Patents

Literature

36results about How to "Improve surface mobility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

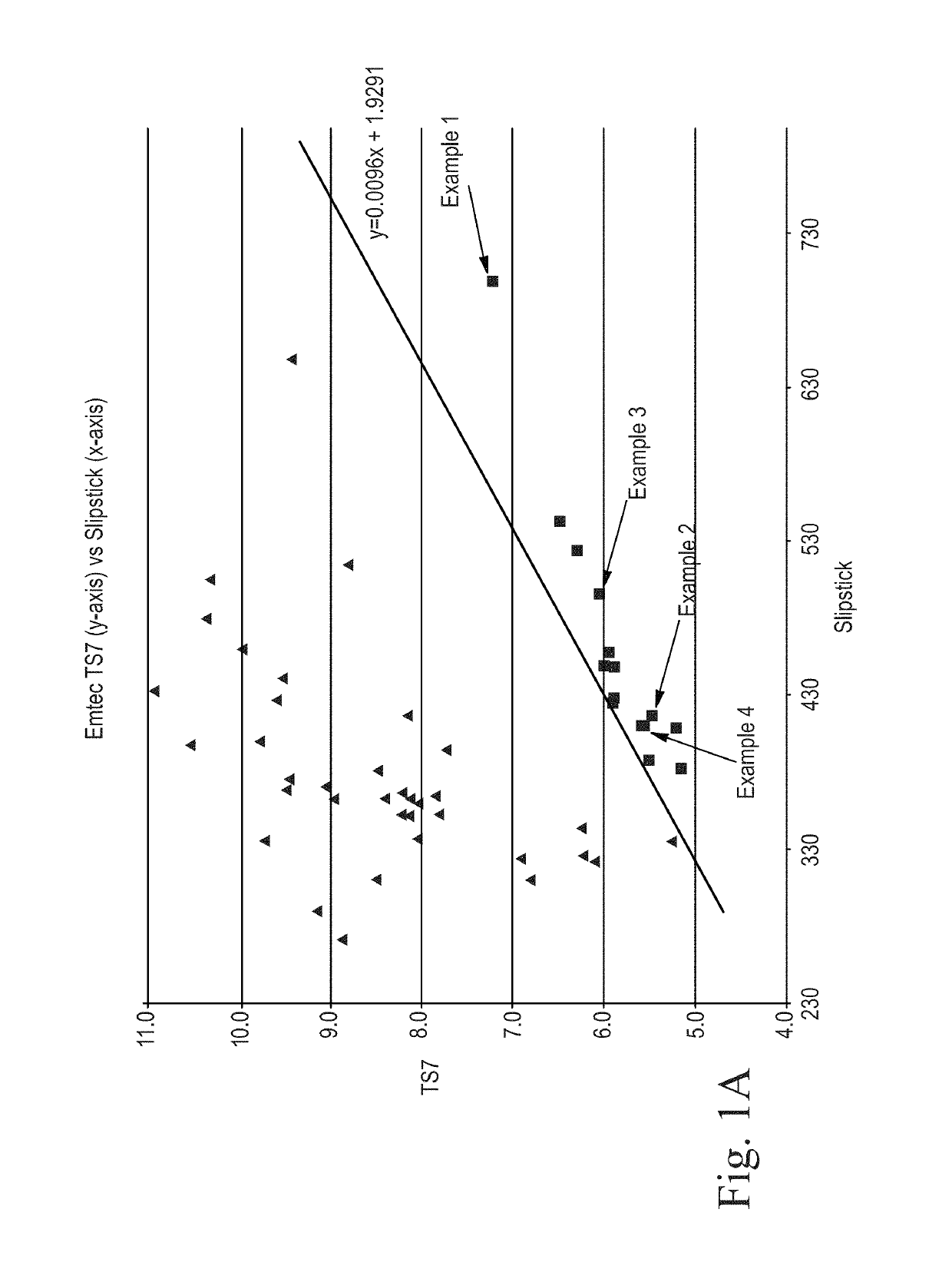

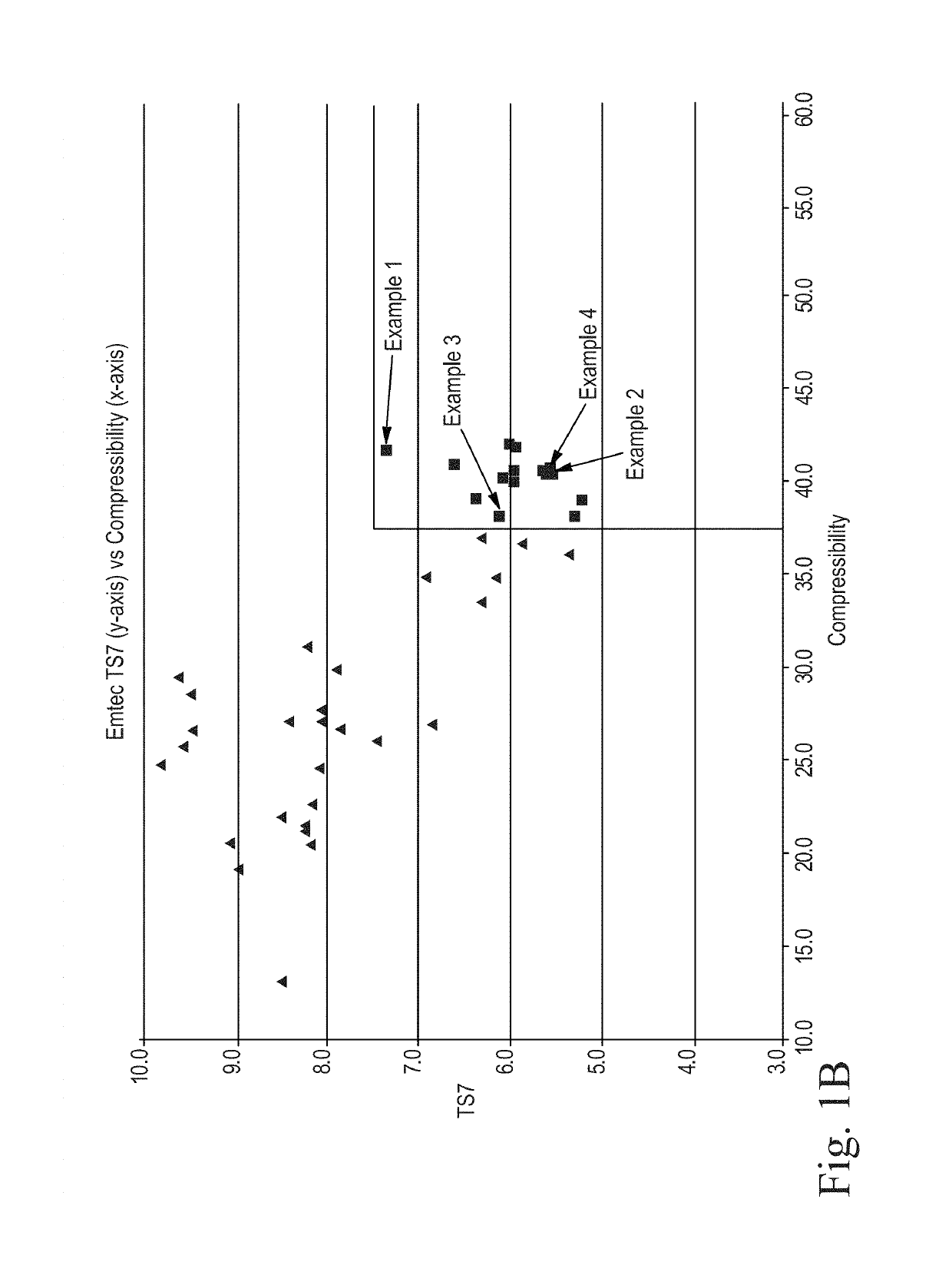

Sanitary Tissue Products

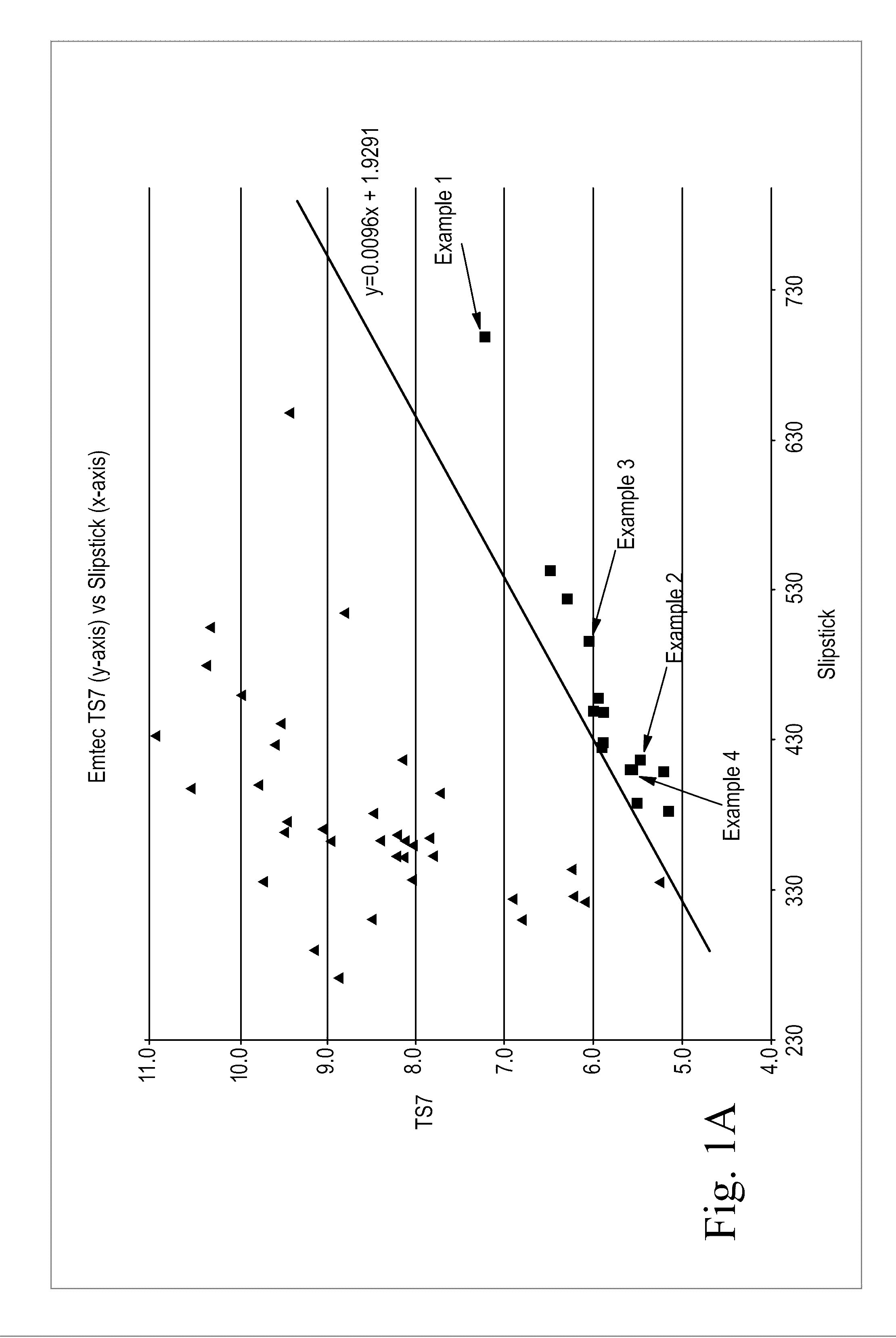

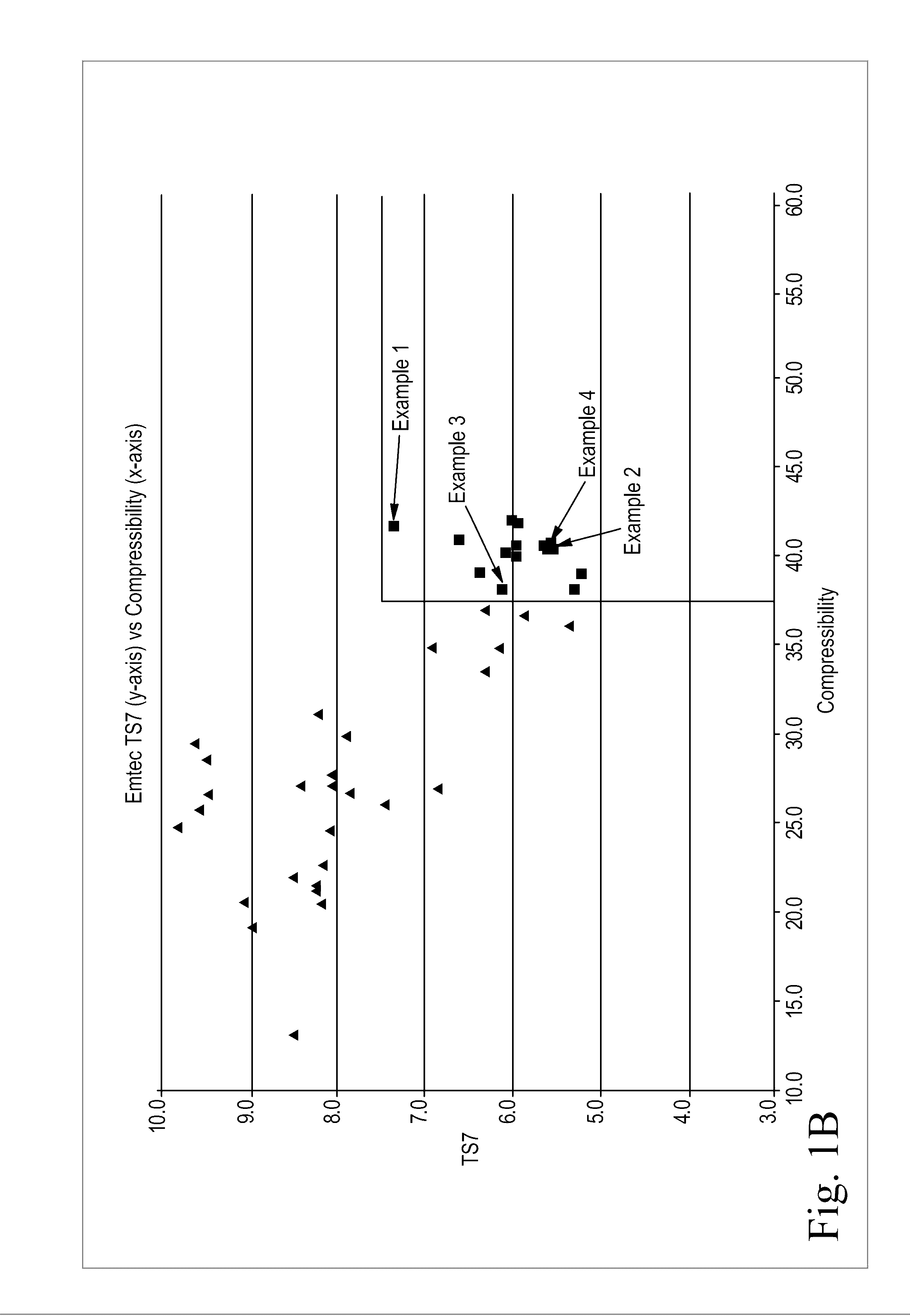

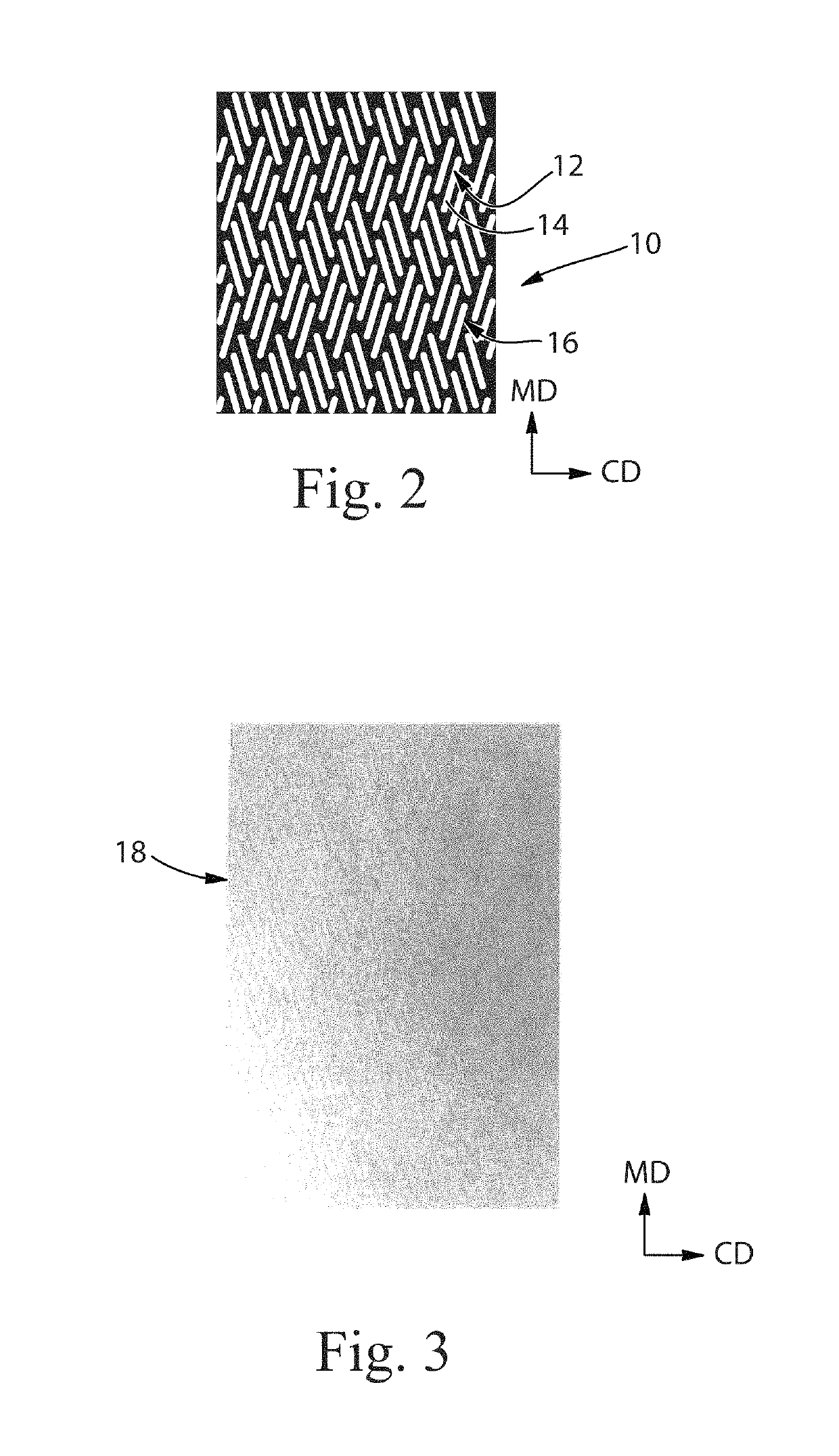

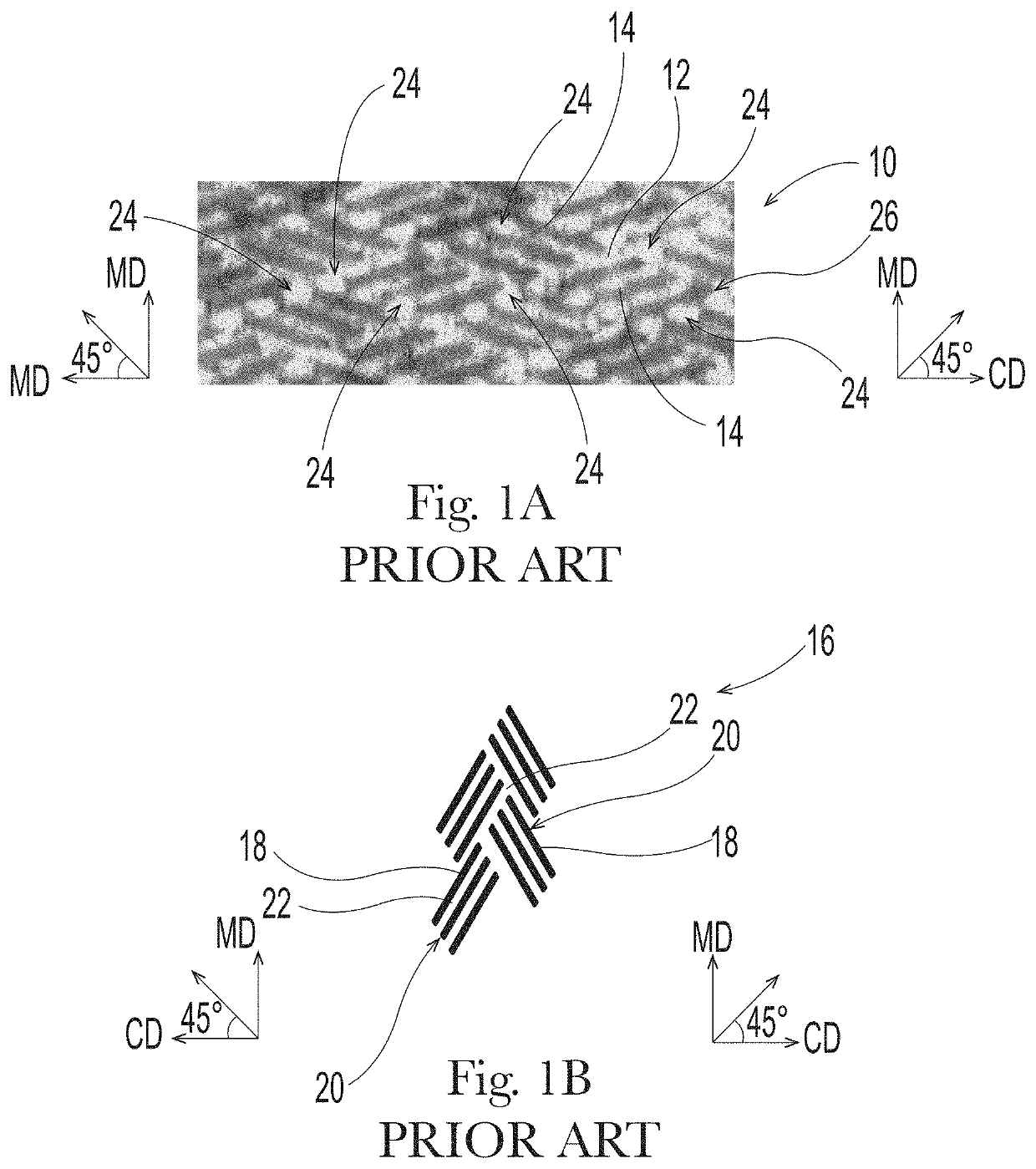

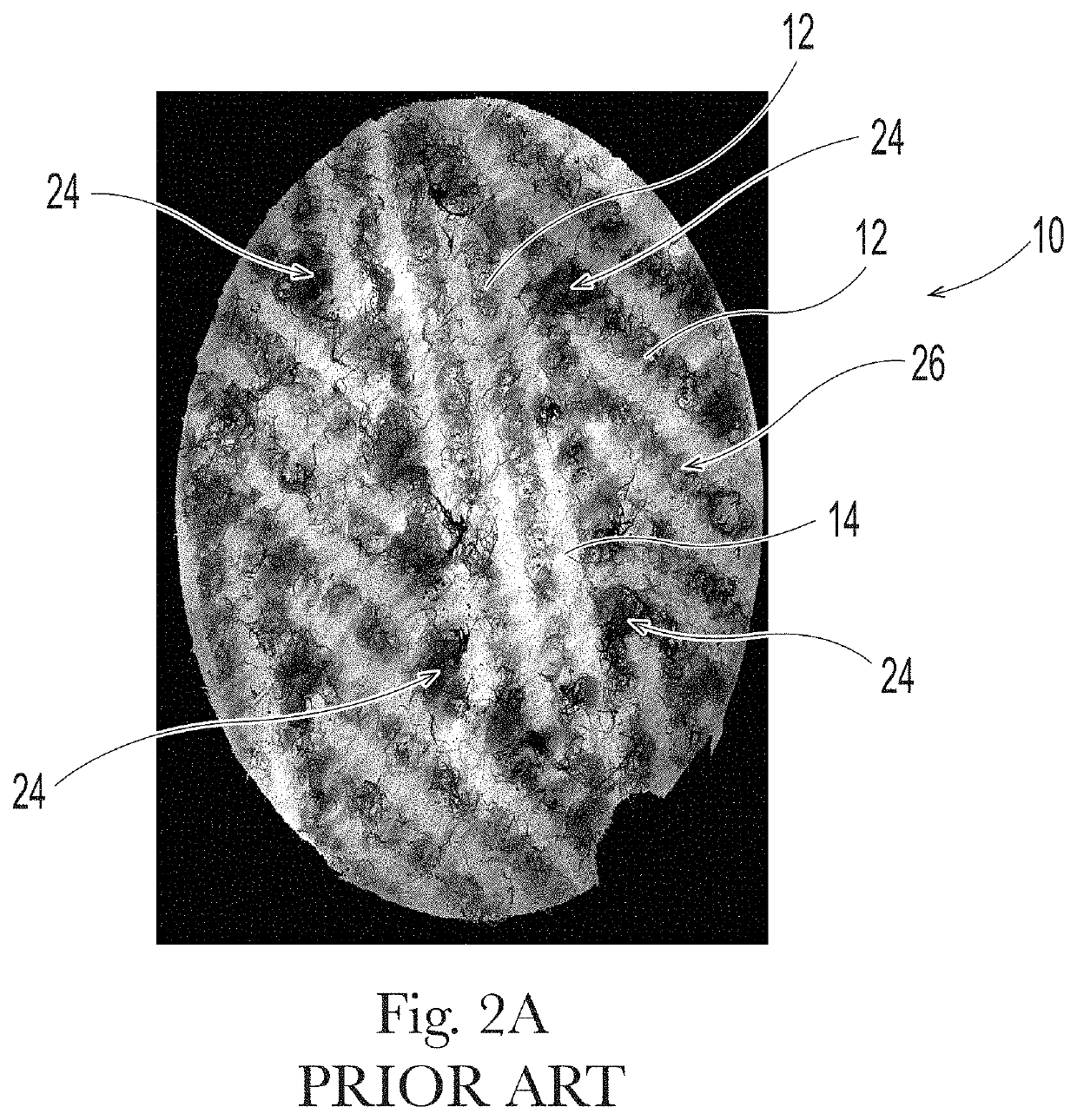

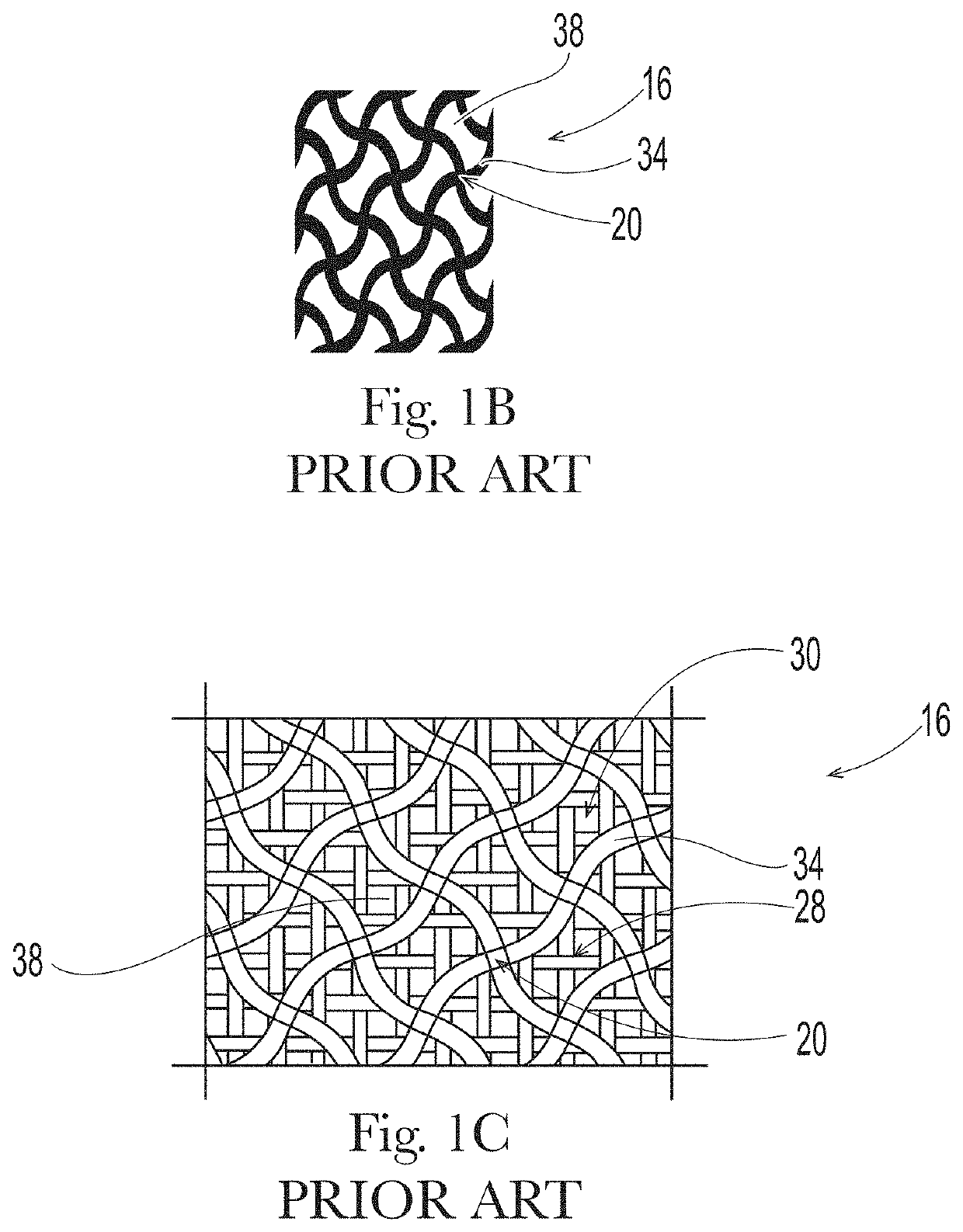

ActiveUS20170022670A1Increase valueImprove surface mobilityApplied substance rearrangementPaper/cardboardFiberCompressibility

Sanitary tissue products employing fibrous structures that exhibit novel combination of average TS7 values and slip stick coefficient of friction and / or compressibility properties and methods for making same.

