Method for synthesizing rare-earth metal codoped yttrium potassium pentafluoride nano crystal from waste fluorescent powder

A rare earth metal and yttrium potassium pentafluoride technology, which is applied in the field of solid waste resource utilization, can solve the problems of insufficient luminescence performance of rare earth fluorescent up-conversion materials, insufficient uniform dispersion, large nanocrystalline size, etc., and achieves good down-conversion. The effect of luminous performance, good luminous performance and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

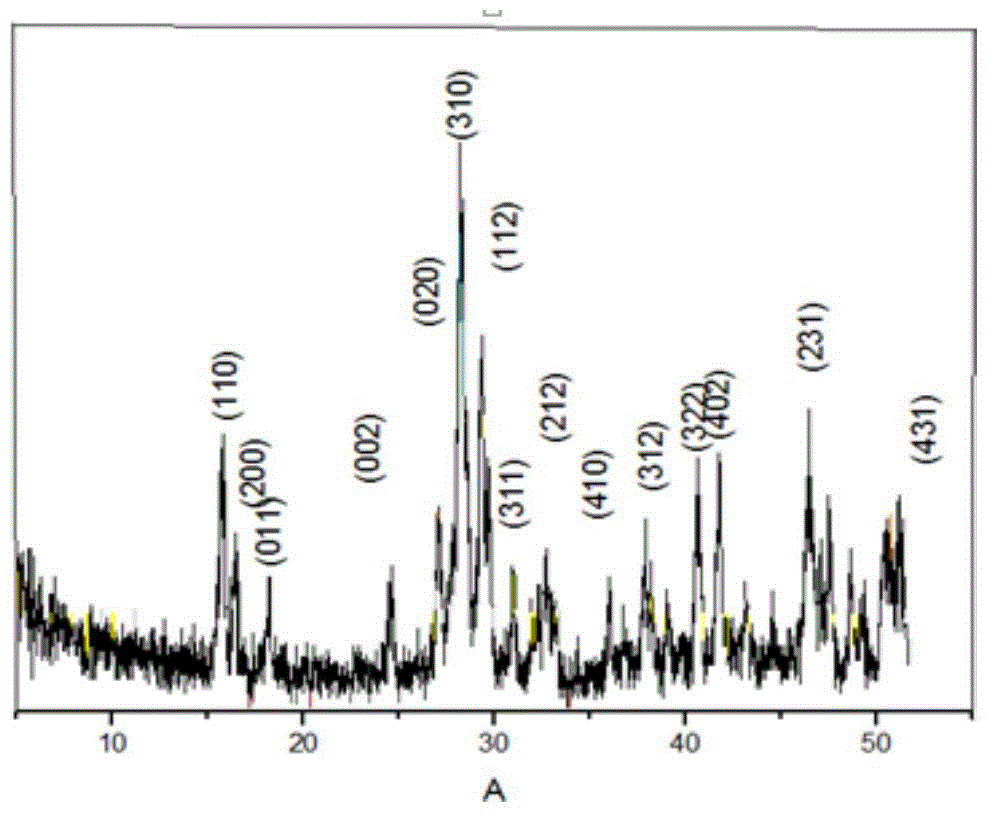

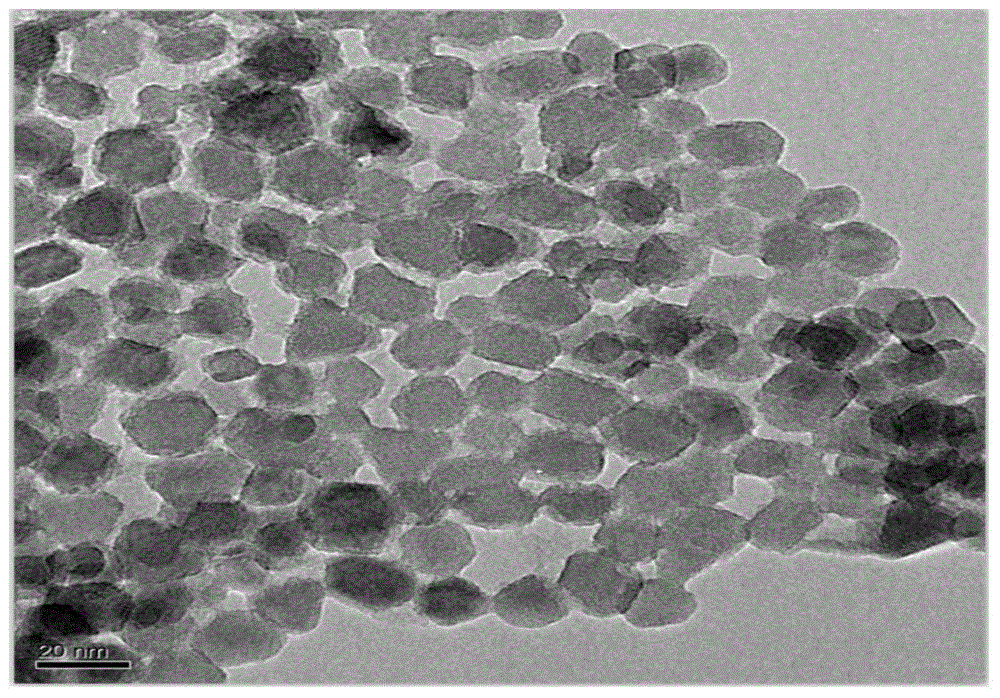

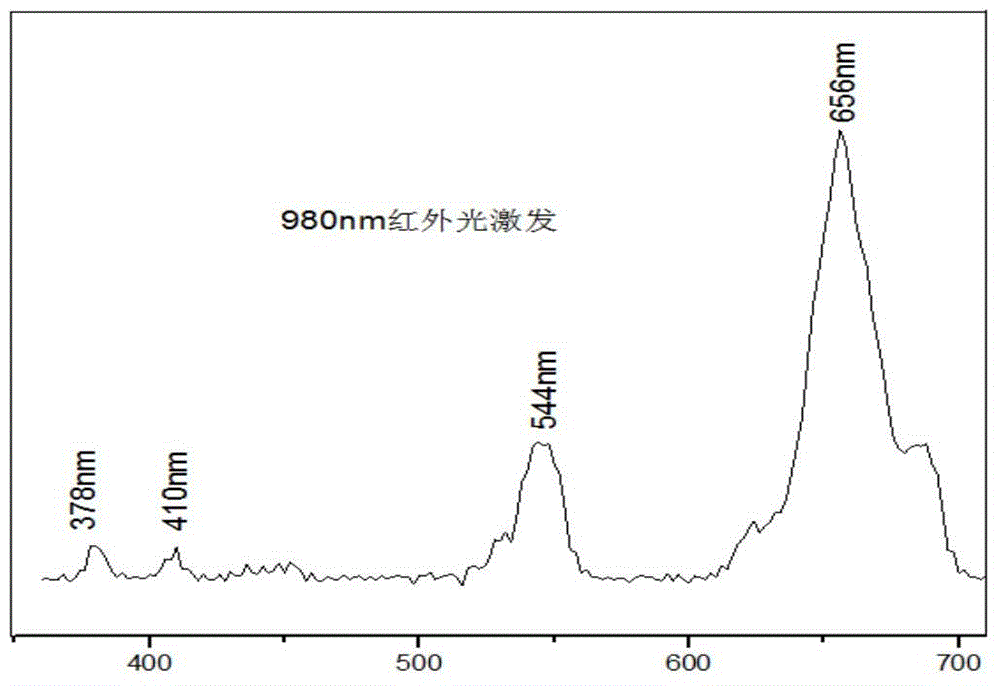

[0036] The embodiment of the rare earth metal three-doped yttrium potassium pentafluoride nanocrystals with a particle size below 20nm prepared by using waste fluorescent powder as a raw material is as follows:

[0037] 1) Take 10g of waste fluorescent powder, add sulfuric acid and hydrochloric acid mixed acid solution (2mol / L sulfuric acid solution and 4mol / L hydrochloric acid solution are prepared at a volume ratio of 1:1) 100ml to leach the fluorescent powder, the speed is 1000rpm / min, add 0.6 ml of 20% H 2 o 2 , temperature 70°C-90°C, leaching for 4h;

[0038] 2) The leached solution is put into a centrifuge for solid-liquid separation to obtain a leaching solution. The leaching solution is mixed with ammonia water, a very dilute potassium sulfide solution and a very dilute potassium sulfate solution to adjust the pH value to 3.5-4, and then put it into a centrifuge for further processing. Solid-liquid separation to obtain the filtrate that removes most of the aluminum, ...

Embodiment 2

[0050] The embodiment of the potassium pentafluoride yttrium potassium pentafluoride double-doped with europium and erbium doped with particle size is prepared as raw material with waste fluorescent powder as follows:

