Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

A technology of powder embedding and special oil, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problem of matrix microstructure, mechanical performance index limitation, failure to meet the mechanical performance requirements of oil and casing, Change the microstructure and properties to achieve good high-temperature oxidation resistance, increase dislocation density, and increase bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 6

[0022] A section of 400mm long N80 oil pipe (new pipe) was acid-washed and coated with a protective coating, and then solid powder aluminized in a box-type resistance furnace at 450°C. Solid solution in iron, the outer layer is FeAl 2, FeAl, and aluminum solid solution coexistence in steel, after cooling in the furnace, the protective coating naturally peels off, the surface of the oil pipe remains clean, the size of each phase of the oil pipe after infiltration is within the allowable range, and the matrix structure does not change significantly, which still meets the requirements. Industry standard requirements.

[0023] Above-mentioned embodiment penetrating agent formula is as follows table:

[0024] Table 1: Percent distribution table of each penetrating agent component of the embodiment, %

[0025] 150 mesh

[0026] ※Among them, in the zinc-aluminum alloy powder, the aluminum content is 58.5% by weight, and in the iron-aluminum alloy powder, the aluminum co...

Embodiment 1

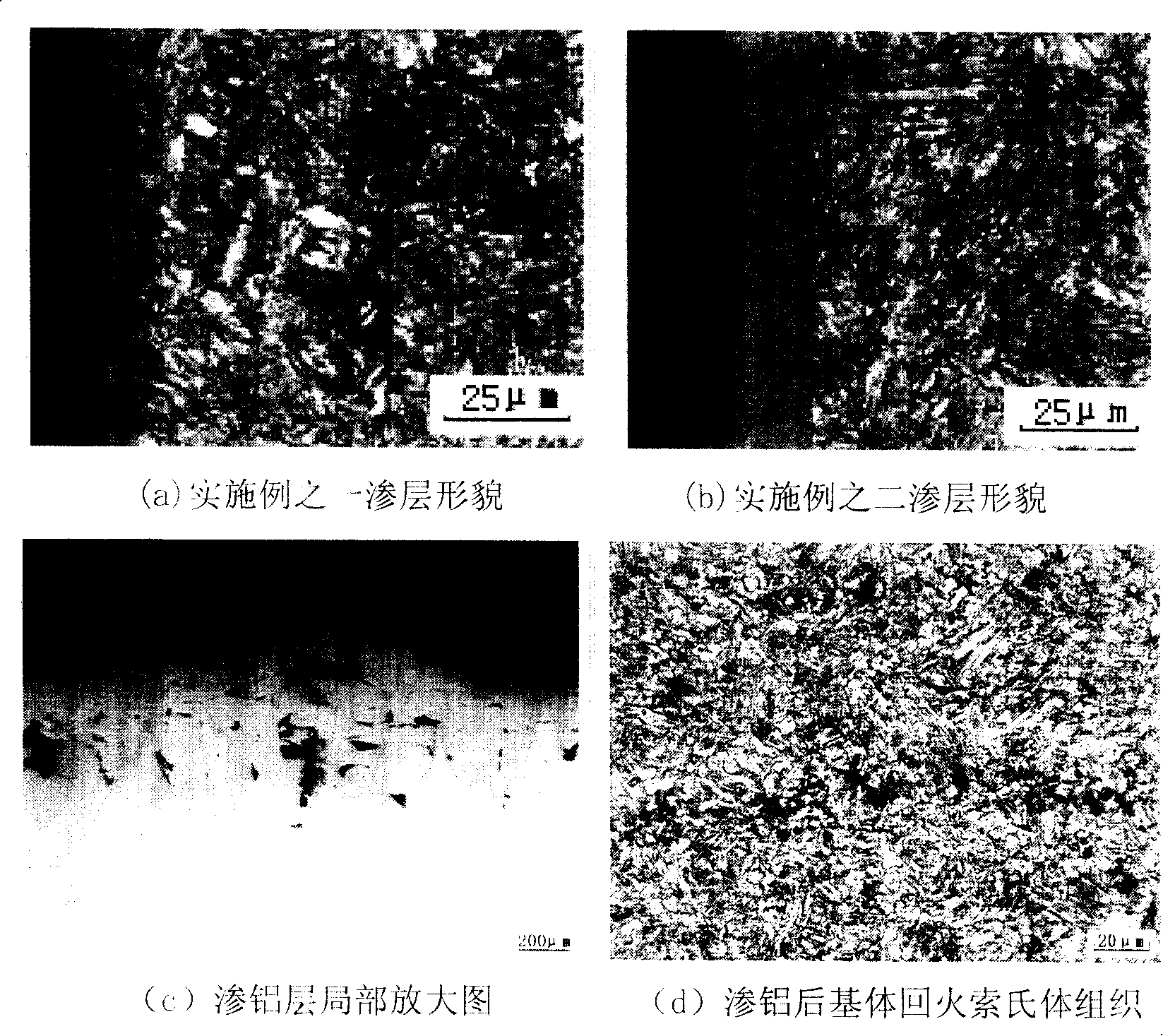

[0027] Example 1 The thickness of the infiltrated layer is 0.12mm, the interface is regular, and it is well combined with the matrix. The matrix structure has not changed, the grain size has changed from 11 to 10, the mechanical properties have not changed much, and it still meets the API standard. The morphology of the infiltrated layer and the matrix structure such as figure 1 (a) shown. The aluminized effect of embodiment 2 is the same as that of embodiment 1.