Owner:THE PROCTER & GAMBLE COMPANY

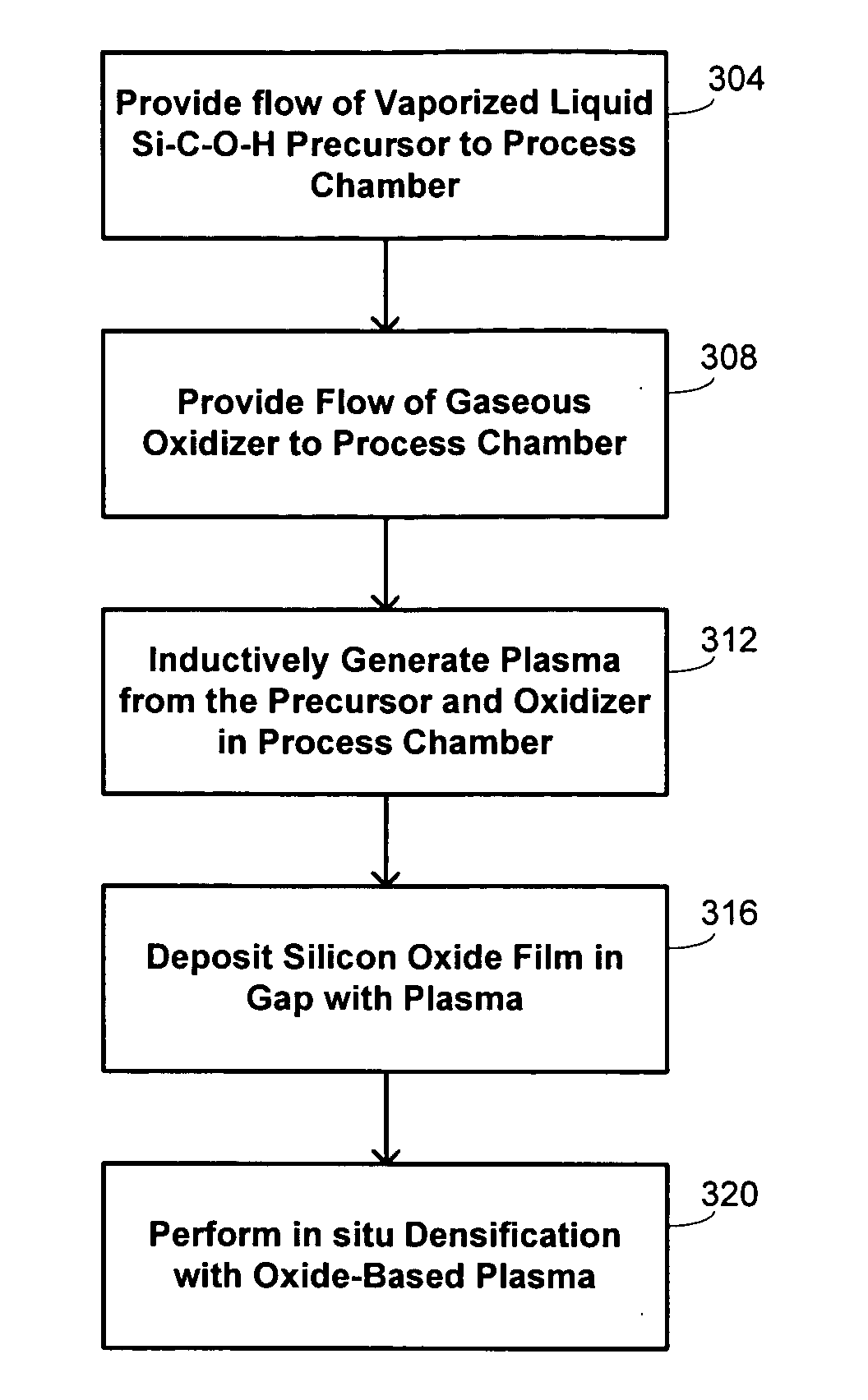

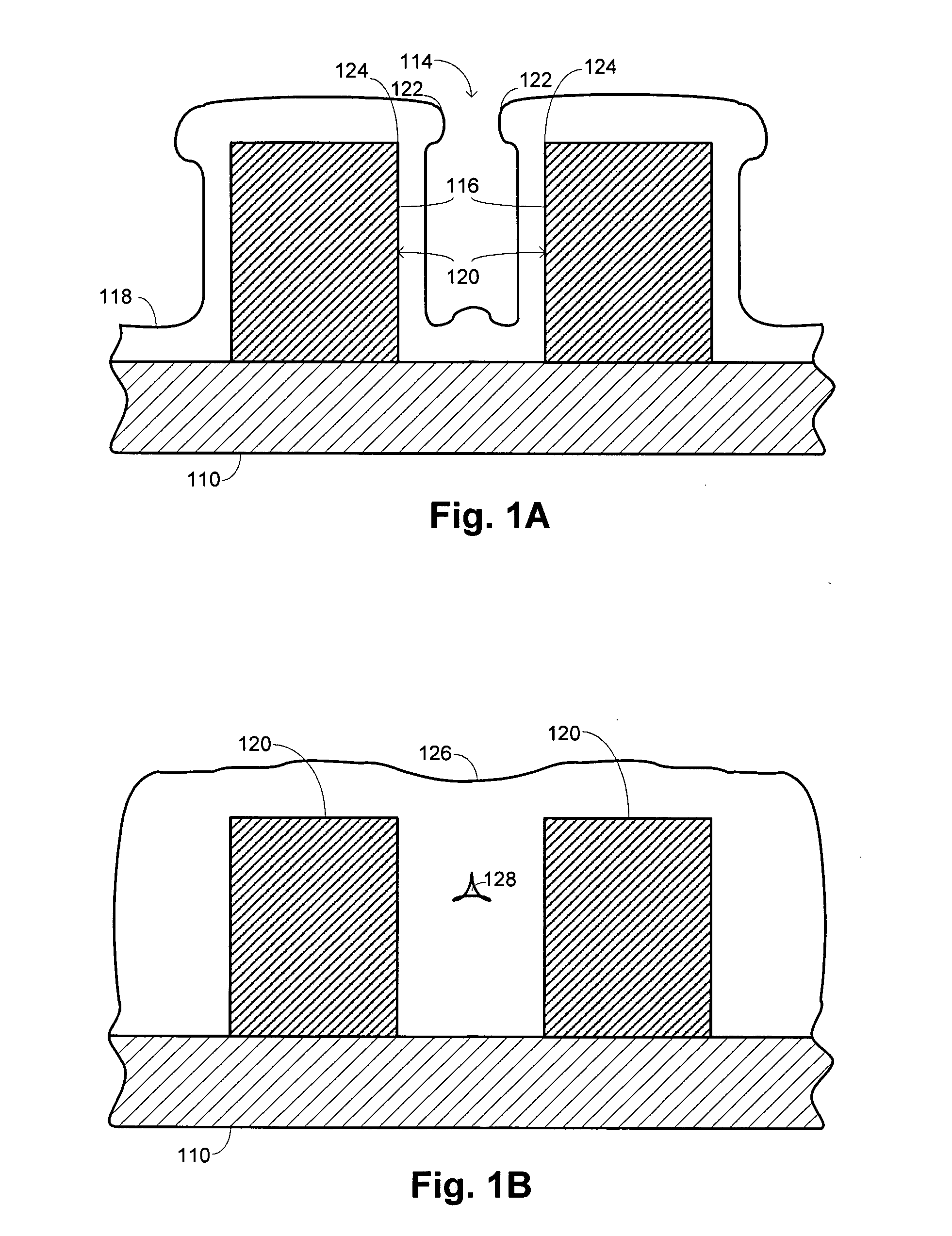

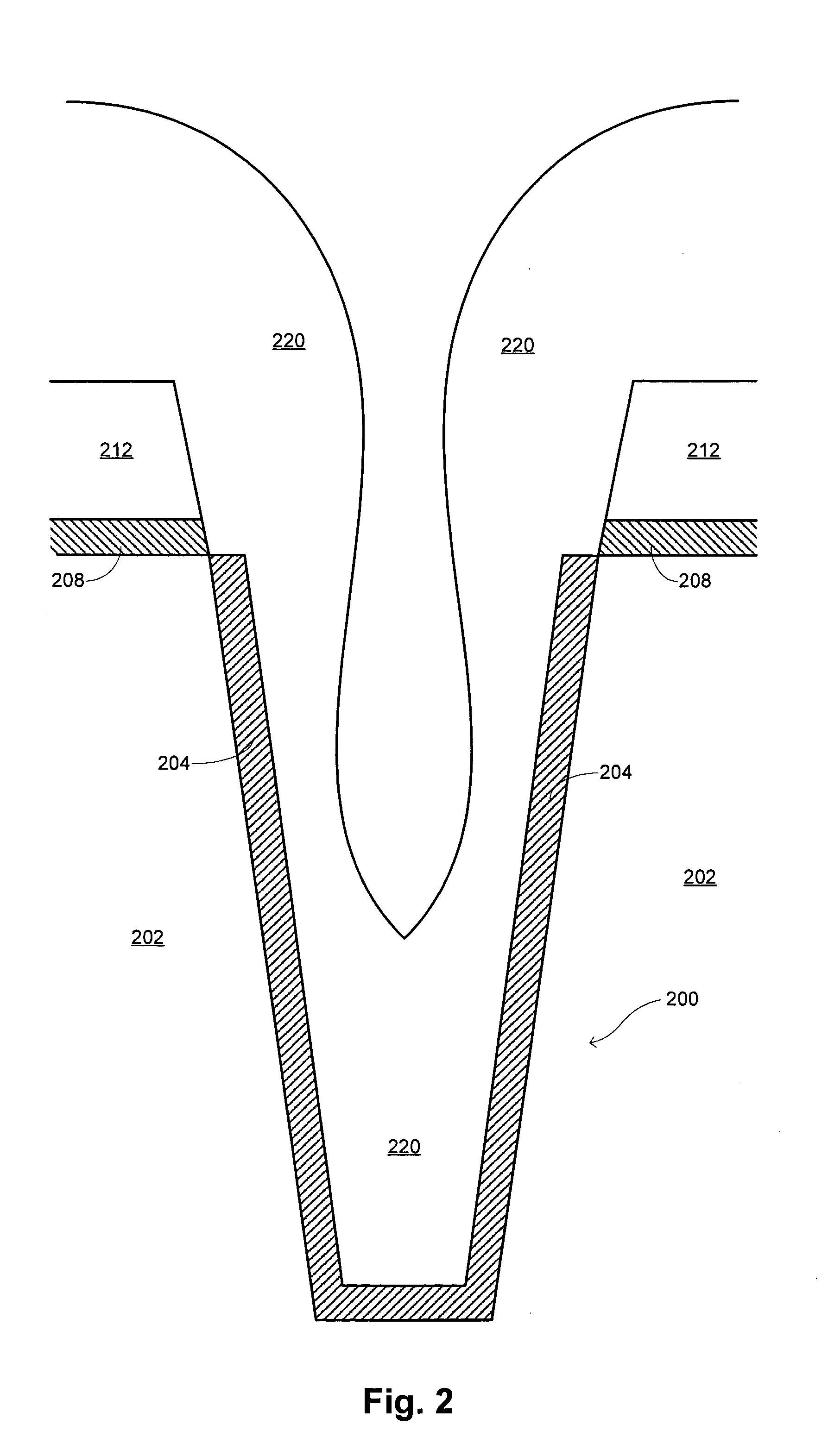

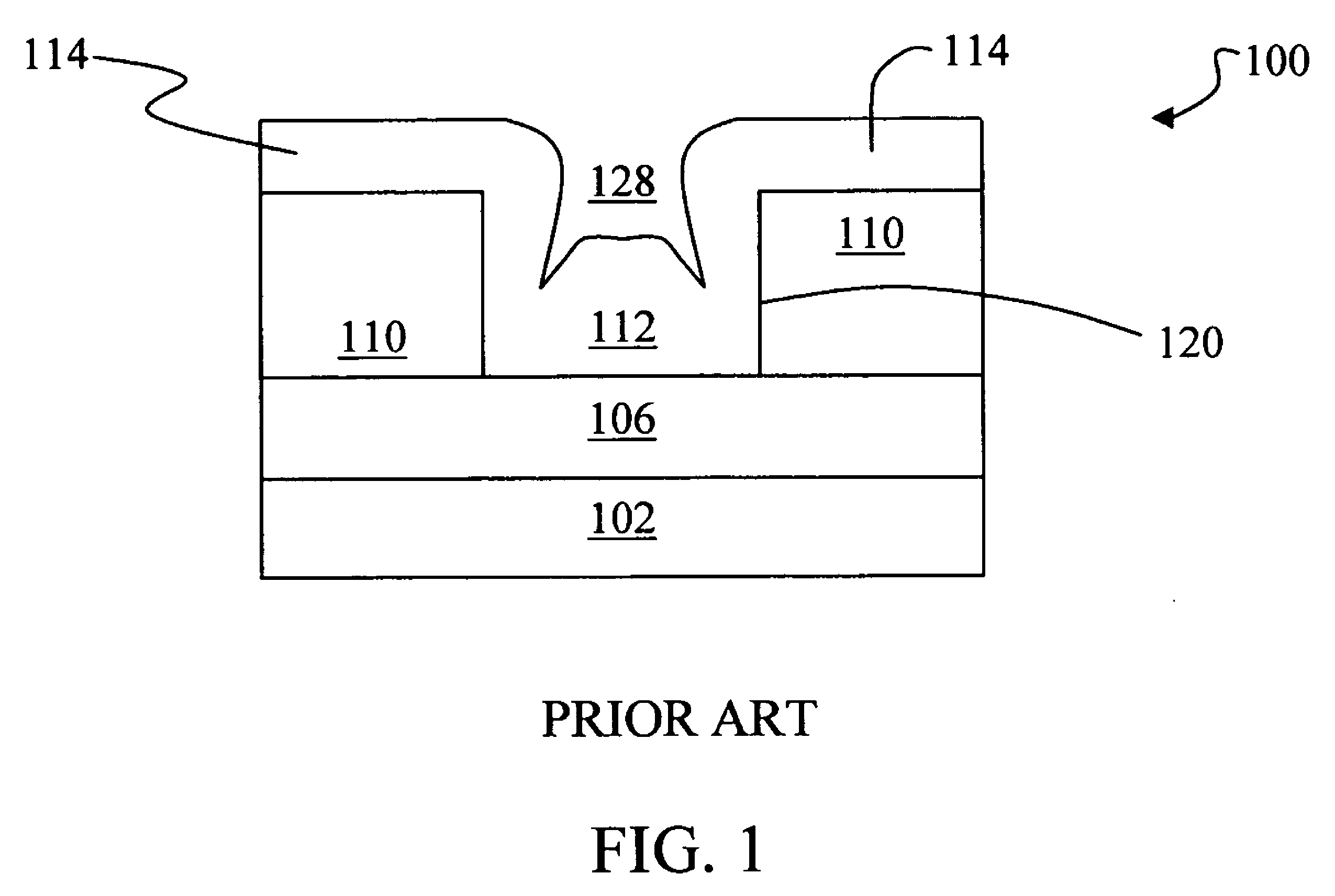

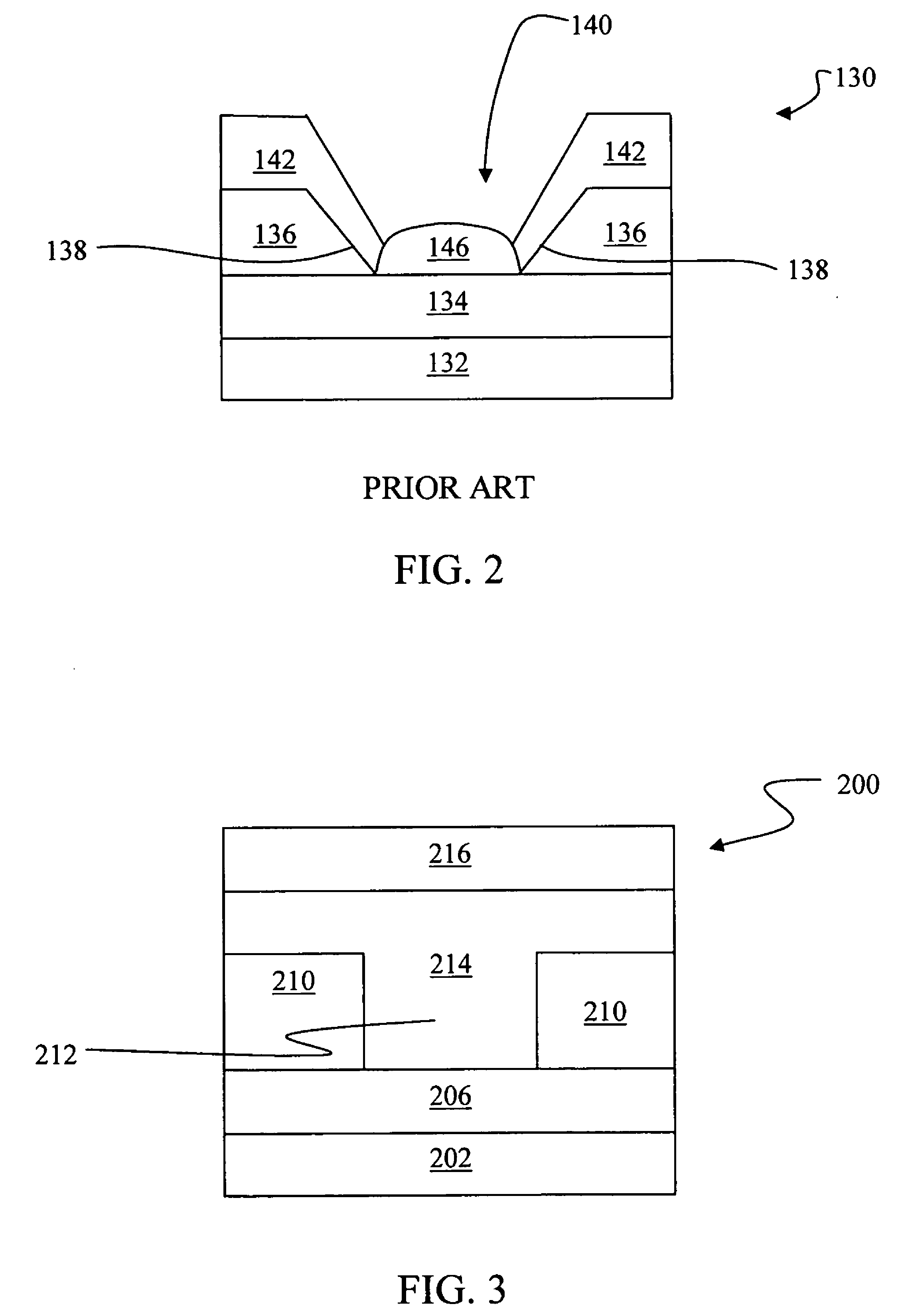

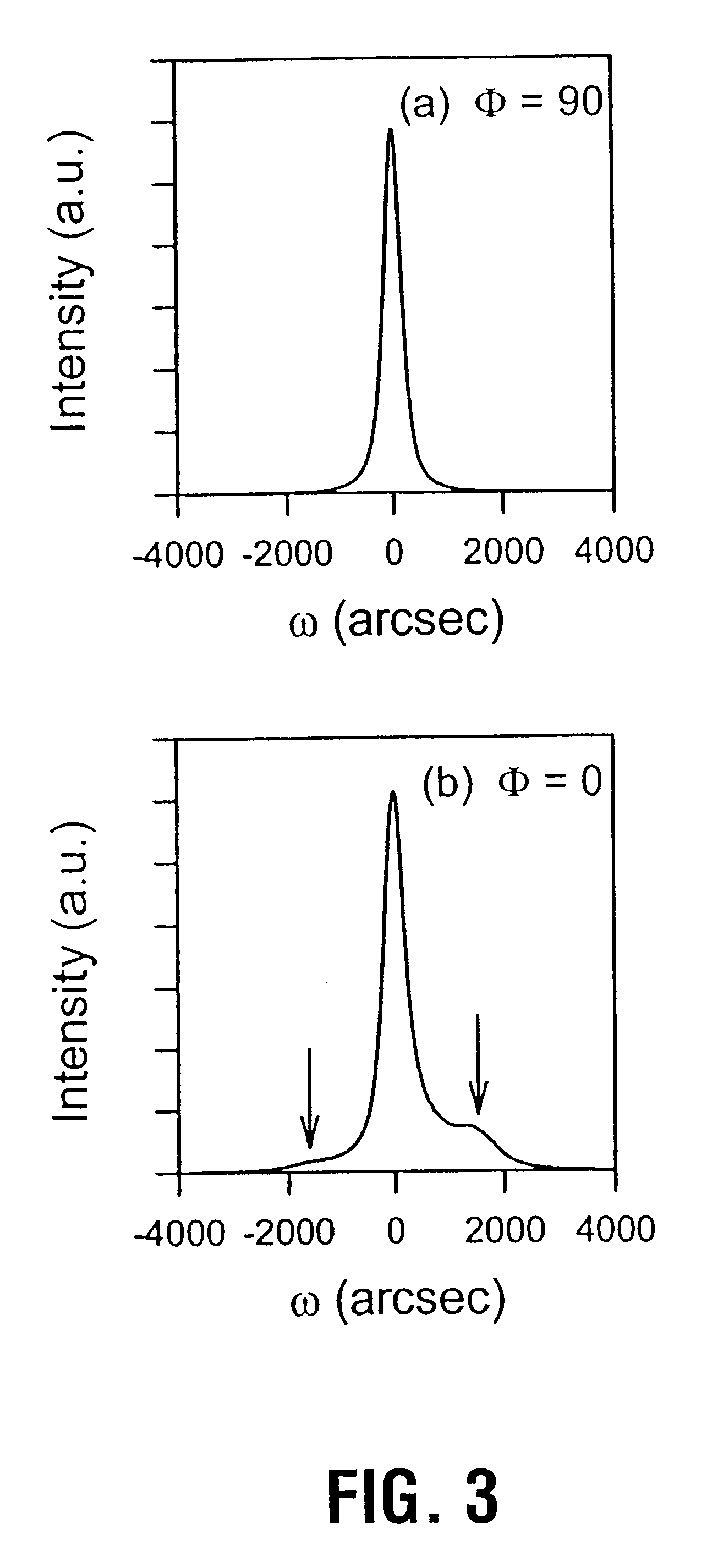

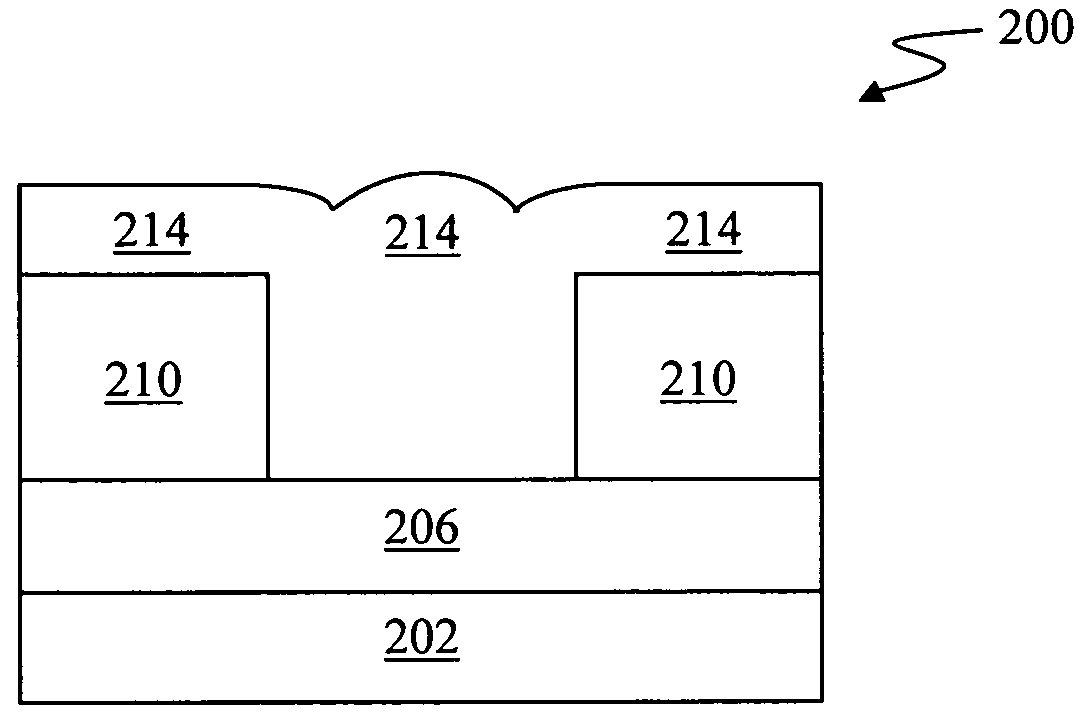

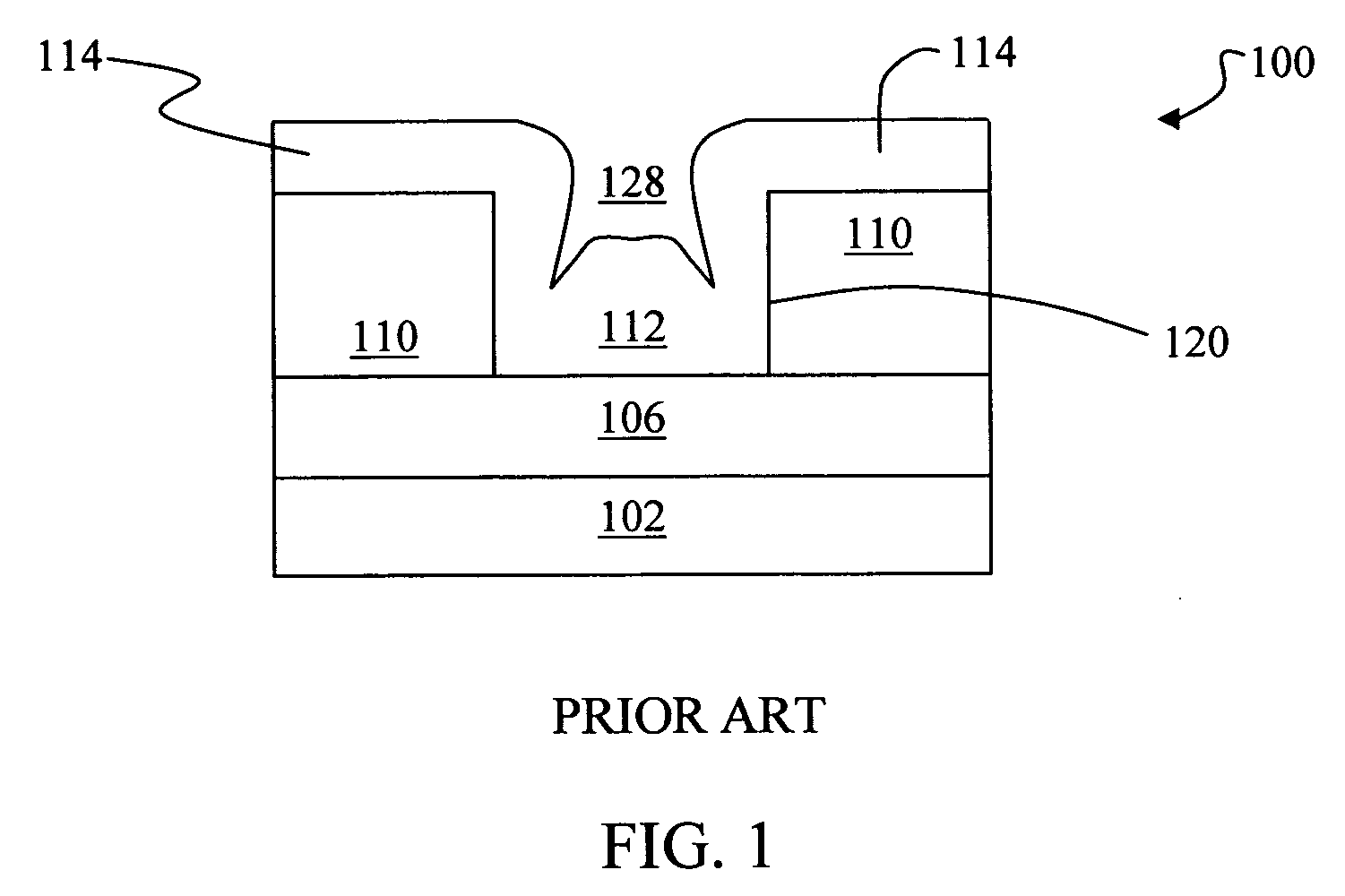

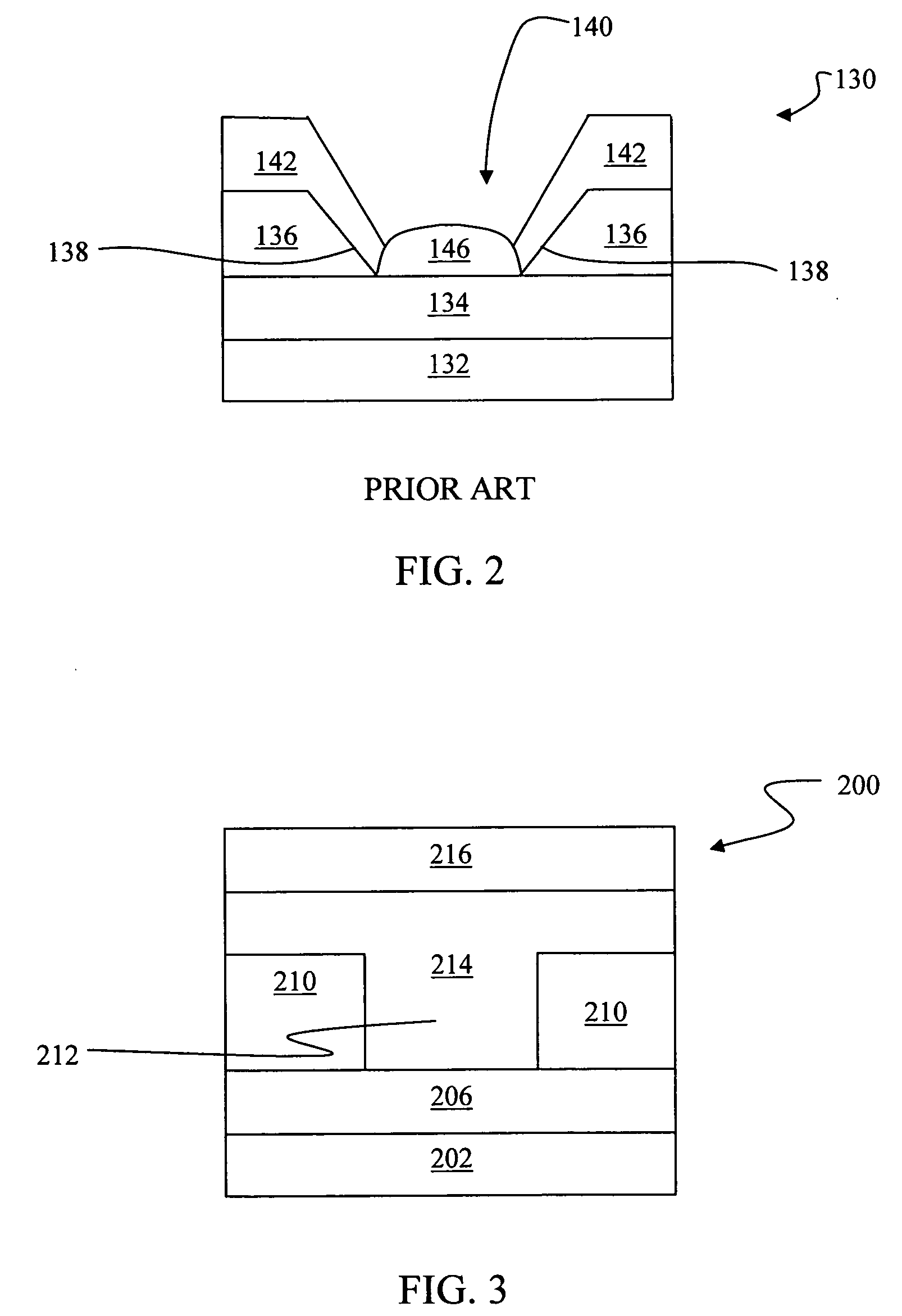

Silicon oxide gapfill deposition using liquid precursors

InactiveUS20060046508A1Improve surface mobilityDecreased sticking coefficientSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemistrySilicon oxide

A silicon oxide film is deposited on a substrate disposed in a substrate processing chamber. The substrate has a gap formed between adjacent raised surfaces. A liquid Si—C—O—H precursor is vaporized. A flow of the vaporized liquid Si—C—O—H precursor is provided to the substrate processing chamber. A gaseous oxidizer is also flowed to the substrate processing chamber. A deposition plasma is generated inductively from the precursor and the oxidizer in the substrate processing chamber, and the silicon oxide film is deposited over the substrate and within the gap with the deposition plasma.

