Testing clamp and method of producing super-short optical palse based on cascade electrical sucking modulator

A technology of electro-absorption modulator and test fixture, which is applied in the direction of instruments, measuring electronics, measuring devices, etc., and can solve problems such as complicated operation, high-frequency probes are expensive, and easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

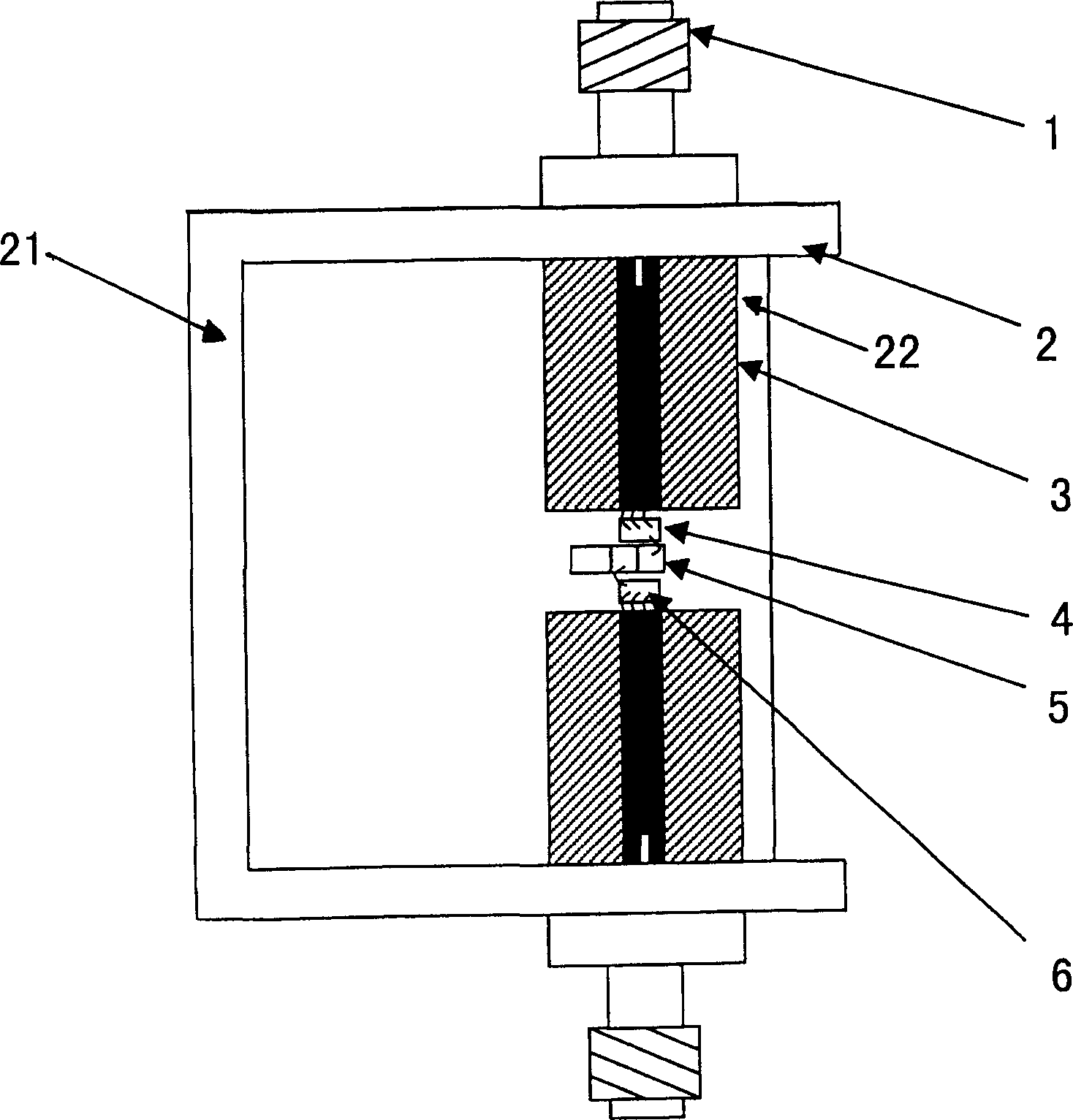

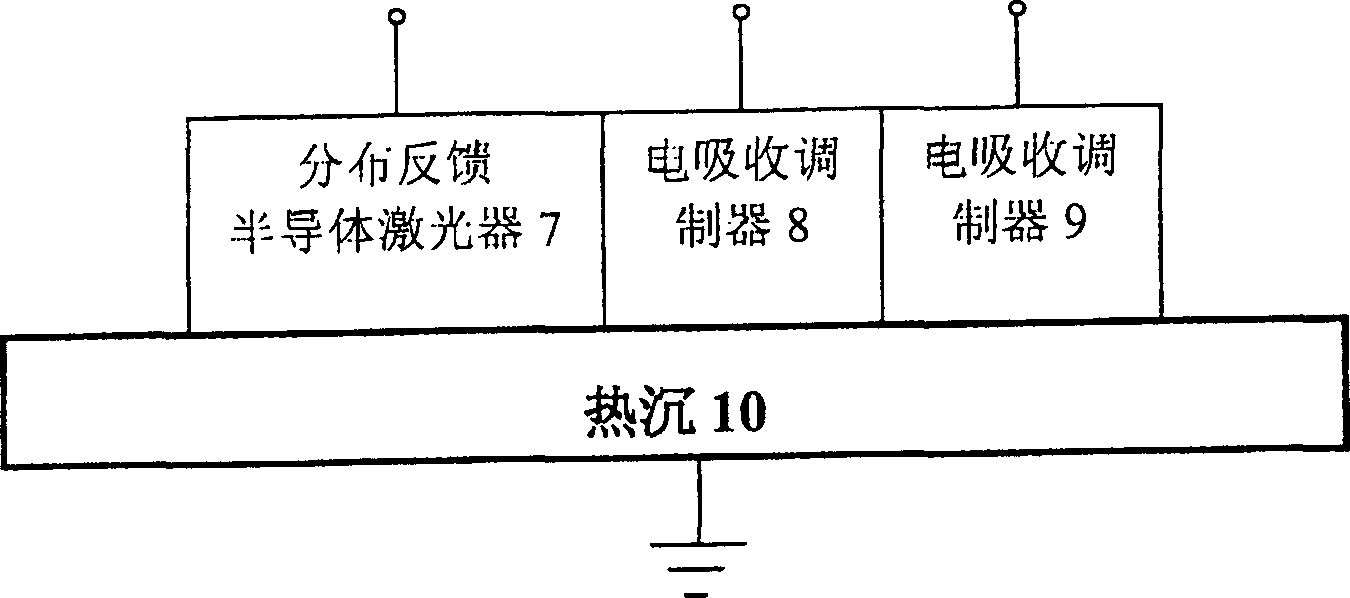

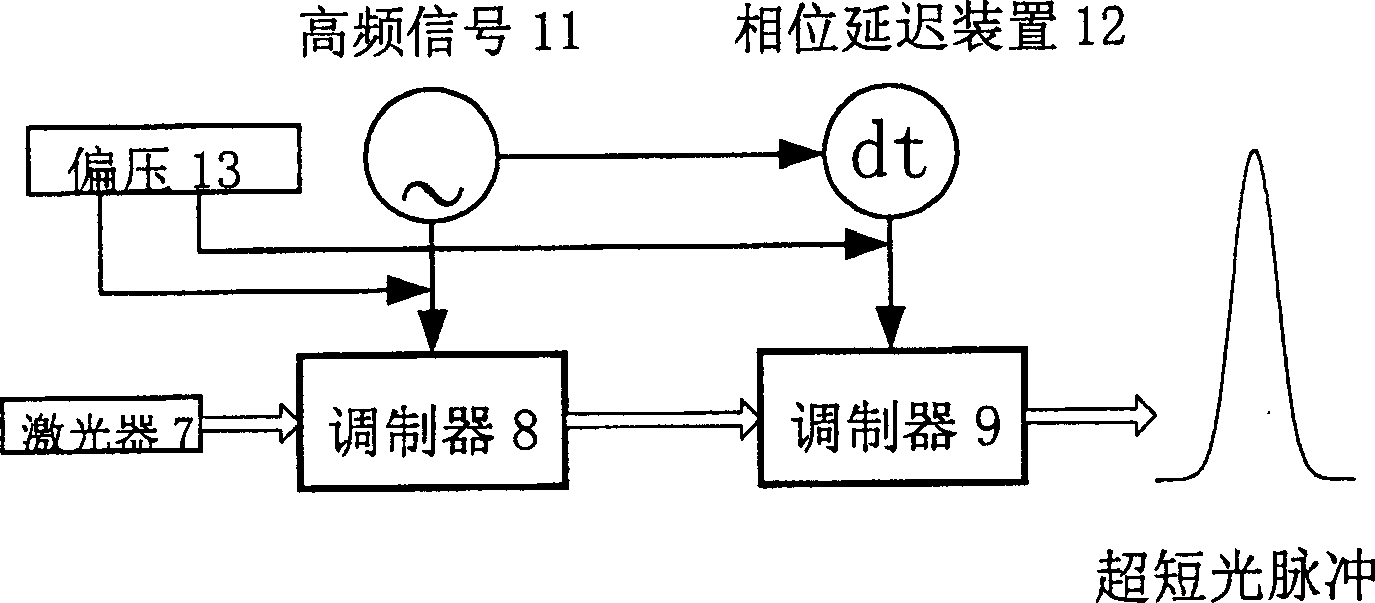

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a test fixture and method for generating ultrashort optical pulses based on cascaded electroabsorption modulators of the present invention, including:

[0042] (1) Design and make test and calibration fixture 2; test and calibration fixture 2 can be made of aluminum or copper, but the surface must be plated with gold, because the excellent conductivity of gold can reduce microwave loss ( figure 1 );

[0043] (2) Design and manufacture the microstrip line 3 . The metal material of the microstrip line 3 can be copper, but the surface must be plated with gold. Due to the excellent conductivity of gold, microwave loss and reflection can be reduced, and the same material as the chip bonding wire (gold wire 6) is easy to solder. The dielectric substrate of the microstrip line 3 can be selected from materials such as ceramics, composite dielectric or polytetrafluoroethylene, and the thickness of the substrate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com