Deposition film preparation method and film plating machine

A coating machine and sputtering deposition technology, which is applied in the field of metal film preparation, can solve problems such as the difficulty in preparing high-thickness and high-density metal films, and achieve the effects of enhancing surface mobility, uniform grains, and reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

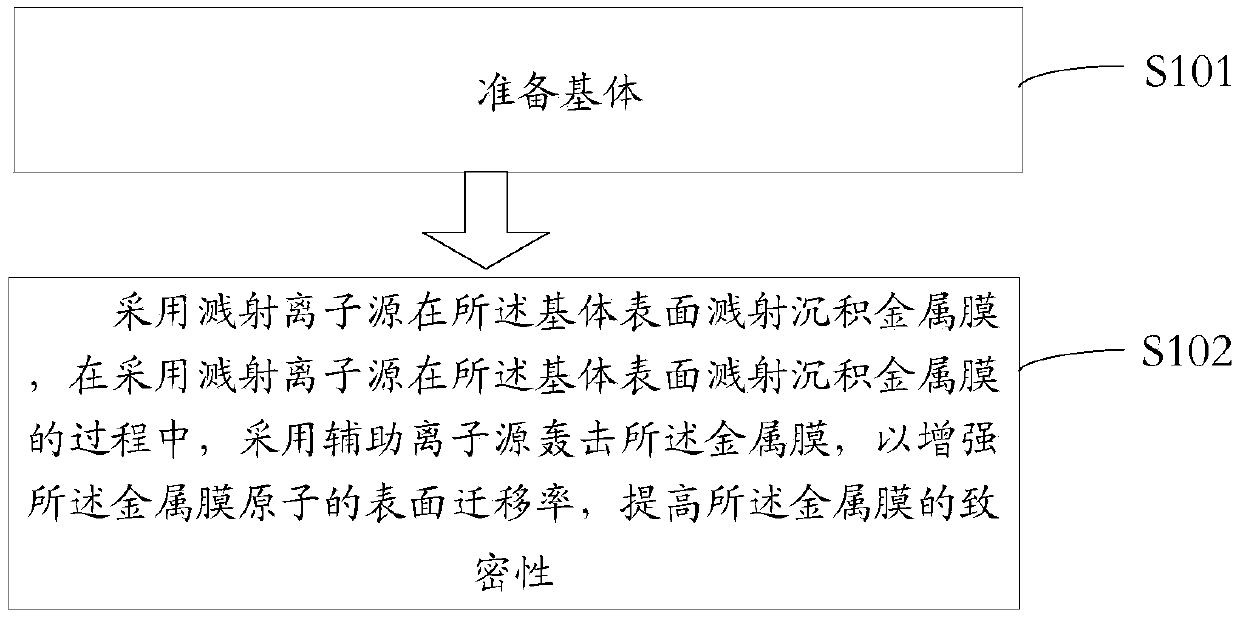

[0045]In this embodiment, a method for depositing and preparing a film is provided, such as figure 1 As shown, the method includes:

[0046] Step S101, preparing a substrate;

[0047] Step S102, using a sputtering ion source to sputter deposit a metal film on the surface of the substrate, wherein, in the process of using a sputtering ion source to sputter deposit a metal film on the surface of the substrate, using an auxiliary ion source to bombard the metal film , so as to enhance the surface mobility of the metal film atoms and improve the compactness of the metal film.

[0048] In the embodiment of the present application, the metal film may be an aluminum film, a copper film, a silver film or a titanium film, which is not limited here and will not be listed one by one.

[0049] Preferably, the metal film is an aluminum film, because the aluminum film has flat and high reflectivity from the ultraviolet region to the infrared region, and there is a layer of transparent Al ...

Embodiment 2

[0093] In this example, if Figure 7 As shown, a coating machine is provided, including:

[0094] target stage 701;

[0095] Workbench 702, the workbench can fix the substrate;

[0096] The sputtering ion source 703 is used to bombard the target stage, and deposit a metal film on the surface of the substrate through sputtering of the target stage;

[0097] The auxiliary ion source 704 is used for bombarding the metal film during sputtering deposition of the metal film by the sputtering ion source, so as to enhance the surface mobility of atoms of the metal film and improve the compactness of the metal film.

[0098] Such as Figure 7 As shown, the workbench 702 corresponds to the position above the target stage 701. In the specific implementation process, the substrate can be fixed below the workbench, so that the target atoms on the target stage 701 are sputtered by the ion source 704 Under the bombardment, it can be sputtered onto the substrate. same as Figure 7 As sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com