Owner:APPLIED MATERIALS INC

Sanitary tissue products

ActiveUS10240296B2Improve surface mobilityGood “cushiness”Paper/cardboardApplied substance rearrangementFiberCompressibility

Sanitary tissue products employing fibrous structures that exhibit novel combination of average TS7 values and slip stick coefficient of friction and / or compressibility properties and methods for making same.

Owner:PROCTER & GAMBLE CO

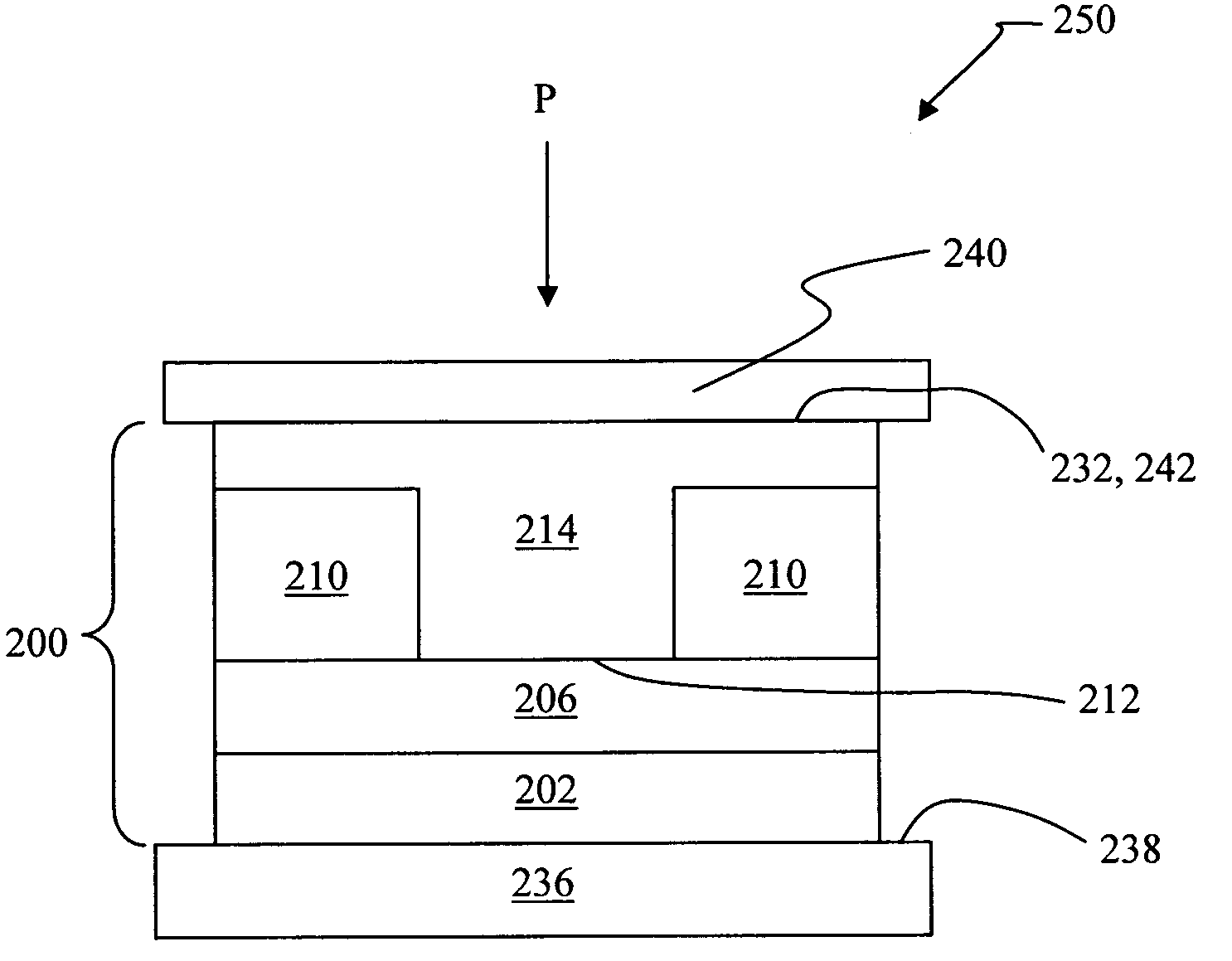

Temperature and pressure control methods to fill features with programmable resistance and switching devices

ActiveUS7994034B2Improve surface mobilityReduce thickness variationSemiconductor/solid-state device manufacturingEngineeringPhase-change material

A programmable resistance, chalcogenide, switching or phase-change material device includes a substrate with a plurality of stacked layers including a conducting bottom electrode layer, an insulative layer having an opening formed therein, an active material layer deposited over both the insulative layer, within the opening, and over selected portions of the bottom electrode, and a top electrode layer deposited over the active material layer. The device uses temperature and pressure control methods to increase surface mobility in an active material layer, thus providing complete coverage or fill of the openings in the insulative layer, selected exposed portions of the bottom electrode layer, and the insulative layer.

Owner:OVONYX MEMORY TECH LLC

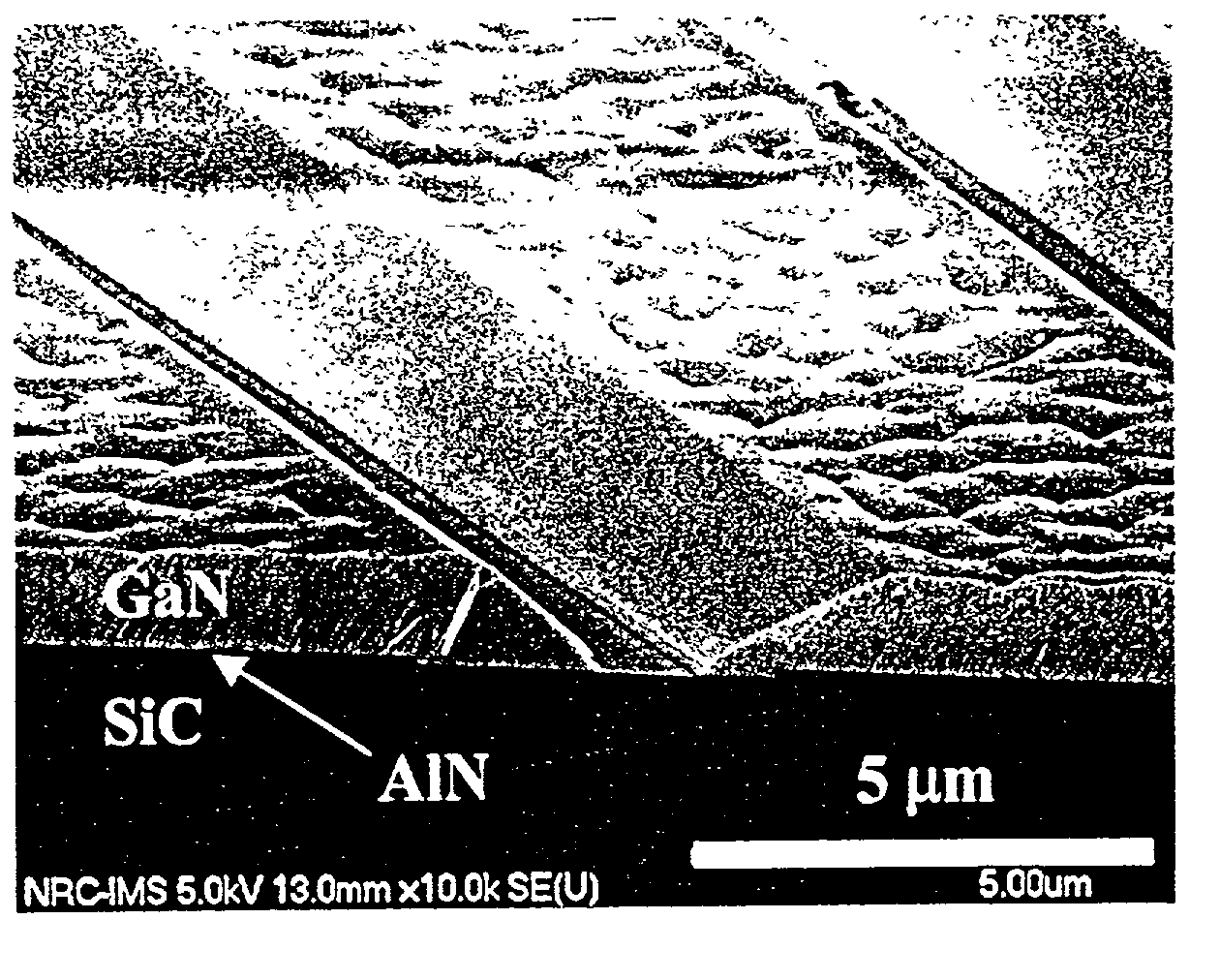

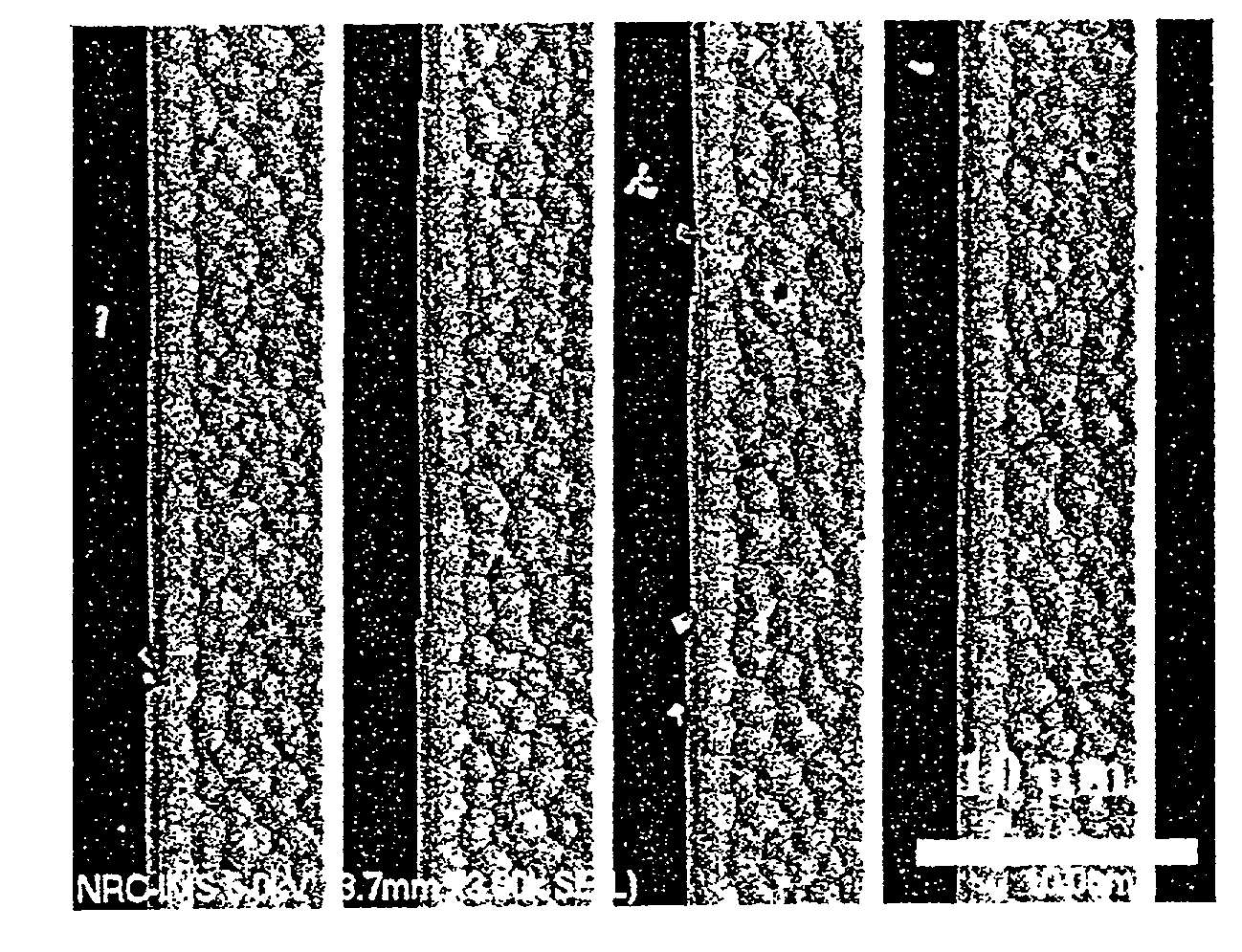

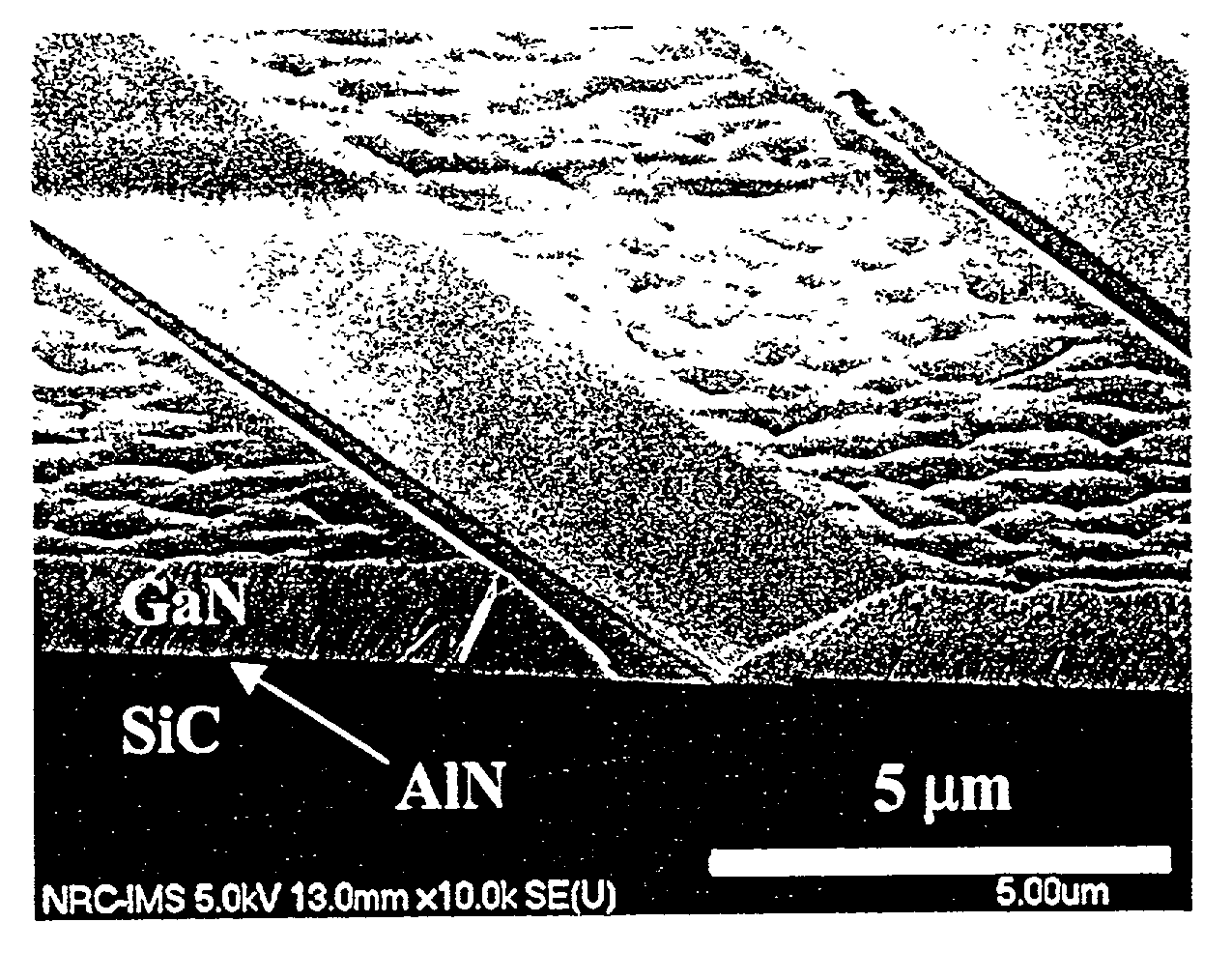

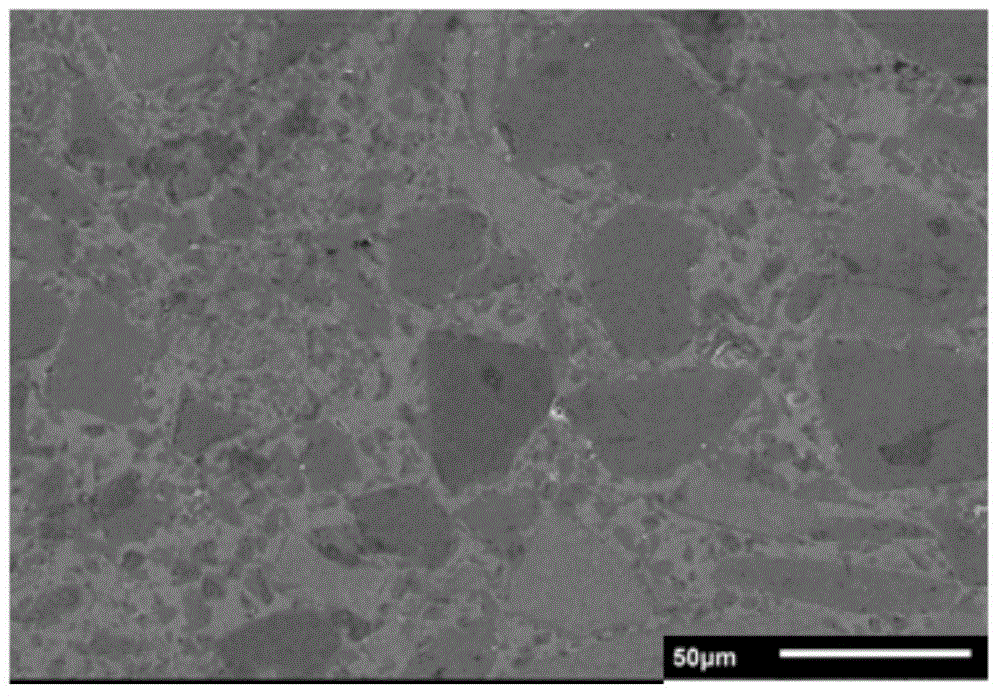

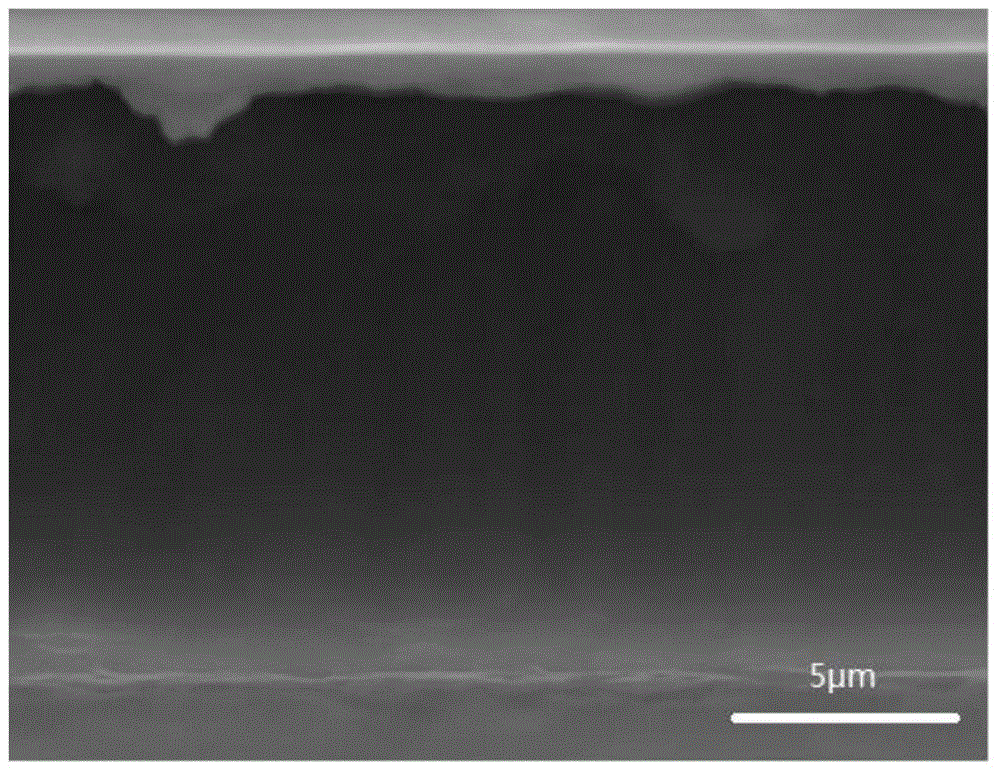

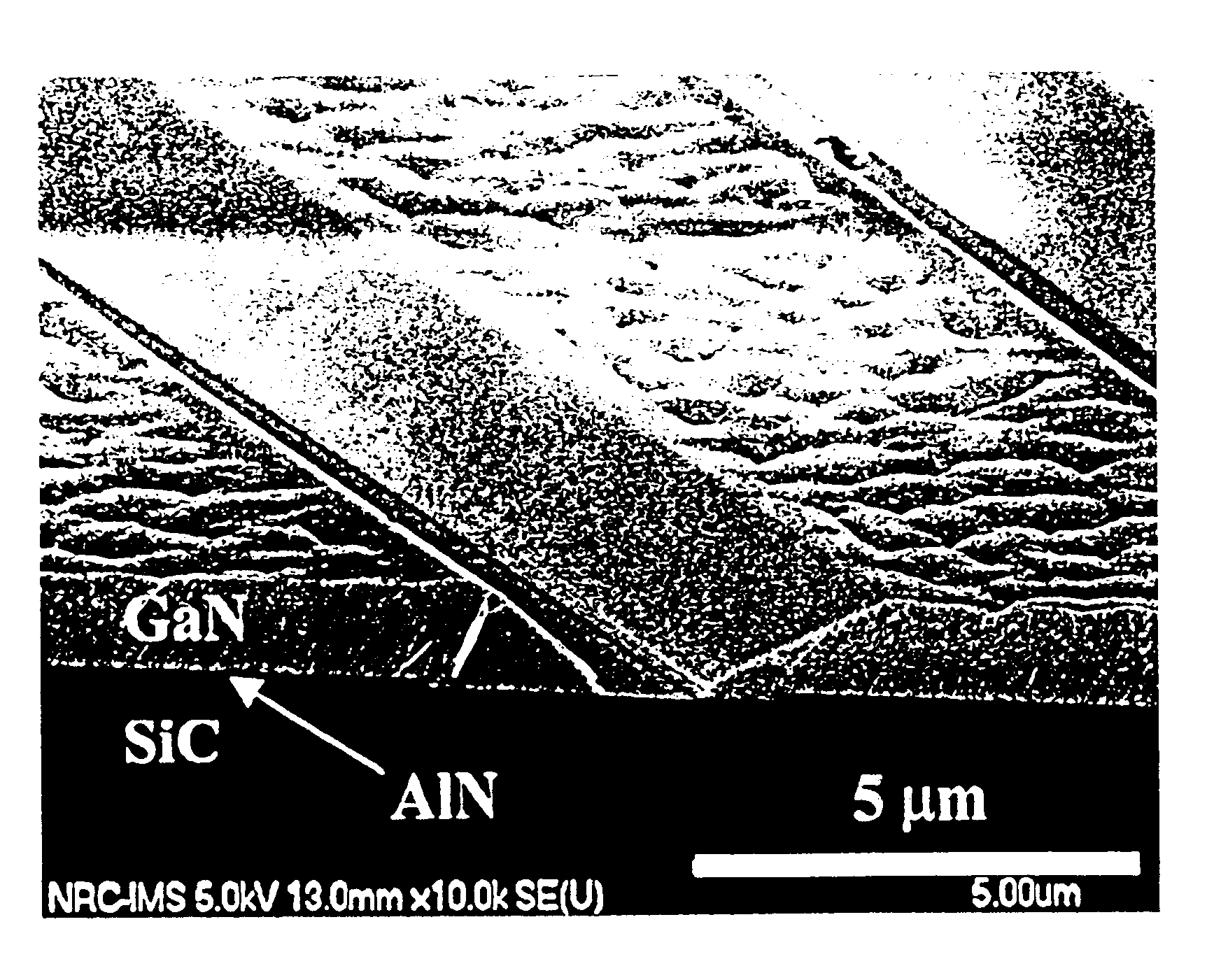

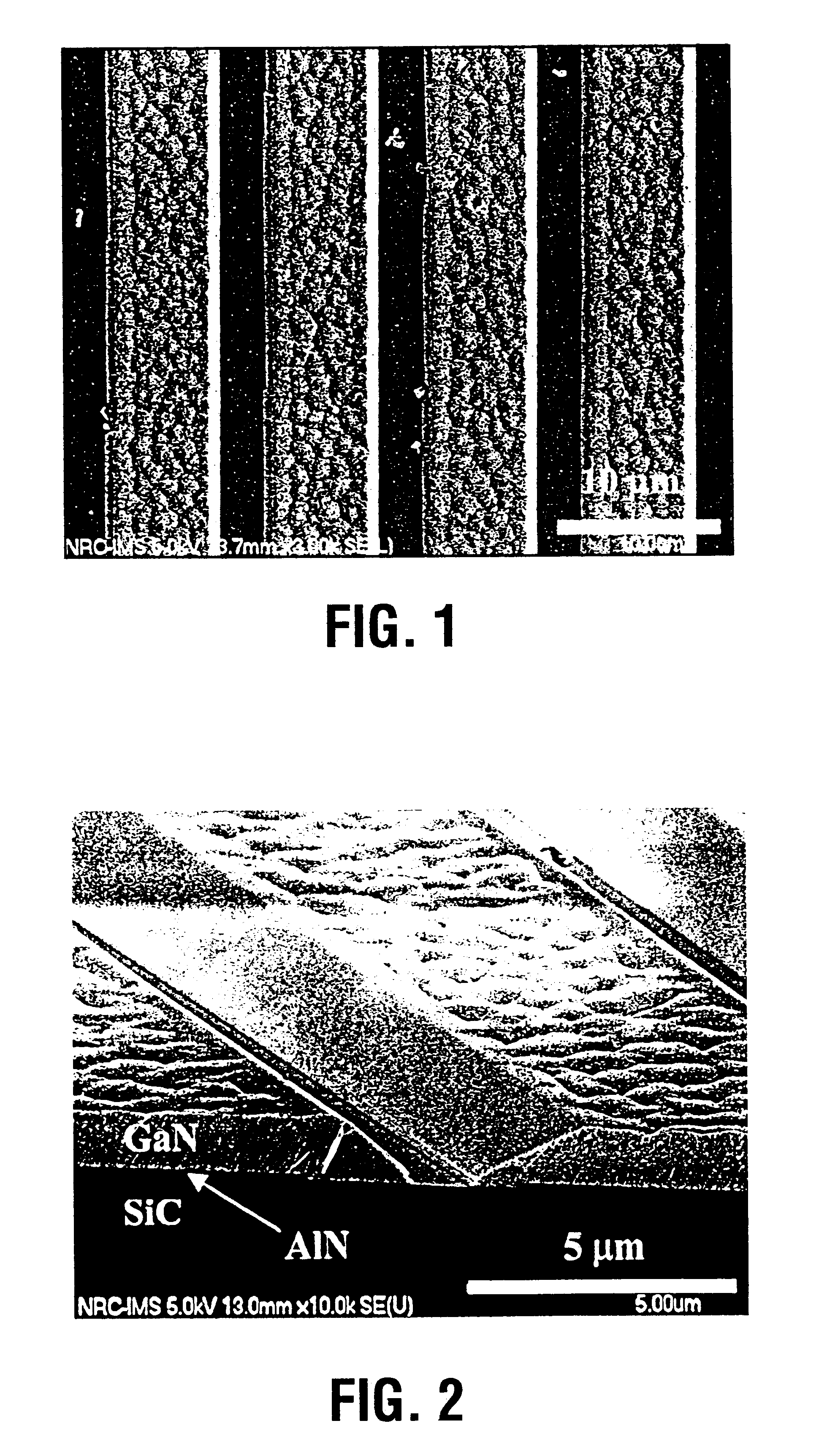

GaN selective growth on SiC substrates by ammonia-source MBE

InactiveUS20020189534A1Improve surface mobilityIncrease flow ratePolycrystalline material growthFrom chemically reactive gasesOptoelectronicsPatterned substrate

A method is described for selectively depositing a GaN epitaxial layer on a substrate. The substrate is first patterned with a seed layer, preferably of AlN, and then the GaN epitxial layer is grown on the resulting patterned substrate by molecular beam epitaxy (MBE) such that growth occurs selectively over the seed layer.

