Green process for preparing diosgenin

A technology of diosgenin and green technology, applied in the direction of steroids, organic chemistry, etc., can solve the problems of reducing saponin quality, increasing uncertainty expectations, and low cost, so as to simplify subsequent processes and improve saponin quality , The effect of low extraction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

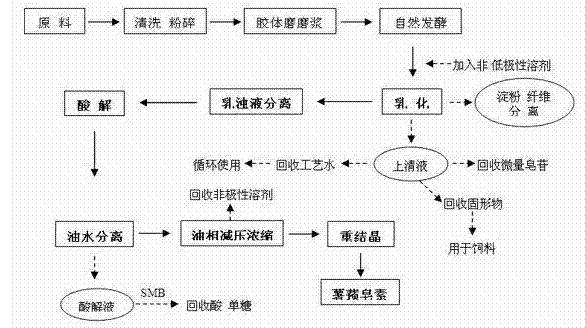

Method used

Image

Examples

Embodiment 1

[0030] Wash 2000g of yam yam fresh material and remove the shavings, then finely grind it with 3 sets of colloid mills used in series to make a slurry, and keep it at 25°C for 48 hours for natural fermentation; after natural fermentation, the slurry is 5 times the quality of the slurry after natural fermentation Water and 3% light gasoline are fed into the colloid mill synchronously for grinding. In order to make the grinding fully, three colloid mills are used in series at the same time; after that, cellulose, starch, supernatant and emulsion are separated by centrifugation. ; Add 2M H in the ratio of acid:emulsion=1:1 2 SO 4 , and stirred and hydrolyzed at 30°C and 1 atmosphere for 6 hours, the hydrolyzate was filtered to obtain dregs, neutralized with ammonia water and washed with 10L of water, 3L of 70% ethanol was added to the dregs to extract diosgenin, the extract was filtered to remove dregs and concentrated to 300ml , refined, crystallized, and 15.94g of diosgenin wi...

Embodiment 2

[0032] Wash 500g of the dry material of Dioscorea chinensis to remove the shavings, and then fully swell it in water. It is finely ground by 4 colloid mills used in series to make a slurry, and it is kept at 30°C for 24 hours for natural fermentation; after natural fermentation, the slurry is 10 times more natural. Water of slurry quality after fermentation and the mixed solution of 5% n-hexane and heptane are synchronously fed into the colloid mill for grinding, and in order to make the grinding fully, 4 colloid mills are used in series at the same time; afterward, by centrifugation, the cellulose, 4 parts of starch, supernatant and emulsion; 2M HCl was added to the ratio of acid:emulsion = 5:1, stirred and hydrolyzed at 30°C and 1 atmosphere for 3 hours, the hydrolyzate was filtered to obtain dregs, ammonia water And, after washing with 10L of water, add 3L of 70% ethanol to the dregs to extract diosgenin, filter the dregs, concentrate to 300ml, refine, crystallize, and obtai...

Embodiment 3

[0034] Wash and remove shavings of 500g pangosaurus dry material, swell fully in water, finely grind it with 5 sets of colloid mills used in series to make a slurry, and keep it at 27°C for 40 hours for natural fermentation; after natural fermentation, the slurry is 8 times after natural fermentation Slurry quality water and 1% mixed solution composed of glyceryl monostearate, Span-60 and tween-40 are synchronously fed into the colloid mill for grinding. In order to make the grinding fully, 5 colloid mills are used in series at the same time; According to the method, 4 parts of cellulose, starch, supernatant and emulsion are separated; wherein 2M H 3 PO 4 , and stirred and hydrolyzed at 30°C and 1 atmosphere for 4 hours, the hydrolyzate was filtered to obtain dregs, neutralized with ammonia water and washed with 10L of water, 3L of 70% ethanol was added to the dregs to extract diosgenin, the extract was filtered to remove dregs and concentrated to 300ml , refined, crystallize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com