High light, high black and high impact polypropylene special material and preparation method thereof

A technology of high-impact polypropylene and special materials, applied in the field of polymers, can solve the problems of high gloss, high impact, frequent contact, long-term light, etc., and achieve good appearance, increased gloss, and improved gloss and blackness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

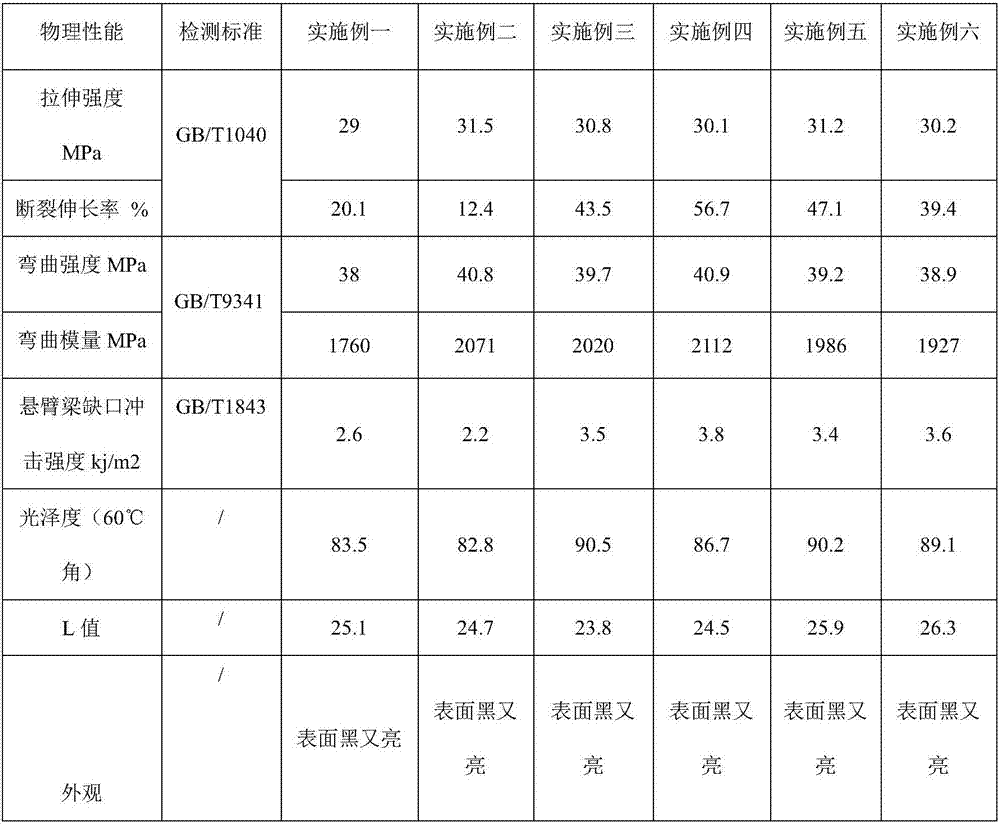

Examples

Embodiment 1

[0027] The high-gloss, high-black, high-impact polypropylene special material in this embodiment is composed of the following raw materials in parts by weight: 80 parts of homopolypropylene resin, 10 parts of random copolymer polypropylene resin, 10 parts of mineral-filled calcium carbonate, sorbitol Nucleating agent NX-8000: 0.2 parts, distearic acid amide dispersant TAS-2A: 0.3 parts, EBS: 0.2 parts, antioxidant 1010: 0.2 parts, antioxidant 168: 0.2 parts, PP carrier black Mother 6258: 3 servings.

[0028] Concrete preparation method comprises the following steps:

[0029] (1) Add 10 parts of calcium carbonate, 0.3 parts of dispersant TAS-2A, and 0.2 parts of dispersant EBS into a high-speed mixer and blend for 3 minutes;

[0030] (2) 80 parts of homopolymerized polypropylene resin, 10 parts of random copolymerized polypropylene resin, 0.2 parts of nucleating agent NX-80000, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, 3 parts of black masterbatch 6258, adde...

Embodiment 2

[0033] The high-gloss, high-black, high-impact polypropylene special material in this embodiment is composed of the following raw materials in parts by weight: 80 parts of homopolypropylene resin, 10 parts of random copolymer polypropylene resin, 10 parts of mineral-filled talcum powder, sorbitol Nucleating agent NX-8000: 0.2 parts, distearic acid amide dispersant TAS-2A: 0.3 parts, stearic acid dispersant calcium stearate: 0.2 parts, antioxidant 1010: 0.2 parts, antioxidant Agent 168: 0.2 parts, PP carrier black masterbatch 6258: 4 parts, 1 part of UV absorber.

[0034] Concrete preparation method comprises the following steps:

[0035] (1) Add 10 parts of talcum powder, 0.3 parts of dispersant TAS-2A, and 0.2 parts of calcium stearate into a high-speed mixer and blend for 5 minutes;

[0036] (2) 80 parts of the remaining homopolymerized polypropylene resin, 10 parts of random copolymerized polypropylene resin, 0.2 parts of nucleating agent NX-8000, 0.2 parts of antioxidant ...

Embodiment 3

[0039] The high-gloss, high-black, high-impact polypropylene special material in this embodiment is composed of the following raw materials in parts by weight: 80 parts of homopolypropylene resin, 10 parts of random copolymer polypropylene resin, and 10 parts of high-purity precipitated barium sulfate filled with minerals , metal phosphate nucleating agent NA-11: 0.2 parts, bisstearic acid amide type dispersant TAS-2A: 0.2 parts, antioxidant 1010: 0.1 parts, antioxidant 168: 0.1 parts, PP carrier black masterbatch 6258: 3 parts, 1 part of surface brightener.

[0040] Concrete preparation method comprises the following steps:

[0041] (1) Add 10 parts of high-purity precipitated barium sulfate and 0.2 parts of dispersant TAS-2A into a high-speed mixer and blend for 3 minutes;

[0042] (2) 80 parts of remaining homopolymerized polypropylene resin, 10 parts of random copolymerized polypropylene resin, 10.2 parts of nucleating agent NA-1, 0.1 part of antioxidant 1010, 0.1 part of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com