Owner:NAT RES COUNCIL OF CANADA

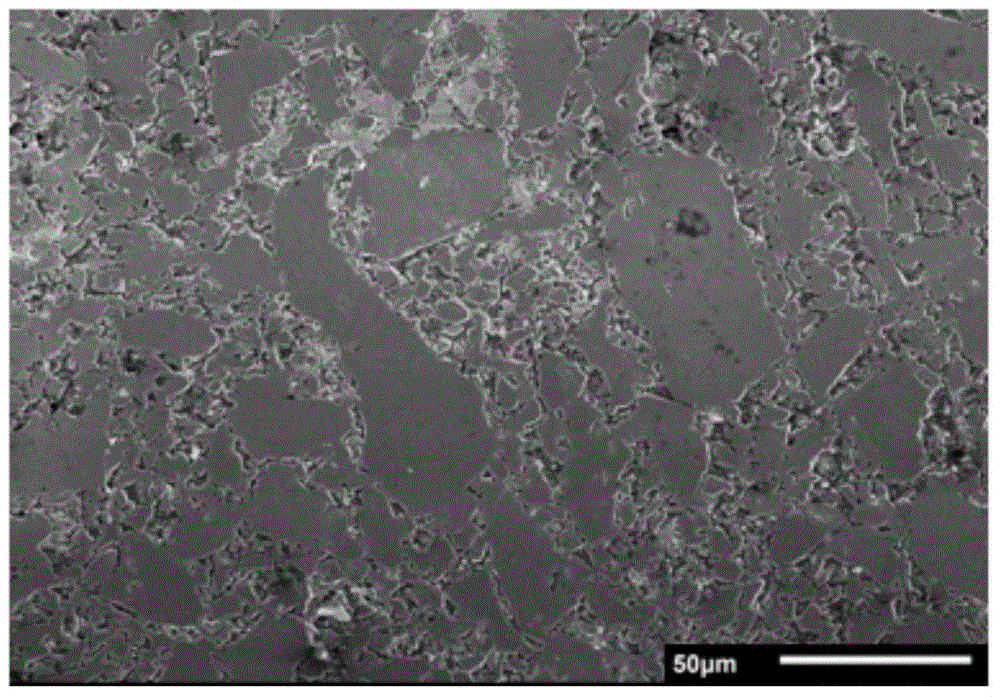

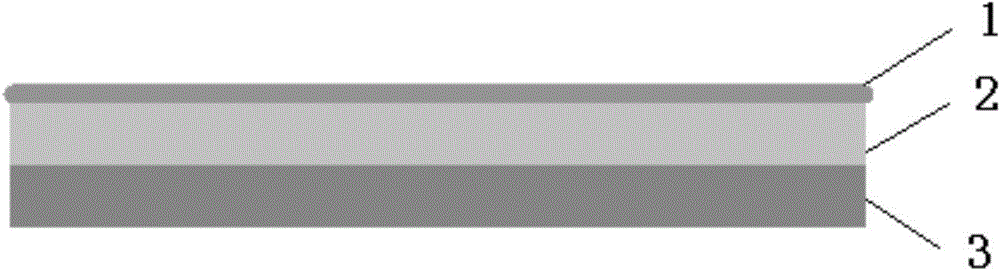

Preparation method of RB-SiC (Reaction Bonded Silicon Carbide) substrate reflector surface modification layer

InactiveCN104451580AImprove optical qualityRaise the incident energyVacuum evaporation coatingSputtering coatingReaction bonded silicon carbideSurface cleaning

The invention provides a preparation method of an RB-SiC (Reaction Bonded Silicon Carbide) substrate reflector surface modification layer, and belongs to the technical field of thin film deposition. The method comprises the following steps: I, preparing filming conditions: mounting a Si target on a twin sputtering cathode of a filming machine, performing surface cleaning treatment on the RB-SiC substrate, fixing to a filming machine workpiece clamp, vacuuming the filming machine and roasting the RB-SiC substrate; II, performing surface treatment on the surface of the Si target of the sputtering cathode: introducing Ar gas into the sputtering cathode, and adjusting medium frequency power supply power to perform sputtering pre-treatment on the surface of the Si target; III, preparing the Si modification layer: increasing the medium frequency power supply power and Ar ventilation volume, and depositing the Si modification layer on the RB-SiC substrate by using a medium frequency magnetron sputtering technology. The preparation process is greatly simplified, the compactness of the film layer is high, the film is uniform, the polishing characteristic is obviously improved, and the optical quality of the surface of the polished substrate is greatly improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

GaN selective growth on SiC substrates by ammonia-source MBE

InactiveUS6599361B2Improve surface mobilityIncrease flow ratePolycrystalline material growthFrom chemically reactive gasesOptoelectronicsPatterned substrate

A method is described for selectively depositing a GaN epitaxial layer on a substrate. The substrate is first patterned with a seed layer, preferably of AlN, and then the GaN epitxial layer is grown on the resulting patterned substrate by molecular beam epitaxy (MBE) such that growth occurs selectively over the seed layer.

Owner:NAT RES COUNCIL OF CANADA

Temperature and pressure control methods to fill features with programmable resistance and switching devices

ActiveUS20090227092A1Improve surface mobilityReduce thickness variationSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesEngineeringPhase-change material

A programmable resistance, chalcogenide, switching or phase-change material device includes a substrate with a plurality of stacked layers including a conducting bottom electrode layer, an insulative layer having an opening formed therein, an active material layer deposited over both the insulative layer, within the opening, and over selected portions of the bottom electrode, and a top electrode layer deposited over the active material layer. The device uses temperature and pressure control methods to increase surface mobility in an active material layer, thus providing complete coverage or fill of the openings in the insulative layer, selected exposed portions of the bottom electrode layer, and the insulative layer.

Owner:OVONYX MEMORY TECH LLC

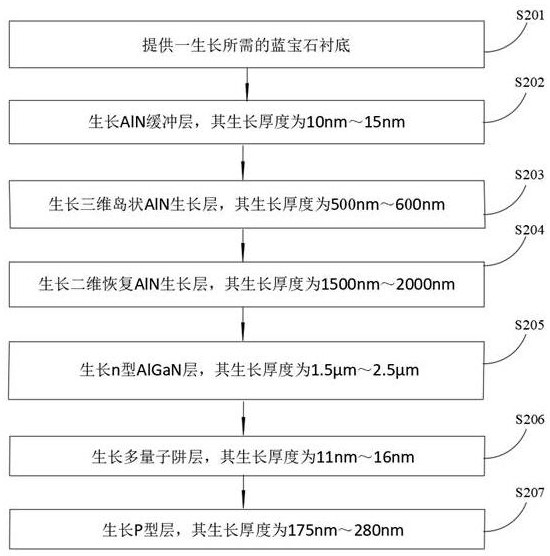

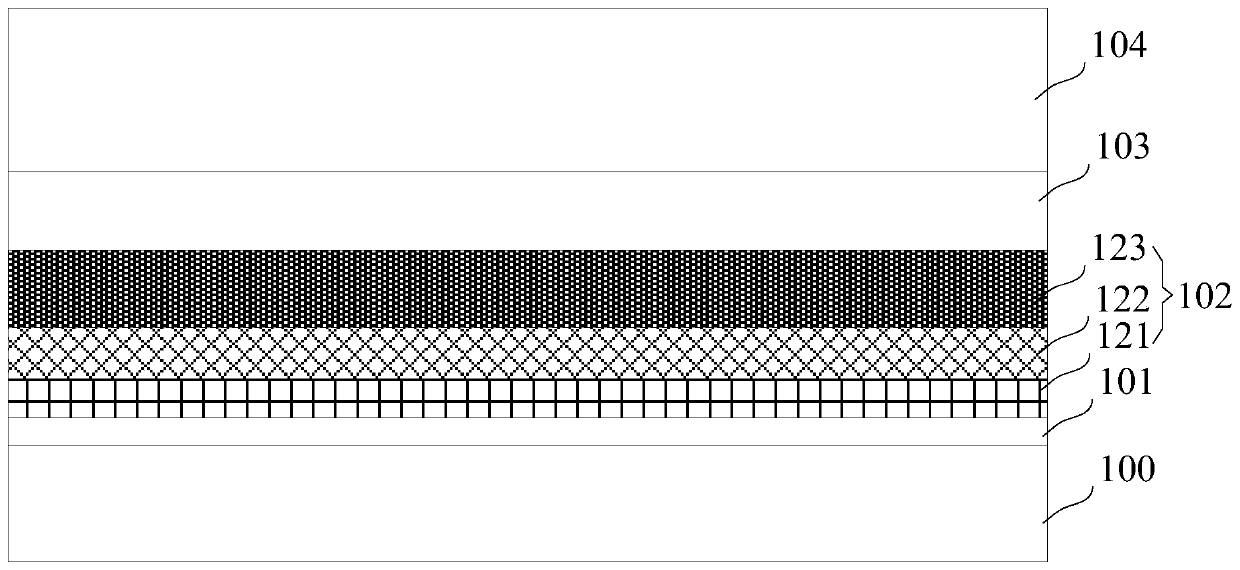

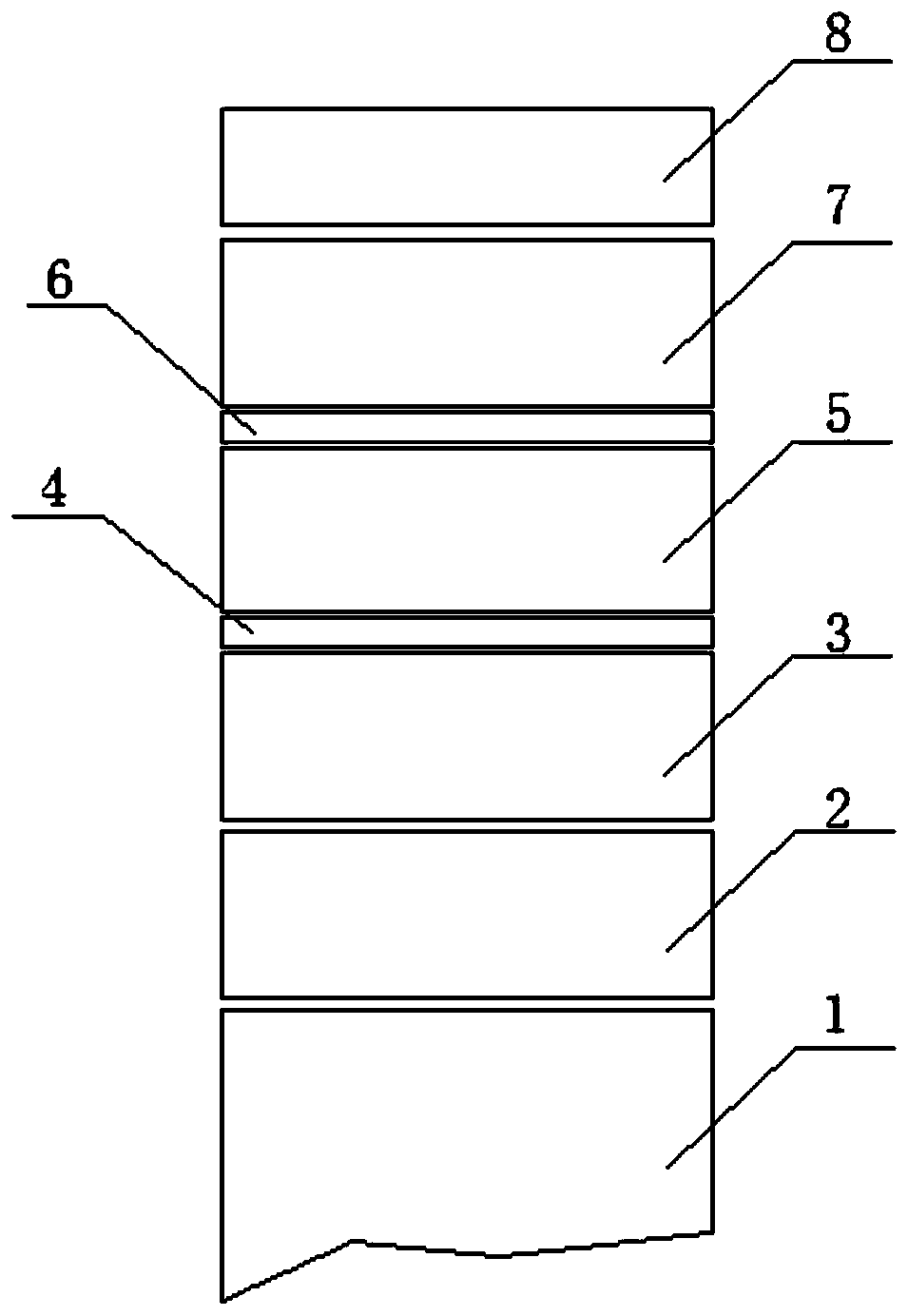

AlN epitaxial layer and preparation method thereof

ActiveCN107516630AImprove migration abilityWeak migration ability and improved crystallization qualitySemiconductor/solid-state device manufacturingDefect repairIsolation layer

An AlN epitaxial layer and preparation method thereof relate to the field of semiconductor epitaxy technology. According to the invention, an N polarity isolation layer grows at a comparatively low temperature, so that the N polarity is isolated well and single Al polarity is formed. Then a nucleating layer is formed on the N-polarity isolation layer at a medium temperature. The surface transfer ability of Al atoms at the medium temperature is improved and the quality of the nucleating layer is improved. The temperature is increased further and a defect repairing layer is settled on the nucleating layer at a comparatively high temperature, so that spot defect concentration can be reduced in a condition with stress release and dislocation annihilation. Finally, the temperature is increased continually and the high transfer ability of the Al atoms is kept at a high temperature, so that quick settlement on the basis of the defect repairing layer is realized and the growth efficiency is improved. The preparation method provided by the invention is simple in technique, convenient to operate and provides high growth efficiency. The AlN epitaxial layer prepared by adopting the preparation method has characteristics of smooth surface, single Al polarity and low dislocation annihilation.

Owner:GUANGDONG INST OF SEMICON IND TECH

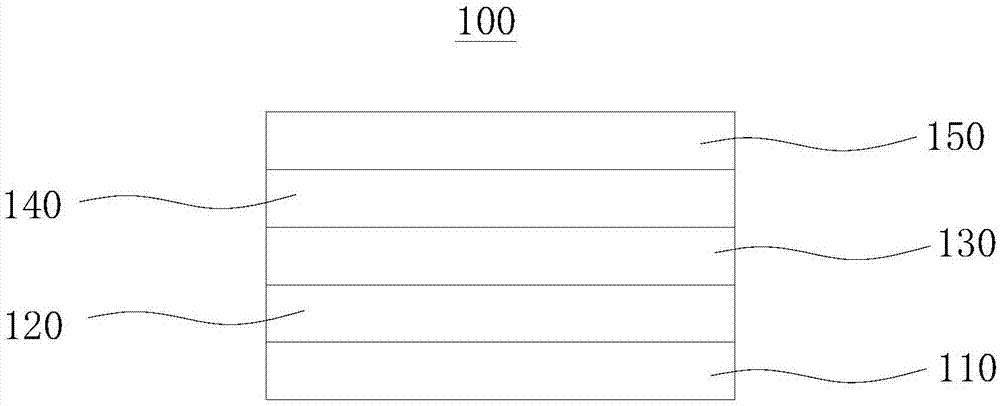

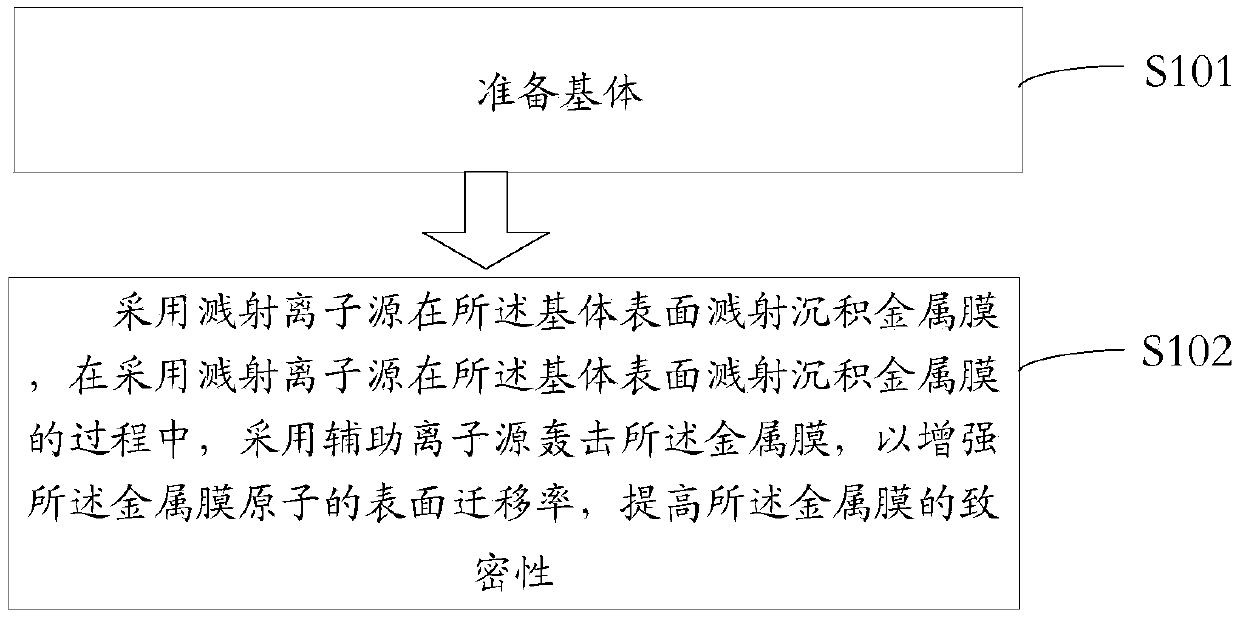

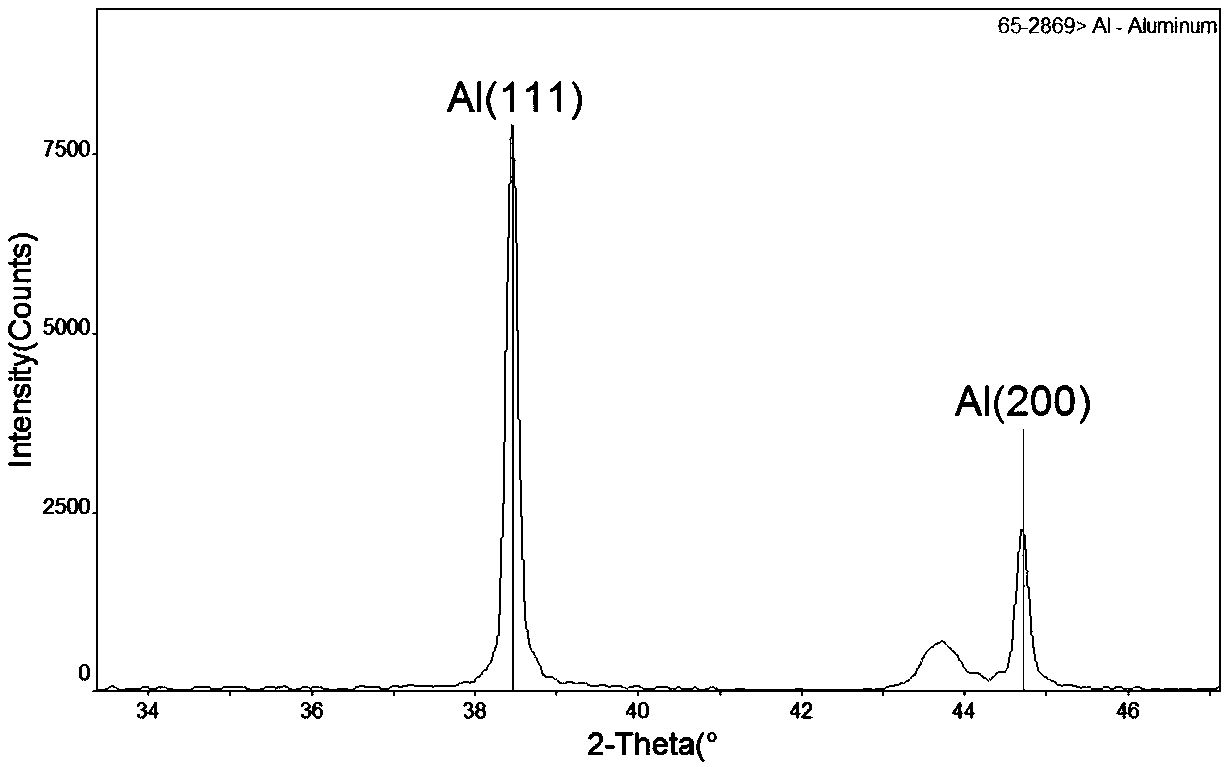

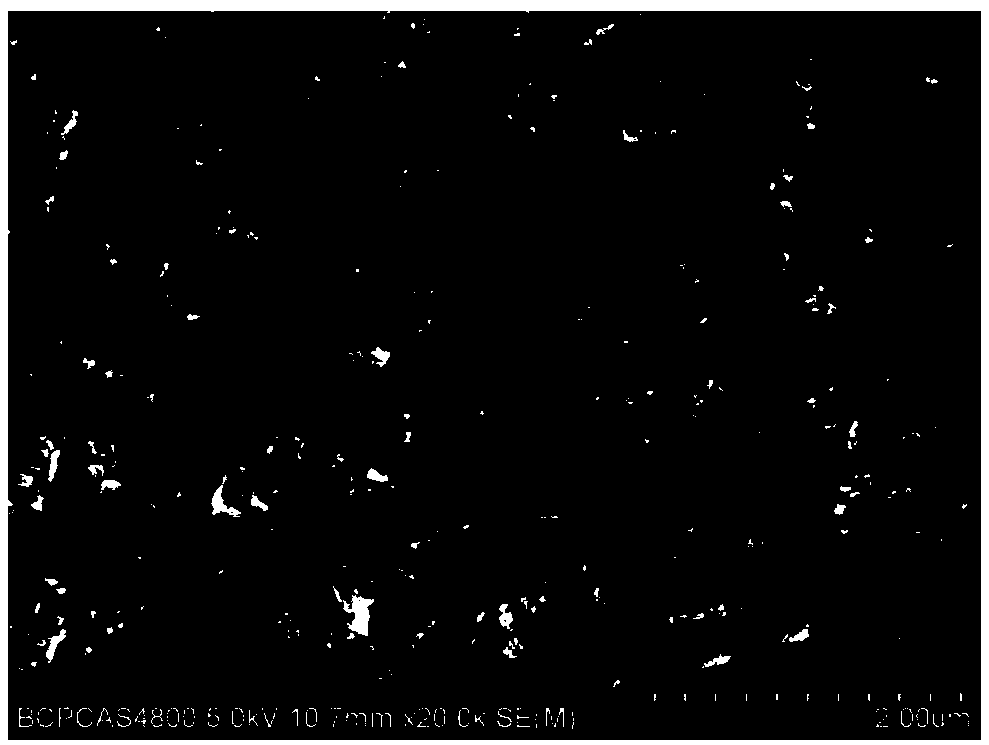

Deposition film preparation method and film plating machine

InactiveCN110541153AReduce porosityImprove compactnessVacuum evaporation coatingSputtering coatingSputter depositionMetal

The invention discloses a deposition film preparation method and a film plating machine. The method includes the following steps: preparing a basal body; and during sputtering deposition of a metal film on the surface of the basal body through adopting a sputtering ion source, adopting an auxiliary ion source to bombard the metal film to enhance the surface migration rate of atoms of the metal film and improve the compactness of the metal film. According to the method and the film plating machine, provided by the invention, the technical problem that in the existing metal film preparation scheme, a metal film with high thickness and high compactness can not be prepared is solved, and the method for generating the metal film with high thickness and high compactness and the film plating machine are provided.

Owner:李紫茵

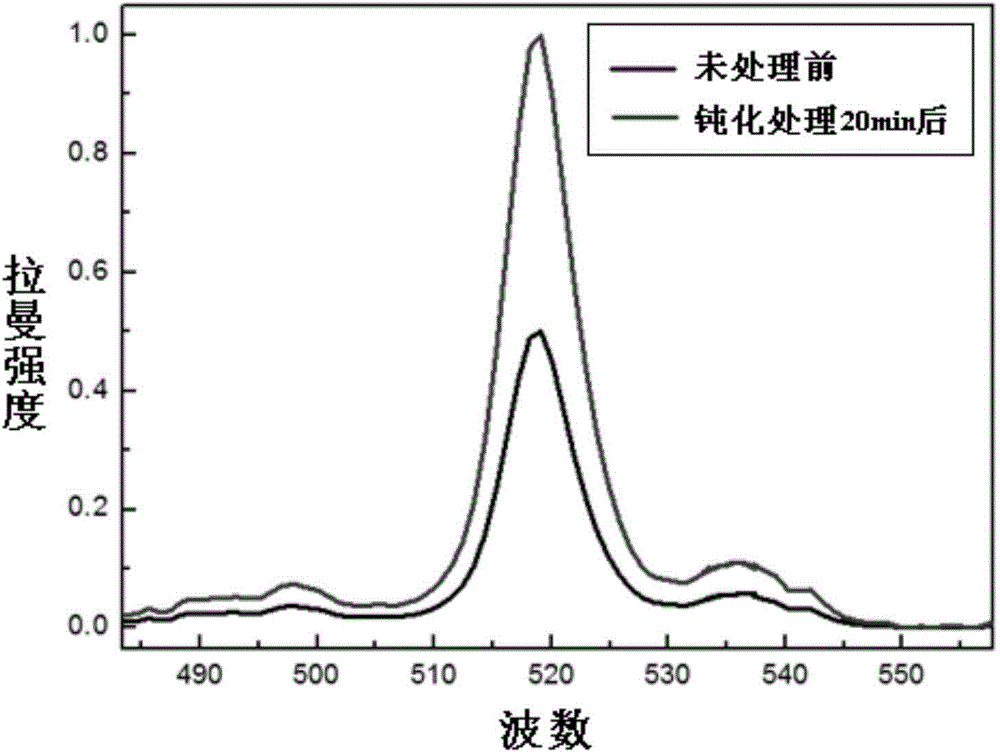

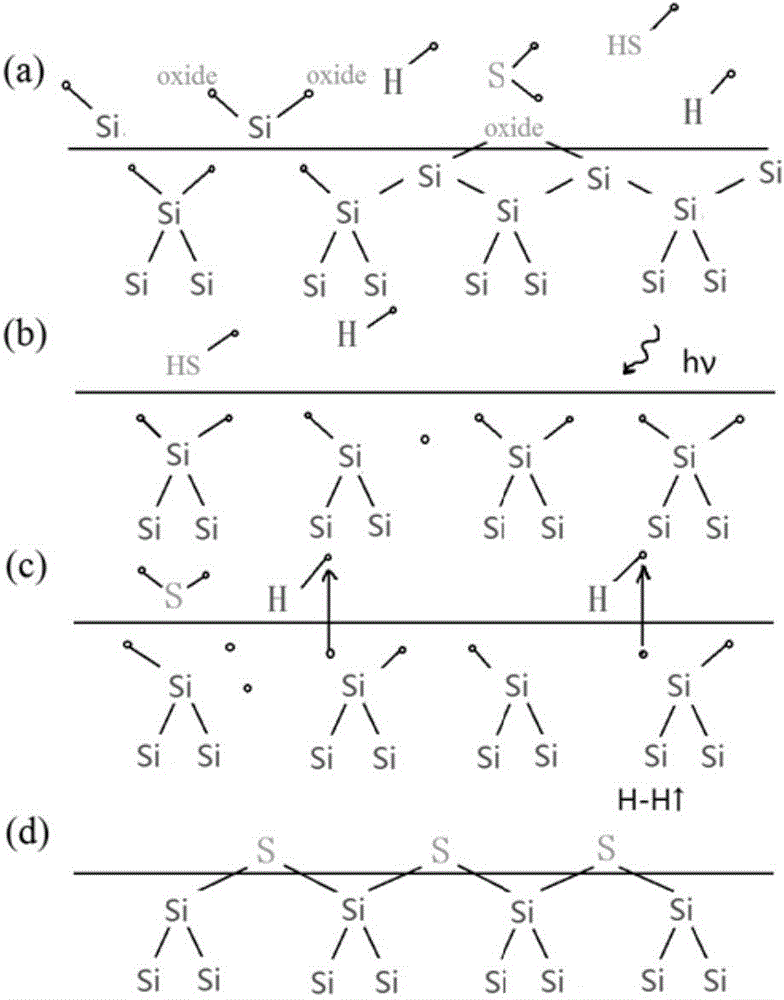

Method for overcoming surface defect of polycrystalline silicon

InactiveCN104795321AImprove surface mobilityExtended service lifeSemiconductor/solid-state device manufacturingHydrogenAmmonium sulfide

The invention relates to the field of semiconductors, and particularly discloses a method for overcoming a surface defect of polycrystalline silicon. The method specifically comprises the steps that surface passivating treatment is conducted on the polycrystalline silicon through sulfur-containing passivating liquid or SCl2 gas, wherein the sulfur-containing passivating liquid is an ammonium sulfide solution or a sodium sulfide solution. According to the method for overcoming the surface defect of the polycrystalline silicon, due to the fact that surface passivating treatment is conducted on the polycrystalline silicon through the sulfur-containing passivating liquid or the SCl2 gas, the surface defect formed on the surface of the polycrystalline silicon in the polycrystalline silicon formation technological process can be effectively overcome, suspended chemical bonds can be effectively removed, the surface mobility of the polycrystalline silicon can be improved to a small extent, and the service life of the high mobility of the polycrystalline silicon can be prolonged. Compared with conventional hydrogen implantation and dehydrogenation technologies, the method has the advantages that operation is easier and more convenient, and the method can be accomplished only through the one-step technological process.

