Method for treating garbage leachate

A technology of landfill leachate and treatment method, applied in chemical instruments and methods, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of unsatisfactory removal effect, poor biodegradability of leachate, and system operation problems such as defects, to shorten the water intake time, reduce the pollution load and toxicity, and prevent sludge expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Get some landfill leachate somewhere. Water quality: taupe, with foul smell, COD Cr The concentration is 3000mg / L, the pH is 7.5, the ammonia nitrogen is 1325mg / L, the turbidity is 614NTU, and the SS is 727.2mg / L.

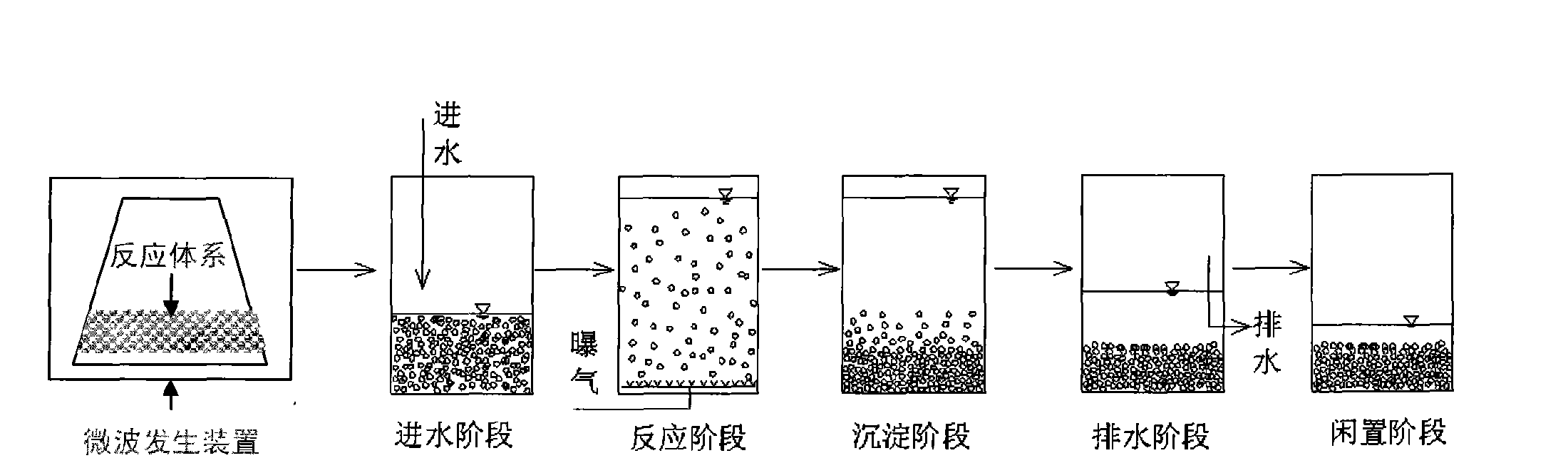

[0028] The landfill leachate treatment method is as follows:

[0029] 1) Pretreatment: take landfill leachate, and then add 0.01mol / LFe to it 2 SO 4 ·7H 2 O, 9g / L activated carbon and 6ml / L H 2 o 2 , at a microwave frequency of 2450Hz and a microwave power of 300W, react for 5 minutes;

[0030] 2) SBR follow-up treatment: SBR follow-up treatment is completed in the same reaction tank, which is installed in a water bath, and the temperature of the water bath is controlled at 24-26°C; the amount of pretreated landfill leachate is controlled by a flow meter, and each cycle The input volume is 1L, enter the reaction tank within 0.4h; aerate for 7h, the aeration rate is 13.5L / h, the pH is controlled to 6.5, and the sludge concentration is 3000mg / L; Discha...

Embodiment 2

[0033] Take landfill leachate that has been piled up somewhere for more than 5 years. Water quality: brown with foul smell, COD Cr The concentration is 4000mg / L, the pH is 7.8, the ammonia nitrogen is 1764.8mg / L, the turbidity is 819.2mg / L, and the SS is 969.6mg / L.

[0034] 1) Pretreatment: take landfill leachate, and then add 0.02mol / LFe to it 2 SO 4 ·7H 2 O, 10g / L activated carbon and 7ml / L H 2 o 2 , at a microwave frequency of 2450Hz and a microwave power of 300W, react for 6 minutes;

[0035] 2) SBR follow-up treatment: SBR follow-up treatment is completed in the same reaction tank, which is installed in a water bath, and the temperature of the water bath is controlled at 24-26°C; the amount of pretreated landfill leachate is controlled by a flow meter, and each cycle The input volume is 1L, enter the reaction tank within 0.5h; aerate for 8h, the aeration rate is 13.5L / h, the pH is controlled to be 7, and the sludge concentration is 3500mg / L; Discharge within 0.5h; ...

Embodiment 3

[0038] Get leachate somewhere. Water quality: dark brown with foul smell, COD Cr The concentration is 5000mg / L, the pH is 8.0, the ammonia nitrogen is 2260mg / L, the turbidity is 1024NTU, and the SS is 1212mg / L.

[0039]1) Pretreatment: take landfill leachate, and then add 0.03mol / LFe to it 2 SO 4 ·7H 2 O, 11g / L activated carbon and 8ml / L H 2 o 2 , under microwave frequency 2450Hz, microwave power 300W, react for 7min;

[0040] 2) SBR follow-up treatment: SBR follow-up treatment is completed in the same reaction tank. The reaction tank is installed in a water bath, and the temperature of the water bath is controlled at 24-26°C; The input volume is 1L, enter the reaction tank within 0.6h; aerate for 9h, the aeration rate is 13.5L / h, the pH is controlled to be 7.5, and the sludge concentration is 4000mg / L; h; after the reaction pool is idle for 0.6h, the subsequent SBR treatment of the landfill leachate in the next cycle will be carried out.

[0041] The water quality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com