Glass frosting powder for processing anti-dazzle glass and preparation method thereof

An anti-glare glass and frosting powder technology, applied in the field of glass manufacturing, can solve the problems of high raw material price, high price, easy to absorb water and deteriorate, and achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

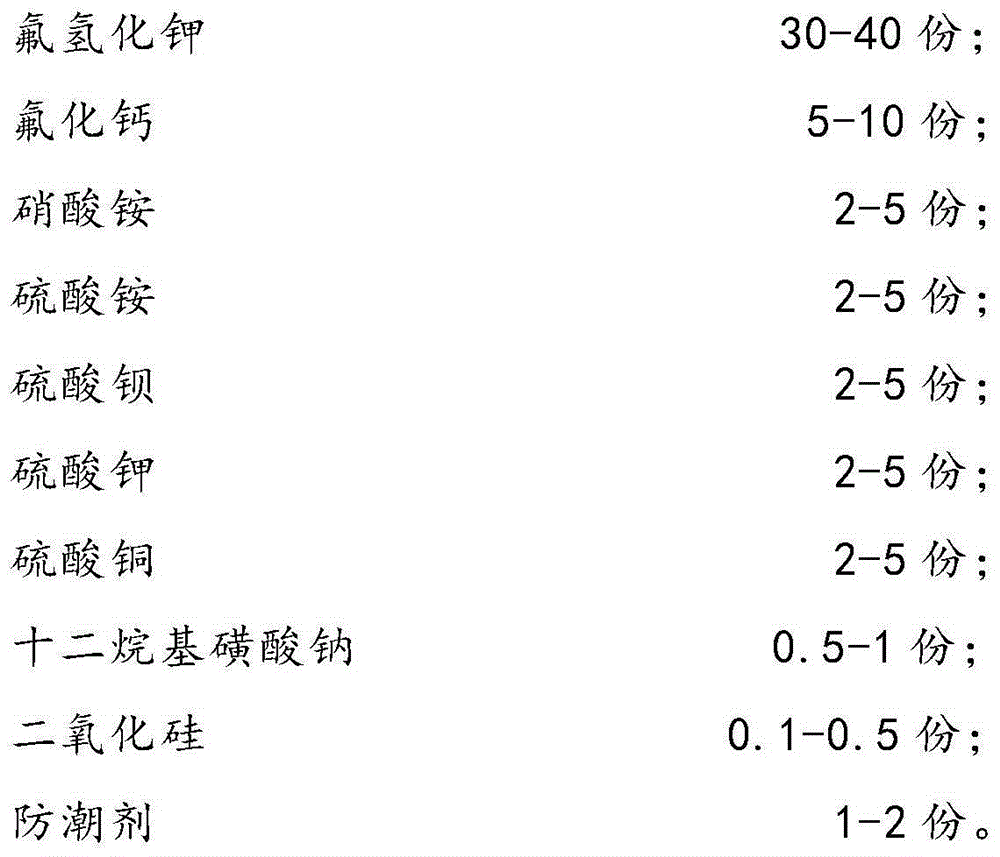

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for frosting powder for processing anti-glare glass, the preparation method comprises the following steps:

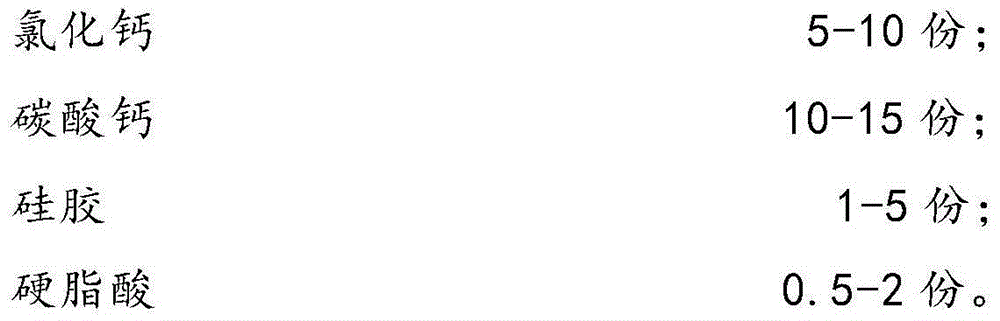

[0025] Step 1: Prepare raw materials for preparing a moisture-proof agent according to the following components and parts by weight: 6 parts of calcium chloride, 12 parts of calcium carbonate, 2 parts of silica gel, and 1.5 parts of stearic acid.

[0026] Step 2: Grind 6 parts of calcium chloride, 12 parts of calcium carbonate, 2 parts of silica gel, and 1.5 parts of stearic acid through a grinder, filter through a 200-mesh filter, and continue grinding the filter residue until all raw materials are filtered through a 200-mesh filter After netting, add all the raw materials into the mixer, the speed of the mixer is controlled at 1000 rpm, and after stirring for 18 minutes, the moisture-proof agent is prepared.

[0027] Step 3: Prepare raw materials for frosting powder according to the following components and parts by weight: 15 parts of ammo...

Embodiment 2

[0030] A preparation method for frosting powder for processing anti-glare glass, the preparation method comprises the following steps:

[0031] Step 1: Prepare raw materials for preparing a moisture-proof agent according to the following components and parts by weight: 6 parts of calcium chloride; 11 parts of calcium carbonate; 2.5 parts of silica gel; 1 part of stearic acid.

[0032] Step 2: Grind 6 parts of calcium chloride, 11 parts of calcium carbonate, 2.5 parts of silica gel, and 1 part of stearic acid through a grinder, filter through a 200-mesh filter, and continue grinding the filter residue until all raw materials pass through a 200-mesh filter After netting, add all the raw materials into the mixer, the speed of the mixer is controlled at 1100 rpm, and after stirring for 15 minutes, the moisture-proof agent is prepared.

[0033] Step 3: Prepare raw materials for frosting powder according to the following components and parts by weight: 25 parts of ammonium fluoride;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com