Owner:BOE TECH GRP CO LTD +1

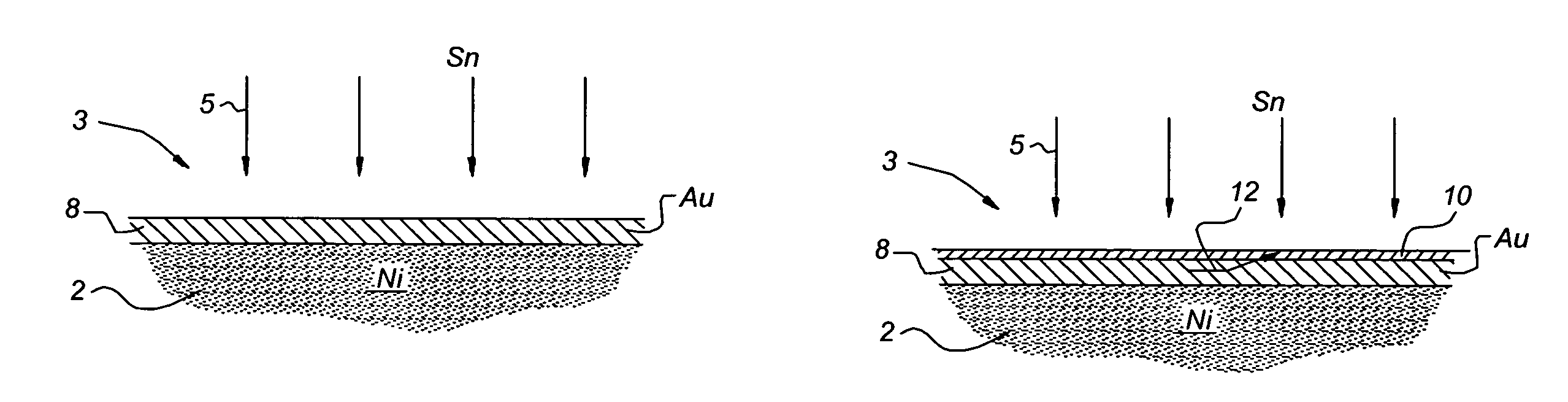

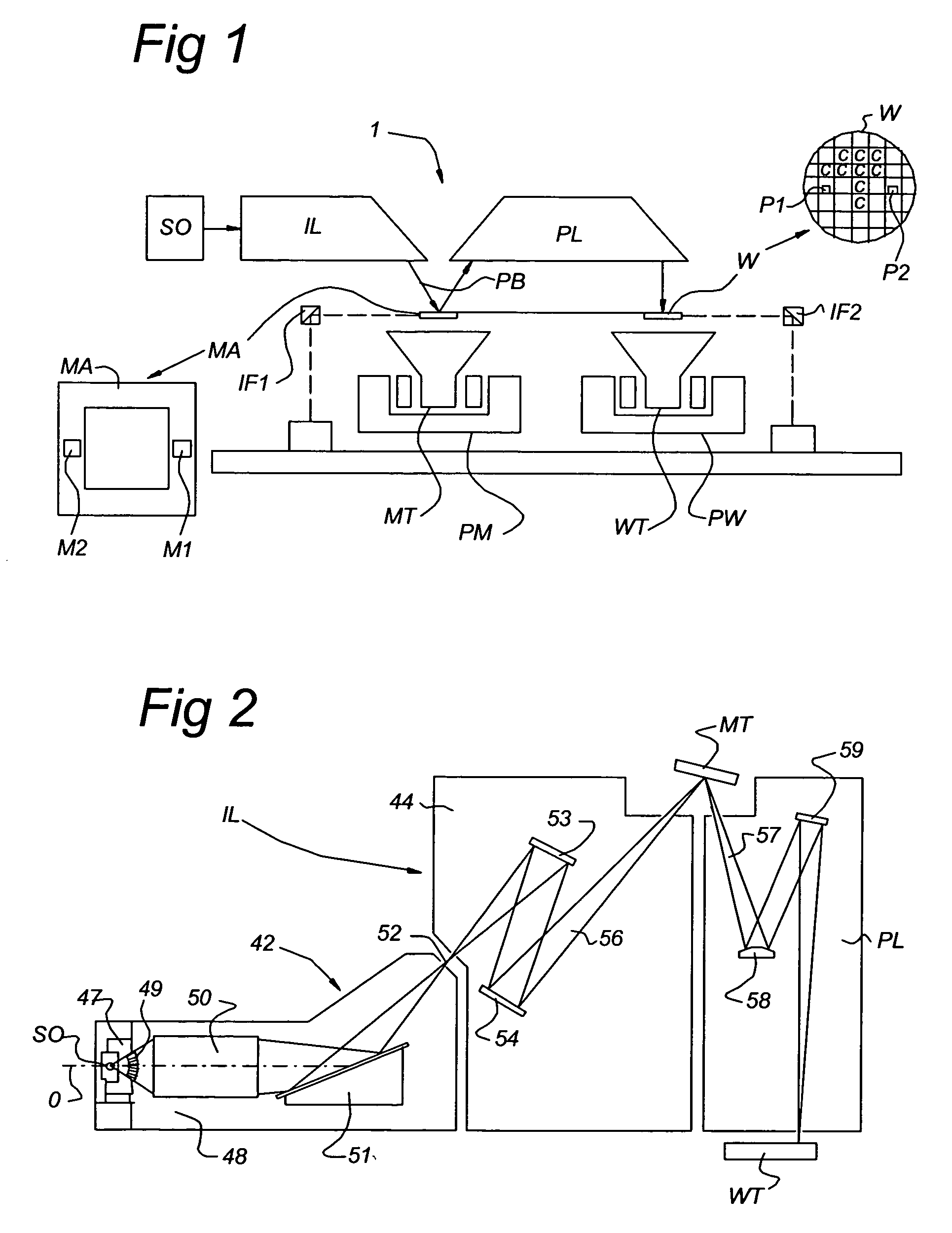

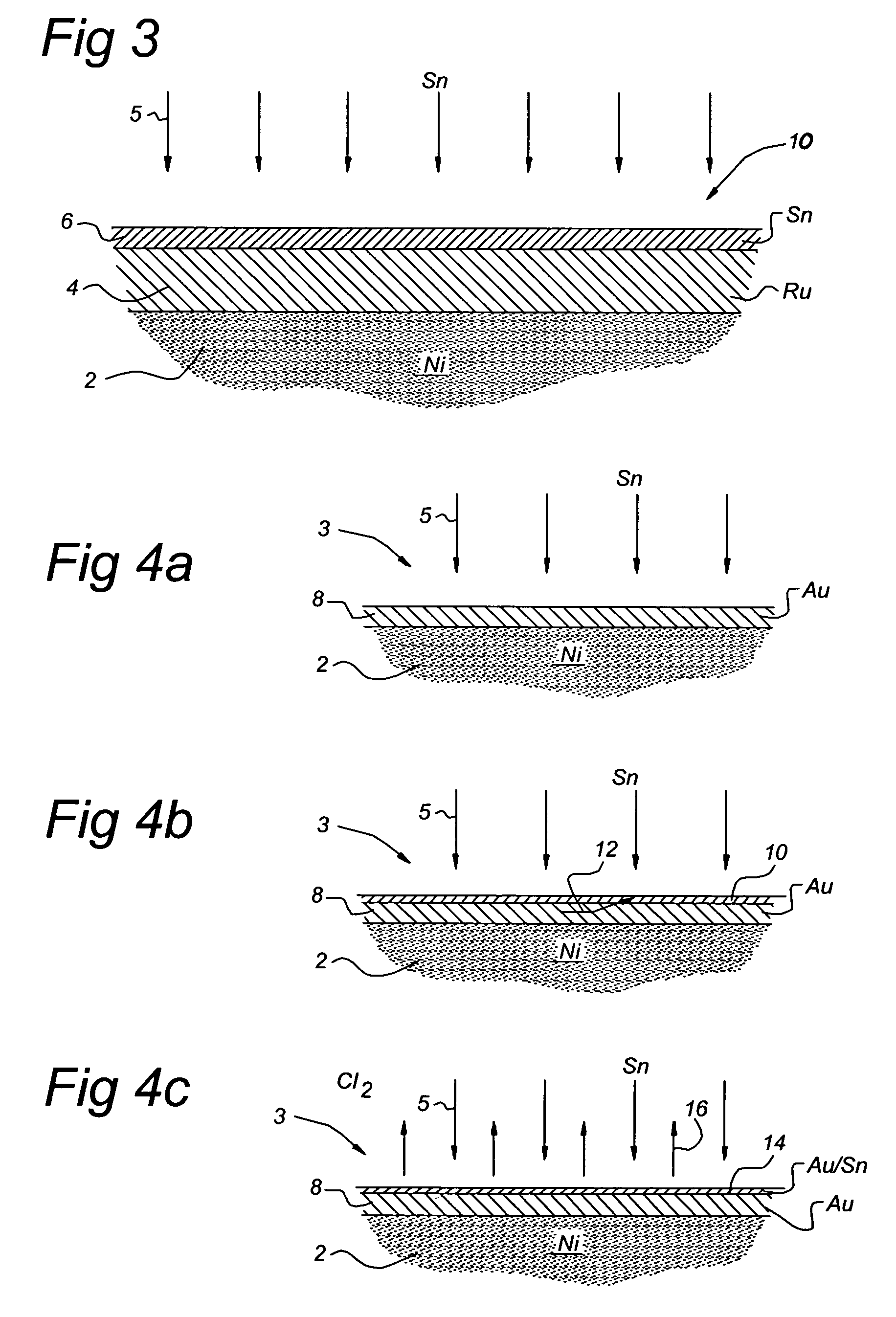

Mirror for use in a lithographic apparatus, lithographic apparatus, device manufacturing method, and device manufactured thereby

A top layer of a predetermined metal is provided on a mirror for use in a lithographic apparatus having source to provide radiation of a desired wavelength. The source generates a stream of undesired metal particles that are deposited to form smaller and larger nuclei on the mirror. The top layer may interdiffuse in a predetermined temperature range with nuclei of the metal deposition. An additional layer of an alloy of the metal particles and the metal of the top layer is formed that has a higher reflectivity than a layer only comprising the metal particles would have.

Owner:ASML NETHERLANDS BV

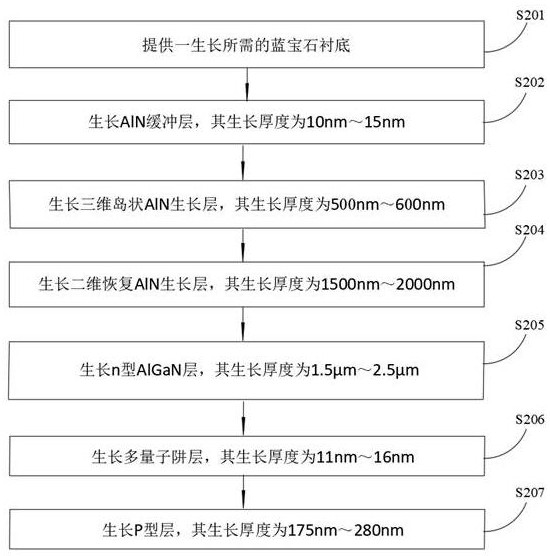

LED epitaxial wafer, epitaxial growth method and LED chip

ActiveCN114256395ASolve low luminous efficiencyLuminous efficiency is stableSemiconductor devicesAcceptorElectron hole

The invention provides an LED epitaxial wafer, an epitaxial growth method and an LED chip, the LED epitaxial wafer comprises a P-type layer, the P-type layer comprises an electron barrier layer, a transition layer and a contact layer, the transition layer comprises a first sub-layer, a second sub-layer and a third sub-layer, the second sub-layer and the third sub-layer are sequentially deposited on the first sub-layer, the first sub-layer is a P-Al1-xScxN layer, the second sub-layer is a GaN layer, and the third sub-layer is an N-Al1-yScyN layer. According to the invention, the first sub-layer and the third sub-layer respectively form a heterojunction interface with the second sub-layer, and piezoelectric polarization charge densities with opposite positive and negative polarities are generated at the heterojunction interface, so that a large number of unbalanced holes are injected into the first sub-layer, and then are injected into an active region to generate radiation recombination with electrons, thereby improving the photoelectric conversion efficiency. The situation that few holes are generated due to high acceptor activation energy of the P-type layer is relieved, and the problem that the light-emitting efficiency of the ultraviolet light-emitting diode is low is solved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

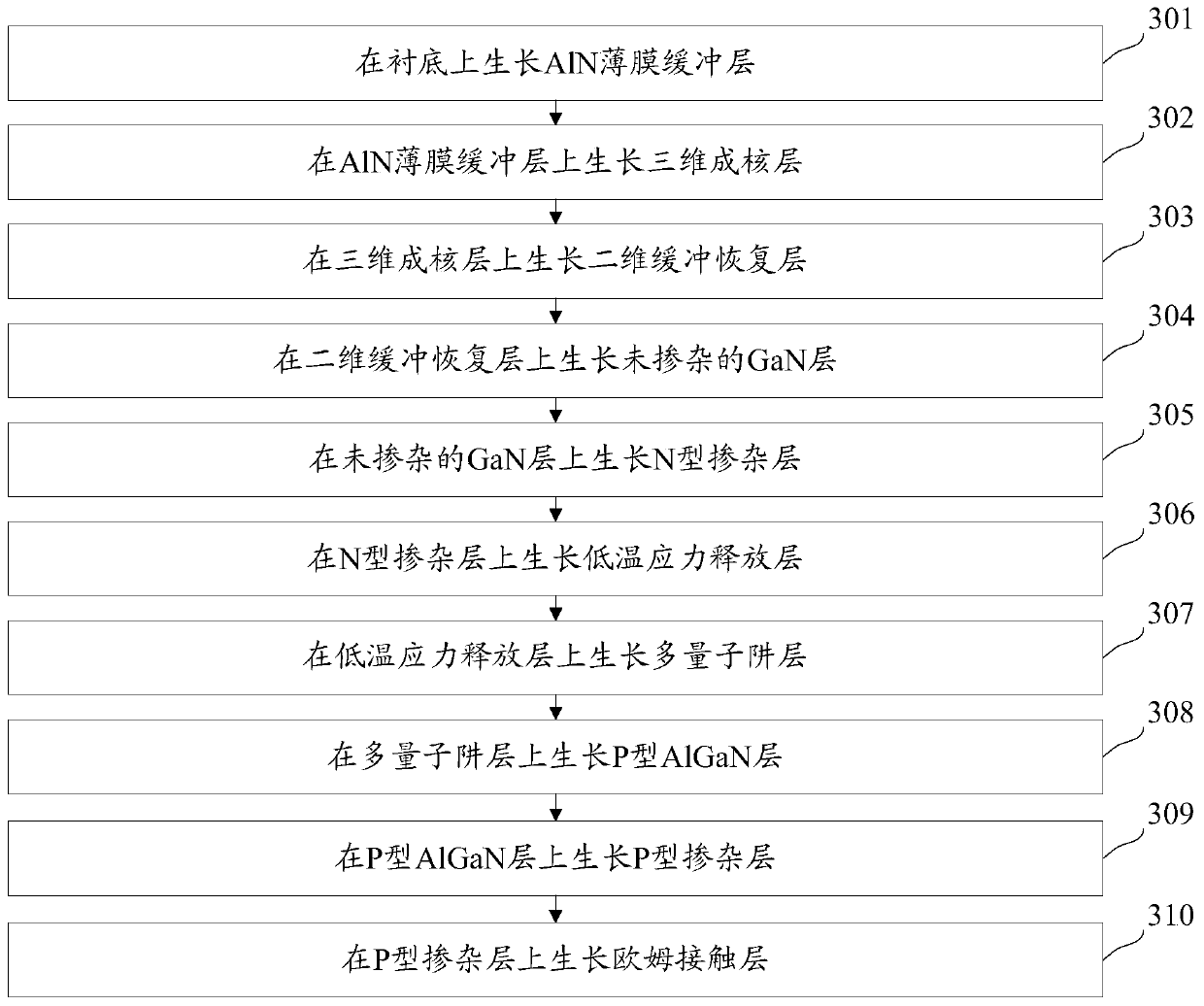

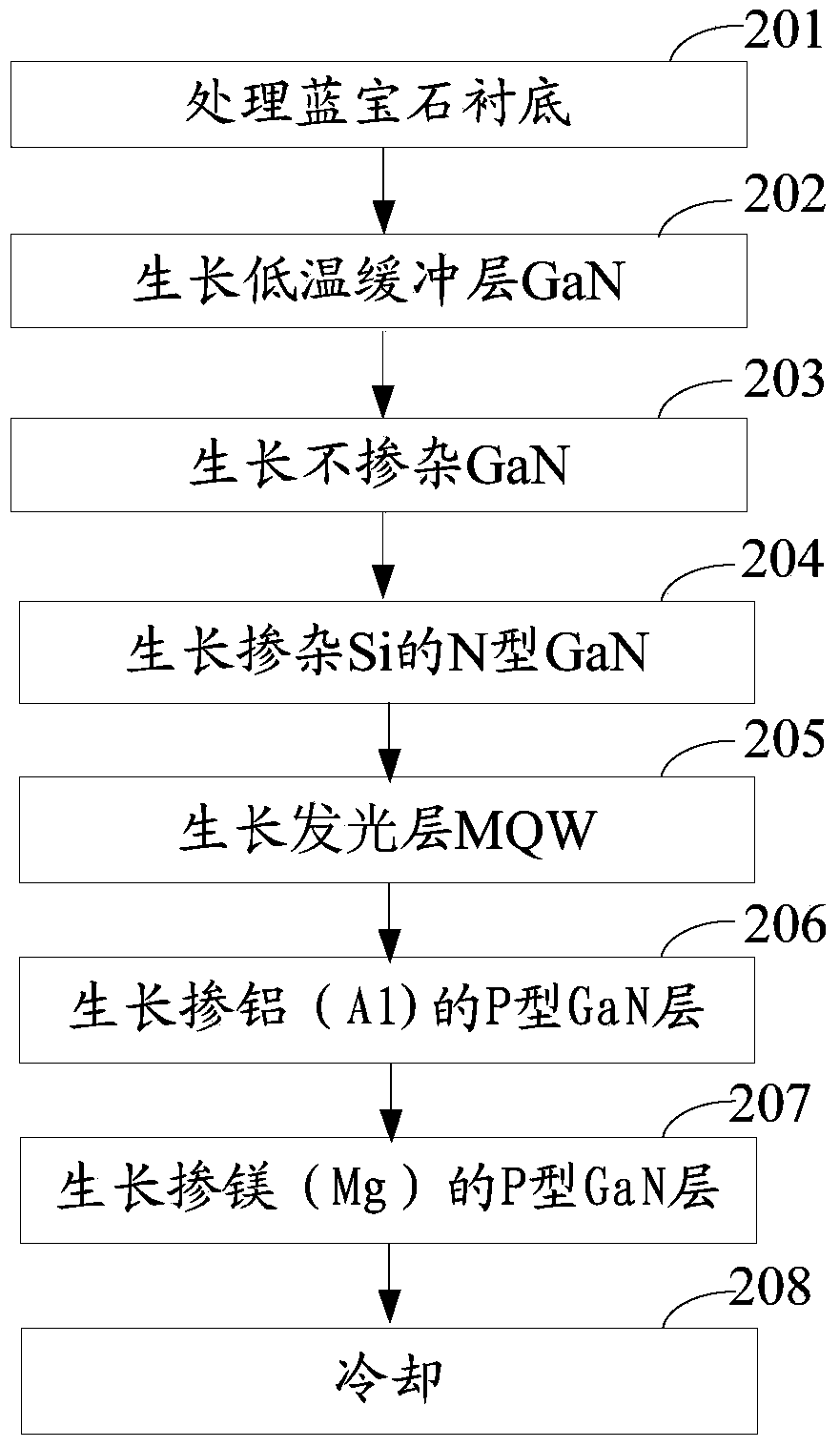

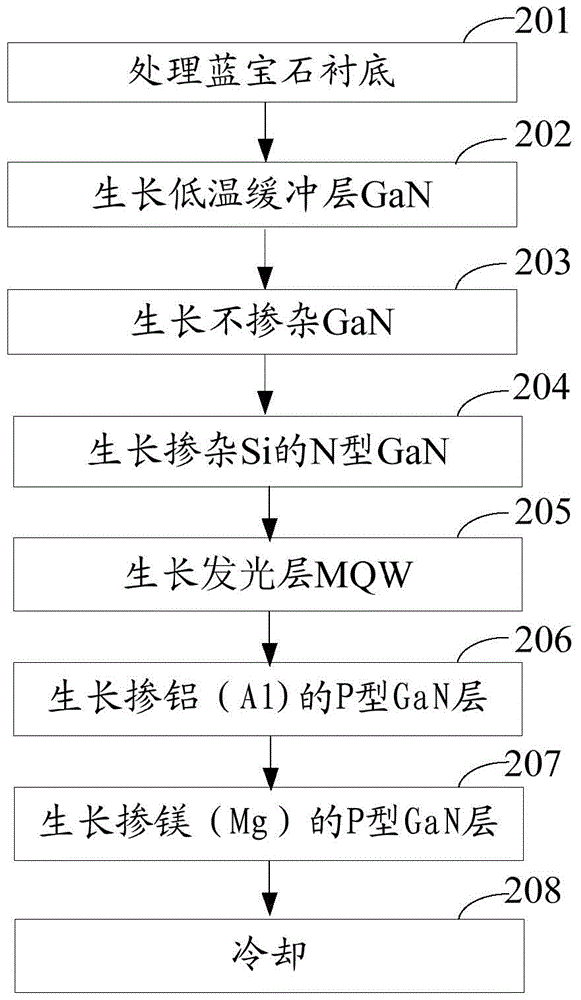

LED epitaxial growth method

PendingCN112687770APromote three-dimensional growthIncrease the number of quantum dotsPolycrystalline material growthAfter-treatment detailsElectron blocking layerMaterials science

The invention discloses an LED epitaxial growth method, which sequentially comprises the steps of processing a substrate, growing a low-temperature GaN buffer layer, growing a non-doped GaN layer, growing a Si-doped N-type GaN layer, growing a multi-quantum well layer, growing an AlGaN electronic barrier layer, growing a Mg-doped P-type GaN layer, and cooling. Wherein the growth of the multi-quantum well layer sequentially comprises the steps of In-doped pretreatment, InGaN well layer growth, Ga2O3 pre-growth, Ga2O3 layer growth, annealing treatment, GaN gradient layer growth and GaN barrier layer growth. According to the method, the problems of low quantum well growth quality and low quantum well radiation recombination efficiency in the existing LED epitaxial growth method are solved, so that the luminous efficiency of the LED is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

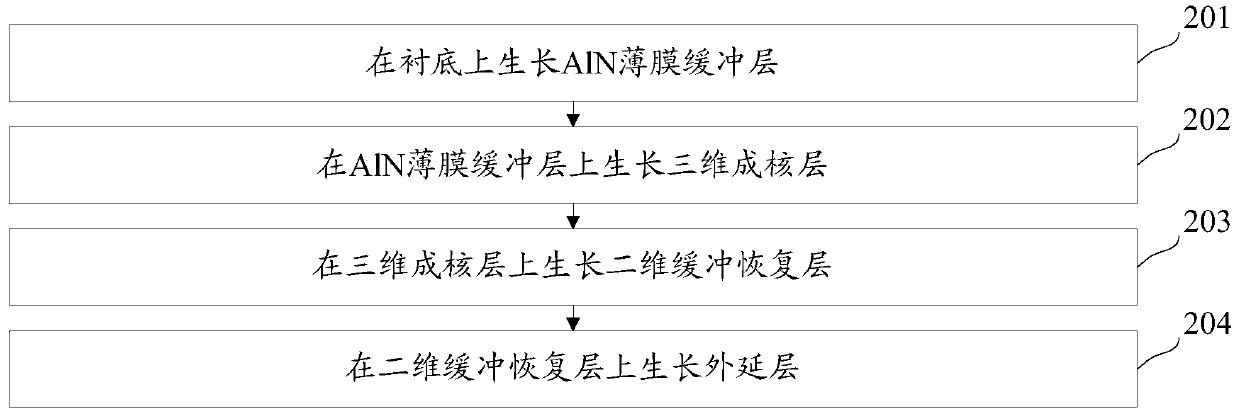

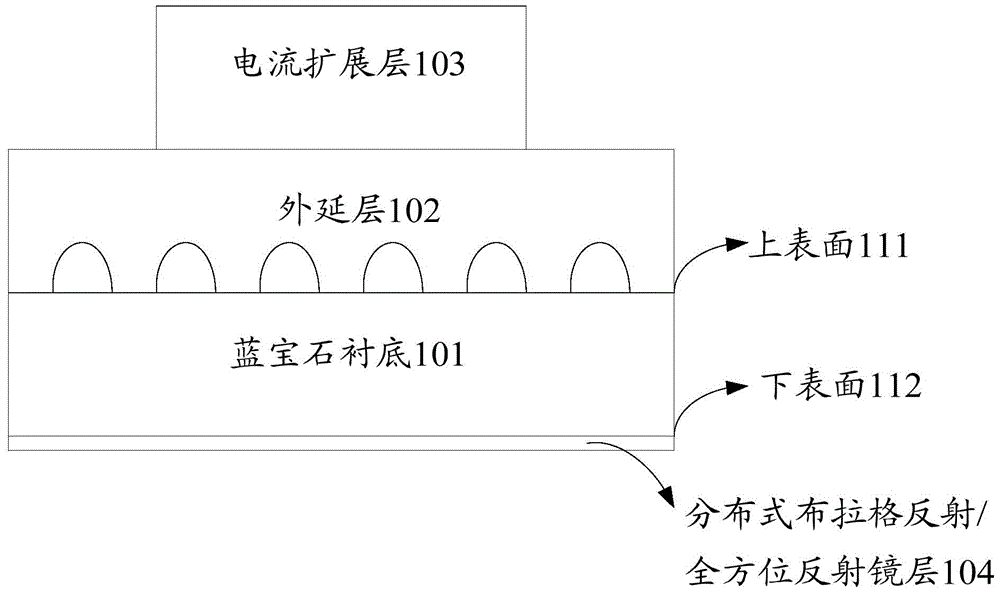

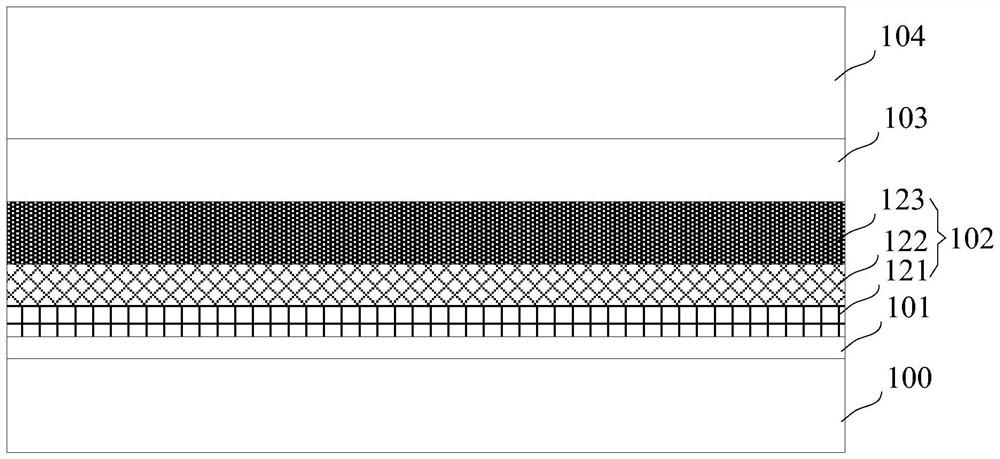

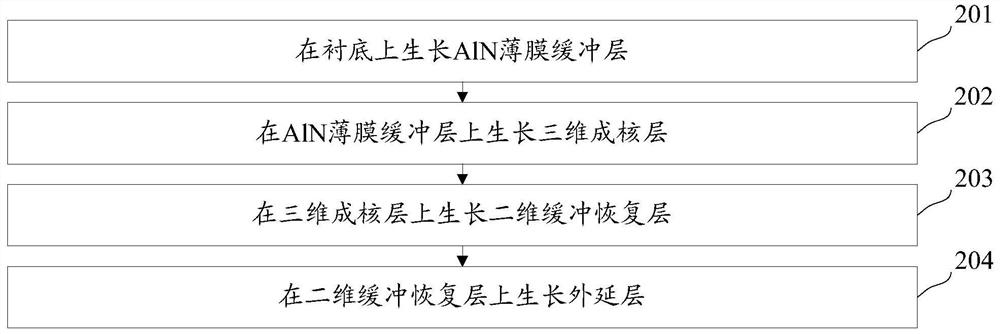

GaN-based light-emitting diode epitaxial wafer, preparation method of GaN-based light-emitting diode epitaxial wafer, and light-emitting diode

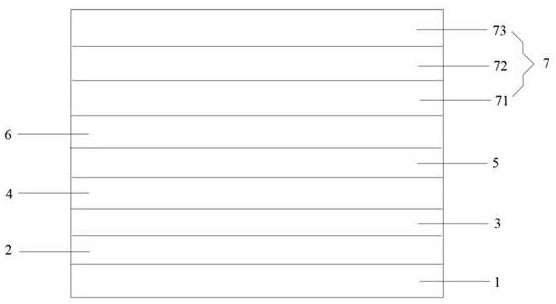

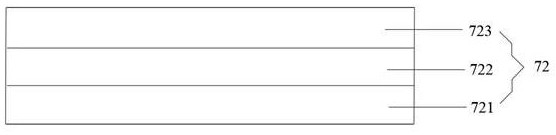

ActiveCN109920722AReduce spacingLow densityVacuum evaporation coatingSputtering coatingLight-emitting diodeDislocation

