Continuous preparation method of hexafluoropropylene tripolymer

A technology of hexafluoropropylene trimer and hexafluoropropylene, which is applied in the field of continuous microchannel preparation of hexafluoropropylene trimer, and can solve the problem of high temperature required for reaction, existence of highly toxic compound carbonyl fluoride, and difficulty in realizing hexafluoropropylene Problems such as selective synthesis of propylene trimer isomers, to achieve the effect of highly selective preparation and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0043] In a dry three-necked flask equipped with a reflux condenser and a magnetic stirrer, add 5.8g (0.1mol) of potassium fluoride, 26.4g (0.1mol) of 18-crown-6 and 500ml of acetonitrile solution (9.56mol) respectively. Set the bath temperature to 82°C, start stirring and heating, add 3.16g (0.01mol) perfluoro-2-ethyl-3,3-dimethyloxirane through a constant pressure dropping funnel, and wait until the temperature of the oil bath is stable Afterwards, keep for 1 h, stop heating, and filter the mixed solution after cooling down to room temperature (25° C.). After filtering, a catalyst is obtained, which is designated as Cat1.

preparation example 2-9

[0045] Preparation 2-9 is the preparation of Cat 2-6 and comparative Cat 1-3, the operation steps are the same as Preparation 1, the difference is that the types of component A, component B, component C and component D are changed during the preparation process Or dosage, see Table 1 below for details.

[0046] Table 1 Preparation of Cat 2-6 and comparative Cat 1-3

[0047]

Embodiment 1

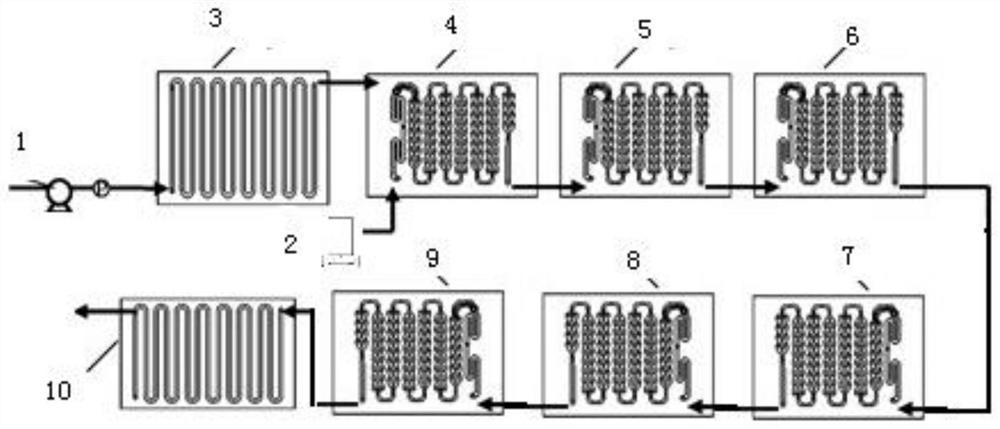

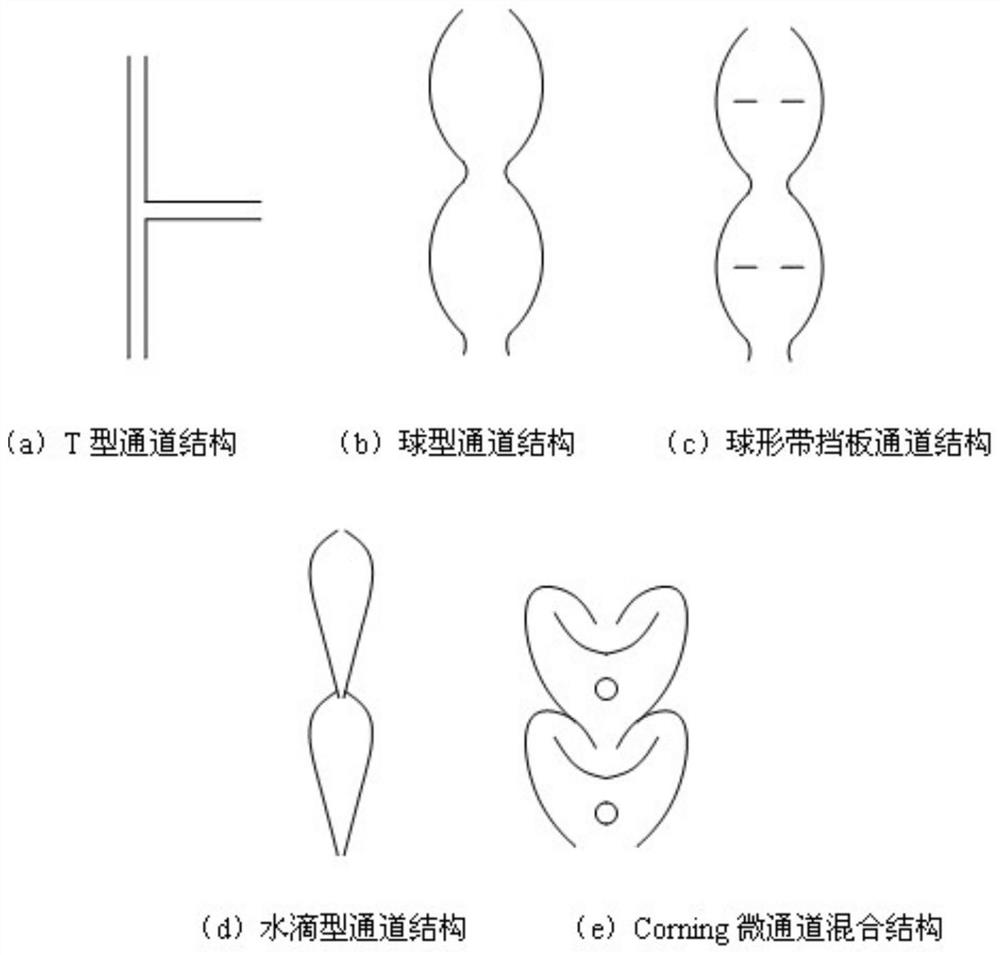

[0049] The microchannel reaction module adopting direct-flow channel structure is used as preheating module 3 and quenching module 10, adopts attached figure 2 The corning "heart-shaped" microchannel reaction module shown in (e) is used as the reaction module, according to the attached figure 1 The reaction process shown constitutes a continuous flow microchannel reaction system. According to the forced heat transfer principle of the microchannel reactor, only two temperature measuring points are set at the reactor inlet and outlet. Before the reaction, the microchannel reaction system and connecting pipelines were dehydrated and dried, and the air tightness was checked at 1.0MPa. The liquid phase catalyst is continuously and stably added to the microchannel reaction system through the liquid phase pump 1; the hexafluoropropylene gas is continuously quantitatively added to the microchannel reaction system through the gas mass flow meter 2.

[0050] Set the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com