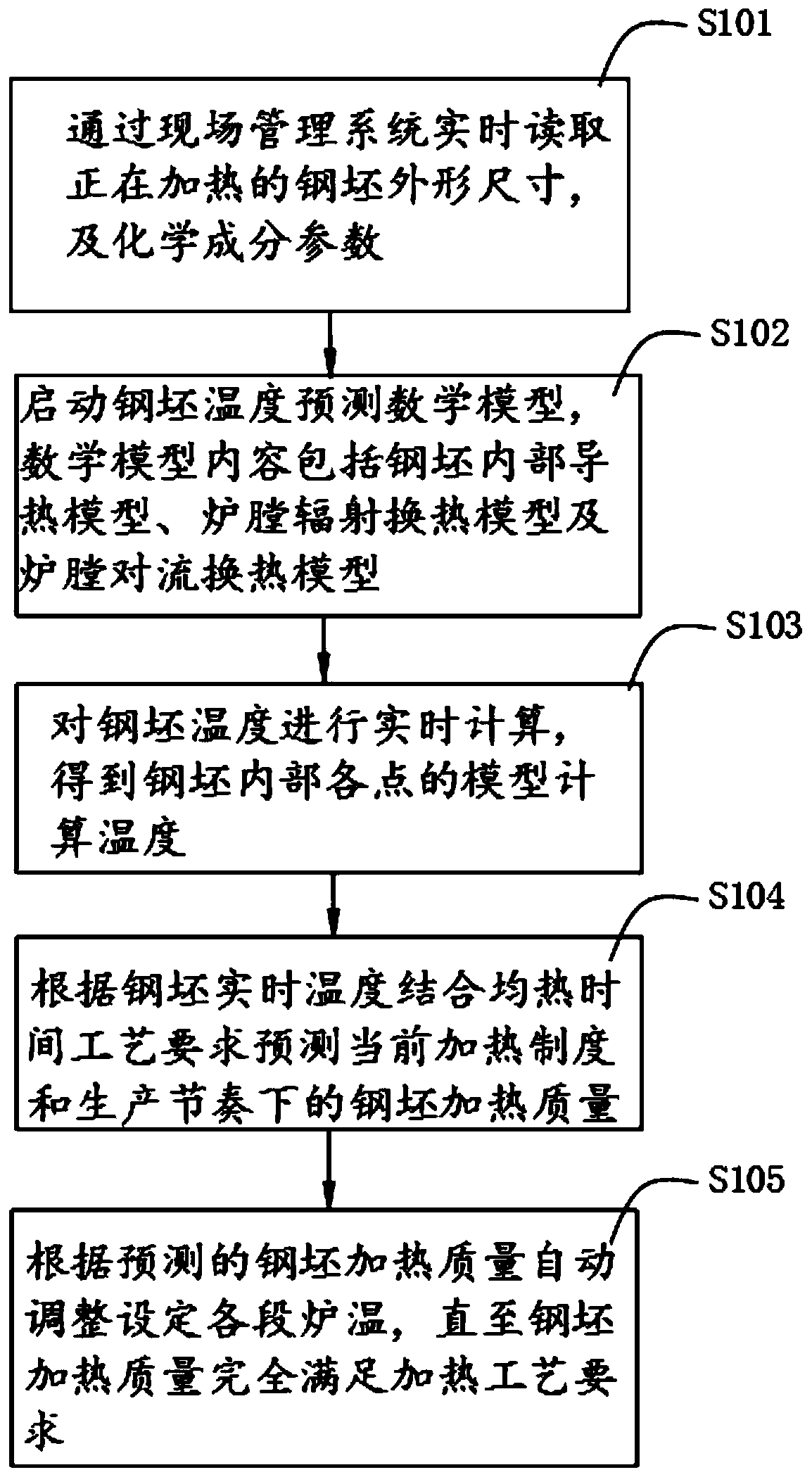

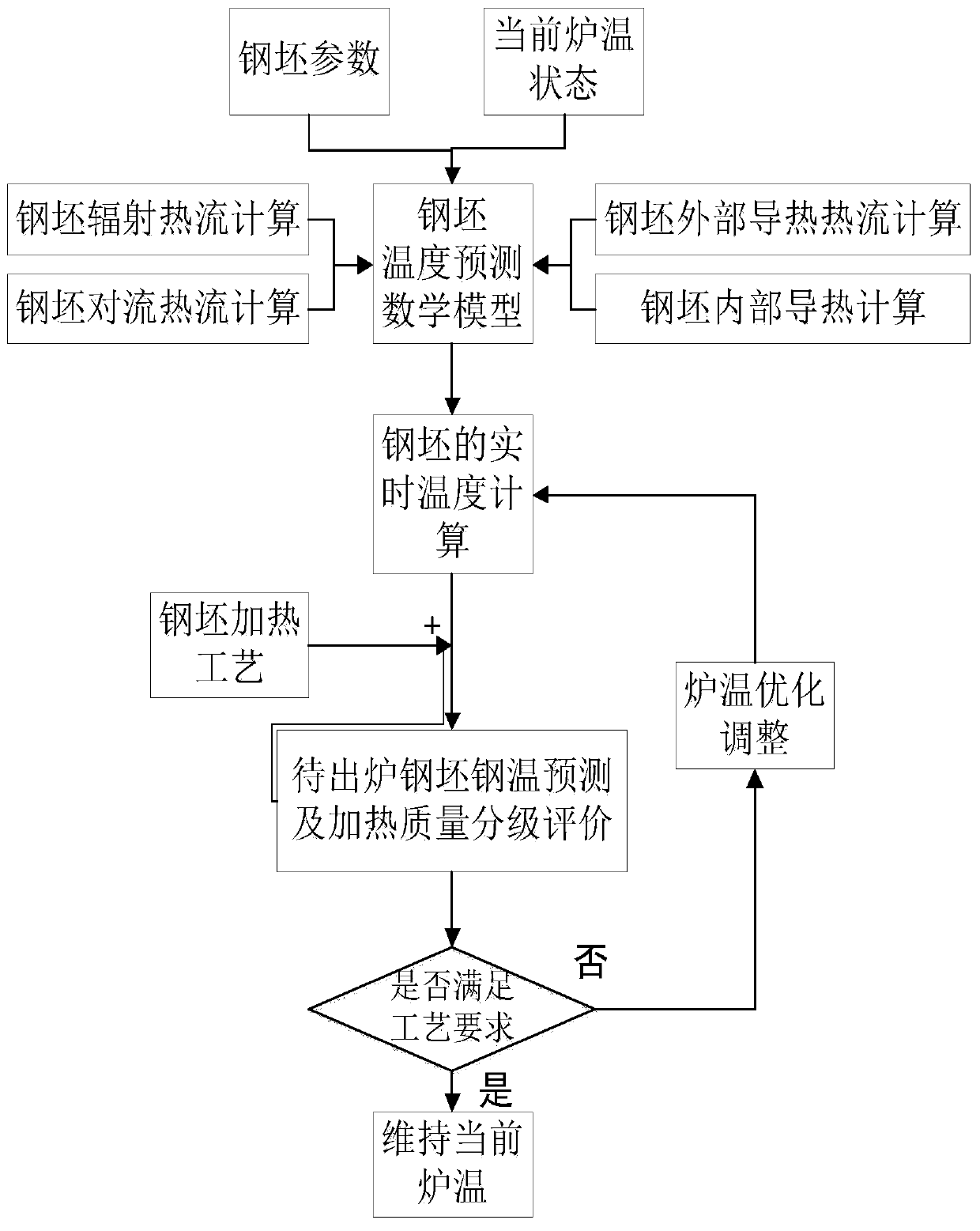

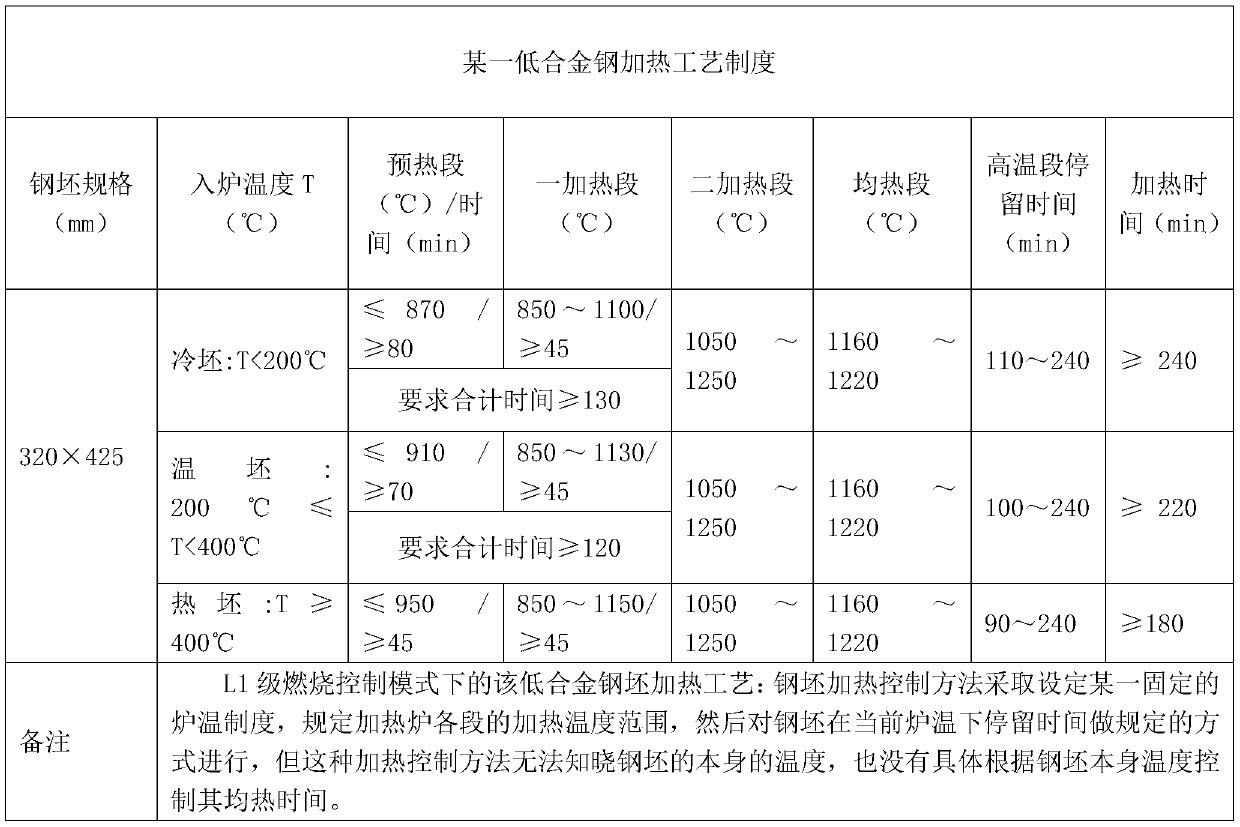

[0032] Such as figure 1 and figure 2 As shown, a refined heating control method, including:

[0033] Step 101: Obtain the dimension data and chemical composition parameters of the steel billet being heated through the on-site management system.

[0034] Step 102: start the billet temperature prediction mathematical model, the billet temperature prediction mathematical model includes the billet internal heat conduction model, furnace radiation heat transfer model and furnace convective heat transfer model.

[0035] Step 103: Carry out real-time calculation to the steel billet temperature, obtain the model calculation temperature of each point inside the steel billet.

[0036] Step 104: Predict the billet heating quality under the current heating regime and production rhythm according to the real-time billet temperature combined with the soaking tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com