The invention discloses a GaN-based light-emitting diode epitaxial wafer, a preparation method of the GaN-based light-emitting diode epitaxial wafer, and a light-emitting diode, and belongs to the technical field of epitaxy. The GaN-based light-emitting diode epitaxial wafer comprises a substrate, an AlN thin-film buffer layer, a three-dimensional nucleating layer, a two-dimensional buffer recovery layer and an epitaxial layer, wherein the AlN thin-film buffer layer, the three-dimensional nucleating layer, the two-dimensional buffer recovery layer and the epitaxial layer are sequentially stacked on the substrate; the three-dimensional nucleating layer is a GaN layer; the three-dimensional nucleating layer comprises a first nucleating sub-layer, a second nucleating sub-layer and a third nucleating sub-layer which are sequentially stacked on the AlN thin-film buffer layer; for the first nucleating sub-layer, the growth pressure of is 150-250 torr, the growth temperature is 1,000-1,100 DEG C, and the V / III ratio is 500-1,000; for the second nucleating sub-layer, the growth pressure is 500-700 torr, the growth temperature is 900-1,000 DEG C, and the V / III ratio is 100-200; and for thethird nucleating sub-layer, the growth pressure is 100-200 torr, the growth temperature is 1,100-1,150 DEG C, and the V / III ratio is 200-300. The interaction of dislocation is enhanced by growing thenucleating layer according to the three sub-layers, so that various dislocations caused by a pressure stress between the AlN thin-film buffer layer and GaN can be reduced, and the surface mobility ofAl atoms is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

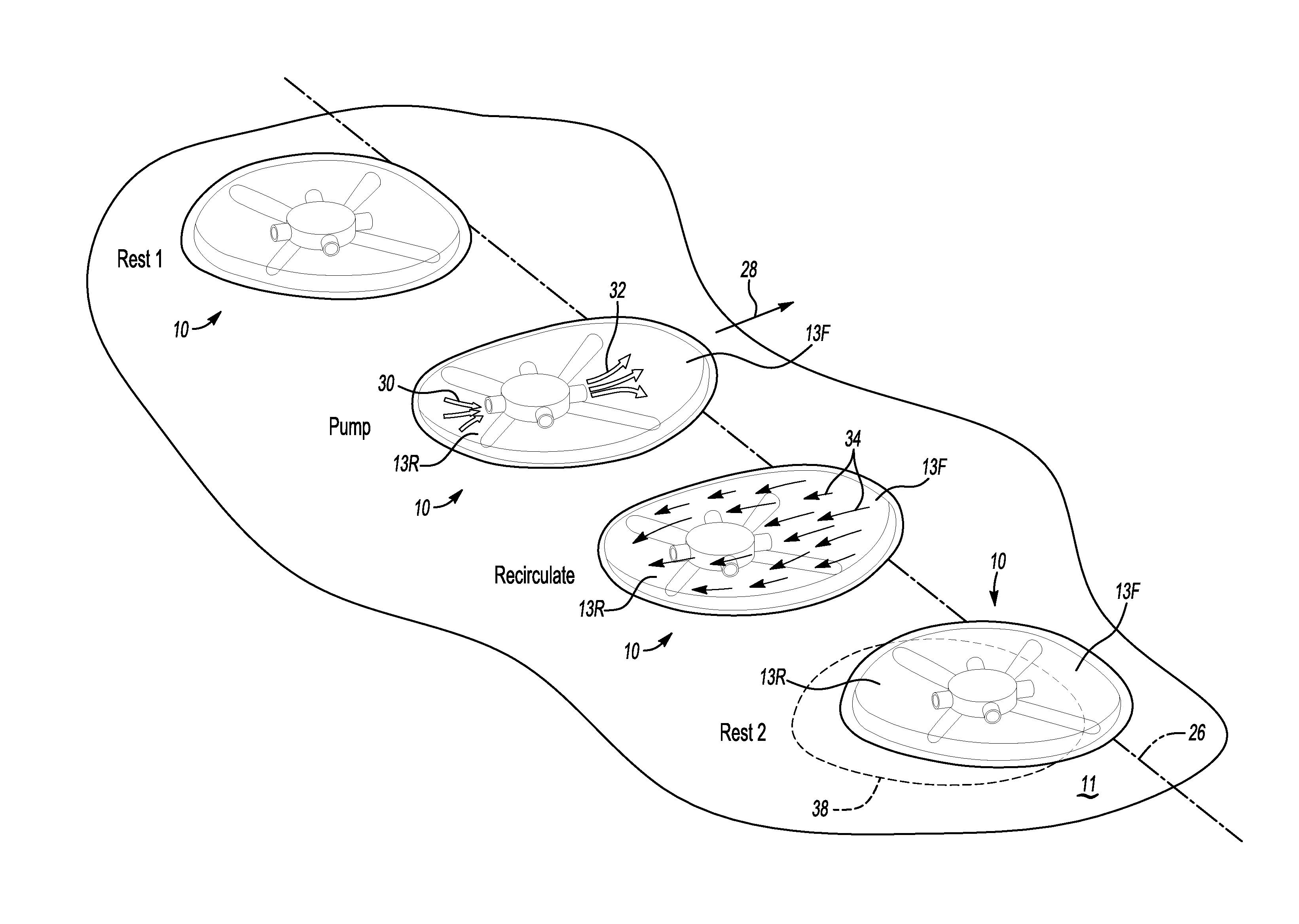

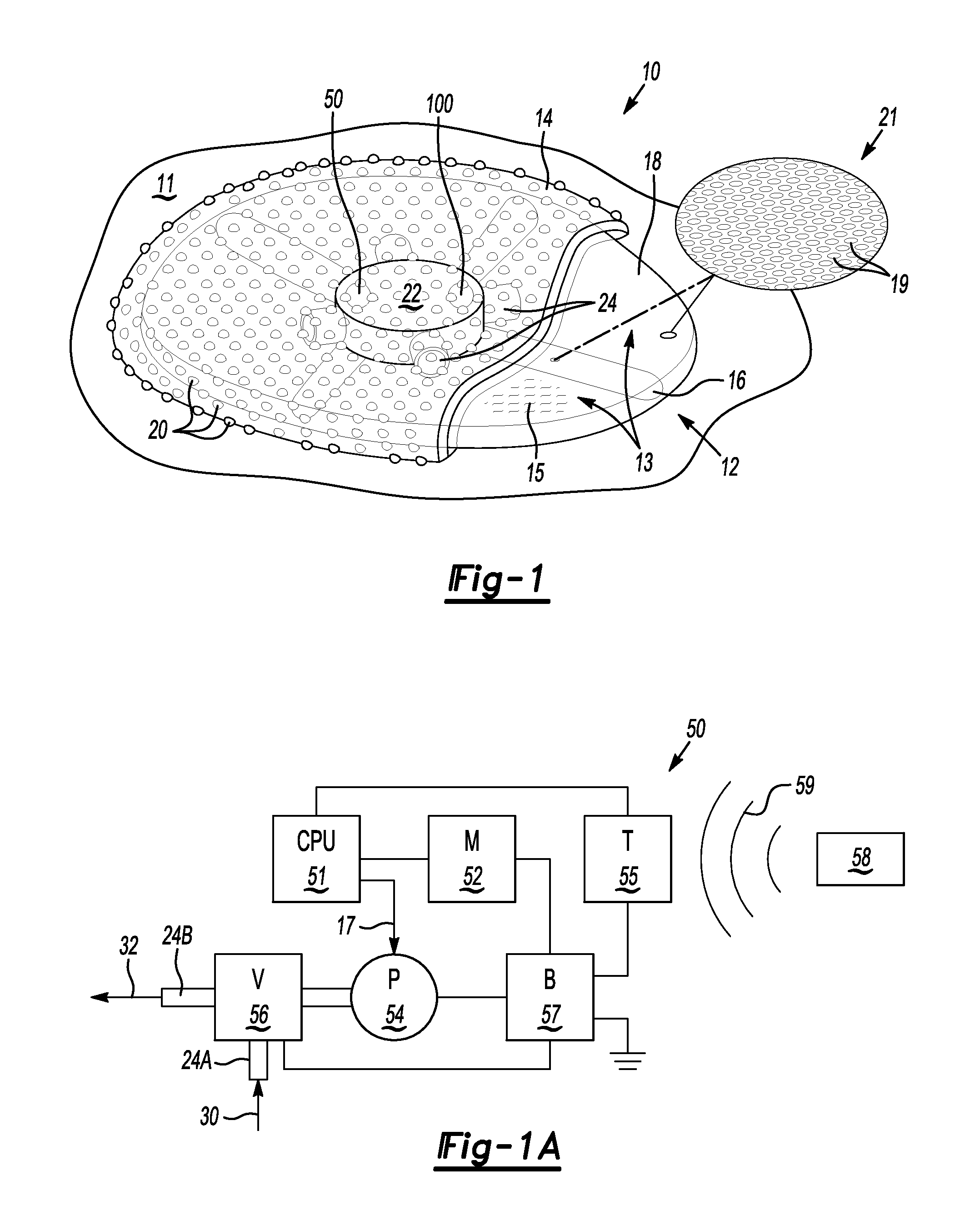

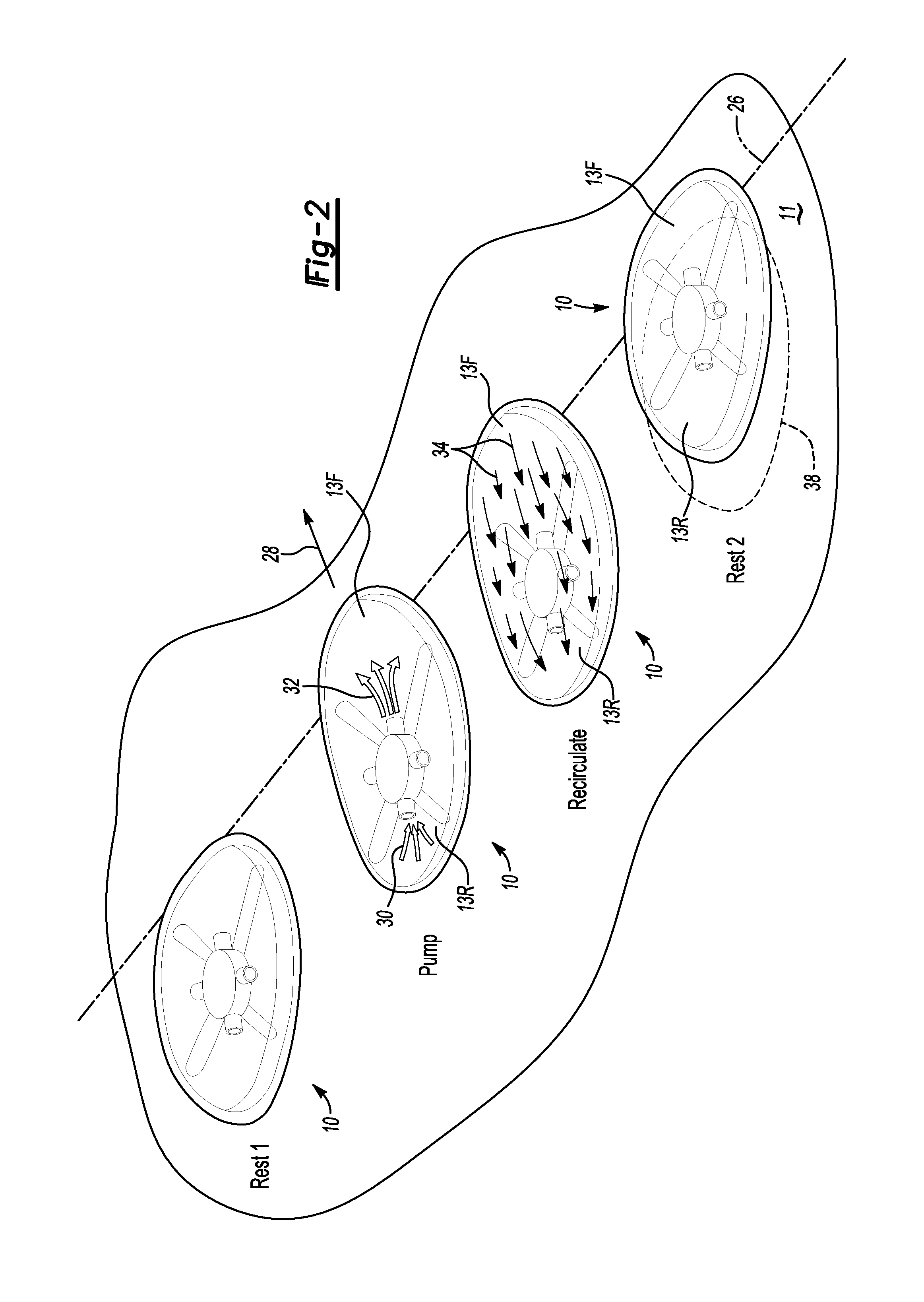

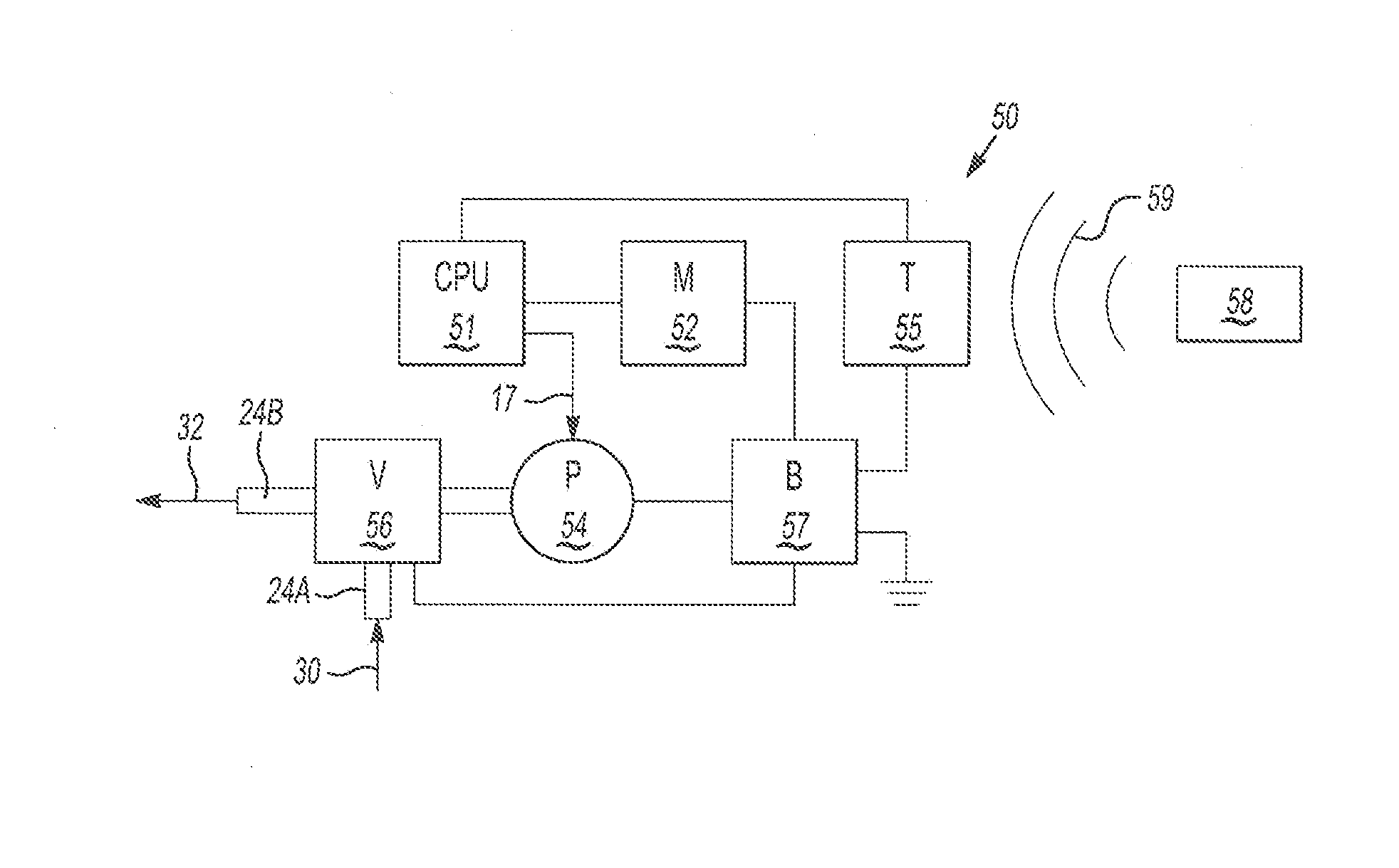

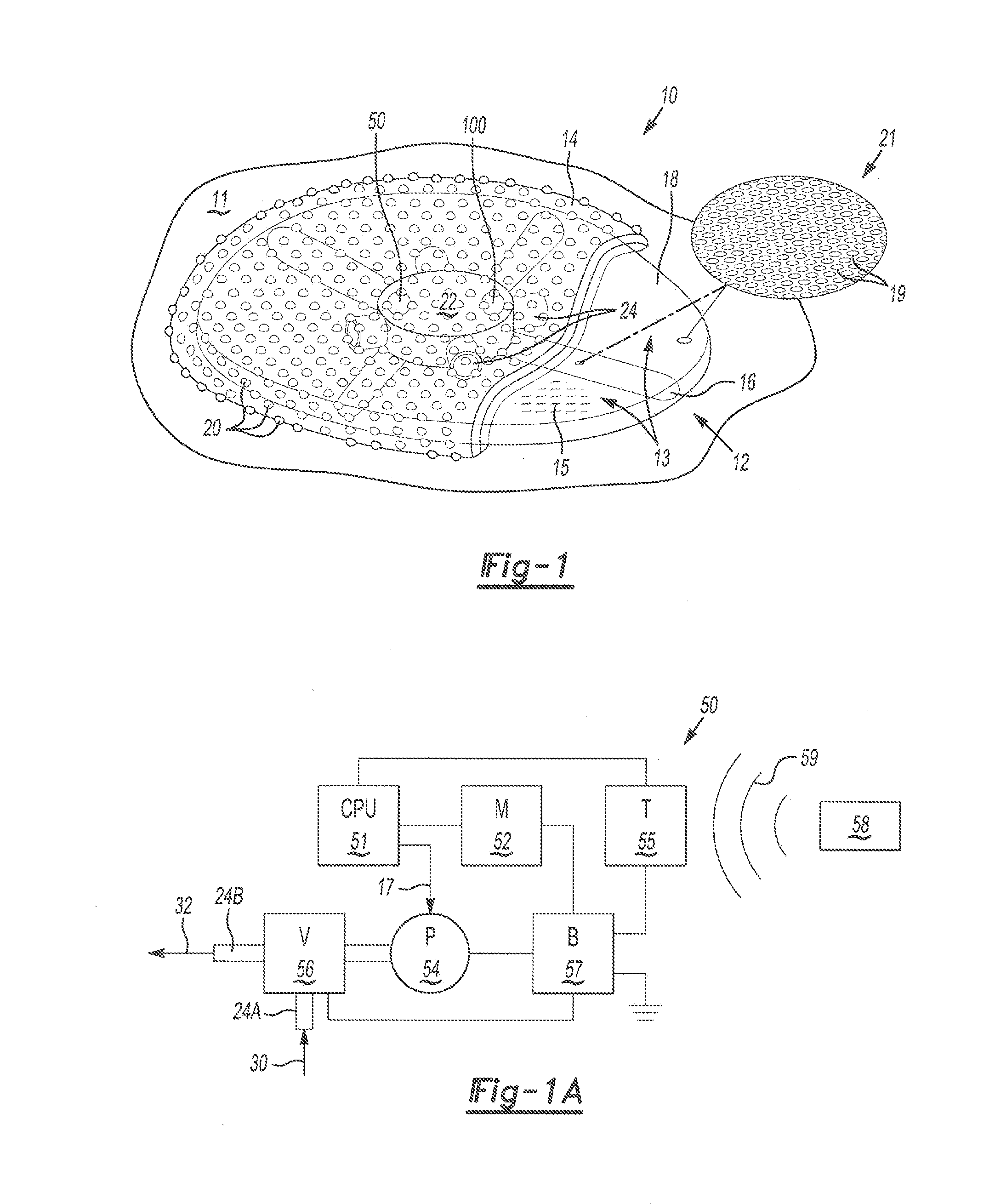

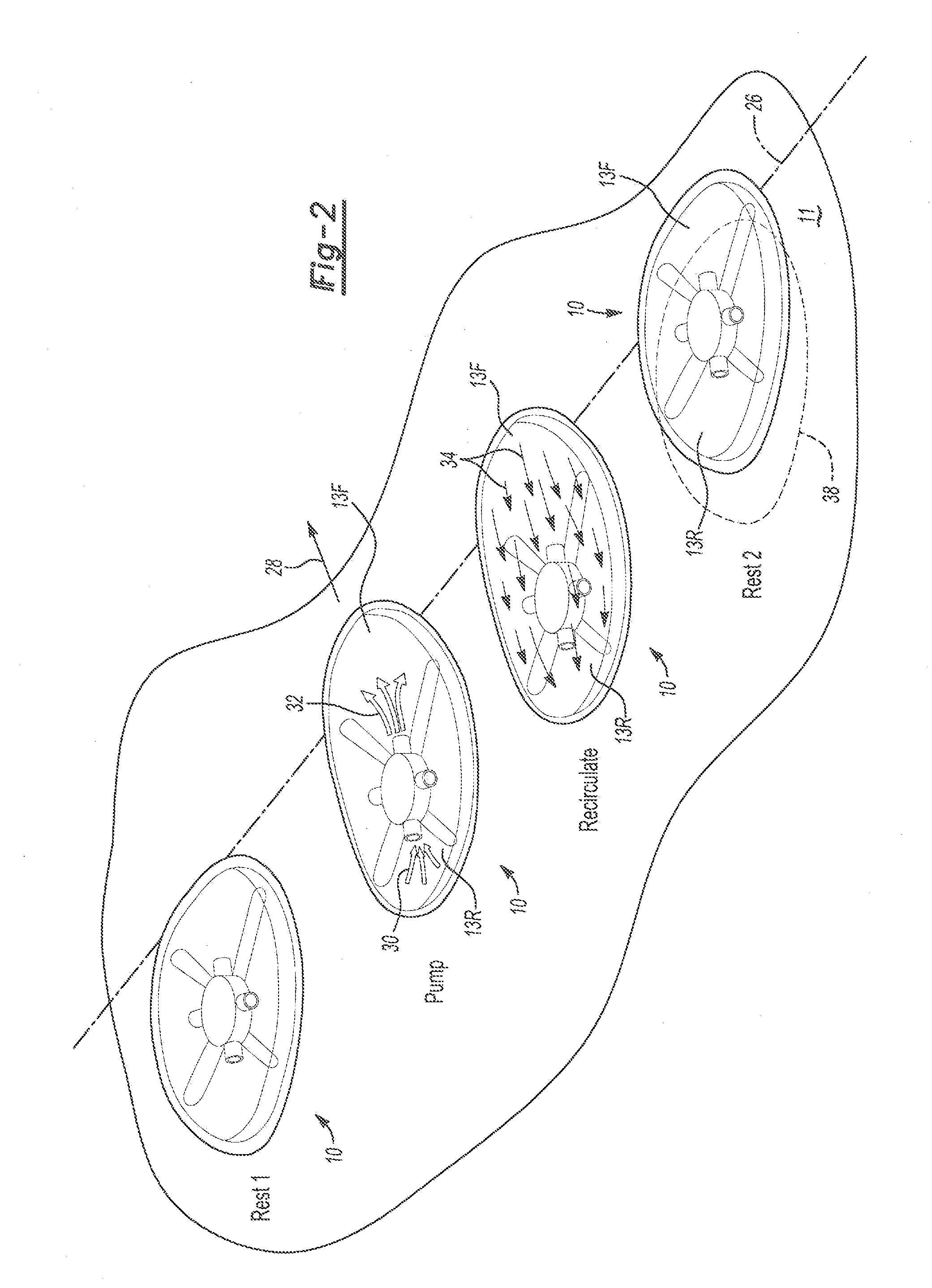

Locomotion of amorphous surface robots

InactiveUS8662213B2Improve surface mobilityImprove protectionExtraterrestrial carsRobotActuatorFerrofluid

An amorphous robot includes a compartmented bladder containing fluid, a valve assembly, and an outer layer encapsulating the bladder and valve assembly. The valve assembly draws fluid from a compartment(s) and discharges the drawn fluid into a designated compartment to displace the designated compartment with respect to the surface. Another embodiment includes elements each having a variable property, an outer layer that encapsulates the elements, and a control unit. The control unit energizes a designated element to change its variable property, thereby moving the designated element. The elements may be electromagnetic spheres with a variable polarity or shape memory polymers with changing shape and / or size. Yet another embodiment includes an elongated flexible tube filled with ferrofluid, a moveable electromagnet, an actuator, and a control unit. The control unit energizes the electromagnet and moves the electromagnet via the actuator to magnetize the ferrofluid and lengthen the flexible tube.

Owner:NASA

Locomotion of Amorphous Surface Robots

InactiveUS20140180524A1Improve surface mobilityImprove protectionExtraterrestrial carsRobotElectrical polarityActuator

An amorphous robot includes a compartmented bladder containing fluid, a valve assembly, and an outer layer encapsulating the bladder and valve assembly. The valve assembly draws fluid from a compartment(s) and discharges the drawn fluid into a designated compartment to displace the designated compartment with respect to the surface. Another embodiment includes elements each having a variable property, an outer layer that encapsulates the elements, and a control unit. The control unit energizes a designated element to change its variable property, thereby moving the designated element. The elements may be electromagnetic spheres with a variable polarity or shape memory polymers with changing shape and / or size. Yet another embodiment includes an elongated flexible tube filled with ferrofluid, a moveable electromagnet, an actuator, and a control unit. The control unit energizes the electromagnet and moves the electromagnet via the actuator to magnetize the ferrofluid and lengthen the flexible tube.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTRATOR NAT AERONAUTICS & SPACE ADMINISTRATION