[0051] 1) Take 10g of waste fluorescent powder, add sulfuric acid and hydrochloric acid mixed acid solution (2mol / L sulfuric acid solution and 4mol / L hydrochloric acid solution are prepared at a volume ratio of 1:1) 100ml to leach the fluorescent powder, the speed is 1000rpm / min, add 0.6 ml of 20% H 2 o 2 , temperature 70°C-90°C, leaching for 4h;

[0052] 2) The leached solution is put into a centrifuge for solid-liquid separation to obtain a leaching solution. The leaching solution is mixed with ammonia water, a very dilute potassium sulfide solution and a very dilute potassium sulfate solution to adjust the pH value to 3.5-4, and then put it into a centrifuge for further processing. Solid-liquid separation to obtain the filtrate that removes most of the alu...

Embodiment 3

[0061] The implementation mode of preparing europium monodoped yttrium potassium pentafluoride nanocrystals with waste fluorescent powder as raw material is as follows:

[0062] 1) Take 10g of waste fluorescent powder, add sulfuric acid and hydrochloric acid mixed acid solution (2mol / L sulfuric acid solution and 4mol / L hydrochloric acid solution are prepared at a volume ratio of 1:1) 100ml to leach the fluorescent powder, the speed is 1000rpm / min, add 0.6 ml of 20% H 2 o 2 , temperature 70°C-90°C, leaching for 4h;

[0063] 2) The leached solution is put into a centrifuge for solid-liquid separation to obtain a leaching solution. The leaching solution is mixed with ammonia water, a very dilute potassium sulfide solution and a very dilute potassium sulfate solution to adjust the pH value to 3.5-4, and then put it into a centrifuge for further processing. Solid-liquid separation to obtain the filtrate that removes most of the aluminum, iron, silicon, magnesium and other impurit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com