Water-soluble solid etching reagent for anti-dazzle high-aluminum glass, and etching process for high-aluminum glass

A high-alumina glass and solid reagent technology, applied in the direction of surface etching compositions, chemical instruments and methods, etc., can solve the problems of poor stability of etching liquid, difficult recycling, strong volatility, etc., to improve etching effect and facilitate storage and transportation, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

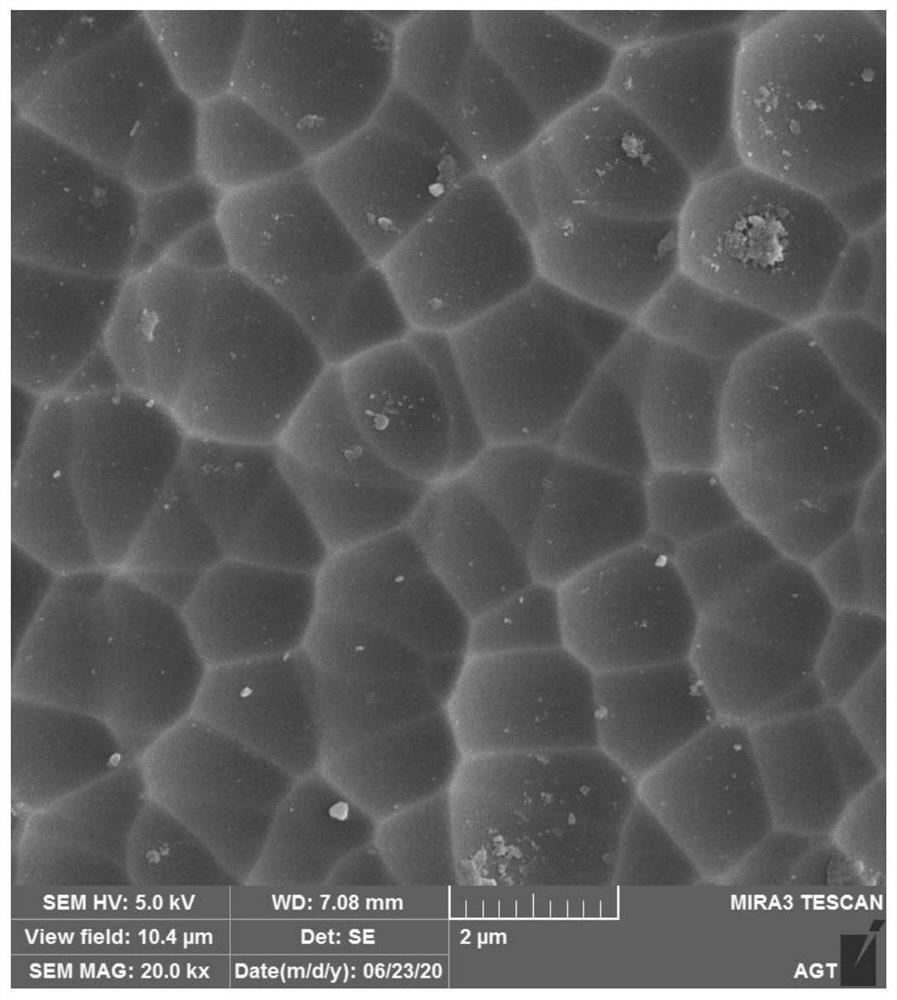

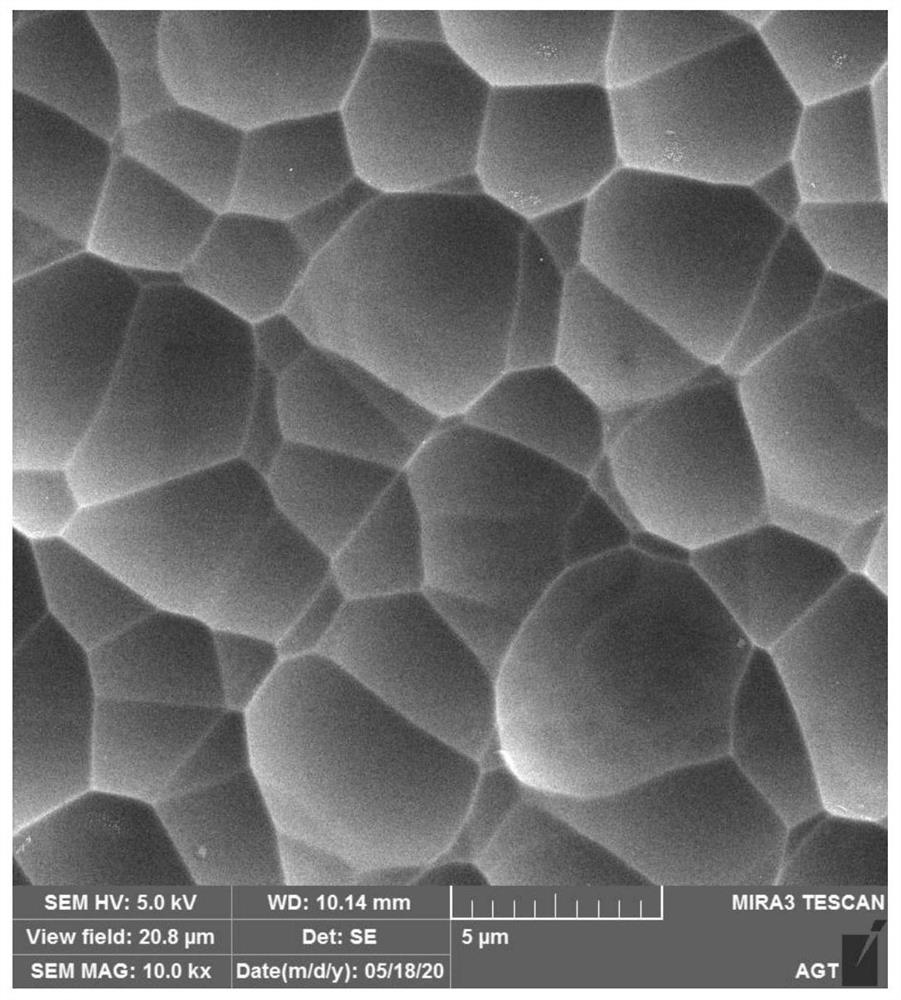

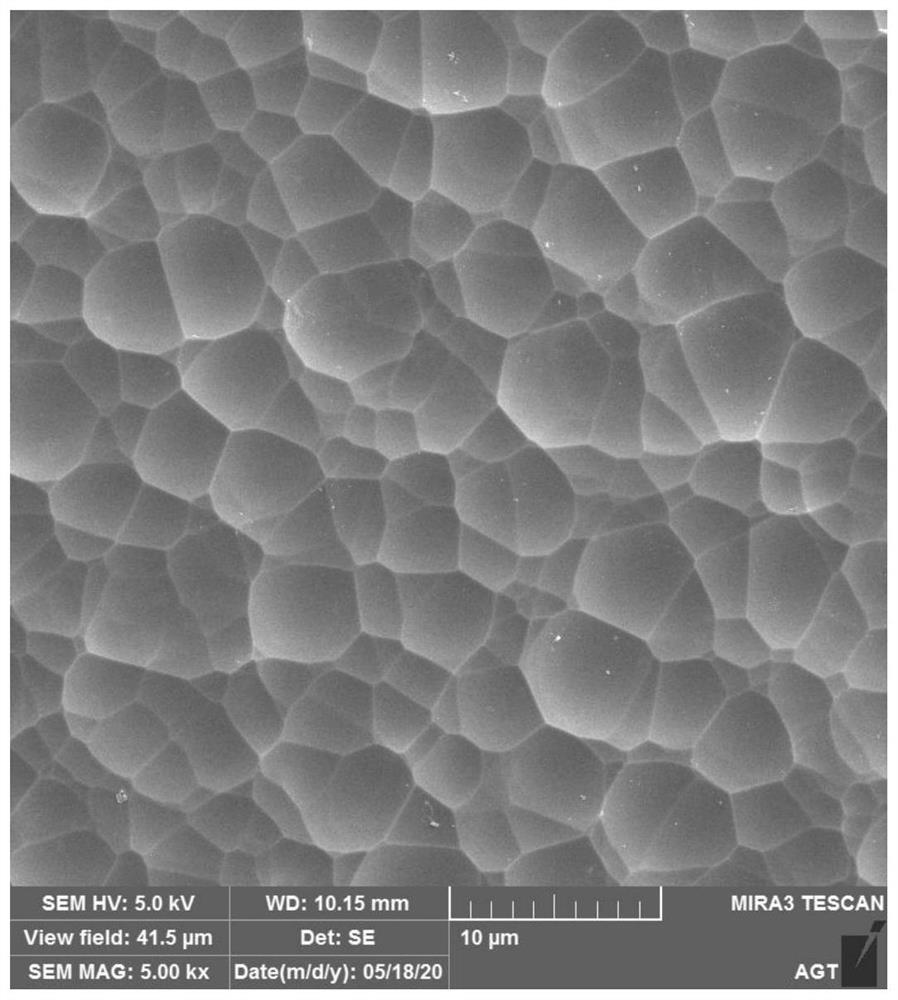

Image

Examples

Embodiment 1

[0044] A water-soluble anti-glare high-alumina glass etching solid reagent comprises the following raw materials in parts by weight: 15 parts of ammonium bifluoride, 30 parts of citric acid, 10 parts of ammonium sulfate, 2 parts of potassium hydrogen fluoride, 3 parts of titanium dioxide, and 5 parts of D-sorbitol.

[0045] The high alumina glass etching process includes the following steps:

[0046] (1) Weigh raw materials according to the above weight ratio: 15 parts of ammonium bifluoride, 30 parts of citric acid, 10 parts of ammonium sulfate, 2 parts of potassium bifluoride, 3 parts of titanium dioxide, 5 parts of D-sorbitol, and add 300 parts of ultrapure water , mix at room temperature, stir evenly at 300r / min, put it into a polytetrafluoroethylene container, and age it ultrasonically at 25°C for 8 hours to prepare an etching solution;

[0047] (2) After cleaning the pre-etched flat high-alumina glass with a surfactant, place it in deionized water mixed with absolute eth...

Embodiment 2

[0051] A water-soluble antiglare high-alumina glass etching solid reagent, the raw materials of which are: 35 parts by weight of ammonium bifluoride, 20 parts of citric acid, 8 parts of ammonium sulfate, 2 parts of potassium hydrogen fluoride, 3 parts of titanium dioxide, and 6 parts of microcrystalline cellulose. The raw materials were weighed according to the above parts by weight. The high alumina glass etching process of this embodiment is different from that of Embodiment 1 in that the aging time of step (1) is 12 hours, and the soaking time of step (4) is 20 minutes.

Embodiment 3

[0053]A water-soluble anti-glare high-alumina glass etching solid reagent comprises the following raw materials in parts by weight: 25 parts of ammonium bifluoride, 30 parts of citric acid, 15 parts of ammonium sulfate, 2 parts of potassium sulfate, 4.5 parts of titanium dioxide, and 5 parts of D-sorbitol. The raw materials were weighed according to the above parts by weight. The high alumina glass etching process of this embodiment is different from that of Embodiment 1 in that the aging time of step (1) is 16 hours, and the soaking time of step (4) is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com