Single-layer high-precision brazed superabrasive grinding wheel and manufacturing method thereof

A super-hard abrasive, high-precision technology, applied in the field of grinding wheels, can solve problems such as the adverse effect of grinding wheel manufacturing accuracy, the increase in the degree of deformation of the brazing material layer, and the reduction of grinding wheel manufacturing accuracy, so as to achieve good controllability, stability, and manufacturing accuracy. High, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

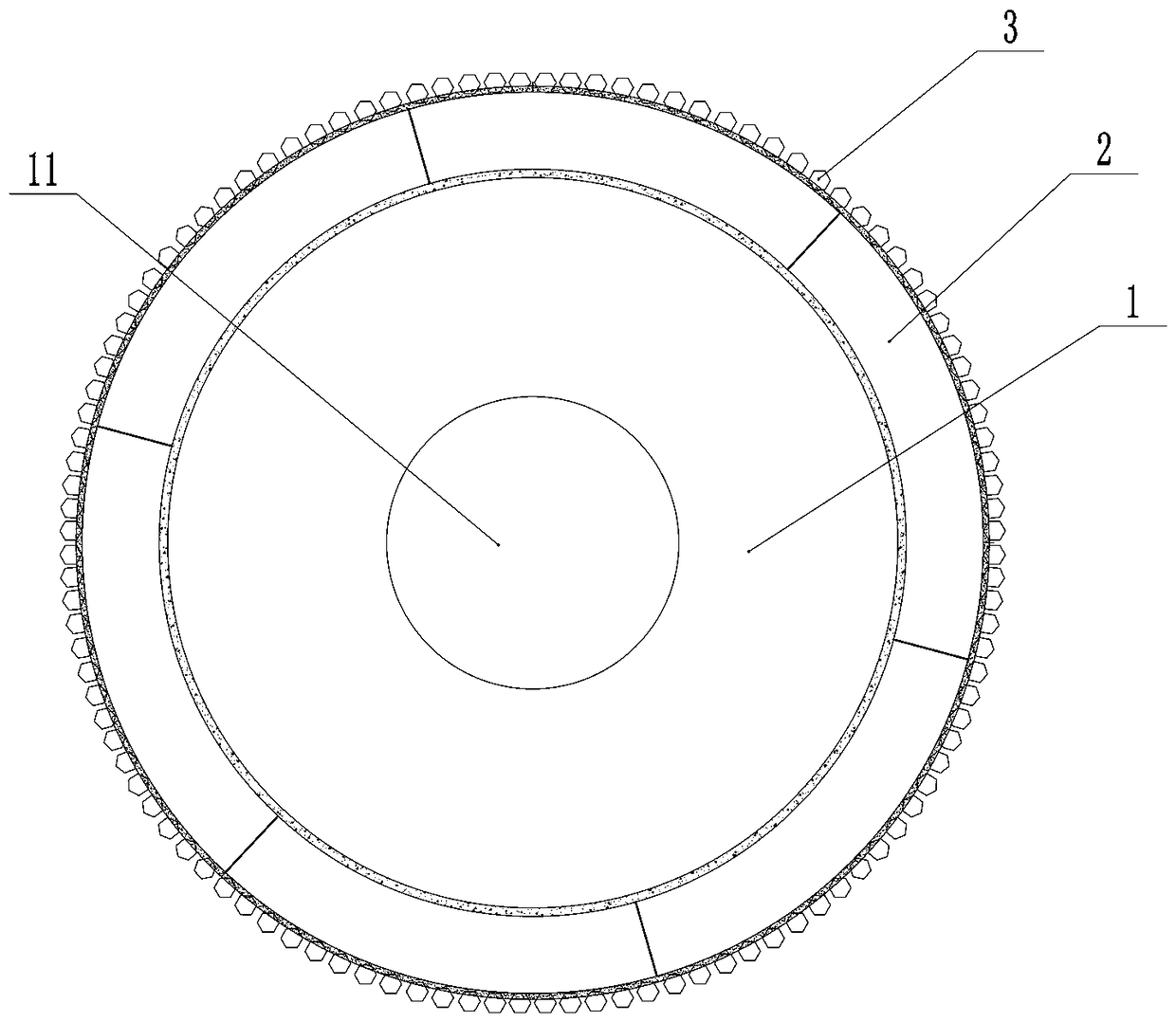

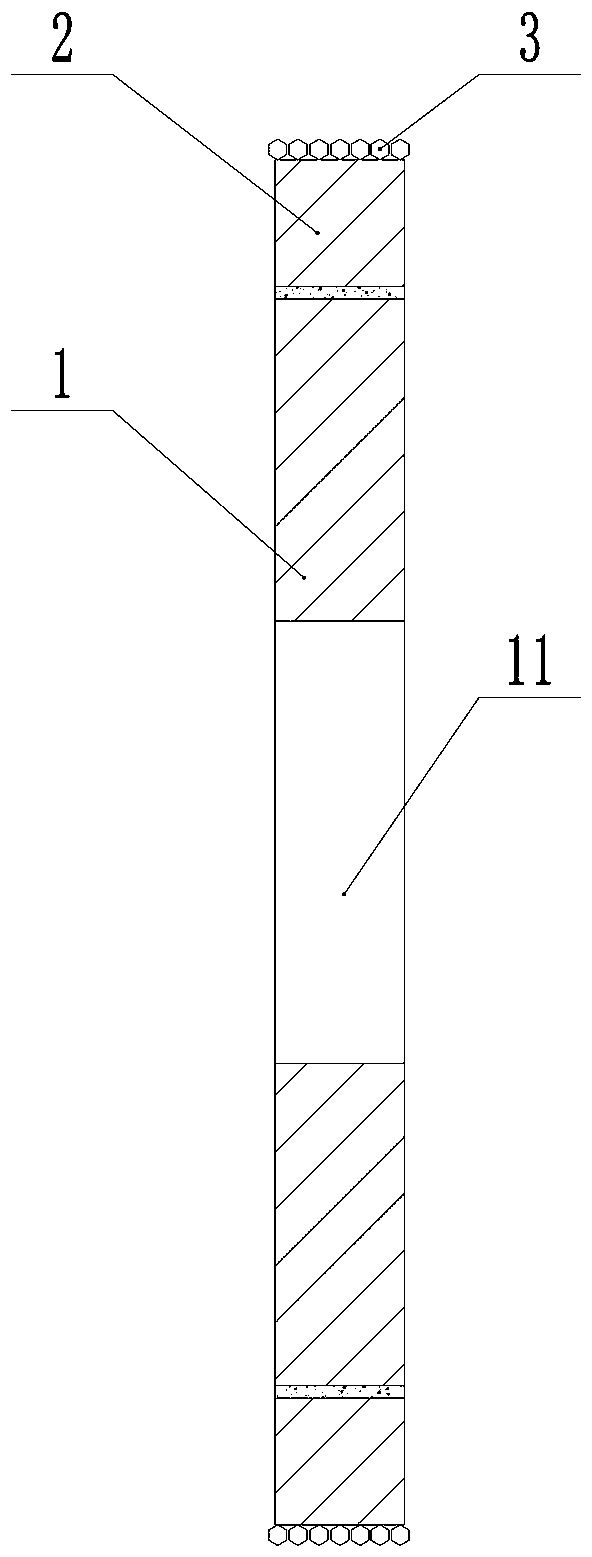

[0039] Such as figure 1 and figure 2 As shown, a single-layer high-precision brazed superabrasive grinding wheel includes a metal base 1, a plurality of metal inserts 2 bonded to the outer peripheral surface of the metal base 1, and several metal inserts 2 are sequentially spliced to form a ring structure. The outer peripheral surface of the metal insert 2 is brazed with an abrasive layer 3, and the abrasive layer can be diamond or cubic boron nitride material.

[0040] Compared with the traditional grinding wheel, the grinding wheel base in this patent is divided into a metal base 1 and a metal insert 2, wherein the metal insert 2 has good brazing processability due to its small size, while the metal base 1 and the metal insert 2 The combined structure can provide a structural basis for accuracy correction after brazing (abrasive layer surface accuracy and abrasive contour), which can solve the problem of accuracy reduction caused by material deformation during the overal...

