Silver-free copper based solder and preparation method thereof

A technology of silver-copper and brazing material, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of high cost, high manufacturing cost, and expensive silver-based brazing material, and achieve uniform distribution, overcoming over-burning, and excellent The effect of wetting and spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

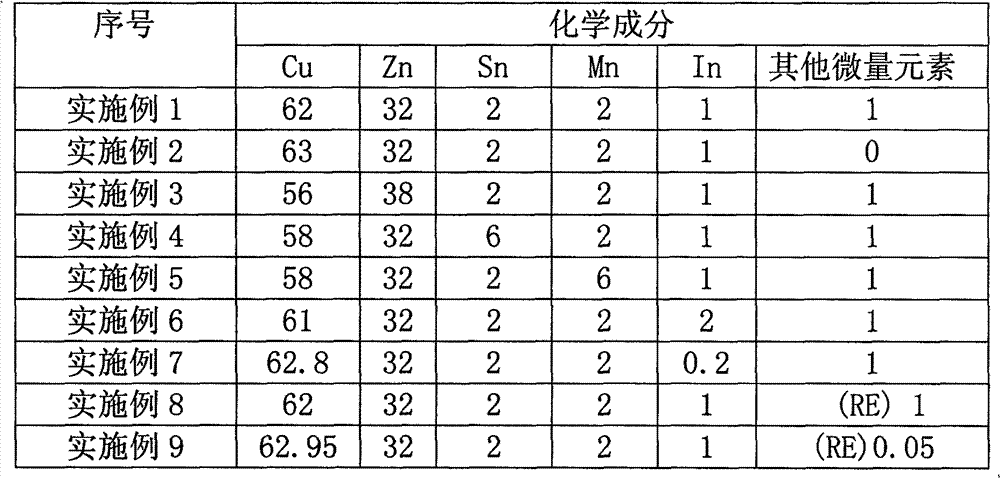

Examples

Embodiment 1

[0034] First, fully melt 62Kg of Cu, 2Kg of Sn, 2Kg of Mn, 1Kg of In and 1Kg of other trace elements at a melting temperature of 1500°C and keep it warm for 2 hours to obtain an intermediate alloy; secondly, cool the above solution to 1100°C , add 32Kg of Zn into the above alloy solution, fully stir and keep warm for 0.5 hours, then pour it on a steel grinding tool, and cool it naturally to make an ingot; finally, the prepared ingot is extruded and drawn , that is, the required solder wire is obtained.

Embodiment 2

[0036] First, fully melt 63Kg of Cu with 2Kg of Sn, 2Kg of Mn, and 1Kg of In at a melting temperature of 1500°C and keep it warm for 2 hours to obtain an intermediate alloy; secondly, cool the above solution to 1100°C, and 32Kg of Zn Add it into the above alloy solution, stir it well and keep it warm for 0.5 hours, then pour it on a steel mold and cool it naturally to make an ingot; finally, the prepared ingot is extruded and drawn to obtain the required brazing wire.

Embodiment 3

[0038] First, fully melt 56Kg of Cu, 2Kg of Sn, 2Kg of Mn, 1Kg of In and 1Kg of other trace elements at a melting temperature of 1500°C and keep it warm for 2 hours to obtain an intermediate alloy; secondly, cool the above solution to 1100°C , add 38Kg of Zn into the above alloy solution, fully stir and keep warm for 0.5 hours, then pour it on the steel grinding tool, and cool it naturally to make an ingot; finally, the ingot made by extrusion, drawing , that is, the required solder wire is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com