Patents

Literature

267results about "Accumulators with bipolar electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

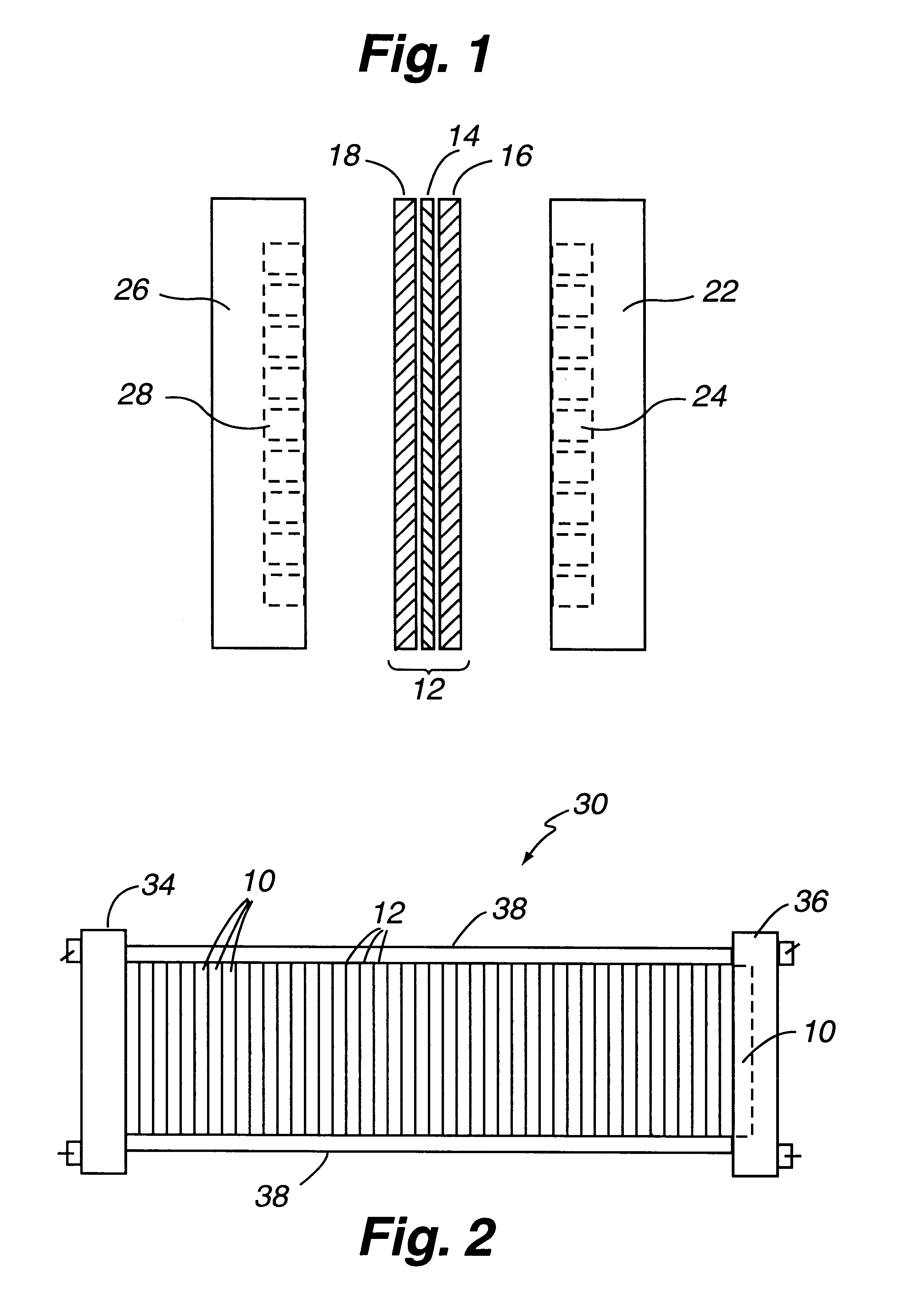

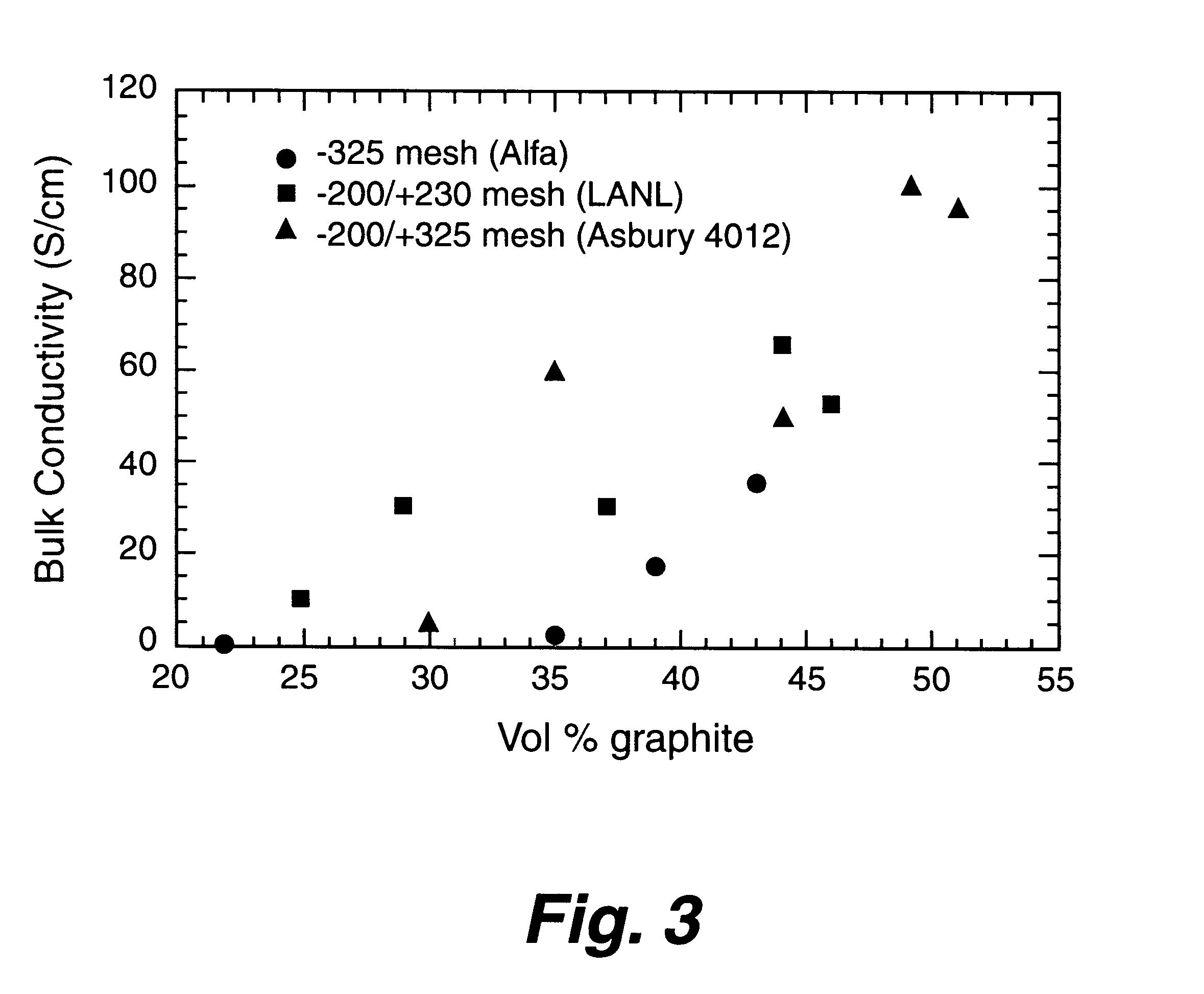

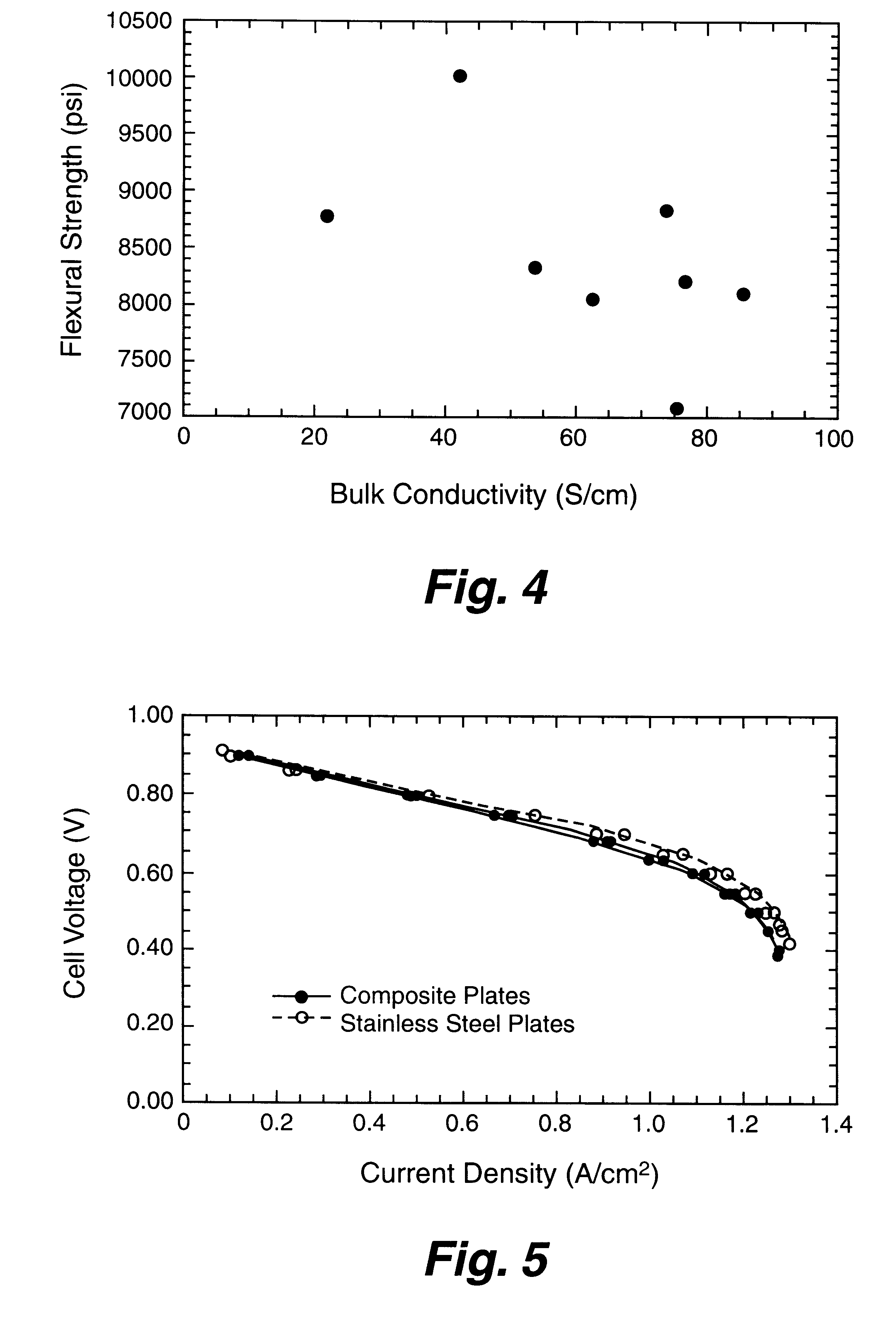

Composite bipolar plate for electrochemical cells

A bipolar separator plate for fuel cells consists of a molded mixture of a vinyl ester resin and graphite powder. The plate serves as a current collector and may contain fluid flow fields for the distribution of reactant gases. The material is inexpensive, electrically conductive, lightweight, strong, corrosion resistant, easily mass produced, and relatively impermeable to hydrogen gas. The addition of certain fiber reinforcements and other additives can improve the properties of the composite material without significantly increasing its overall cost.

Owner:TRIAD NAT SECURITY LLC

Bipolar articles and related methods

ActiveUS20050026037A1Diffusion distance is shortReduce volumeElectrolytic capacitorsElectrode carriers/collectorsEngineeringMechanical engineering