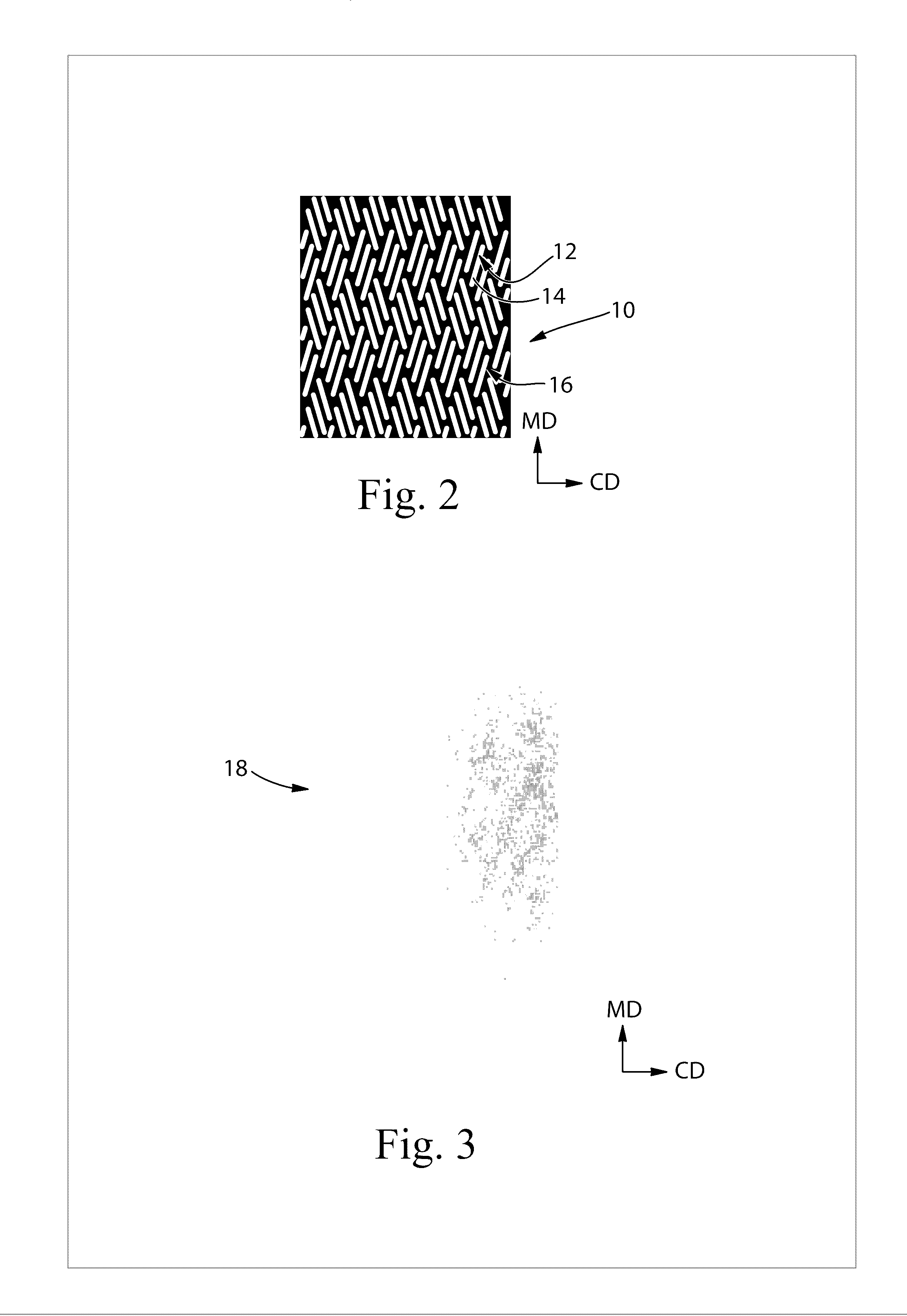

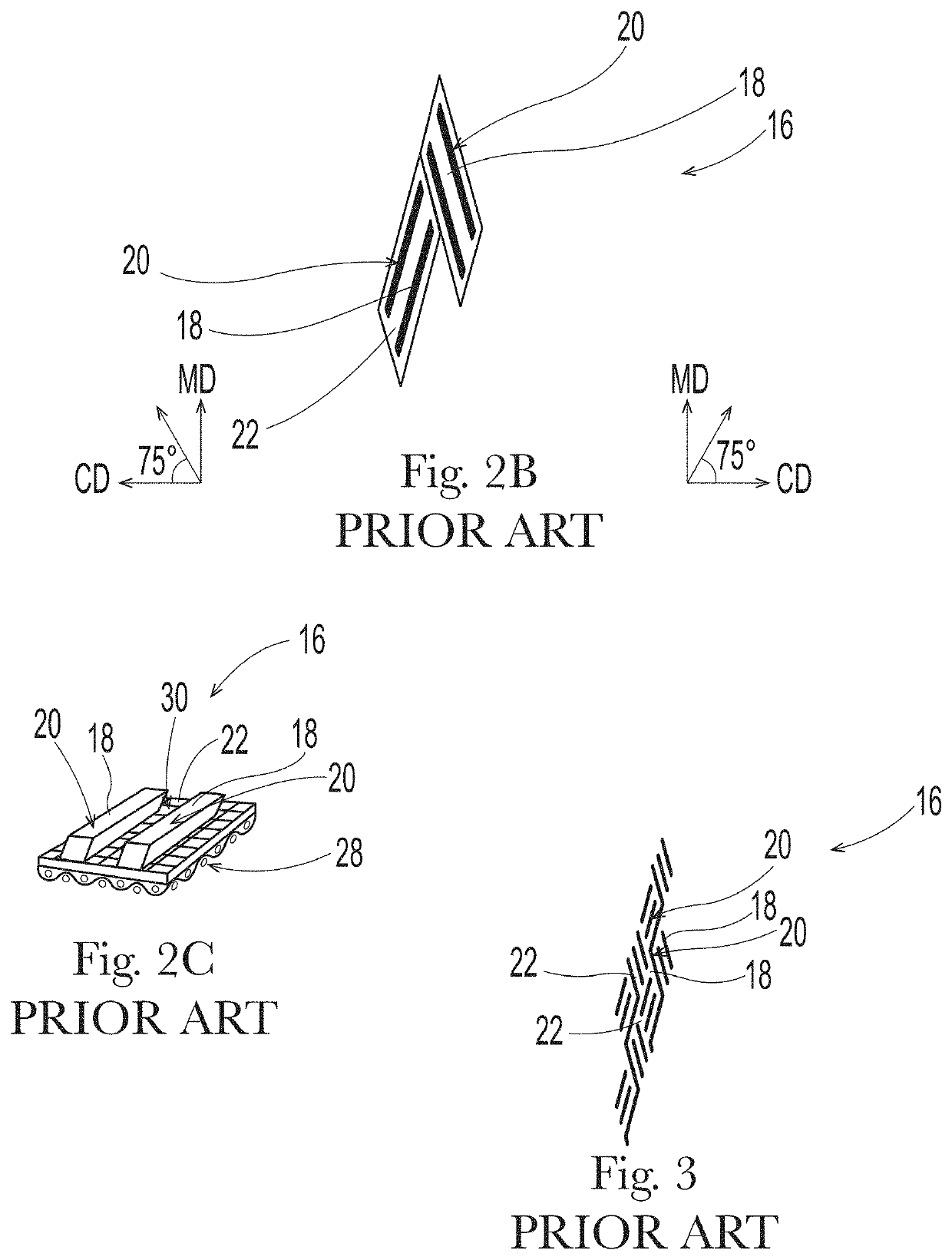

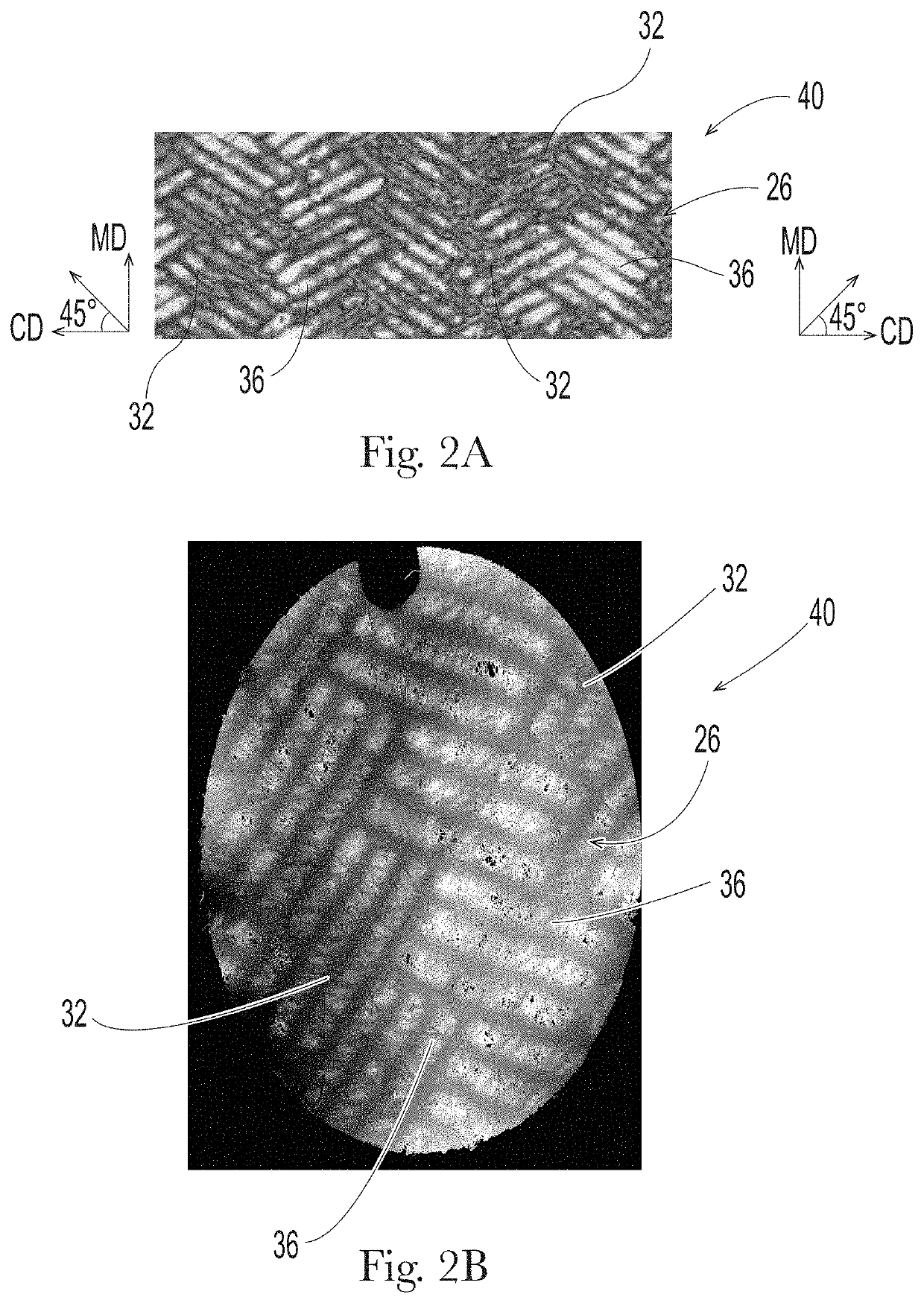

Fibrous Structures and Methods for Making Same

PendingUS20210332531A1Good flexibilityEasy to controlDryer sectionPaper/cardboardSurface patternClassical mechanics

Fibrous structures having a surface pattern of a continuous knuckle region and a plurality of discrete pillow regions such that the fibrous structures exhibit improved softness compared to known fibrous structures and better sheet control during the making of such fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

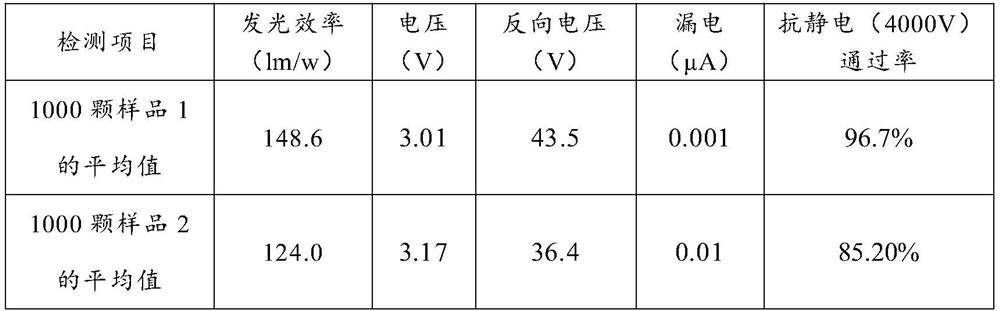

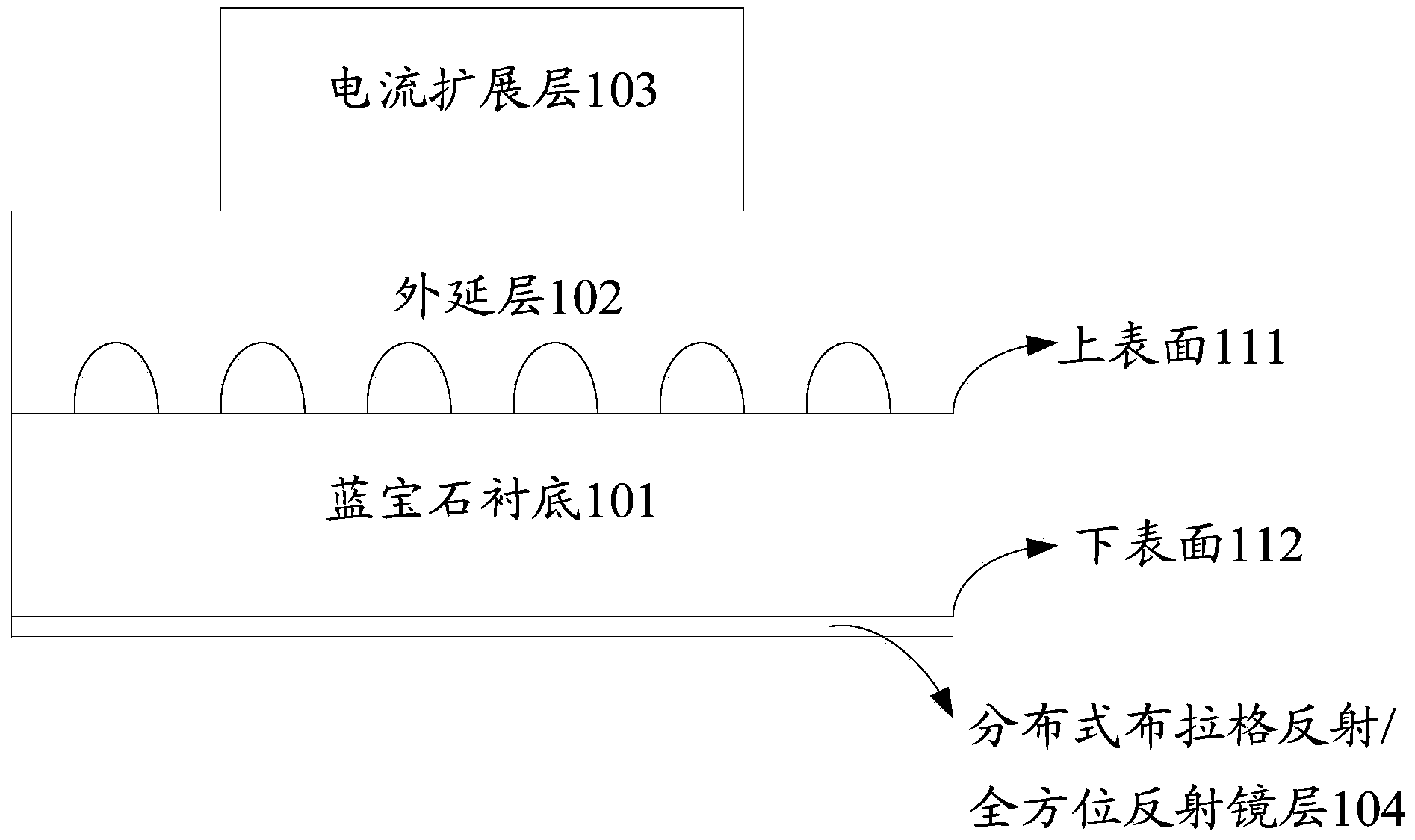

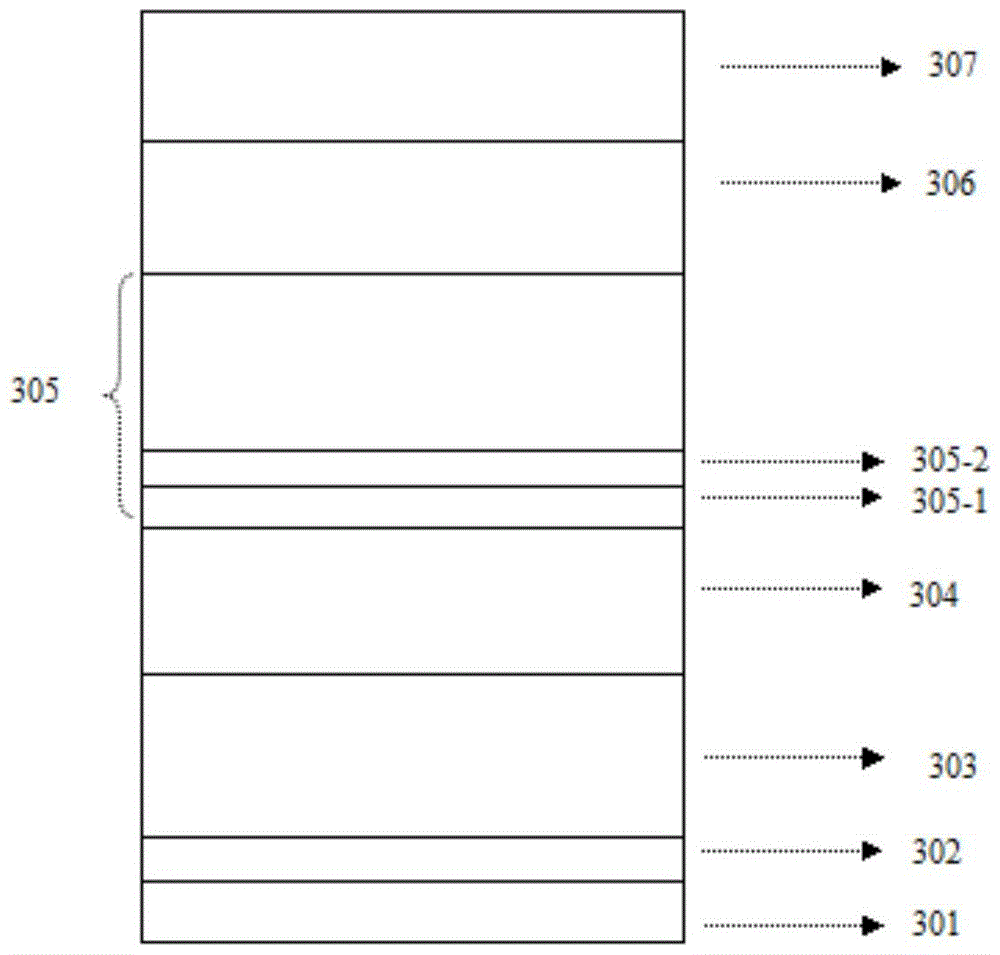

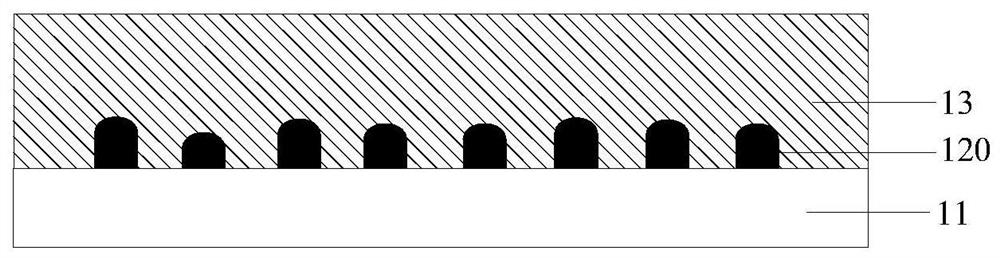

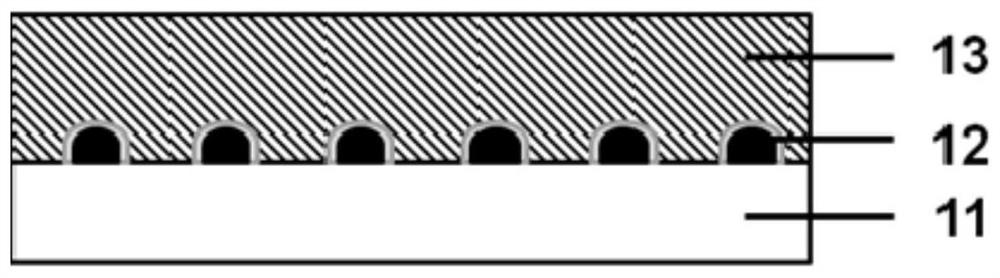

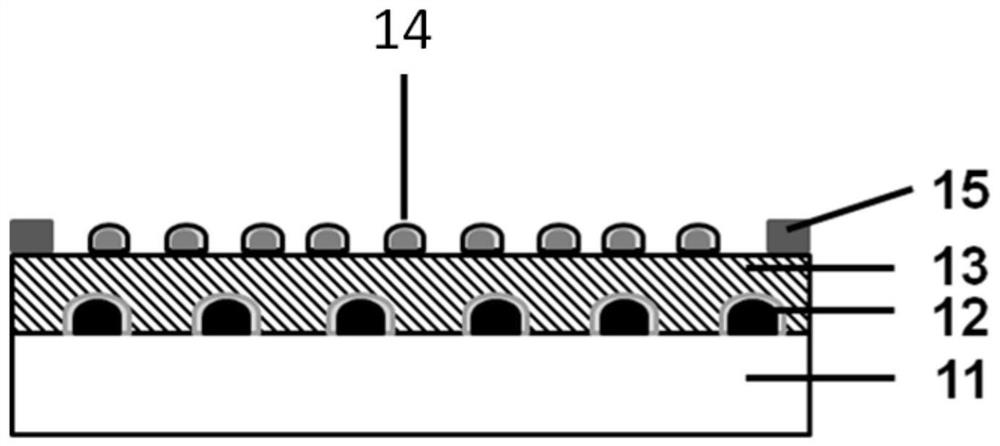

Epitaxial wafer of light emitting diode and manufacturing method of epitaxial wafer of light emitting diode

ActiveCN104269475AImprove surface mobilityChange surface topographySemiconductor devicesPhysicsEpiwafer

The invention discloses an epitaxial wafer of a light emitting diode and a manufacturing method of the epitaxial wafer of the light emitting diode. The manufacturing method relates to a low-temperature buffer layer GaN, an undoped GaN layer, a Si-doped N-type GaN layer, a light emitting layer, a P-type GaN layer and a high-temperature P-type GaN layer, wherein the undoped GaN layer is located on the low-temperature buffer layer GaN, the Si-doped N-type GaN layer is located on the undoped GaN layer, the light emitting layer is located on the Si-doped N-type GaN layer, the P-type GaN layer is located on the light emitting layer, and the high-temperature P-type GaN layer is located on the P-type GaN layer. The light emitting layer comprises InGaN layers and GaN layers in a plurality of periods, and the InGaN layer in each period grows through time slicing. By means of the epitaxial wafer of the light emitting diode and the manufacturing method of the epitaxial wafer of the light emitting diode, InGaN of the light emitting layer grows in a subsection mode, the feature of the surface can be changed, the surface migration rate of In atoms is improved, and the light emitting rate of the light emitting diode is accordingly improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Lotioned Fibrous Structures and Methods for Making Same

PendingUS20220341096A1Improved lotion transferGood sheet controlNon-fibrous pulp additionDryer sectionSurface patternStructural engineering

Fibrous structures having a surface pattern of a continuous knuckle region and a plurality of discrete pillow regions such that the fibrous structures exhibit improved lotion transfer compared to known fibrous structures and better sheet control during the making of such fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

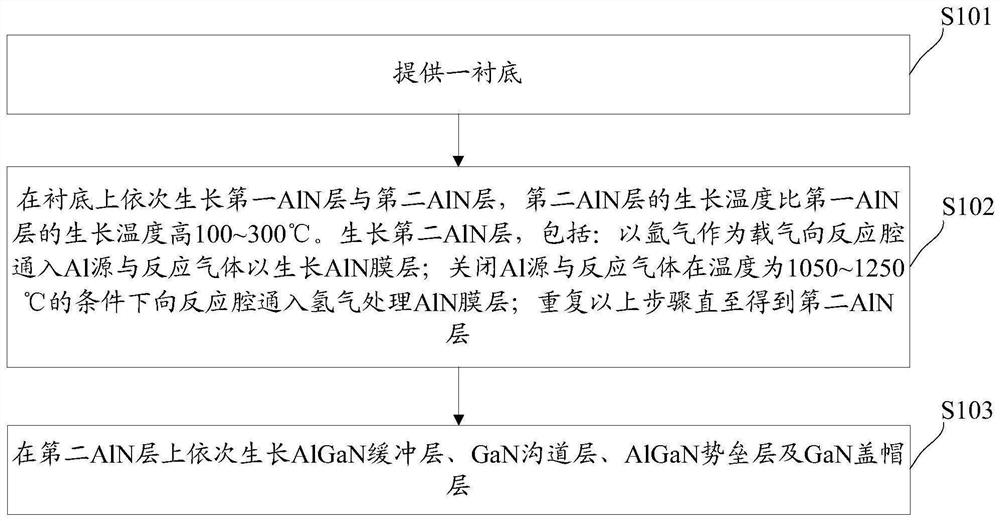

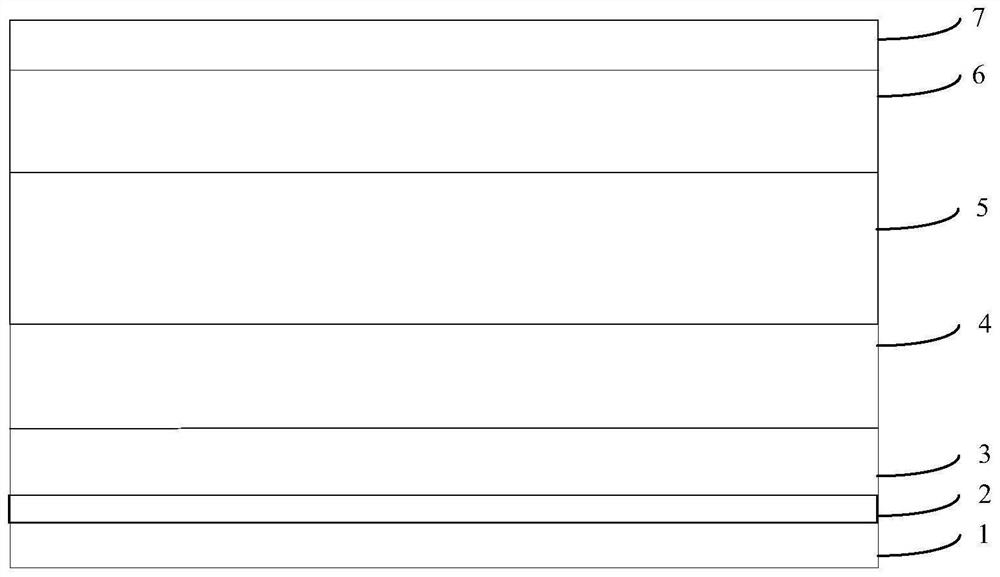

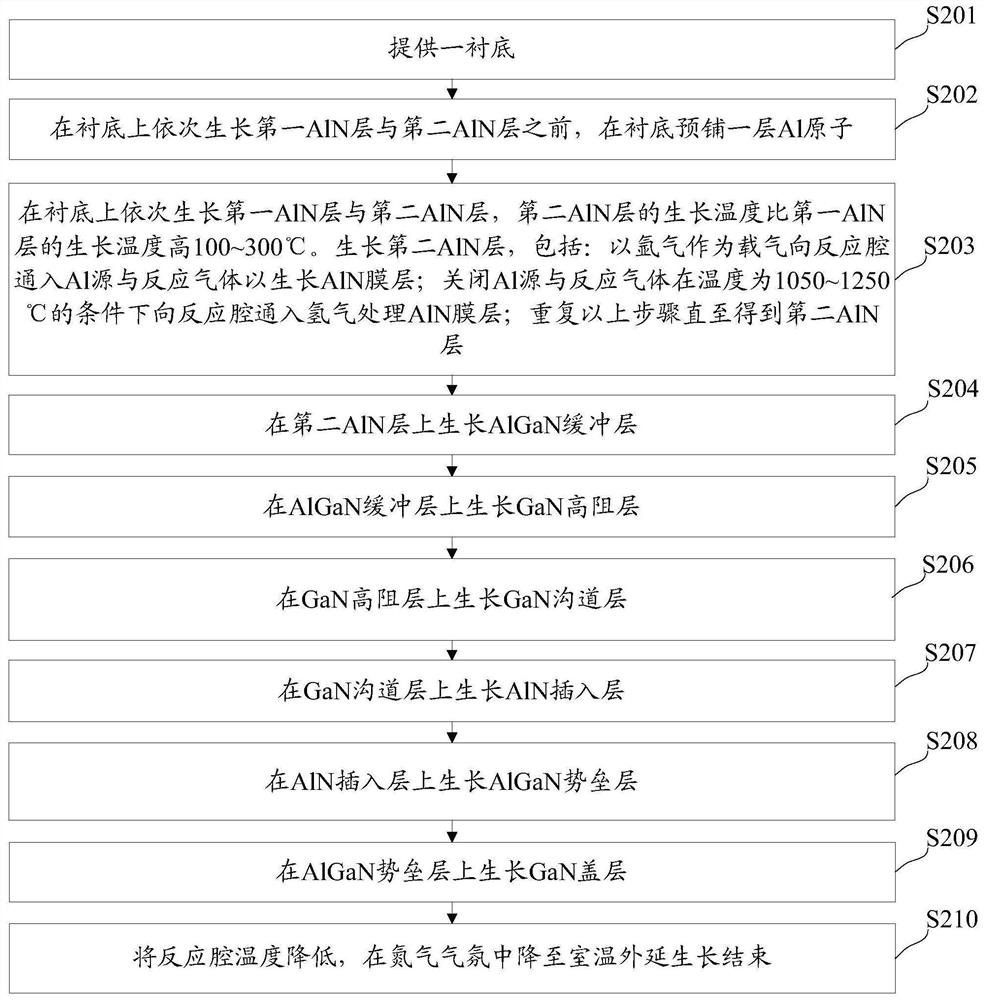

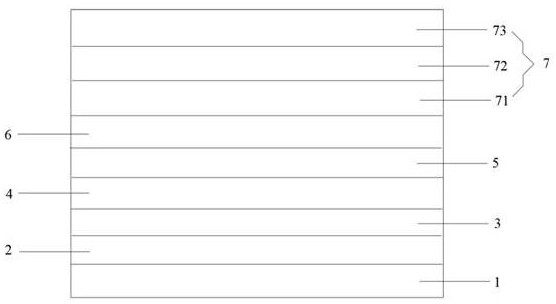

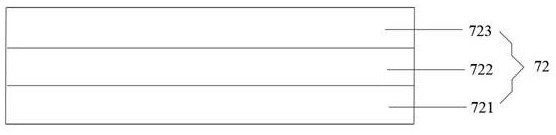

Preparation method for improving quality of high electron mobility transistor epitaxial wafer

PendingCN114220729AHigh atomic massQuality improvementPolycrystalline material growthAfter-treatment detailsDevice materialPhysical chemistry

The invention provides a preparation method for improving the quality of a high-electron-mobility transistor epitaxial wafer, and belongs to the technical field of semiconductor devices. The first AlN layer and the second AlN layer are sequentially grown on the substrate, the growth temperature of the second AlN layer is 100-300 DEG C higher than that of the first AlN layer, stress is released, and quality is improved. In the process of growing the second AlN layer, Ar is used as carrier gas for growth, plane movement of Al atoms is promoted, and the growth uniformity is improved. For the AlN film layer formed in the process of growing the second AlN layer, H2 treatment is carried out under the high temperature condition to reduce dislocation, the quality of the second AlN layer is improved, and the quality of the first AlN layer, the quality of the second AlN layer and the growing AlGaN buffer layer can also be improved. The quality improvement of the bottom layer structure can improve the quality of the high-electron-mobility transistor epitaxial wafer which finally grows continuously on the bottom layer structure.

