A kind of p-type Aln thin film and its preparation method and application

A thin-film, p-type technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of difficult breakthrough of AlN thin film and difficulty in activation of AlN thin film, and achieve good application prospects, good optical performance, and improved Effect of Crystal Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content, achieved objectives and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments.

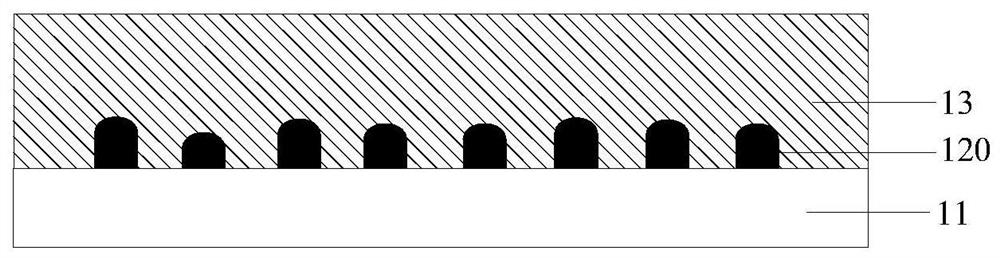

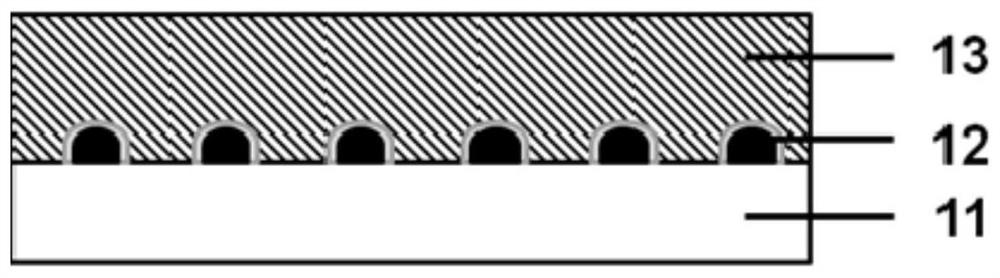

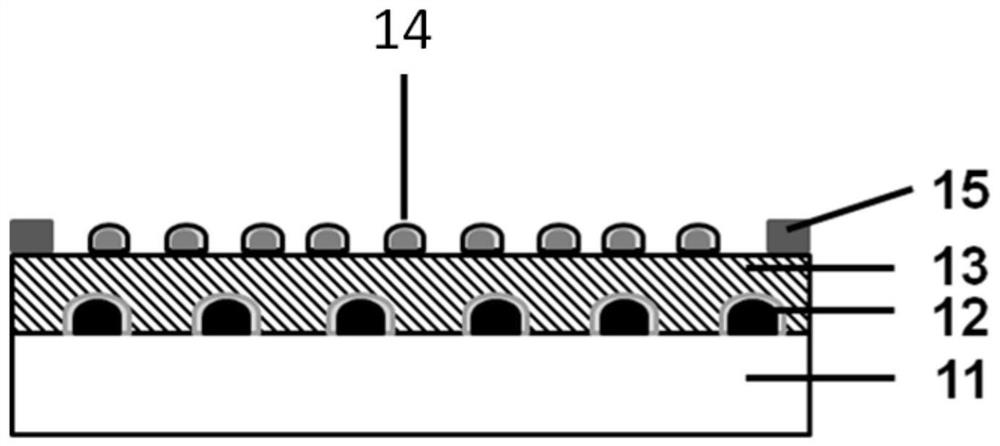

[0034] Embodiment 1 of the present invention is: a p-type AlN thin film, such as figure 1 As shown, its structure from bottom to top is a substrate 11 , a nanoparticle layer 120 (also called a PtLi layer) and an AlZnLiN thin film layer 13 . The specific steps are as follows:

[0035] (1) Firstly, a PtLi layer with a thickness of 10 nm is formed on the Si substrate 11 by sputtering method, followed by rapid annealing at 600° C. for 120 s to obtain a nanoparticle layer 120 with a diameter of 10-100 nm.

[0036] (2) A 150nm AlZnN film was grown at 200°C by magnetron sputtering, and kept at 900°C for 1h. During high-temperature growth or high-temperature annealing, Li atoms overflow into the AlZnN film layer, and co-dope AlN with Zn; activate Li and Zn doping during high-temperature a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com