Pb-free Sn-Bi alloy solder and preparation method thereof

A lead-free solder, tin-bismuth alloy technology, used in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of poor reliability, easy peeling, unstable interface layer, etc. Good property, good wetting and spreading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

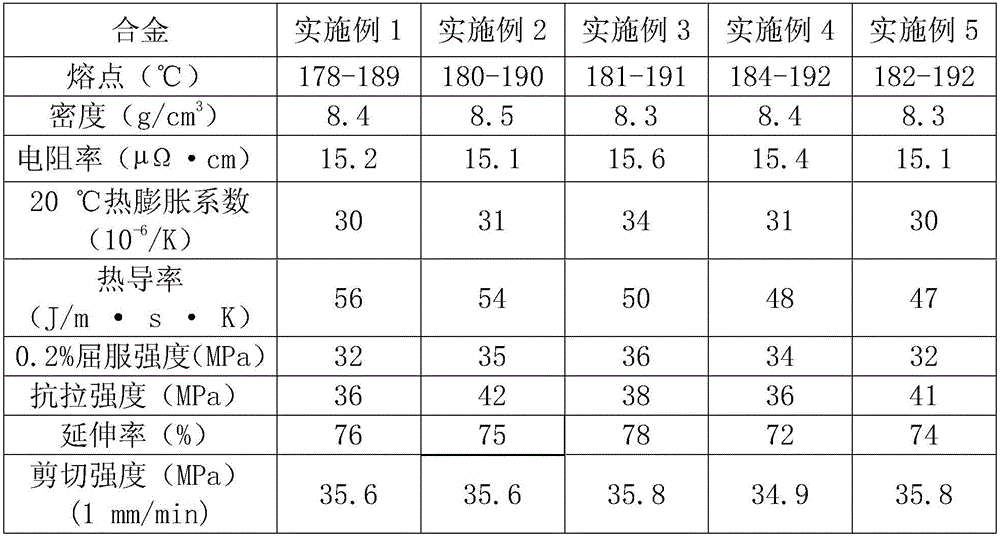

Examples

Embodiment 1

[0017] This embodiment provides a lead-free solder of tin-bismuth alloy consisting of the following components by weight percentage: Bi17%, Ag0.5%, Fe0.2%, Zn0.2%, Sb0.2%, and the balance is Sn .

[0018] The preparation method of the lead-free solder of above-mentioned tin-bismuth alloy comprises the following steps:

[0019] (1) take Sn, Bi and Ag by proportioning, place in vacuum smelting furnace, prepare SnBiAg master alloy;

[0020] (2) Add the prepared SnBiAg master alloy, Fe, Zn and Sb into the vacuum melting furnace, cover the surface of the SnBiAg master alloy with an anti-oxidation solvent, heat the alloy to 350°C, keep it warm for 35min, remove the oxidized slag on the surface, and cast The alloy ingot is made in the mold, and further processed into filament products according to the process requirements.

Embodiment 2

[0022] This embodiment provides a lead-free solder of tin-bismuth alloy consisting of the following components by weight percentage: Bi16%, Ag0.8%, Fe0.1%, Zn0.3%, Sb0.1%, and the balance is Sn .

[0023] The preparation method of the lead-free solder of above-mentioned tin-bismuth alloy comprises the following steps:

[0024] (1) take Sn, Bi and Ag by proportioning, place in vacuum smelting furnace, prepare SnBiAg master alloy;

[0025] (2) Add the prepared SnBiAg master alloy, Fe, Zn and Sb into the vacuum melting furnace, cover the surface of the SnBiAg master alloy with an anti-oxidation solvent, heat the alloy to 250°C, keep it warm for 45min, remove the surface oxidation slag, and cast The alloy ingot is made in the mold, and further processed into strip products according to the process requirements.

Embodiment 3

[0027] This embodiment provides a lead-free solder of tin-bismuth alloy consisting of the following components by weight percentage: Bi18%, Ag0.3%, Fe0.3%, Zn0.1%, Sb0.3%, and the balance is Sn .

[0028] The preparation method of the lead-free solder of above-mentioned tin-bismuth alloy comprises the following steps:

[0029] (1) take Sn, Bi and Ag by proportioning, place in vacuum smelting furnace, prepare SnBiAg master alloy;

[0030] (2) Add the prepared SnBiAg master alloy, Fe, Zn and Sb into the vacuum melting furnace, cover the surface of the SnBiAg master alloy with an anti-oxidation solvent, heat the alloy to 400°C, keep it warm for 25min, remove the surface oxidation slag, and cast The alloy ingot is made in the mold, and further processed into sheet products according to the process requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com