Owner:HC SEMITEK ZHEJIANG CO LTD

A kind of LED epitaxial wafer, epitaxial growth method and LED chip

ActiveCN114256395BSolve low luminous efficiencyLuminous efficiency is stableSemiconductor devicesElectron holeElectron radiation

The invention provides an LED epitaxial wafer, an epitaxial growth method, and an LED chip. The LED epitaxial wafer includes a P-type layer, the P-type layer includes an electron blocking layer, a transition layer and a contact layer, and the transition layer includes a first sublayer and is sequentially deposited on the second sublayer. Second and third sublayers on one sublayer, first sublayer is P‑Al 1‑x sc x N layer, second sublayer is GaN layer, third sublayer is N‑Al 1‑y sc y N layers. In the present invention, the first sublayer and the third sublayer respectively form a heterojunction interface with the second sublayer, and opposite positive and negative piezoelectric polarization charge densities are generated at the heterojunction interface, which will cause a large number of Non-equilibrium holes are injected into the first sublayer, and then injected into the active region to undergo radiative recombination with electrons, which alleviates the situation of less hole generation due to the high acceptor activation energy of the P-type layer, and solves the problem of ultraviolet light-emitting diodes. The problem of low luminous efficiency.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

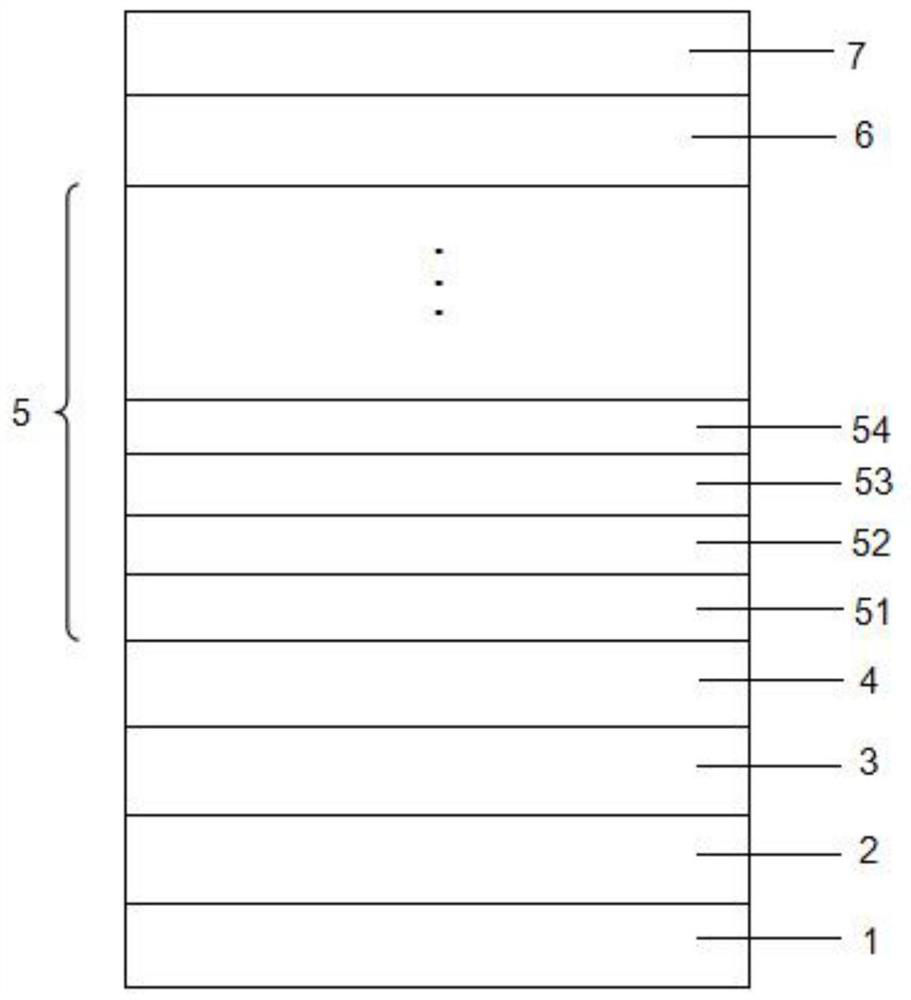

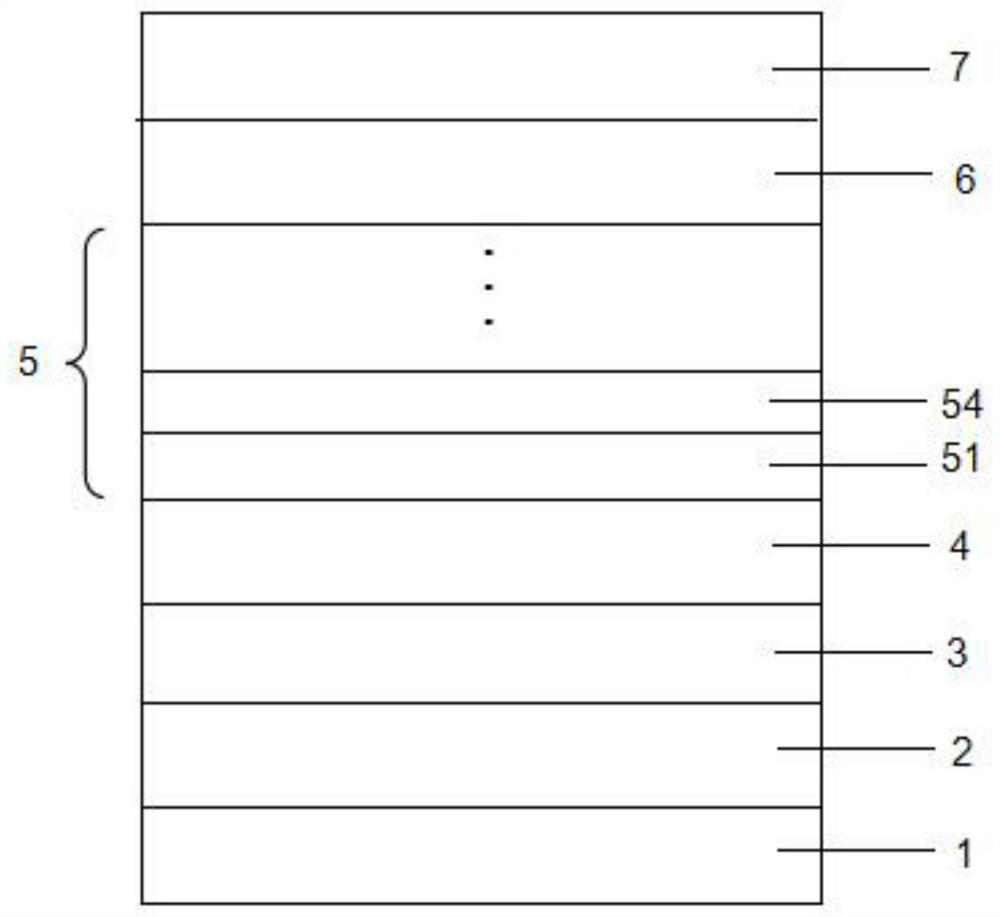

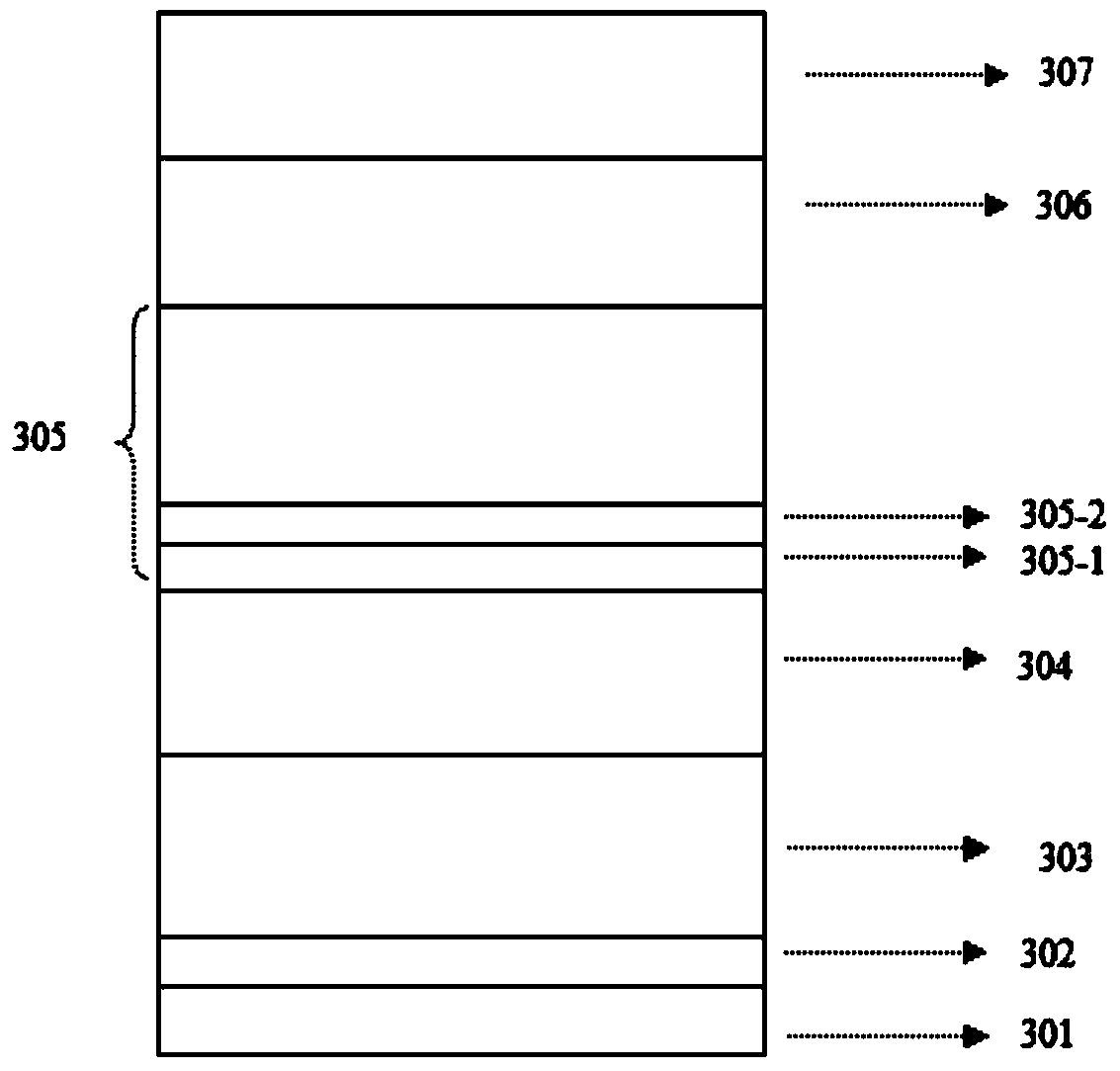

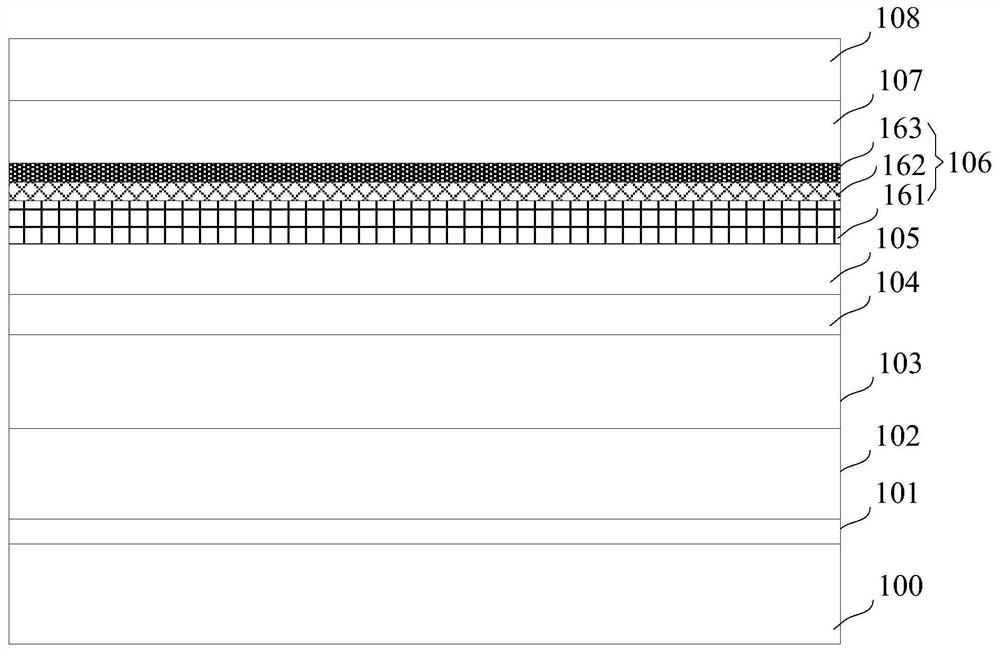

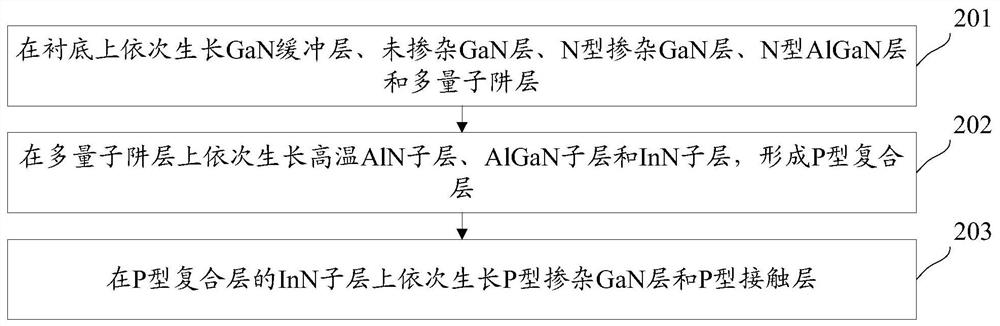

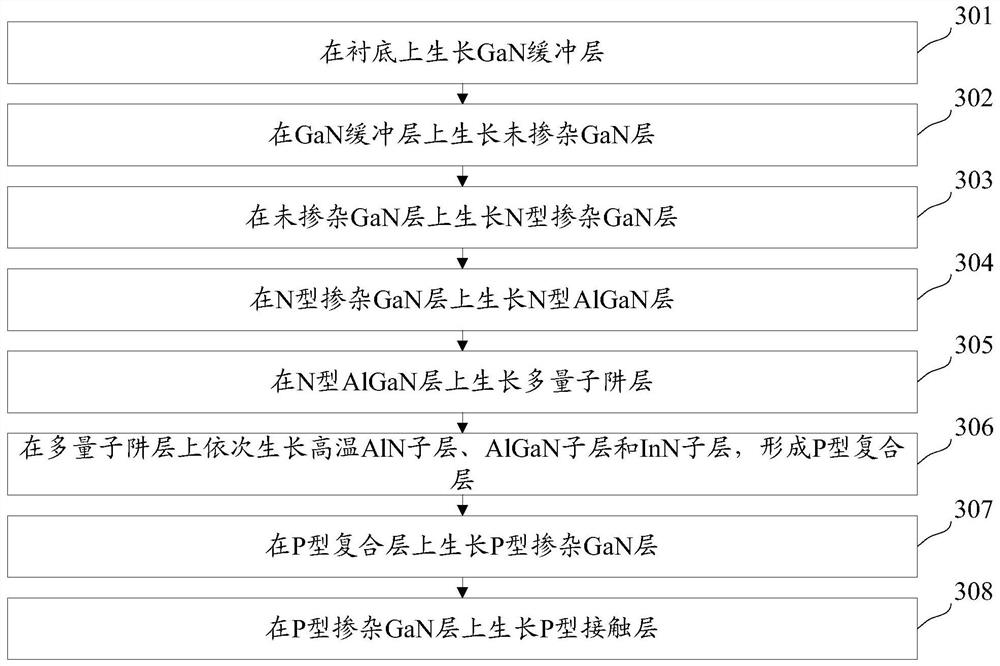

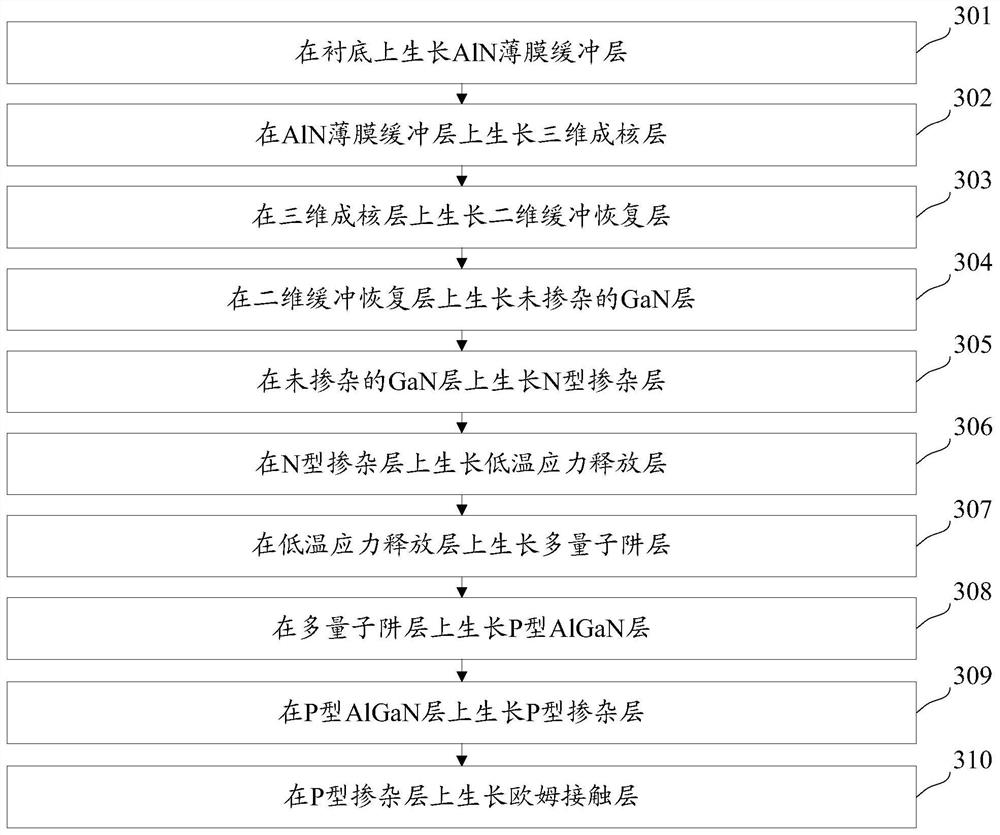

Light-emitting diode epitaxial wafer and preparation method thereof, light-emitting diode

The invention discloses a light emitting diode, and an epitaxial wafer and a preparation method thereof, and belongs to the technical field of epitaxy. The epitaxial wafer of the light emitting diodecomprises: a substrate, and a gallium nitride buffer layer, an undoped gallium nitride layer, an N-type doped gallium nitride layer, an N-type aluminum gallium nitride layer, a multi-quantum well layer, a P-type composite layer, a P-type doped gallium nitride layer and a P-type contact layer, which are laminated on the substrate in sequence; the P-type composite layer comprises: a high-temperaturealuminum nitride sub-layer located on the multi-quantum well layer, an aluminum gallium nitride sub-layer located on the high-temperature aluminum nitride sub-layer, and an indium-containing nitridesub-layer located on the aluminum gallium nitride sub-layer, and the P-type doped gallium nitride layer is located on the indium-containing nitride sub-layer. By means of the P-type composite layer comprising three sub-layers, the electron blocking effect is improved on one hand, and the smooth pass of holes is ensured on the other hand.

Owner:HC SEMITEK ZHEJIANG CO LTD

Epitaxial wafer of light emitting diode and manufacturing method thereof

ActiveCN104269475BImprove surface mobilityChange surface topographySemiconductor devicesLight-emitting diodeSi doped

The invention discloses an epitaxial wafer of a light emitting diode and a manufacturing method of the epitaxial wafer of the light emitting diode. The manufacturing method relates to a low-temperature buffer layer GaN, an undoped GaN layer, a Si-doped N-type GaN layer, a light emitting layer, a P-type GaN layer and a high-temperature P-type GaN layer, wherein the undoped GaN layer is located on the low-temperature buffer layer GaN, the Si-doped N-type GaN layer is located on the undoped GaN layer, the light emitting layer is located on the Si-doped N-type GaN layer, the P-type GaN layer is located on the light emitting layer, and the high-temperature P-type GaN layer is located on the P-type GaN layer. The light emitting layer comprises InGaN layers and GaN layers in a plurality of periods, and the InGaN layer in each period grows through time slicing. By means of the epitaxial wafer of the light emitting diode and the manufacturing method of the epitaxial wafer of the light emitting diode, InGaN of the light emitting layer grows in a subsection mode, the feature of the surface can be changed, the surface migration rate of In atoms is improved, and the light emitting rate of the light emitting diode is accordingly improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

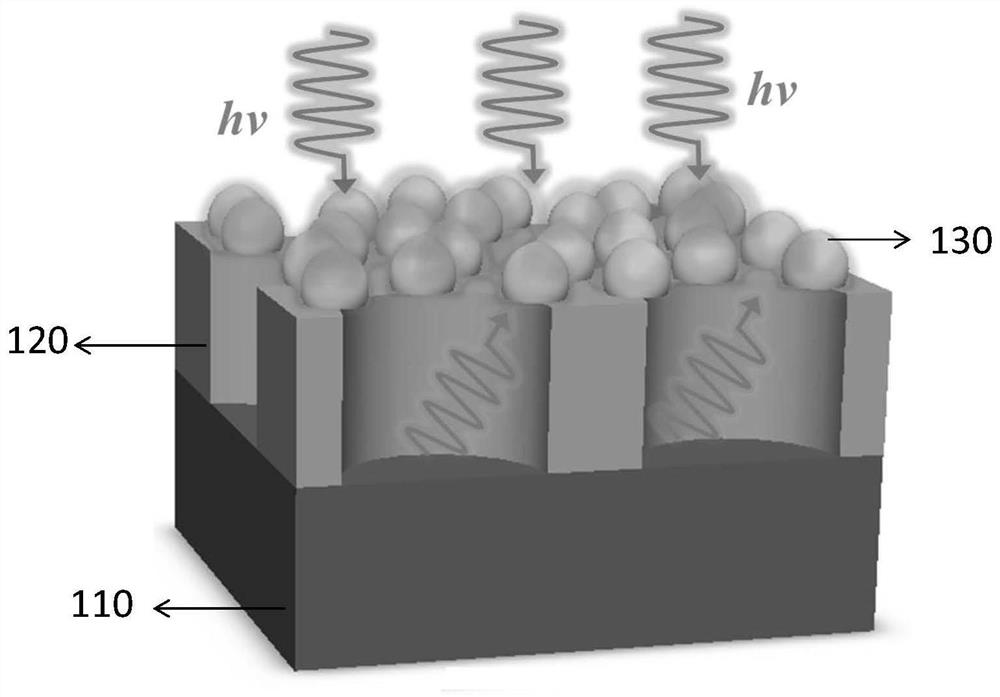

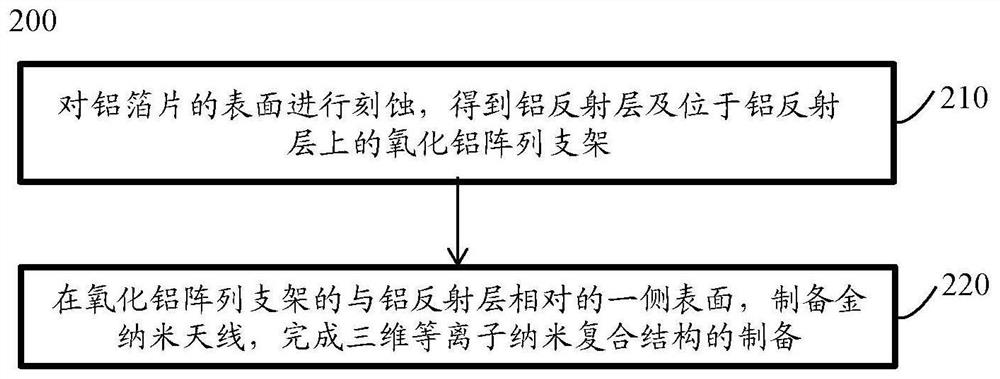

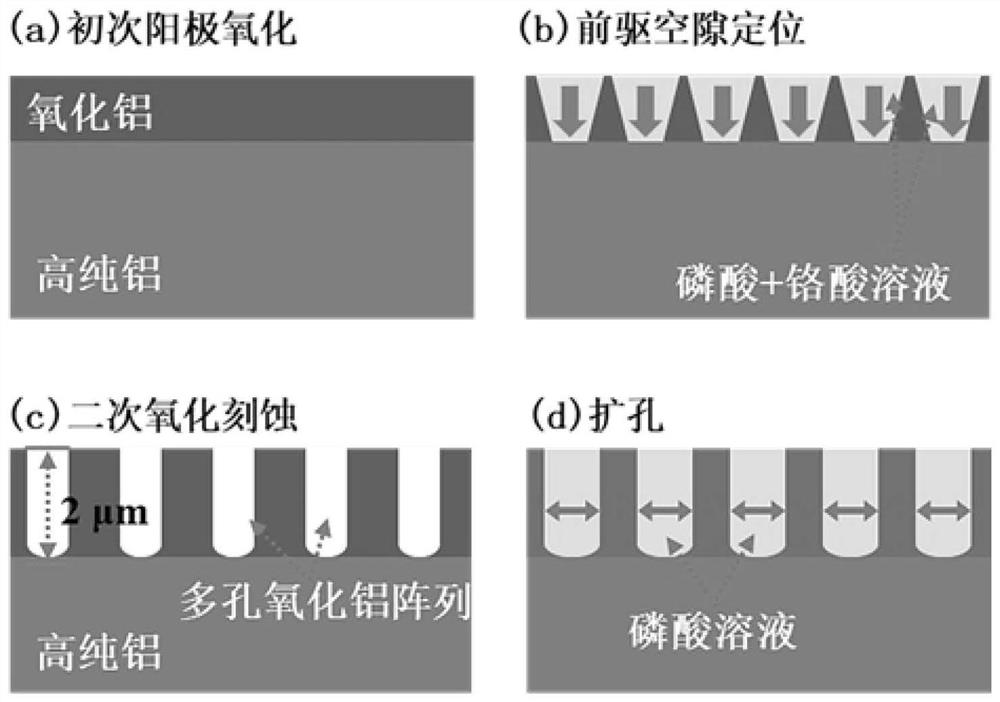

A three-dimensional plasmonic nanocomposite structure and its preparation method and application

ActiveCN110190141BRealize repeated useAchieve captureMaterial nanotechnologyFinal product manufactureMaterials scienceComposite structure

The invention discloses a three-dimensional plasma nanocomposite structure and its preparation method and application. The structure comprises: an aluminum reflection layer, an aluminum oxide array bracket, and a gold nanometer antenna. The aluminum oxide array bracket is arranged on the aluminum reflection layer; the gold nano-antenna is arranged on the side surface of the aluminum oxide array bracket opposite to the aluminum reflection layer. In order to prevent the overflow of the incident light, the present invention introduces the aluminum reflective layer and the aluminum oxide array resonant cavity, and combines the advantages of the aluminum reflective layer with strong light interference effect, the aluminum oxide array resonant cavity and the self-assembled gold nano antenna with strong surface plasmon effect, through The coupling effect of the reflective layer, the aluminum oxide array support and the gold nano-antenna can effectively clamp the light wave on the surface of the nanocomposite structure, realize the repeated utilization of the incident light wave, effectively improve the light utilization rate of the light-sensitive layer, and break through the light of traditional light detection materials. Absorption rate limitation.

Owner:HUAZHONG UNIV OF SCI & TECH +1

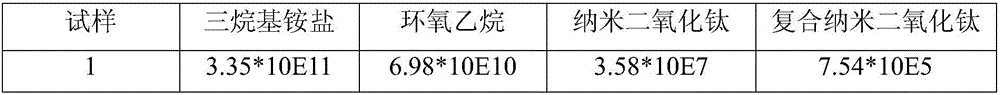

Semiconductor modified polypropylene and preparation method thereof

InactiveCN106009257AIncrease the precipitation rateImprove conductivityAntistatic agentSurface conductivity

The invention discloses semiconductor modified polypropylene (PP) and a preparation method thereof. The preparation method comprises the following steps: 1) drying polypropylene plastic particles; 2) adding the dried polypropylene plastic particles, POE, filler and anti-static agent HKD-151 into a mixer, and mixing for 25-30min; and 3) extruding and blending the mixture obtained in the step 2) by a twin-screw extruder at 185-220 DEG C, wherein the screw speed is 40-45rpm; and performing extrusion, staying, cooling and granulation to obtain semiconductor modified PP particles, wherein 9-11V voltage is applied to the mouth mould position of the twin-screw extruder. The invention also discloses semiconductor modified polypropylene prepared by the preparation method. In the invention, by adding a proper antistatic agent and improving the technology, the surface conductivity of the product is improved so as to reduce static generation as much as possible.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

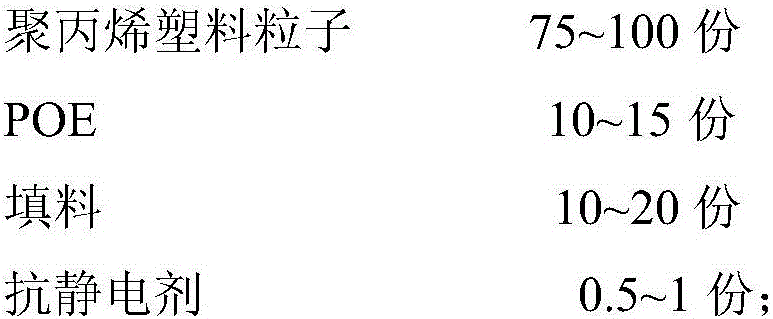

Modified polypropylene material for improving antistatic property

The invention discloses a modified polypropylene material for improving the antistatic property. The modified polypropylene material is prepared from, by weight, 75-100 parts of polypropylene plastic particles, 10-15 parts of POE, 10-20 parts of filler and 0.5-1 part of an antistatic agent. The antistatic agent is prepared from nano-titanium oxide, ethylene oxide and trialkyl ammonium salt at the mass ratio of (40-50):(30-40):(10-30). According to the modified polypropylene material for improving the antistatic property, the surface conductivity of the product is improved by adding the proper antistatic agent, and thus static is reduced as much as possible.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

LED wafer and its preparation method and LED lamp

ActiveCN107808916BImprove surface mobilityQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesQuantum wellComposite substrate

Owner:ZHEJIANG SHUAIKANG ELECTRIC

A kind of p-type Aln thin film and its preparation method and application

ActiveCN111146299BImprove crystal qualityGood optical performanceFinal product manufactureSemiconductor devicesNanodotOptical property

The invention discloses a p-type AlN thin film and its preparation method and application. The structure of the thin film from bottom to top is a substrate, a PtLi or PtLi@PtLiO nano-dot layer and an AlZnLiN thin film layer. The preparation method comprises the following steps: S1, forming a PtLi layer on a substrate, annealing the PtLi layer to obtain a nanoparticle layer; S2, growing an AlZnN thin film layer on the substrate processed by the above steps, and (600-900) ° C and keep it warm for (0.5-12) h, Li atoms overflow into the AlZnN thin film layer, thereby obtaining the AlZnLiN thin film layer. The invention has ingenious scheme design, simple preparation and operation, and the prepared material has good crystal quality and optical performance.

Owner:WUYI UNIV

Gan-based light-emitting diode epitaxial wafer and preparation method thereof, light-emitting diode

ActiveCN109920722BReduce spacingLow densityVacuum evaporation coatingSemiconductor/solid-state device manufacturingThin membraneLight-emitting diode

The invention discloses a GaN-based light-emitting diode epitaxial wafer, a preparation method thereof, and a light-emitting diode, belonging to the field of epitaxy technology. The GaN-based light-emitting diode epitaxial wafer includes a substrate, and an AlN thin film buffer layer, a three-dimensional nucleation layer, a two-dimensional buffer recovery layer and an epitaxial layer stacked on the substrate in sequence. The three-dimensional nucleation layer is a GaN layer; the three-dimensional nucleation layer includes The first nucleation sublayer, the second nucleation sublayer and the third nucleation sublayer stacked on the AlN film buffer layer in sequence; wherein, the growth pressure of the first nucleation sublayer is 150-250torr, and the growth temperature is 1000-1100°C, The V / III ratio is 500‑1000; the growth pressure of the second nucleation sublayer is 500‑700torr, the growth temperature is 900‑1000°C, and the V / III ratio is 100‑200; the growth pressure of the third nucleation sublayer is 100‑ 200torr, the growth temperature is 1100-1150℃, and the V / III ratio is 200-300. By growing the nucleation layer in three sublayers to enhance the interaction of dislocations, it can finally reduce various dislocations caused by the compressive stress between the AlN film buffer layer and GaN, and improve the surface mobility of Al atoms.

Owner:HC SEMITEK ZHEJIANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com