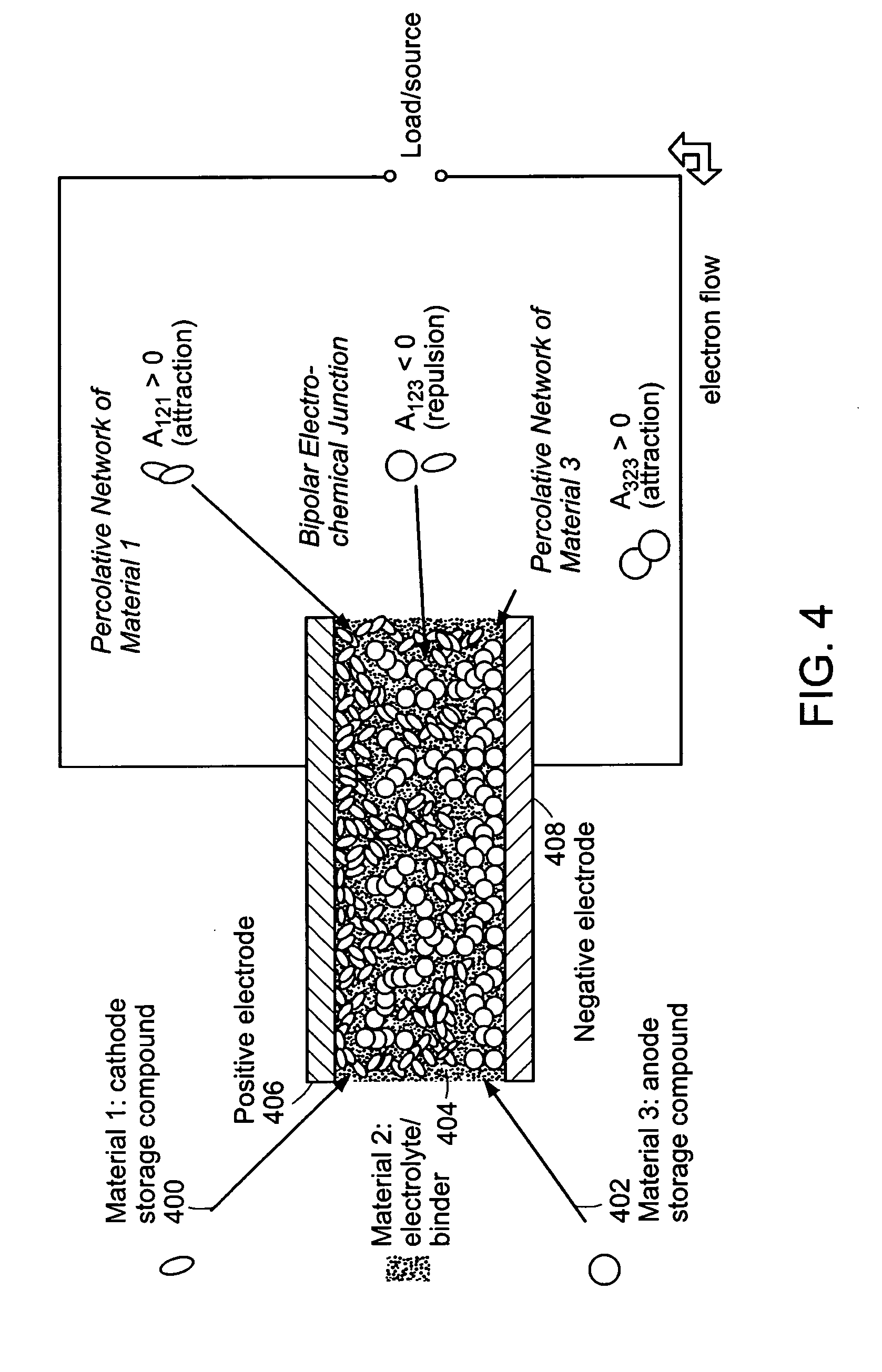

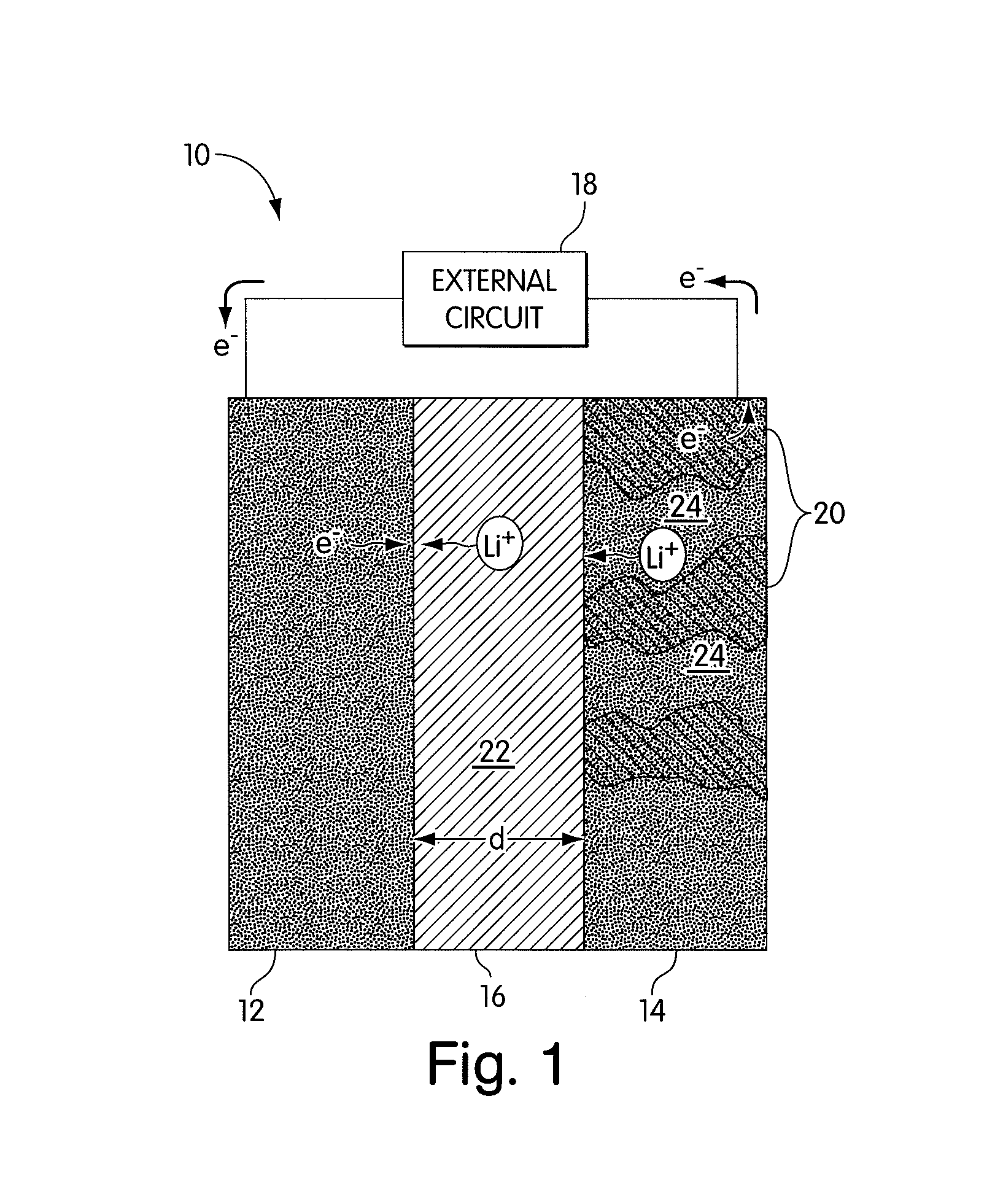

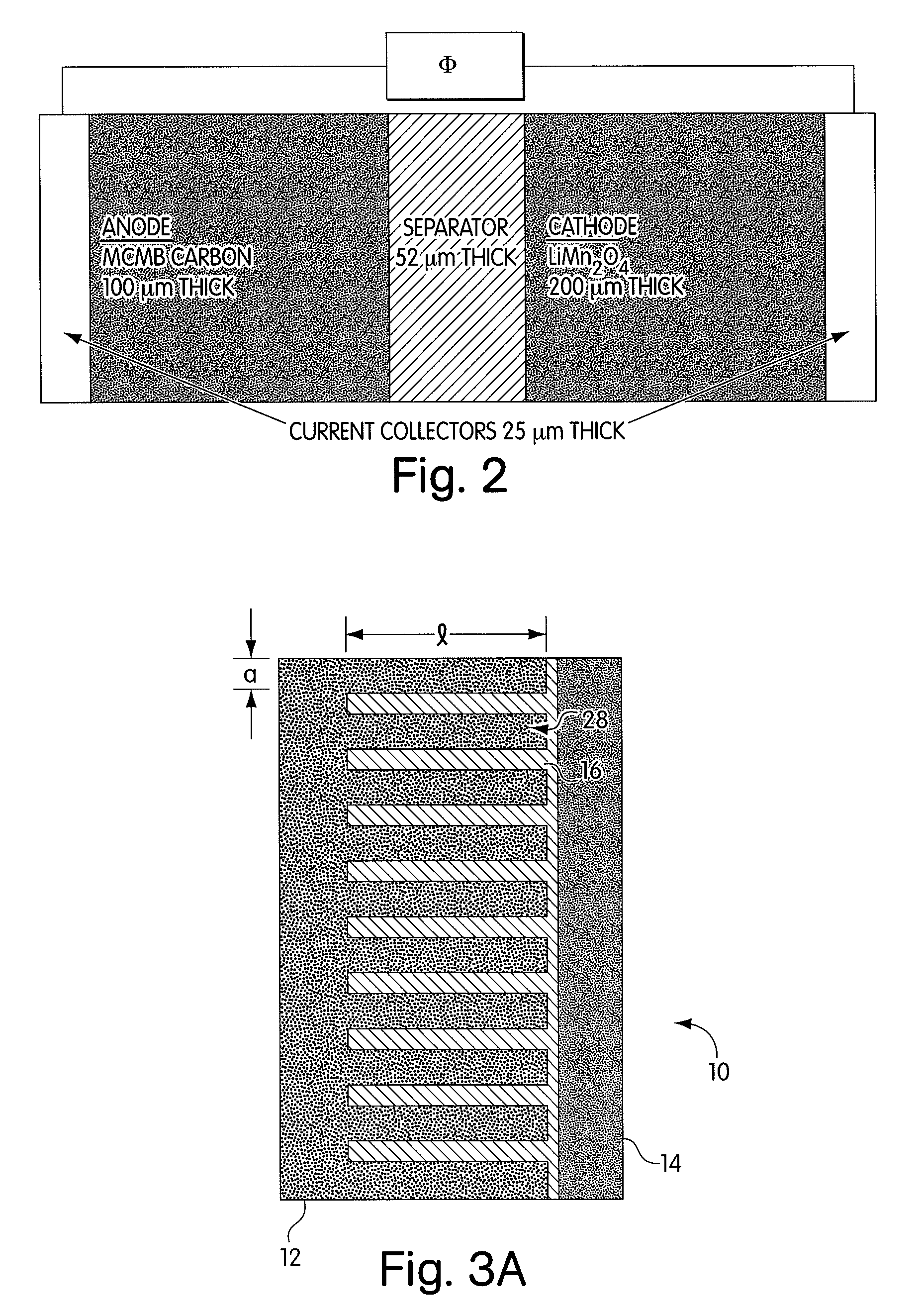

The invention provides bipolar articles (e.g., batteries and capacitors) with new architectures and methods of making and using the same. Articles are provided with interpenetrating anode and cathode structures that allow for improved power density, and arbitrary form factors that allow for formation in substantially any desired shape. The articles are useful for embedding or integral formation in various electronic devices to provide more efficient use of space in the devices. The articles optionally include self-organizing bipolar structures.