Embodiment 2

[0042] A method for manufacturing the single-layer high-precision brazing superabrasive grinding wheel, it comprises the following steps:

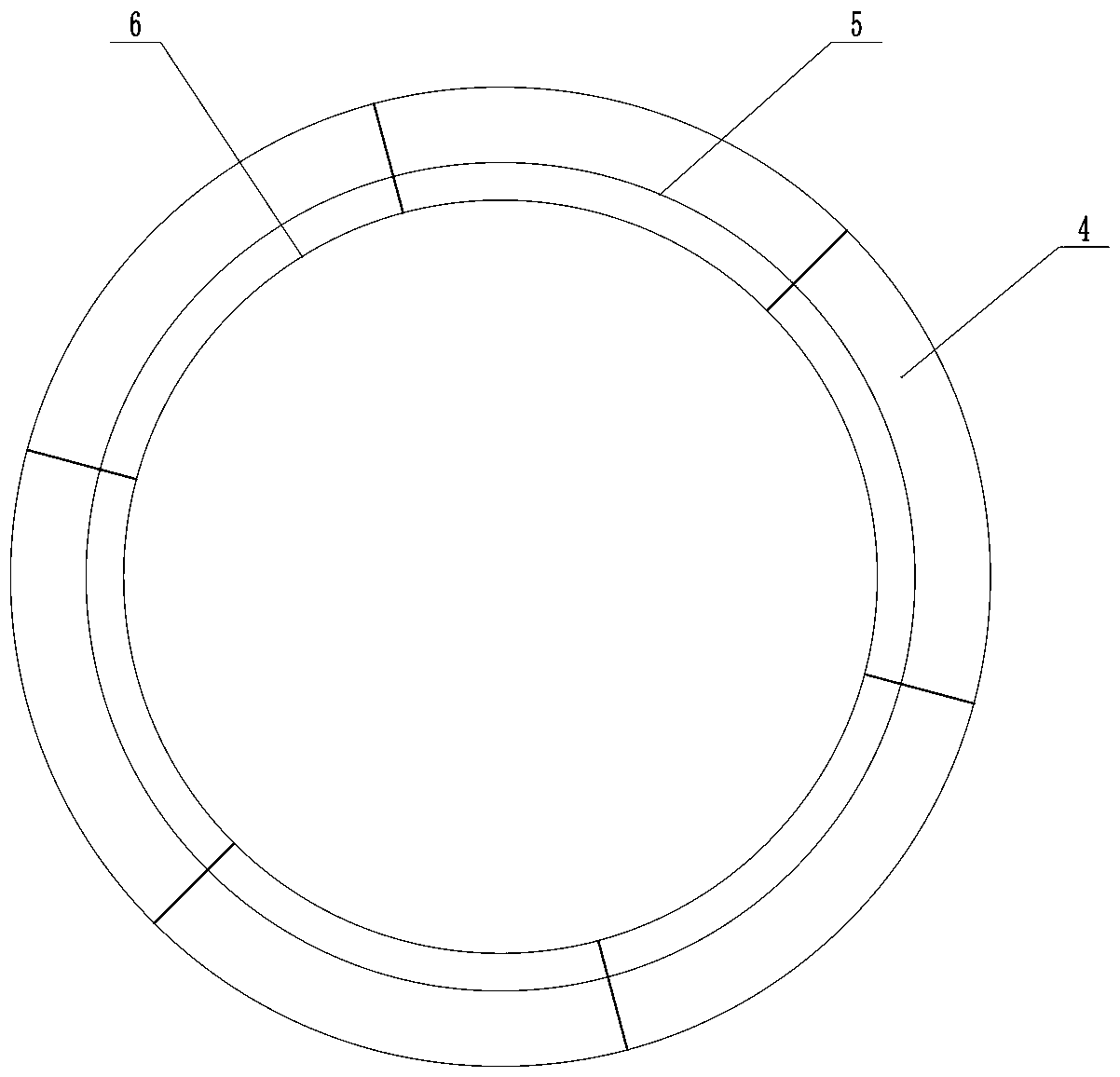

[0043] 1) Manufacture a certain number of female modules 4, each female module 4 is spliced to form a ring-shaped female mold structure, and the female modules are made of graphite;

[0044] 2), processing the inner surface, such as Figure 4 As shown, the female module 4 is installed and fixed on a ferrule fixture with an annular inner cavity to form the female mold structure. The fixing process can be bonded by melting and re-solidifying the paraffin wax. Process the inner surface 6, which is opposite to the working surface of the grinding wheel. At the same time, on the structure of the female mold, an equivalent reference surface 5 is processed corresponding to the inner surface. The equivalent reference surface 5 is the same as the inner surface. A circular surface with the same axis as the shape surface 6;

[0045] Such as imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com