Method for comprehensively recovering valuable metals through oxygen pressure treatment of tin anode mud

A technology of tin anode slime and valuable metals, applied in the field of hydrometallurgy, can solve the problems of high pollution, low recovery rate of valuable metals, low energy consumption, etc., and achieve the effect of complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

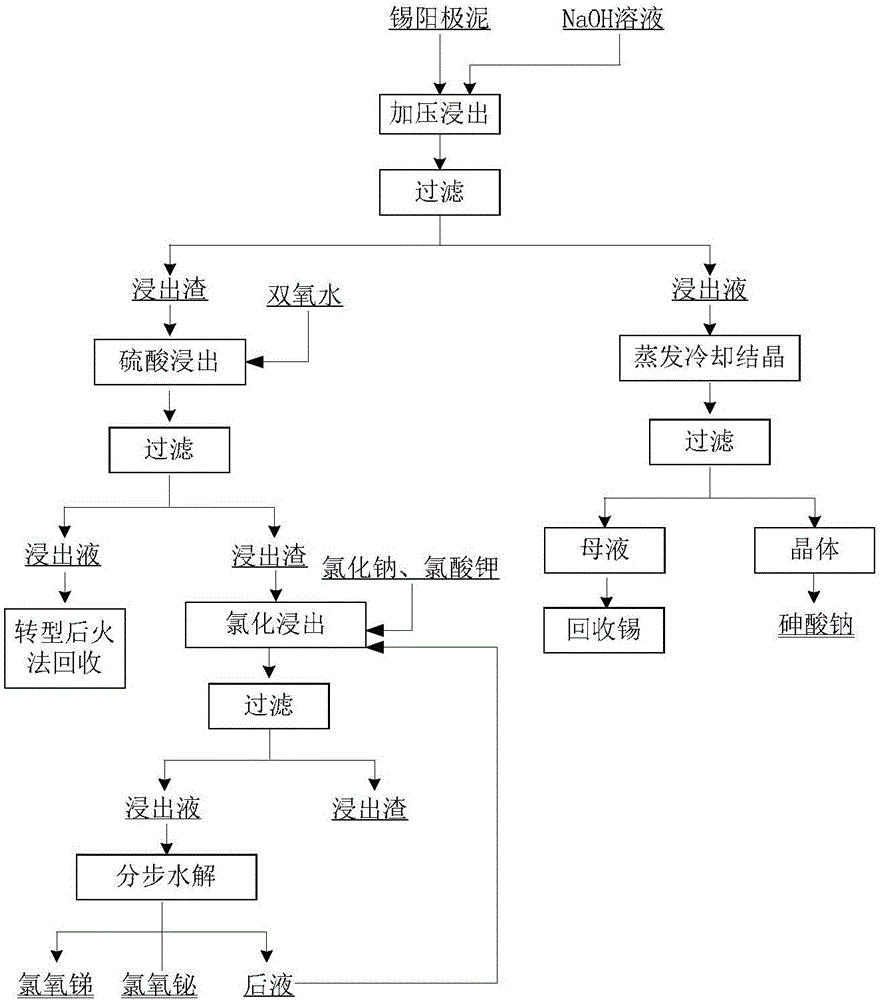

Method used

Image

Examples

Embodiment 1

[0056] 100Kg of tin anode slime that has been stored for more than 10 days and crushed to less than 0.4mm after drying (the specific components are Sn: 46.77%, Pb: 5.64%, Cu: 3.3%, Ag: 0.119%, As: 10.13%, Sb: 15.08%, Bi: 5.09%, In: 0.21%) added to 1.0m 3 In the high-pressure reactor, control the concentration of sodium hydroxide at 3mol / L, temperature at 200°C, oxygen partial pressure at 1.5MPa, liquid-solid ratio at 8:1, reaction time at 4h, and stirring speed at 500rpm during leaching. After the reaction, cool the slurry to 70°C, open the autoclave safely after the pressure is released, and separate the liquid and solid while it is hot, wash the filter residue with hot water for 2 to 3 times, and obtain a leaching solution with a tin content of 4.14 and arsenic content of 0.46 The leaching rates of slag, tin and arsenic can reach 95.91% and 97.90% respectively, and the leaching rates of other valuable metals are very low or not leached. The leaching solution is evaporated a...

Embodiment 2

[0062] 100Kg of tin anode slime that has been stored for more than 10 days and crushed to less than 0.4mm after drying (the specific components are Sn: 37.94%, Pb: 5.92%, Cu: 3.9%, Ag: 0.15%, As: 7.25%, Sb: 15.73%, Bi: 4.8%, In: 0.34%) added to 1.0m 3 In the high-pressure reactor, the concentration of sodium hydroxide is controlled at 2.5mol / L during leaching, the temperature is 200°C, the oxygen partial pressure is 1.5MPa, the liquid-solid ratio is 7:1, the reaction time is 4h, and the stirring speed is 500rpm. After the reaction is over, cool the slurry to 70°C, open the autoclave safely after the pressure is released, and separate the liquid and solid while it is hot, wash the filter residue with hot water for 2 to 3 times, and obtain a leaching solution with a tin content of 5.23 and an arsenic content of 0.317 The leaching rates of slag, tin and arsenic can reach 94.21% and 98.98% respectively, a small amount of copper is leached, and other valuable metals are hardly leac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com