Owner:A123 SYSTEMS LLC

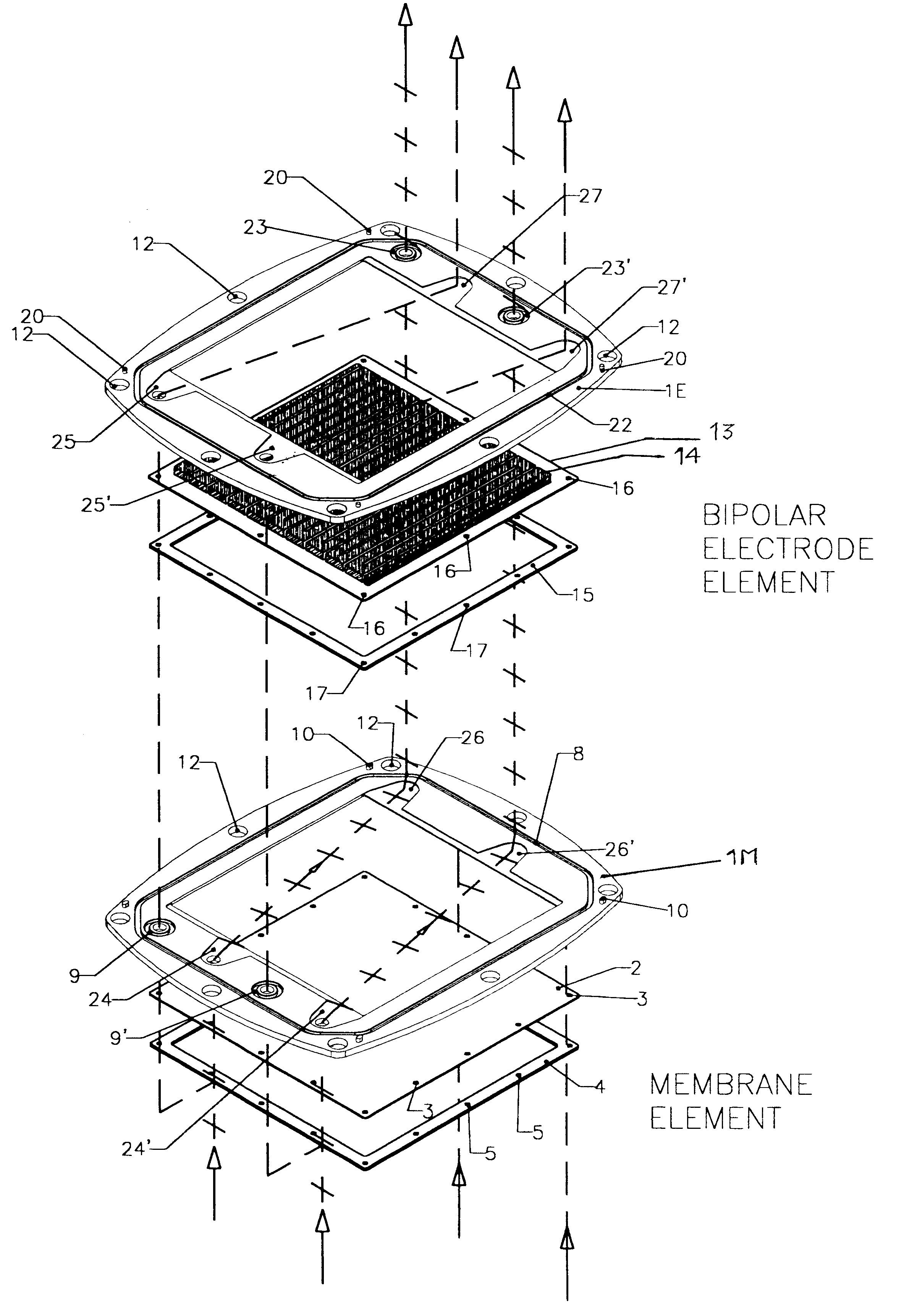

