Vacuum brazing method of high-temperature alloy and cobalt-based powder metallurgy material

A technology of powder metallurgy and superalloy, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of complex shape and high dimensional accuracy of precision valves, achieve good weld uniformity and ensure coaxiality The effect of degree dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment, but not as any limitation to the present invention.

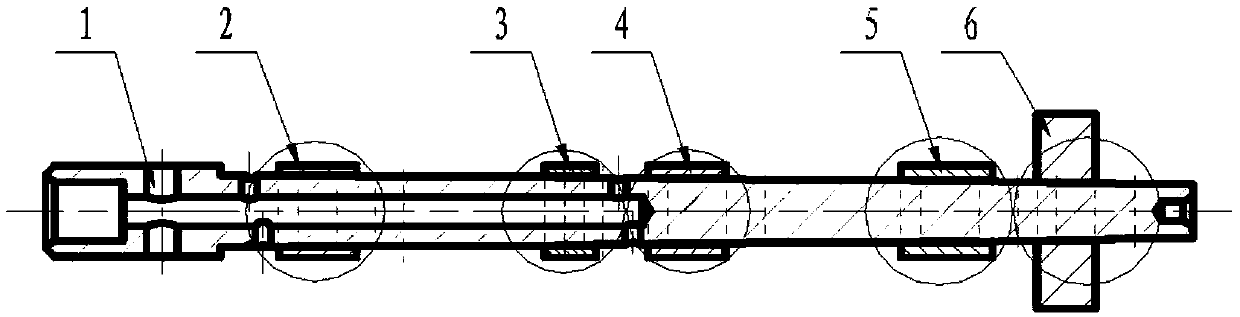

[0023] The invention is used for the manufacture of long-life and high-speed precision valves. In view of the high hardness of the cobalt-based powder metallurgy material, which is difficult to process into a complex valve structure, the present invention uses a vacuum brazing method to weld the cobalt-based powder metallurgy material on the valve shaft 1 to provide excellent friction performance and meet the working requirements of the high-speed valve .