Embodiment 3

[0028] Example 3 The seepage layer on the inner wall of the oil pipe is about 0.21 mm, and from the outside to the inside are solid solutions of aluminum in steel, FeAl, FeAl 2 , Fe 2 al 5 , The solid solution of zinc in iron, the dimensions of the oil pipe after seepage are within the allowable range. The interface of the infiltrated layer is regular, and it is well combined with the matrix. The matrix structure and mechanical properties have not changed significantly. The morphology of the obtained infiltrated layer and the matrix structure after infiltration are as follows: figure 1 (b) shown. The aluminized effect of Examples 4-6 is the same as that of Example 3.

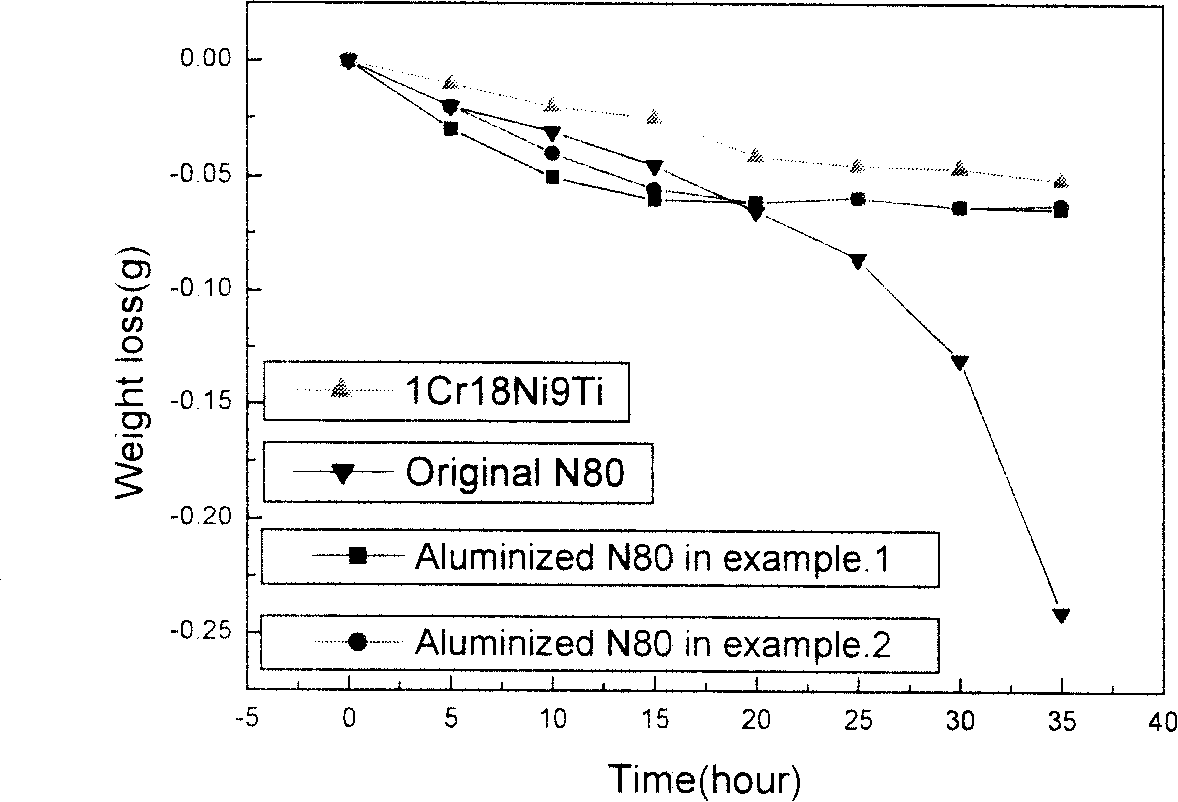

[0029] After sealing the oil pipe samples obtained in the above two examples 2 and 6 from both ends with ceramics (with a small hole at one end), each inject 10% H 2 S+3%NaCl solution, after being sealed, the corrosion resistance test was carried out. At the same time, the 1Cr18Ni9Ti stainless steel pipe and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com