AlN epitaxial layer and preparation method thereof

An epitaxial layer and isolation layer technology, applied in the field of AlN epitaxial layer and its preparation, can solve the problems of high density misfit dislocation, AlN surface cracking, device performance deterioration, etc., achieve rapid deposition, surface flattening, and reduce the concentration of point defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing an AlN epitaxial layer provided in an embodiment of the present invention further includes:

[0030] S3. Deposit AlN on the nucleation layer at 1000-1100° C. to form a defect repair layer.

[0031] After creative work, the inventors found that if the rapid growth is performed directly at high temperature after the formation of the nucleation layer, the strain cannot be fully relaxed and threading dislocations can be effectively annihilated. Second, the inventors deposited a layer of defect repair layer on the nucleation layer before rapid growth. This defect repair layer can effectively reduce the concentration of point defects while ensuring strain release and dislocation annihilation, so as to provide future The high-temperature rapid growth process lays the foundation for obtaining higher-quality AlN epitaxial layers. The temperature range of 1000-1100° C. is the result of optimization by the inventors, and the effect of repairing defects in t...

Embodiment 1

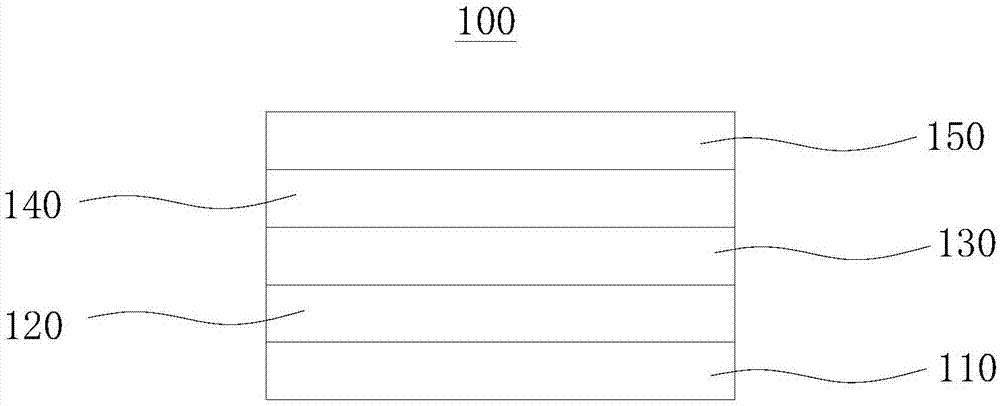

[0043] This embodiment provides an Al epitaxial layer 100 and its preparation method. The laminated structure of the Al epitaxial layer 100 is as follows: figure 1 As shown, the instrument used is Aixtron 3×2”FT CCS MOCVD, the substrate is a 2-inch (0001) sapphire substrate 110 with an offcut of 0.2 degrees on the c to m axis, the carrier gas is hydrogen, and the nitrogen source is ammonia , the organic aluminum source is TMAl.

[0044] S1. Introduce hydrogen gas, and bake the sapphire substrate 110 at 900° C. for 300 seconds under the condition that the reaction chamber pressure is 75 mbar.

[0045] The temperature of S2 is lowered to 650° C., and the pressure of the reaction chamber is 50 mbar, and TMAl2s is pre-spread, and the source flow rate is 22 sccm.

[0046] S3. Growing a 2nm N-polar isolation layer 120 on the sapphire substrate 110 at 650° C. and a reaction chamber pressure of 50 mbar. Wherein, the molar flow ratio of ammonia gas and TMAl is 50.

[0047] S4. Raise...

Embodiment 2

[0052] This embodiment provides a kind of Al epitaxial layer and preparation method thereof, the instrument adopted is Aixtron 3 * 2 " FTCCS MOCVD, the substrate is the 2-inch (0001) plane sapphire substrate whose offcut is c to m axis 0.2 degree, The carrier gas is hydrogen, the nitrogen source is ammonia, and the organic aluminum source is TMAl.

[0053] S1. Introduce hydrogen gas, and bake the sapphire substrate at 930° C. for 200 seconds under the condition that the reaction chamber pressure is 100 mbar.

[0054] The temperature of S2 is lowered to 650°C, and the pressure of the reaction chamber is 50mbar, pre-spreading TMAl5s, and the source flow rate is 15sccm.

[0055] S3. At 650° C. and the pressure of the reaction chamber at 50 mbar, a 5 nm N polarity isolation layer is grown. Wherein, the molar flow ratio of ammonia gas and TMAl is 35.

[0056] S4. Raise the temperature to 930° C. and grow a 40 nm nucleation layer under the condition that the reaction chamber press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com