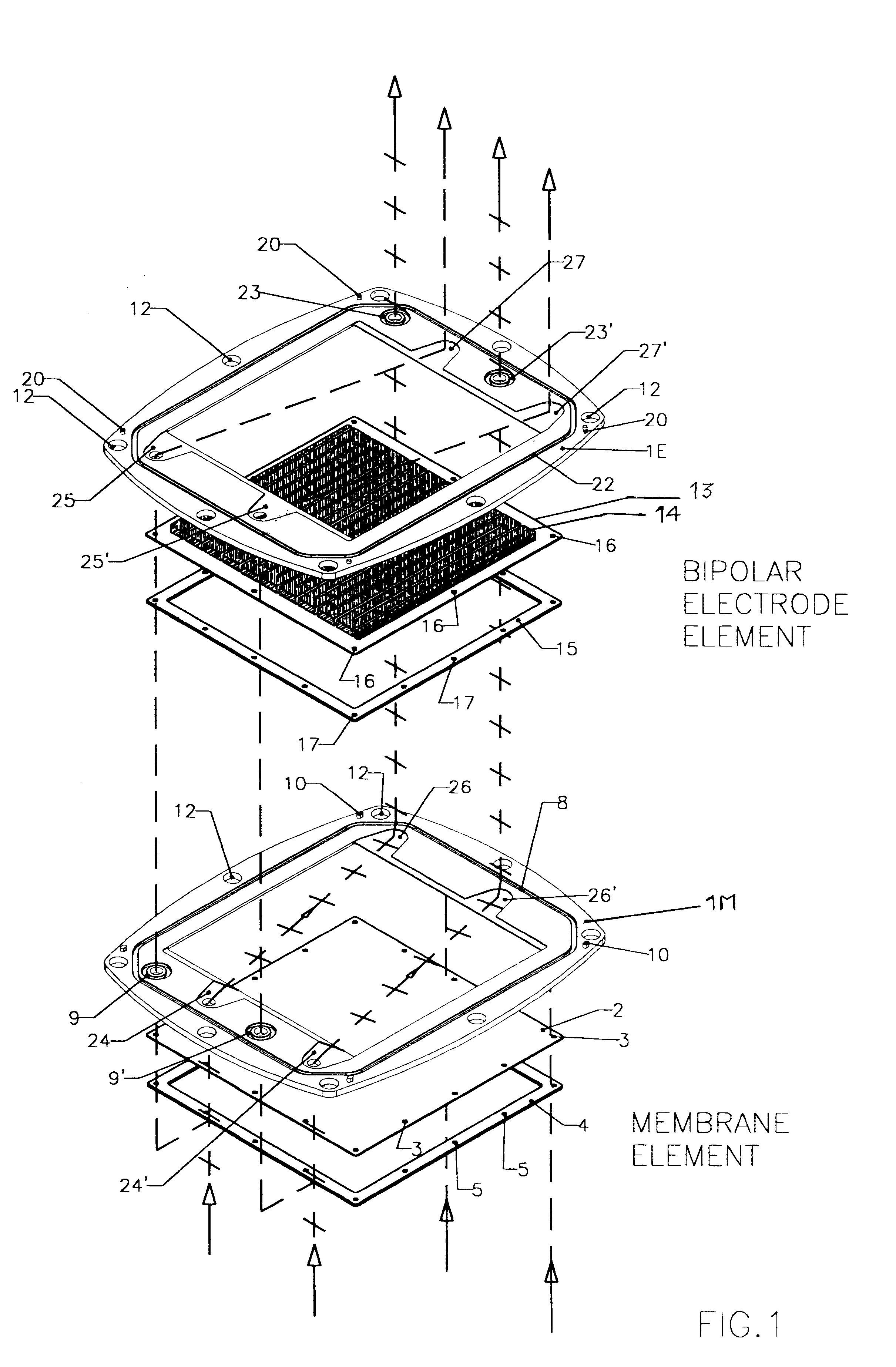

