A three-dimensional plasmonic nanocomposite structure and its preparation method and application

A nanocomposite, plasma technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low utilization rate, low photoelectric conversion efficiency, etc. Utilization, the effect of enhancing the light absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

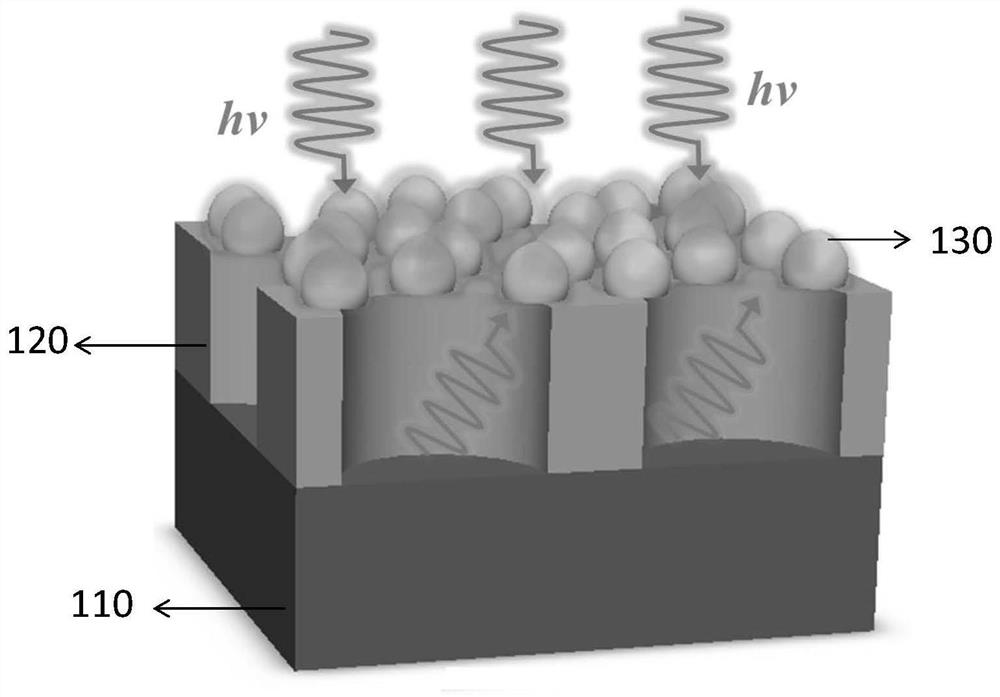

[0048] A three-dimensional plasmonic nanocomposite structure 100, such as figure 1As shown, it includes: an aluminum reflective layer 110 , an aluminum oxide array support 120 , and a gold nano-antenna 130 . The aluminum oxide array bracket is arranged on the aluminum reflection layer; the gold nano-antenna is arranged on the side surface of the aluminum oxide array bracket opposite to the aluminum reflection layer.

[0049] At present, most of the existing technologies use a single metal nano-antenna, and use the surface plasmon resonance effect to achieve a clamping effect on the incident light wave, thereby enhancing the light absorption rate of the light-affecting layer. Metal nanoantennas are affected by their normal size, so the optical coupling effect is limited, and the light transmission phenomenon is still serious. In order to prevent the overflow of incident light, this embodiment introduces an aluminum reflective layer and an aluminum oxide array resonant cavity, ...

Embodiment 2

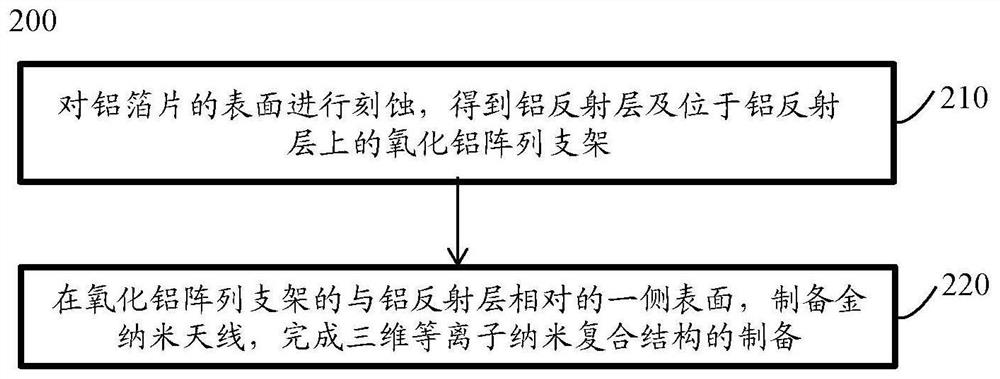

[0057] A method 200 for preparing a three-dimensional plasmonic nanocomposite structure as described in Embodiment 1, such as figure 2 shown, including:

