Modified polypropylene material for improving antistatic property

A polypropylene material and antistatic technology, applied in the field of improving antistatic modified polypropylene material and its preparation, can solve the hazards of circuit boards and electronic components, excessive PM2.5 in the car, and easy to absorb a large amount of dust and other problems, to achieve the effects of good antistatic performance, improved electrical conductivity, and improved surface mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

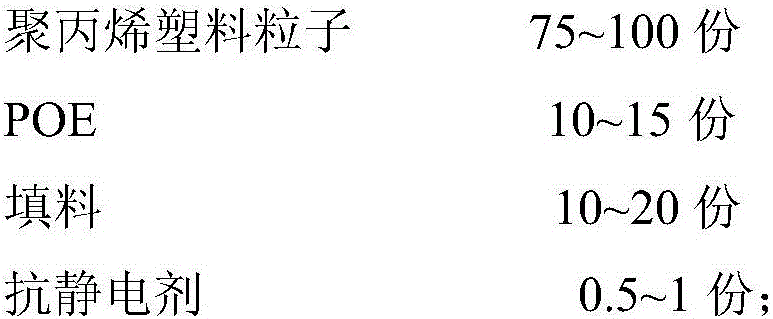

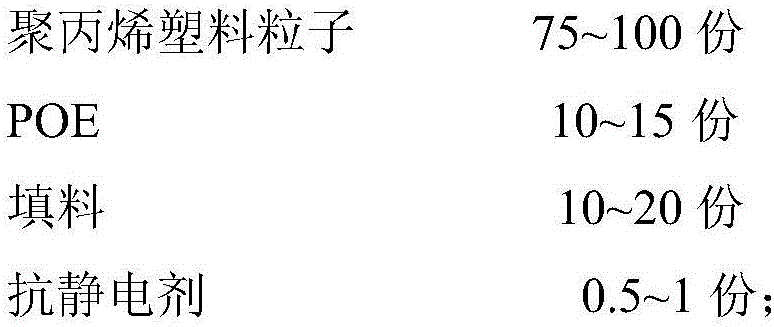

[0036] A general method for preparing a modified polypropylene material with improved antistatic properties, including:

[0037] 1) Drying the PP plastic particles, the drying method is as follows: treat the PP plastic particles at 80°C for 2 hours;

[0038] 2) Add the dried PP plastic particles, POE, filler talc powder and antistatic agent into the high-speed mixer, and mix at high speed for a period of time;

[0039] 3) The mixture prepared in step 2) is extruded and blended by a twin-screw extruder at 195-220°C, the die position is loaded with 10V voltage, the screw speed is 45rpm / min, after extrusion, stretching, cooling, Granulating to obtain a modified polypropylene material with improved antistatic properties.

Embodiment 1

[0041] Observe the effect of different antistatic agents on resistivity. The steps are:

[0042] 1) Dry the PP plastic particles (80°C, 2h);

[0043] 2) Add PP plastic particles, POE, talc powder and antistatic agent composite nano-titanium dioxide into a high-speed (mixing speed of 300 rpm) mixer, and mix at high speed for 28 minutes;

[0044] 3) The mixture prepared in step 2) is extruded and blended by a twin-screw extruder at 195-220°C, no voltage is applied to the die position, and the screw speed is 45rpm, after extrusion, stretching, cooling, and granulation , to obtain modified PP granular materials with improved antistatic properties;

[0045] 4) Homogenize the obtained modified PP particle samples with improved antistatic properties in the homogenization chamber for 30 minutes, then dry them at 120°C for 12 hours, and then injection mold them into standard test discs. The injection molding temperature is 215°C and the injection pressure is 30Mpa; After the wafer s...

Embodiment 2

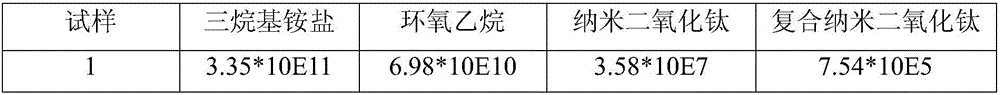

[0054] Separately use trialkylammonium salt, ethylene oxide, nano-titanium dioxide and compound nano-titanium dioxide of the present invention formula D to investigate its influence on the antistatic property of modified PP. The experimental steps are as follows:

[0055] 1) Dry the PP plastic particles (80°C, 2h);

[0056] 2) Add PP plastic particles, POE, talcum powder and antistatic agent into a high-speed (mixing speed of 300 rpm) mixer, and mix at high speed for 28 minutes;

[0057] 3) The mixture prepared in step 2) is extruded and blended by a twin-screw extruder at 195-220°C, no voltage is applied to the die position, and the screw speed is 45rpm, after extrusion, stretching, cooling, and granulation , to obtain modified PP particles with improved antistatic properties;

[0058] 4) Homogenize the obtained modified PP particle samples with improved antistatic properties in the homogenization chamber for 30 minutes, then dry them at 120°C for 12 hours, and then injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com