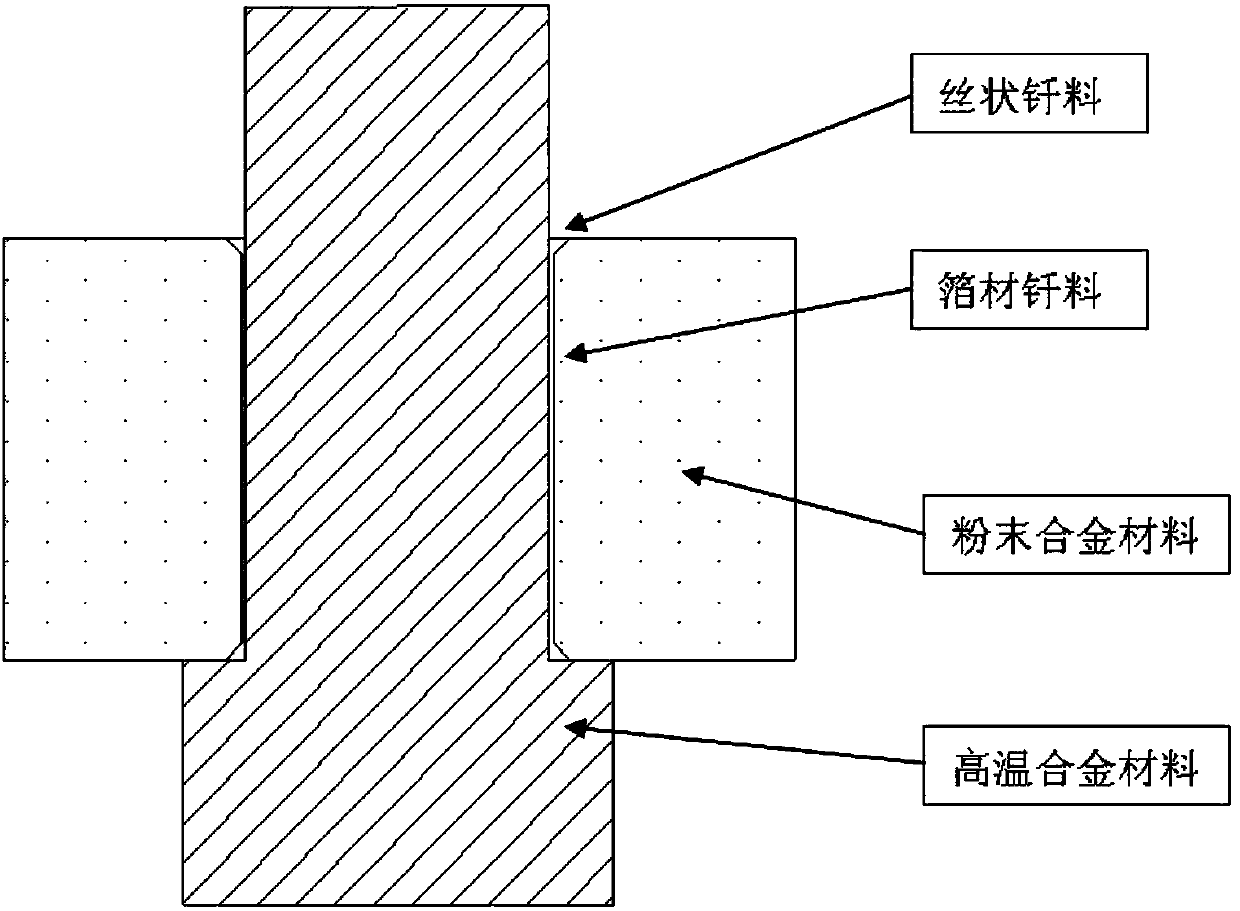

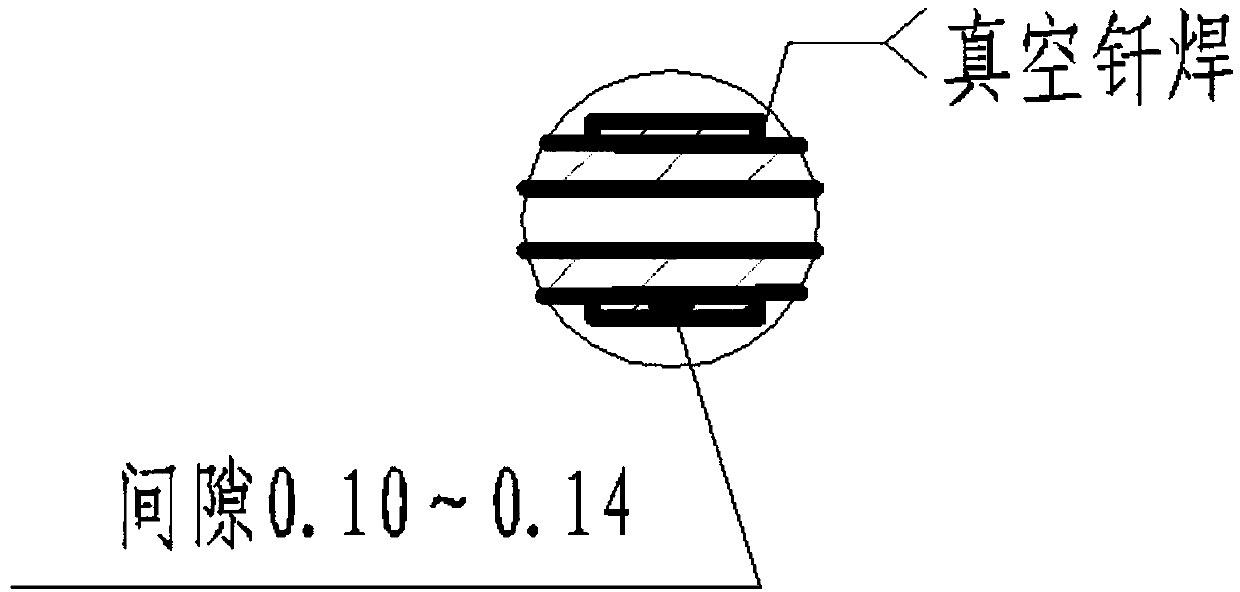

[0024] The design of the valve structure: the valve is composed of two parts, such as figure 2 and image 3 shown. Valve shaft 1 is processed by high-temperature alloy material, sleeve 1 2, sleeve 2 3, sleeve 3 4, sleeve 4 5 and sleeve 5 6 are processed by cobalt-based powder metallurgy materials, and the two are connected together by vacuum high-temperature brazing process. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com