Injection molding method of PWM (Pulse Width Modulation) controller shell body and metal pins

An injection molding and controller technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of increasing the process requirements of injection molding and processing PCB boards, changing the position of metal pins, and complicated installation processes, and shortening the injection molding process. time, improved accuracy, simplified machining process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

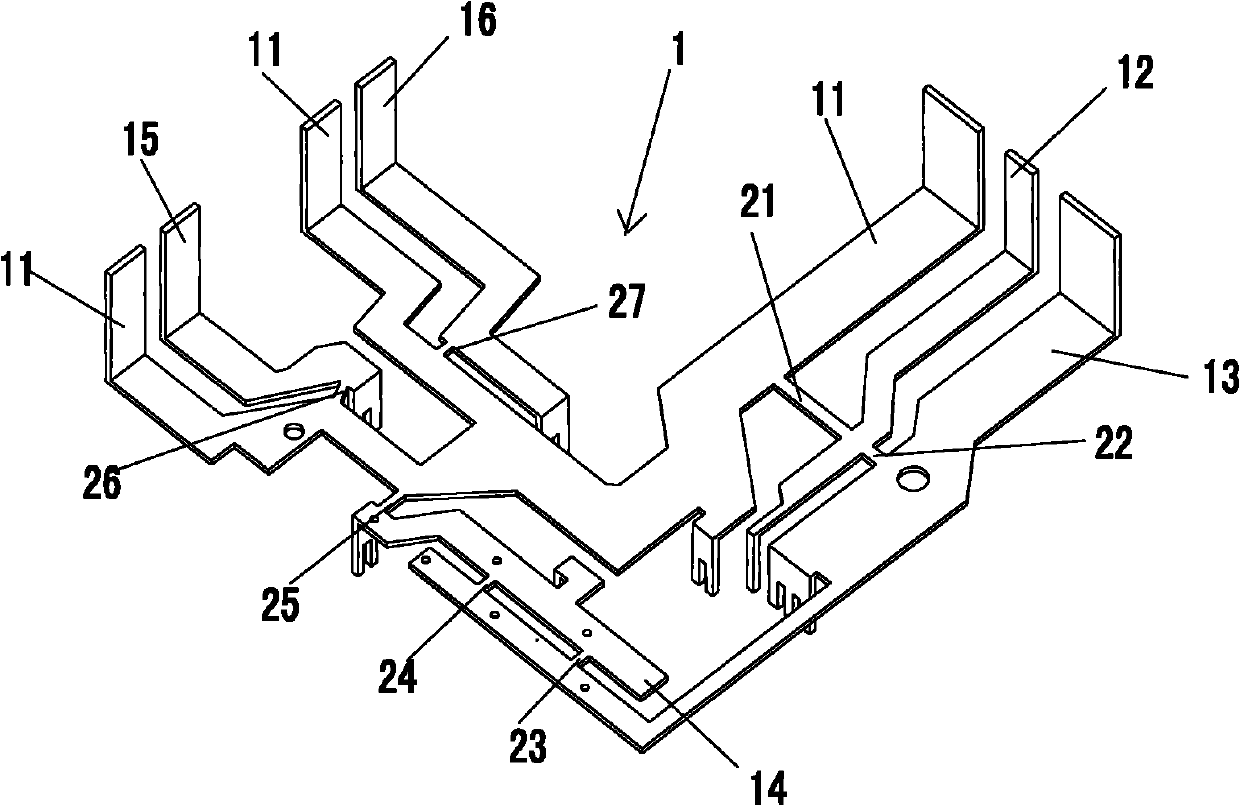

