Si element contained Ti-based amorphous alloy and preparing method thereof

A technology of amorphous alloys and elements, applied in the field of Ti-based amorphous alloys and their preparation, can solve the problems of low Ti content and low amorphous forming ability, and achieve improved stability, improved amorphous forming ability, and improved wettability spreading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

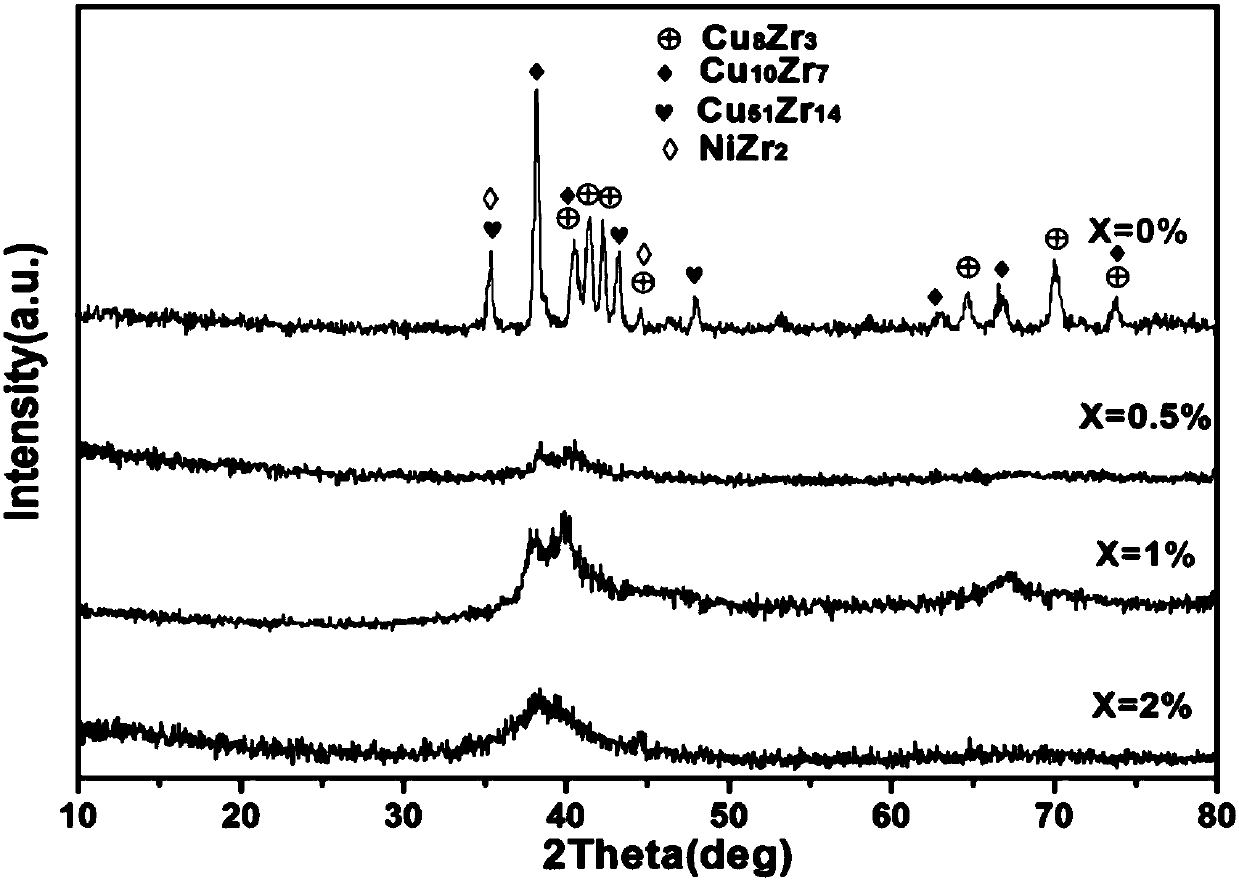

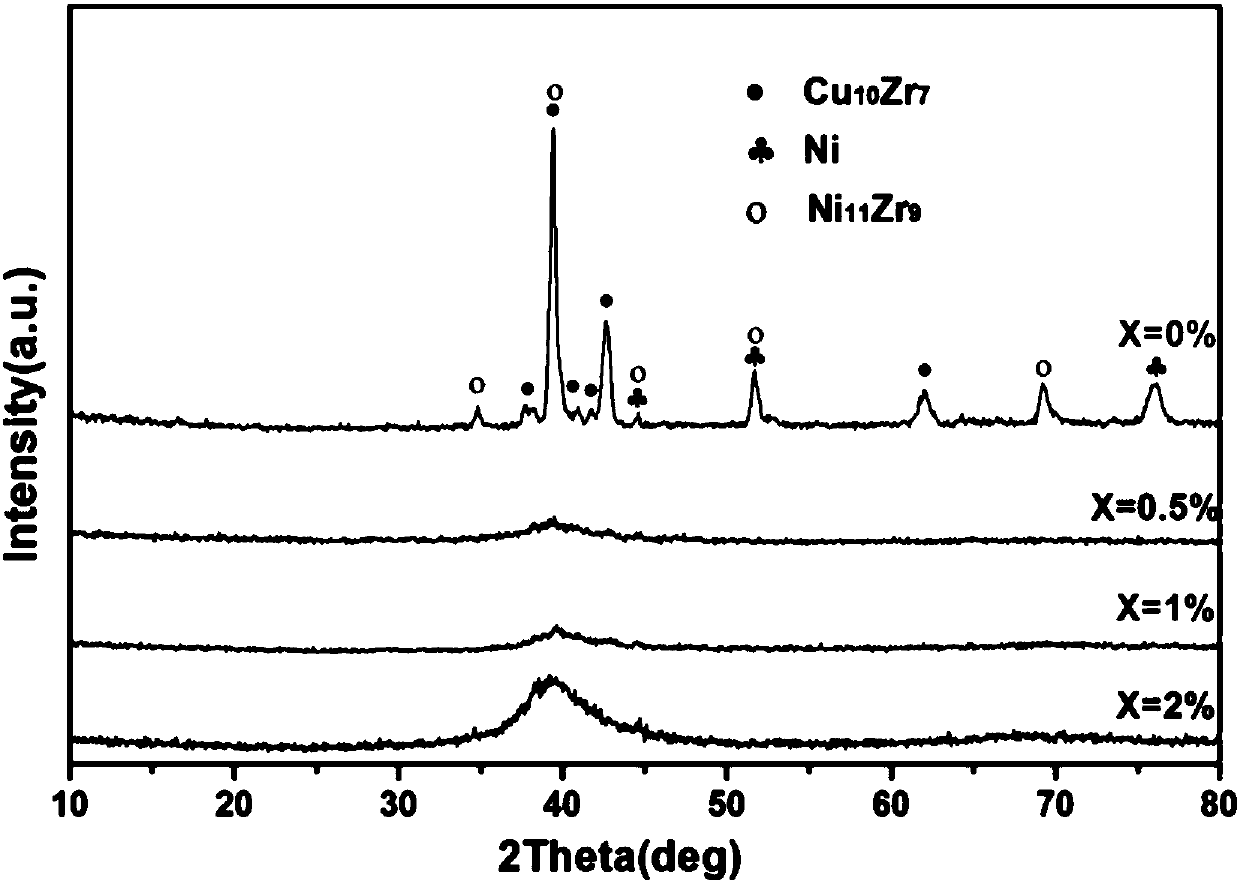

Embodiment 1

[0027] This embodiment adopts melt spin quenching method to prepare (Ti 0.46 Cu 0.14 Zr 0.27 Ni 0.13 ) 100% Si 0% Amorphous alloy strip specimens.

[0028] Step 1: According to the atomic percentage of Ti, Cu, Zr, Ni, Si element, calculate and take out the weight of the simple substance of each element;

[0029] Step 2: Melting preparation (Ti 0.46 Cu 0.14 Zr 0.27 Ni 0.13 ) 100% Si 0% Master alloy, put the elemental raw materials of Ti, Cu, Zr, Ni, and Si elements weighed in step 1 into a vacuum electric arc furnace, and adjust the vacuum degree to 5×10 -3 Pa, filled with inert protective gas, the gas pressure is 0.05-0.07Mpa; start the electromagnetic stirring device and arc melting device, adjust the current 100-400A, and the melting temperature is 2000-3000K; repeat the melting for more than three times, and take it out after cooling with the furnace (Ti 0.46 Cu 0.14 Zr 0.27 Ni 0.13 ) 100% Si 0% master alloy;

[0030]Step 3: Put the master alloy prepared i...

Embodiment 2

[0032] This embodiment adopts melt spin quenching method to prepare (Ti 0.46 Cu 0.14 Zr 0.27 Ni 0.13 ) 99.5% Si 0.5% Amorphous alloy strip specimens.

[0033] Step 1: According to the atomic percentage of Ti, Cu, Zr, Ni, Si element, calculate and take out the weight of the simple substance of each element;

