Method for overcoming surface defect of polycrystalline silicon

A polysilicon, defect technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as lattice defects, complex temperature control, cumbersome implementation process, etc., to improve service life, easy operation, and improve surface migration rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

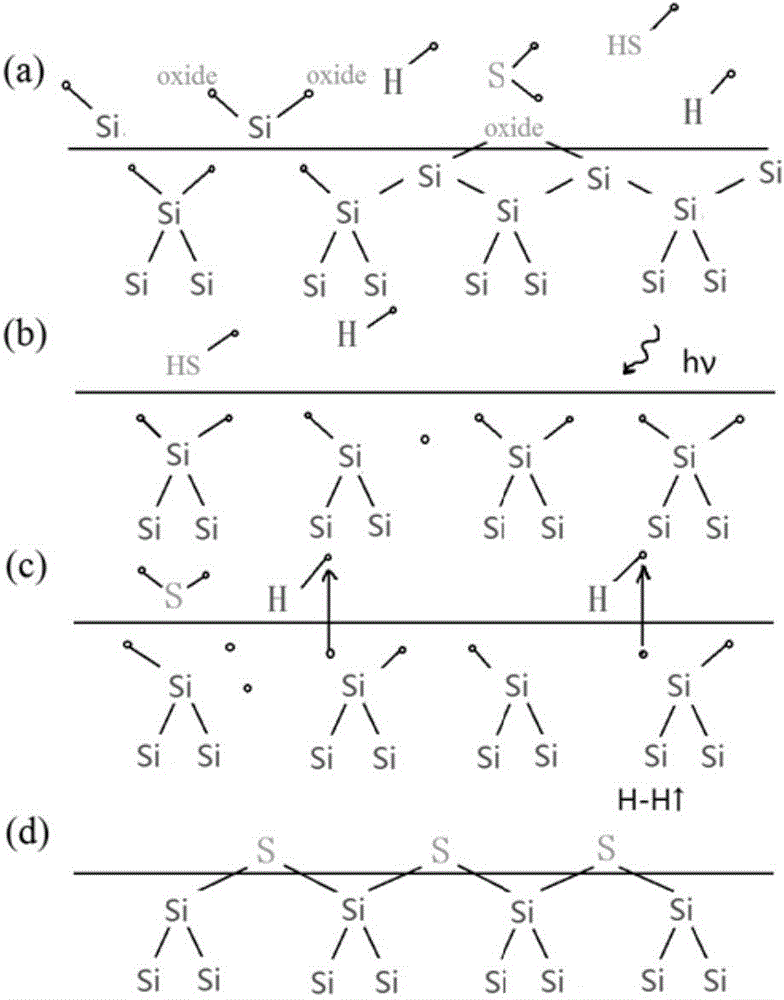

[0035] This embodiment provides a method for improving polysilicon surface defects by using a sulfur-containing passivation solution, specifically as follows:

[0036] After the laser-melted polysilicon substrate is formed, slowly spray a passivation solution with a temperature of 50°C onto the surface of the substrate formed by polysilicon (the passivation solution is a saturated solution of ammonium sulfide alcohol), and the action lasts for 20 minutes to complete the surface passivation process After the surface is passivated, the residual solution on the surface of the substrate is cleaned with deionized water.

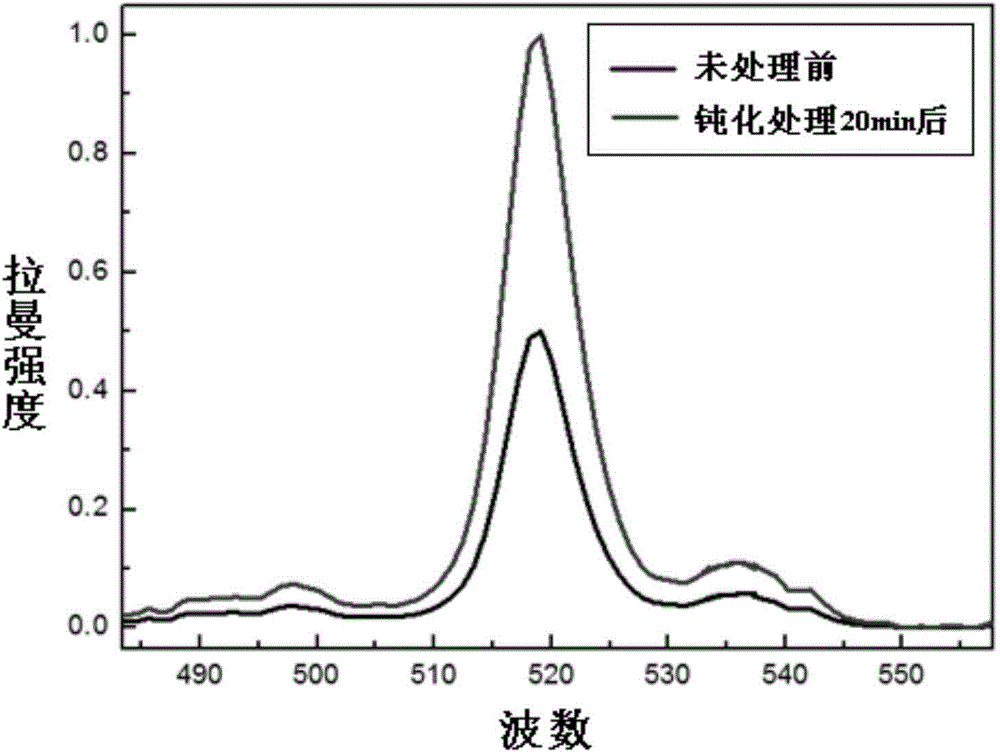

[0037] figure 1 It is a schematic diagram of the test results of polysilicon Raman spectrum after surface passivation treatment by the above method, from figure 1 The results show that the Raman spectrum intensity of the polysilicon substrate after the passivation solution treatment increases significantly, and it can be seen that the passivation solution has a g...

Embodiment 2

[0045] Compared with Example 1, the method described in this example differs only in that: in this example, the sulfur-containing passivation solution is a sodium sulfide alcohol saturated solution, its temperature is 60 ° C, and the surface passivation treatment time is 30 minutes .

Embodiment 3

[0047] Compared with the method described in Example 1, the method described in this example differs only in that the temperature of the sulfur-containing passivation solution in this example is 40° C., and the surface passivation treatment time is 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com