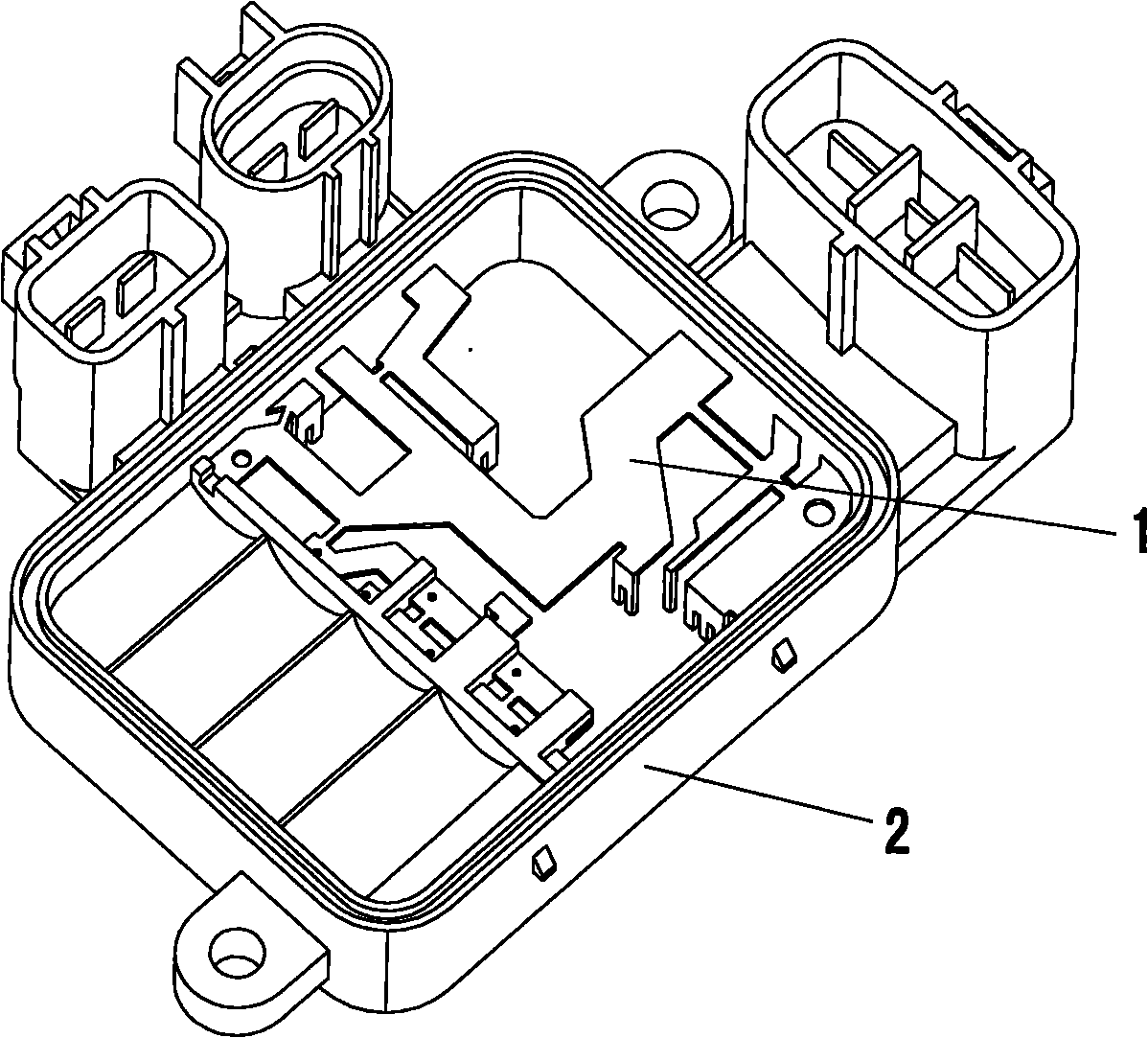

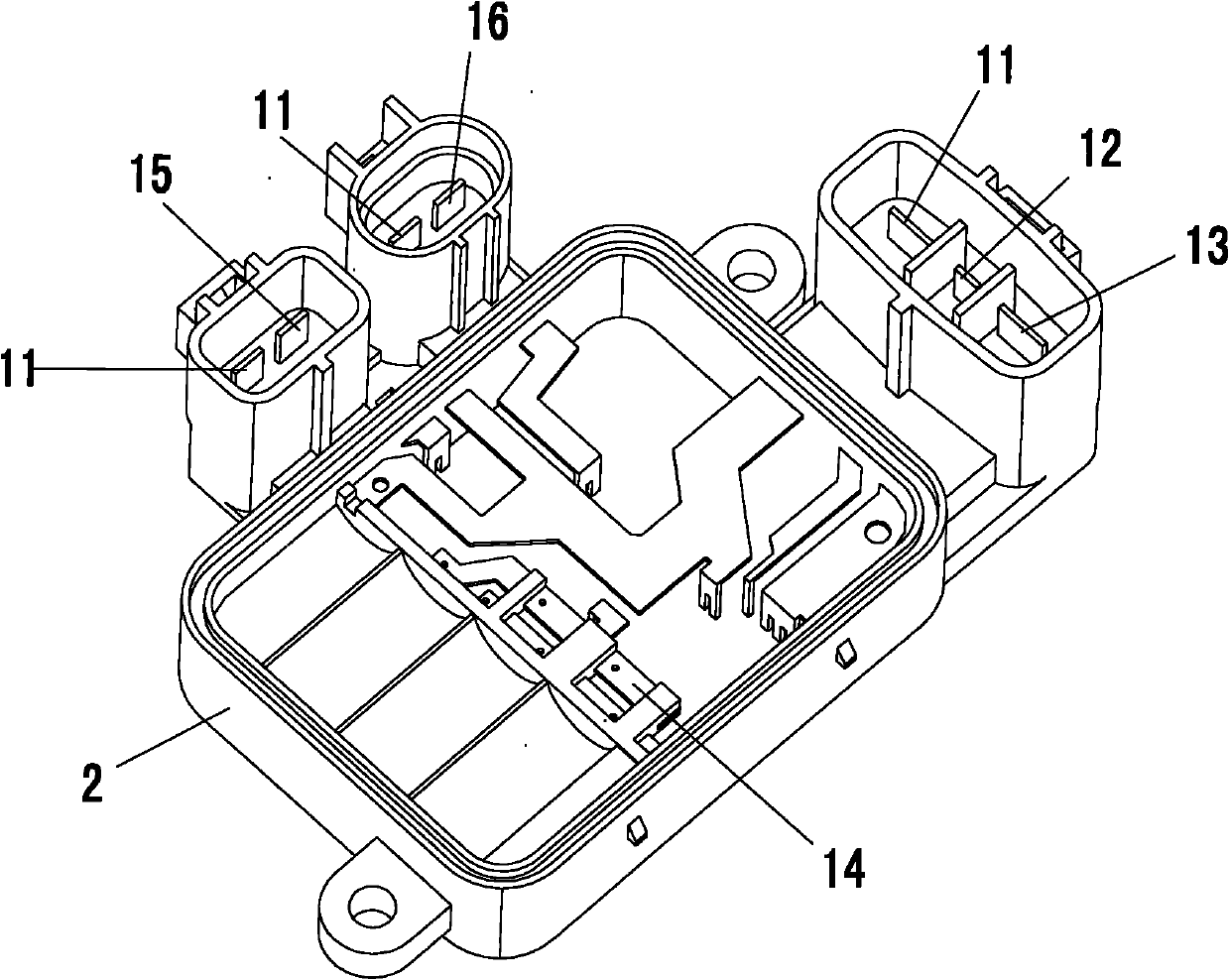

[0013] The injection molding method of the PWM controller housing and the metal pins of the present invention is that first, a plurality of metal pins that need to be separated after molding are integrally designed, and are connected to each other by a plurality of connecting blocks and punched into a shape such as figure 1 The monolithic metal part 1 shown. The plurality of metal pins include a first pin 11 , a second pin 12 , a third pin 13 , a fourth pin 14 , a fifth pin 15 and a sixth pin 16 . The plurality of connection blocks include a first connection block 21 , a second connection block 22 , a third connection block 23 , a fourth connection block 24 , a fifth connection block 25 , a sixth connection block 26 and a seventh connection block 27 . Wherein, the first connecting block 21 is connected between the first pin 11 and the second pin 12, the second connecting block 22 is connected between the second pin 12 and the third pin 13, and the third connecting block 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com