[0034] Step 2: Melting preparation (Ti 0.46 Cu 0.14 Zr 0.27 Ni 0.13 ) 99.5% Si 0.5% Master alloy, put the elemental raw materials of Ti, Cu, Zr, Ni, and Si elements weighed in step 1 into a vacuum electric arc furnace, and adjust the vacuum degree to 5×10 -3 Pa, filled with an inert protective gas, the gas pressure is 0.05-0.07Mpa; start the electromagnetic stirring device and the arc melting device, adjust the current 100-400A, and the melting temperature 2000-3000K; repeat the melting for more than three times, and take it out after cooling with the furnace (Ti 0.46 Cu 0.14 Zr 0.27 Ni 0.13 ) 99.5% Si 0.5% master alloy;

[0035] Step 3: Put the master al...

Embodiment 3

[0037] This embodiment adopts melt spin quenching method to prepare (Ti 0.46 Cu 0.14 Zr 0.27 Ni 0.13 ) 99% Si 1% Amorphous alloy strip specimens.

[0038] Step 1: According to the atomic percentage of Ti, Cu, Zr, Ni, Si element, calculate and take out the weight of the simple substance of each element;

[0039] Step 2: Melting preparation (Ti 0.46 Cu 0.14 Zr 0.27 Ni 0.13 ) 99% Si 1% Master alloy, put the elemental raw materials of Ti, Cu, Zr, Ni, and Si elements weighed in step 1 into a vacuum electric arc furnace, and adjust the vacuum degree to 5×10 -3 Pa, filled with an inert protective gas, the gas pressure is 0.05-0.07Mpa; start the electromagnetic stirring device and the arc melting device, adjust the current 100-400A, and the melting temperature 2000-3000K; repeat the melting for more than three times, and take it out after cooling with the furnace (Ti 0.46 Cu 0.14 Zr 0.27 Ni 0.13 ) 99% Si 1% master alloy;

[0040] Step 3: Put the master alloy prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com