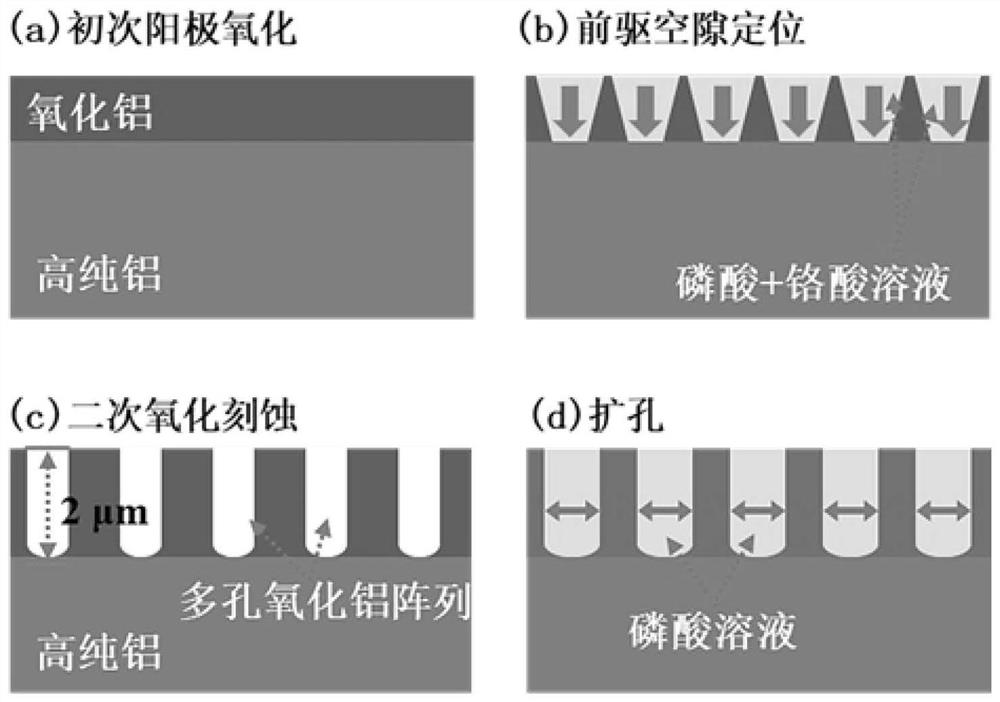

[0058] Step 210, etching the surface of the aluminum foil to obtain an aluminum reflective layer and an aluminum oxide array support located on the aluminum reflective layer;

[0059] Step 220 , preparing gold nano-antennas on the surface of the aluminum oxide array support opposite to the aluminum reflective layer, and completing the preparation of a three-dimensional plasmonic nano-composite structure.

[0060] It should be noted that the preparation method of the gold nano-antenna can be chemical synthesis method, photolithography method and the like.

[0061] In this embodiment, the aluminum oxide array support is prepared on the aluminum foil and the gold nano-antenna is prepared on the aluminum oxide array support to realize the combination of the aluminum oxide array support and the gold nano-antenna, so as to impro...

Embodiment 3

[0082] A photodetector 300, such as Figure 5 As shown, it includes: an electrode and a photosensitive layer stacked in sequence, and also includes: the three-dimensional plasma nanocomposite structure as described above, and the three-dimensional plasma nanocomposite structure is stacked on the side of the photosensitive layer opposite to the electrode.

[0083] The pore diameters of the periodic porous alumina arrays are respectively selected as 90 and 130 nm, and there are 6 samples in total, corresponding to different deposition thicknesses of the gold nanofilms. Such as Figure 6 Shown, the deposition thickness of gold nano film is respectively: Figure 6 (a)-(b) is 6nm, Figure 6 (c)-(d) are 10nm, Figure 6 (e)-(f) is 15nm; the apertures of alumina are: Figure 6 (a), (c), (e) are 90nm, Figure 6 (b), (d), and (f) are 130 nm.

[0084] Under each aperture, the self-assembled gold nanoantennas showed obvious size extension and shape irregularity with the gradual incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com