Epoxy resin composite Sn-Bi lead-free soldering paste

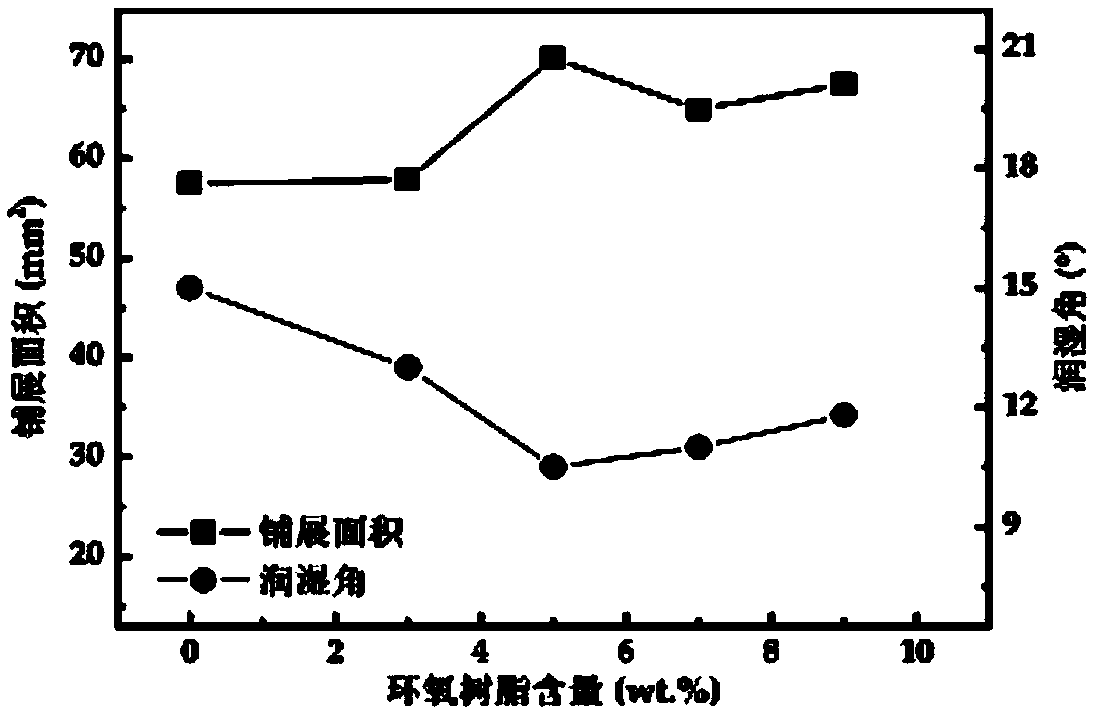

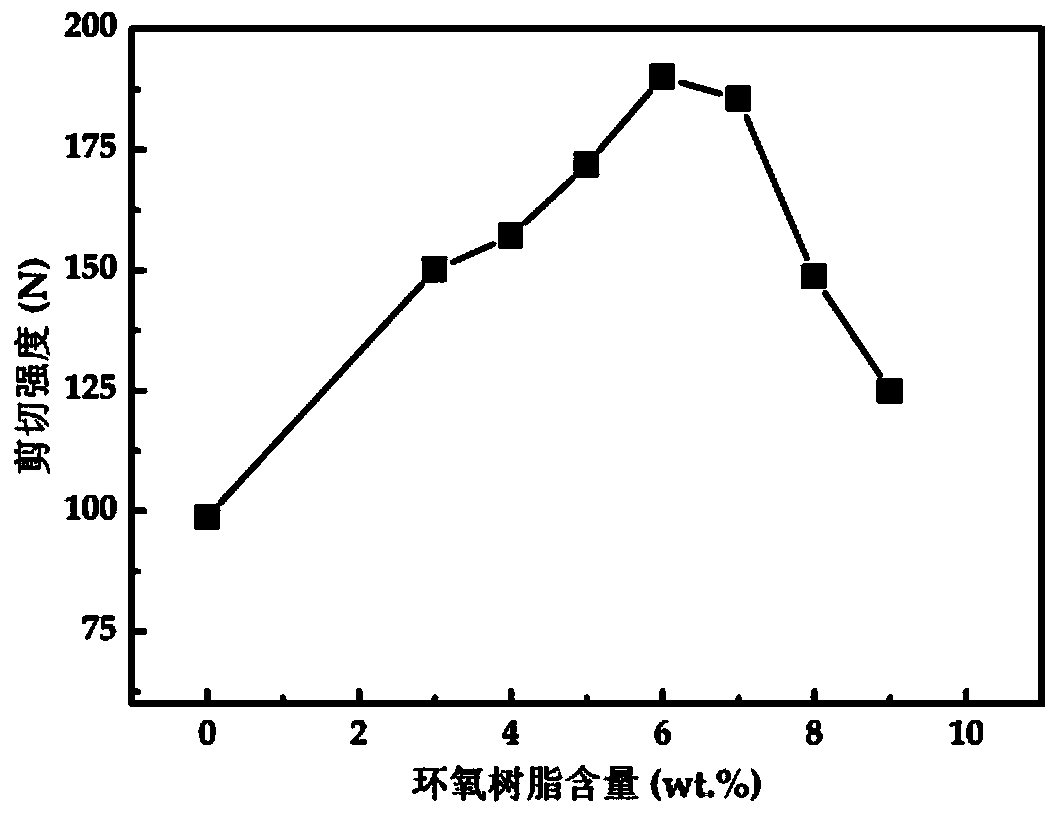

An epoxy resin, lead-free solder paste technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of increased production costs, prolonged solder smelting process, difficult control, etc. Shear strength, effect of improving wetting and spreading properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An epoxy resin composite Sn-Bi lead-free solder paste is characterized in that its composition is a mixture of 3% epoxy resin, curing agent and accelerator by mass percentage ratio (each component accounts for the composition mass percentage The proportion is epoxy resin: curing agent: accelerator = 100: 8: 1), and the balance is commercially available Sn-Bi solder paste (specifically EcoLM-C10X). The epoxy resin is a combination of NPEL-127H type bisphenol A and E51 type bisphenol A in a mass ratio of 1:1; the curing agent is a combination of m-phenylenediamine and dicyandiamide in a mass ratio of 1:2; the accelerator It is the combination of SH-A80 and SH-A150 according to the mass ratio of 1:3. In the commercially available Sn-Bi solder paste used, the Sn-Bi alloy powder accounts for 85% of the commercially available Sn-Bi solder paste, and the balance is commercially available flux (specifically ECO Flux 823). For the Sn-Bi alloy powder in the commercially availabl...

Embodiment 2

[0028] An epoxy resin composite Sn-Bi lead-free solder paste is characterized in that its composition is a mixture of 8% epoxy resin, curing agent and accelerator by mass percentage proportioning (each component accounts for the composition mass percentage The ratio is epoxy resin: curing agent: accelerator = 100: 30: 10), and the balance is commercially available Sn-Bi solder paste (not specifically EcoLM-C10X). The epoxy resin is a combination of E44 type bisphenol A and E51 type bisphenol A in a mass ratio of 2:1; the curing agent is a combination of m-phenylenediamine and p-phenylenediamine in a mass ratio of 1:4; the accelerator is SH- The combination of A90, SH-A100, and SH-A150 is in a mass ratio of 1:2:1.5. The Sn-Bi alloy powder in the commercially available Sn-Bi solder paste used accounts for 95% of the commercially available Sn-Bi solder paste, and the balance is commercially available flux (specifically ECO Flux823). In the Sn-Bi alloy powder in the commercially ...

Embodiment 3

[0031] An epoxy resin composite Sn-Bi lead-free solder paste is characterized in that its composition is a mixture of 6% epoxy resin, curing agent and accelerator by mass percentage ratio (each component accounts for the composition mass percentage The proportion is epoxy resin: curing agent: accelerator = 100: 10: 3), and the balance is commercially available Sn-Bi solder paste (specifically EcoLM-C10X). The epoxy resin is NPEL-127H type bisphenol A; the curing agent is m-phenylenediamine; the accelerator is SH-A150. In the commercially available Sn-Bi solder paste used, the Sn-Bi alloy powder accounts for 90% of the commercially available Sn-Bi solder paste, and the balance is commercially available flux (specifically ECO Flux823). In the Sn-Bi alloy powder in the commercially available Sn-Bi lead-free solder paste, the Bi element accounts for 58% of the alloy powder, P accounts for 0.02%, Ni accounts for 0.05%, and the balance is Sn. The particle diameter of the alloy powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com