Solution for deashing and processing surface of silicon aluminum composite material

A silicon-aluminum composite material and a technology for treating solutions, which are applied in the field of metal surface treatment, can solve problems such as easy bulging, incompleteness, and falling off, and achieve the effects of stable process quality, uniform and dense surface, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

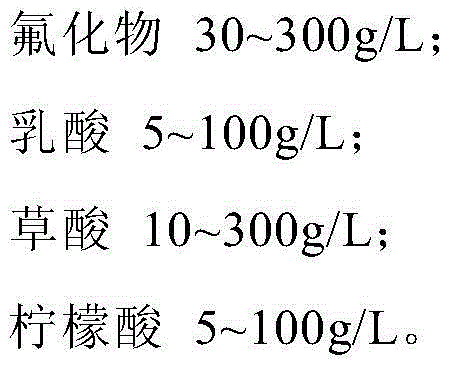

[0017] Prepare the ash-removing solution for silicon-aluminum composite materials according to the following components:

[0018] Ammonium fluoride: 300g / L;

[0019] Lactic acid: 5g / L;

[0020] Oxalic acid: 10g / L;

[0021] Citric acid: 5g / L.

[0022] The silicon-aluminum composite material with a silicon content of 80% was used as the experimental sample. Firstly, after the prepared silicon-aluminum composite material sample is degreasing and rinsed with water, etc., the sample is immersed in a strong acid solution to remove the aluminum alloy oxide film. There is a black loose film layer on the surface of the sample, and the sample is placed on the above-mentioned silicon-aluminum composite material to remove the oxide film. In the ash solution, the temperature is room temperature. After 30s, the sample is taken out and rinsed with clean water to obtain a clean surface that removes the aluminum alloy’s own oxide film and floating ash on the surface. Then, the surface is tr...

Embodiment 2

[0024] Prepare the ash-removing solution for silicon-aluminum composite materials according to the following components:

[0025] Ammonium fluoride: 30g / L;

[0026] Lactic acid: 100g / L;

[0027] Oxalic acid: 300g / L;

[0028] Citric acid: 5g / L.

[0029] The silicon-aluminum composite material with a silicon content of 10% was used as the experimental sample. Firstly, after the prepared silicon-aluminum composite material sample is degreasing and rinsed with water, etc., the sample is immersed in a strong acid solution to remove the aluminum alloy oxide film. There is a black loose film layer on the surface of the sample, and the sample is placed on the above-mentioned silicon-aluminum composite material to remove the oxide film. In the ash solution, the temperature is room temperature. After 30s, the sample is taken out and rinsed with clean water to obtain a clean surface with the aluminum alloy’s own oxide film and surface floating ash removed. Then, the surface is treated...

Embodiment 3

[0031] Prepare the ash-removing solution for silicon-aluminum composite materials according to the following components:

[0032] Ammonium fluoride: 100g / L;

[0033] Lactic acid: 20g / L;

[0034] Oxalic acid: 100g / L;

[0035] Citric acid: 20g / L.

[0036] The silicon-aluminum composite material with a silicon content of 30% was used as the experimental sample. Firstly, after the prepared silicon-aluminum composite material sample is degreasing and rinsed with water, etc., the sample is immersed in a strong acid solution to remove the aluminum alloy oxide film. There is a black loose film layer on the surface of the sample, and the sample is placed on the above-mentioned silicon-aluminum composite material to remove the oxide film. In the ash solution, the temperature is room temperature. After 30s, the sample is taken out and rinsed with clean water to obtain a clean surface with the aluminum alloy’s self-oxidized film and surface floating dust removed, and then hang-coated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com