Method for enriching rhodium from rhodium-containing organic waste liquid

An organic waste liquid, enrichment technology, applied in the field of enrichment of rhodium, can solve problems such as difficulty in generating precipitation, and achieve the effects of simple subsequent treatment process, cost reduction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

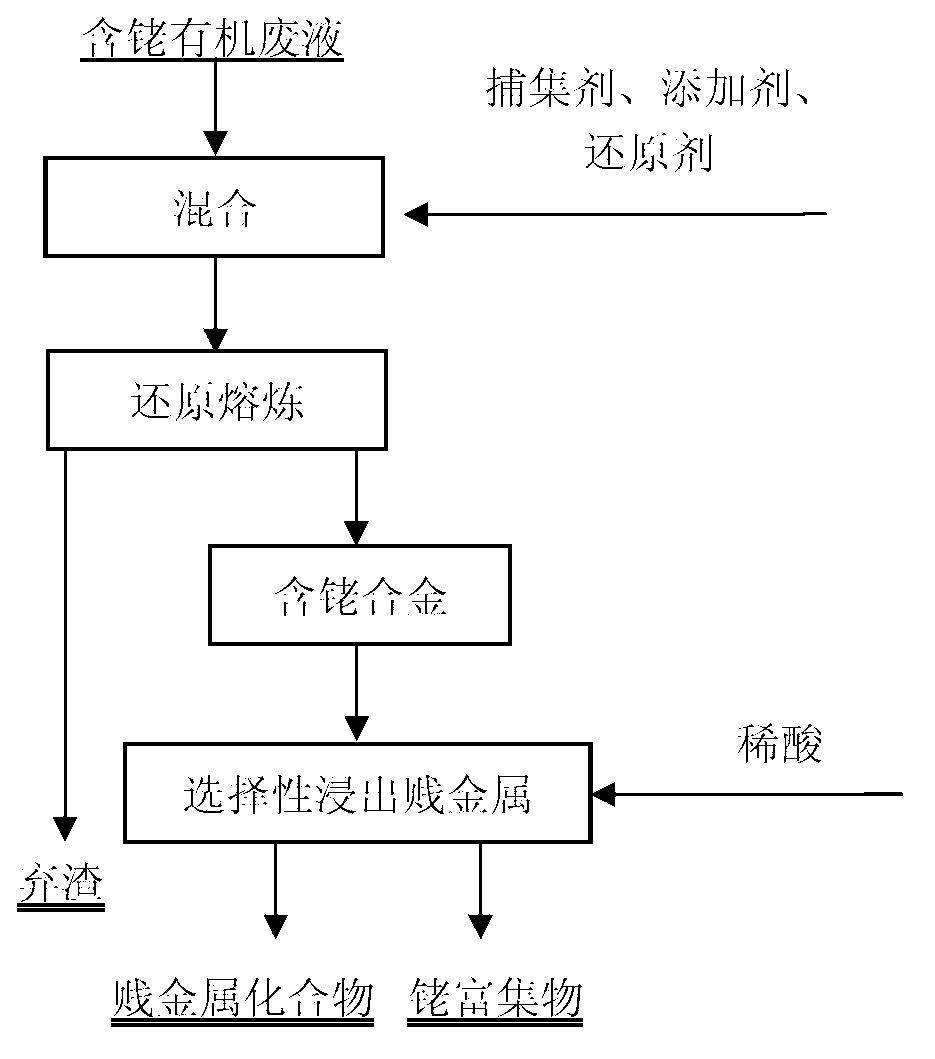

[0021] Embodiment 1, see attached figure 1 In the experiment, we weighed 500g of trapping agent, reducing agent (including 82.19% of fixed carbon) with a ratio of 5% of the trapping agent, additives with a ratio of 30% of the trapping agent, mixed with a three-dimensional mixer, and added organic rhodium The solution is 500ml, and it is reduced and smelted in a high-temperature resistance furnace, the reduction temperature is 1300°C, and the reduction time is 10h. The obtained rhodium alloy is selectively leached base metals with dilute acid (20%) to obtain rhodium enrichment, and the direct recovery rate is 99.2%.

Embodiment 2

[0022] Embodiment 2, see attached figure 1 In the experiment, we weighed 500g of trapping agent, reducing agent (including 82.19% of fixed carbon) with a ratio of 5% of the trapping agent, additives with a ratio of 30% of the trapping agent, mixed with a three-dimensional mixer, and added organic rhodium The solution is 500ml, and it is reduced and smelted in a high-temperature resistance furnace, with a reduction temperature of 1350°C and a reduction time of 8 hours. The obtained rhodium alloy is selectively leached base metals with dilute acid (20%) to obtain rhodium enrichment, and the direct recovery rate is 99.5%.

Embodiment 3

[0023] Example 3, the experiment weighed 500g of trapping agent, reducing agent (containing 82.19% of fixed carbon) ratio is 5% of trapping agent, additive ratio is 30% of trapping agent, using a three-dimensional mixer to mix, Add 500ml of organic rhodium solution, and carry out reduction smelting in a high-temperature resistance furnace, the reduction temperature is 1400°C, and the reduction time is 6h. The obtained rhodium alloy is selectively leached base metals with dilute acid (20%) to obtain rhodium enrichment, and the direct recovery rate is 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com