LED epitaxial wafer, epitaxial growth method and LED chip

An LED epitaxial wafer and epitaxial growth technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency of ultraviolet light-emitting diodes, and achieve the effects of enhancing surface mobility, reducing trapping, and avoiding a large number of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

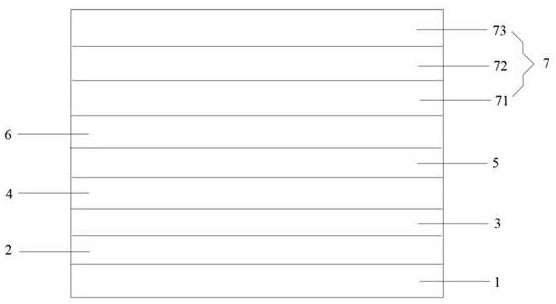

[0031] see figure 1 and figure 2 , shows the LED epitaxial wafer in Embodiment 1 of the present invention, including a sapphire substrate 1, an AlN buffer layer 2 epitaxially grown on the sapphire substrate 1, a three-dimensional island-shaped AlN growth layer 3, and a two-dimensional recovery AlN growth layer. layer 4, n-type AlGaN layer 5, multiple quantum well layer 6 and p-type layer 7.

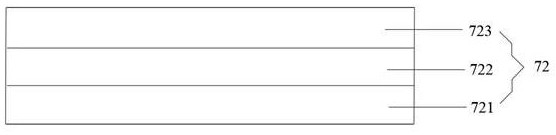

[0032] In this embodiment, the P-type layer 7 is a structure formed by sequentially growing an electron blocking layer 71, a transition layer 72, and a contact layer 73, wherein the transition layer 72 is formed by sequentially growing the first sublayer 721 on the electron blocking layer 71. , the second sublayer 722 and the third sublayer 723, it should be noted that the first sublayer 721 is P-Al 1-x sc x N layer, the second sublayer 722 is a GaN layer, and the third sublayer 723 is N-Al 1-y scy N layer, since the growth process of the epitaxial layer generally grows gradually fro...

Embodiment 2

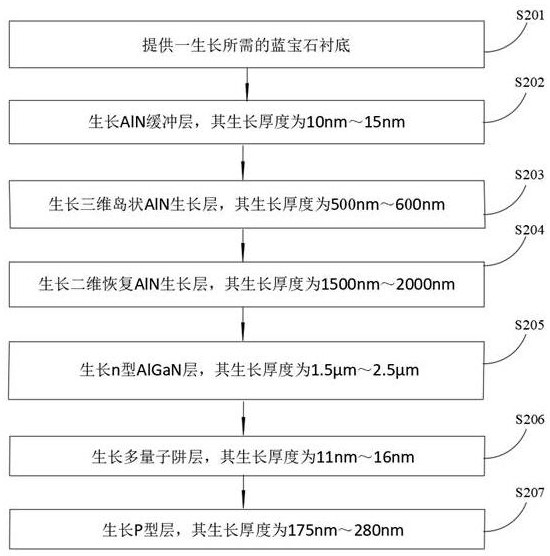

[0036] see image 3 , shows an epitaxial growth method for LED epitaxial wafers proposed in Embodiment 2 of the present invention, which is used to prepare the LED epitaxial wafers in Embodiment 1 above. The method specifically includes steps S201 to S207, wherein:

[0037] Step S201, providing a sapphire substrate required for growth.

[0038] In this embodiment, the substrate is a patterned sapphire substrate, which has the advantages of mature technology and low cost. It is an example and not limiting. In some preferred embodiments of this embodiment, the substrate can also be a Si substrate or SiC substrate.

[0039] In addition, before the growth process, the surface of the substrate needs to be cleaned to avoid impurities from being mixed into the epitaxial wafer, which is conducive to improving the growth quality of the epitaxial wafer. The specific process of cleaning is to introduce the substrate into the MOCVD reaction chamber, Anneal in a hydrogen atmosphere for 1...

Embodiment 3

[0065] Embodiment 3 of the present invention provides an LED chip, including the LED epitaxial wafer in the first embodiment above, and the LED epitaxial wafer can be epitaxially grown by the epitaxial growth method of the LED epitaxial wafer in the second embodiment above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com