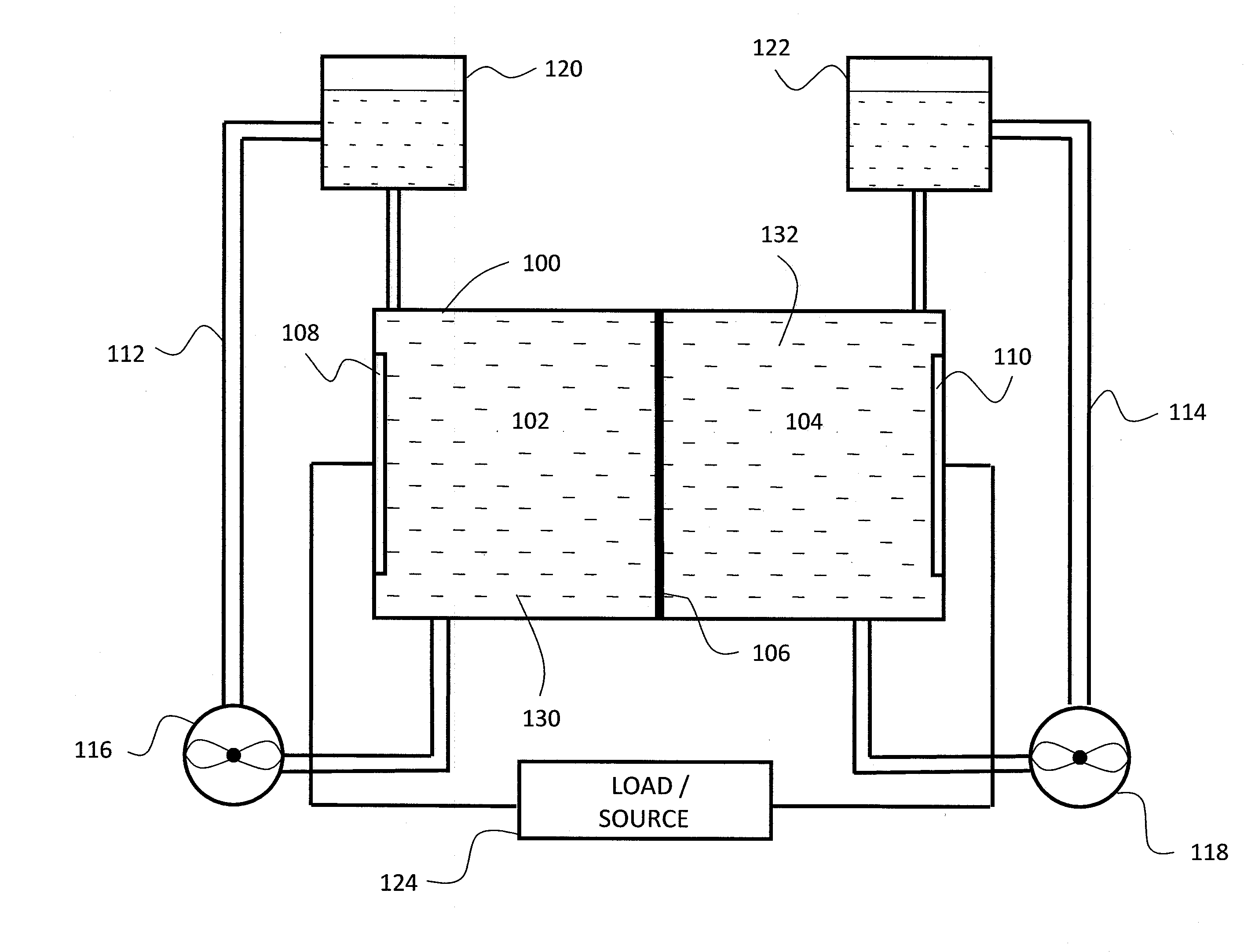

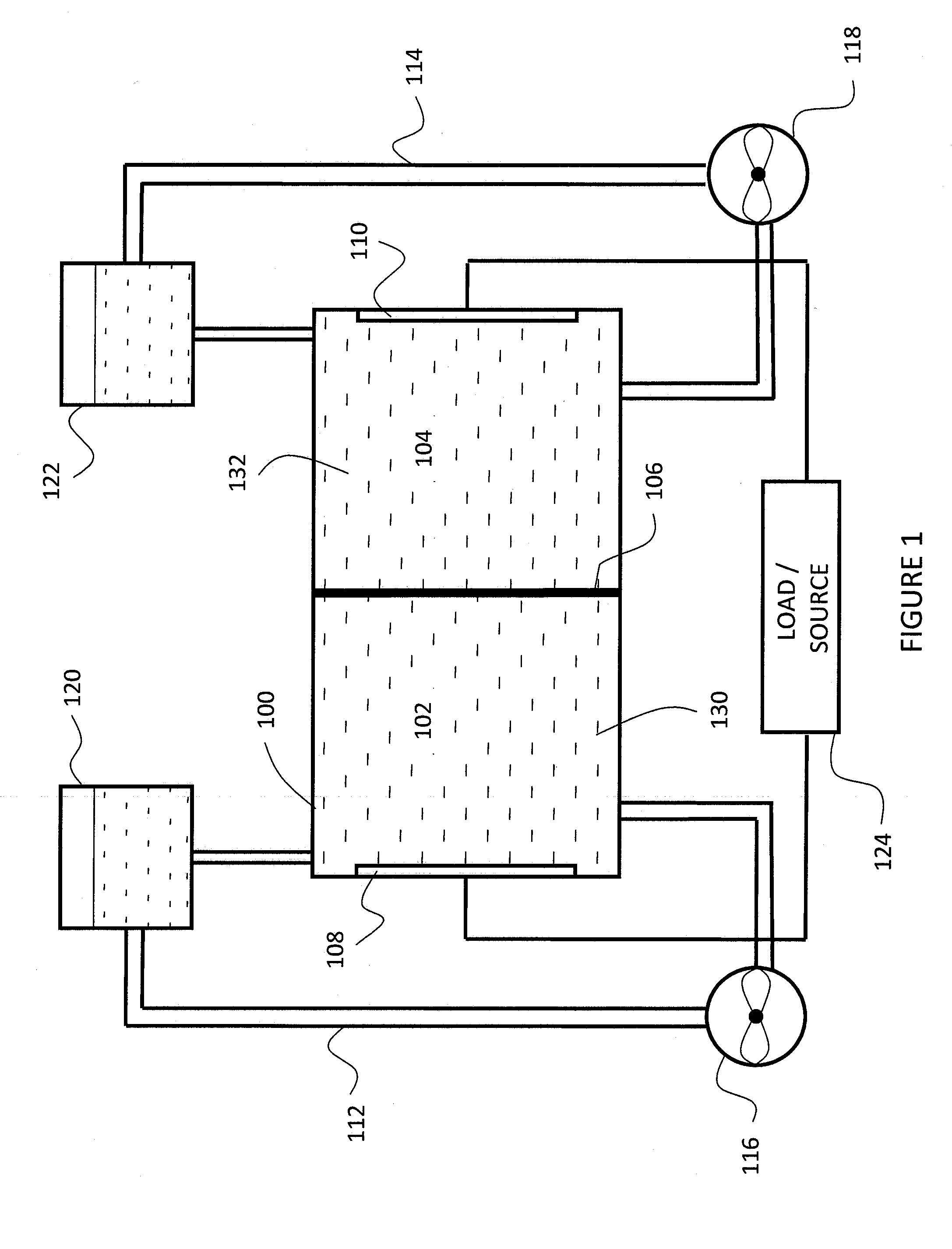

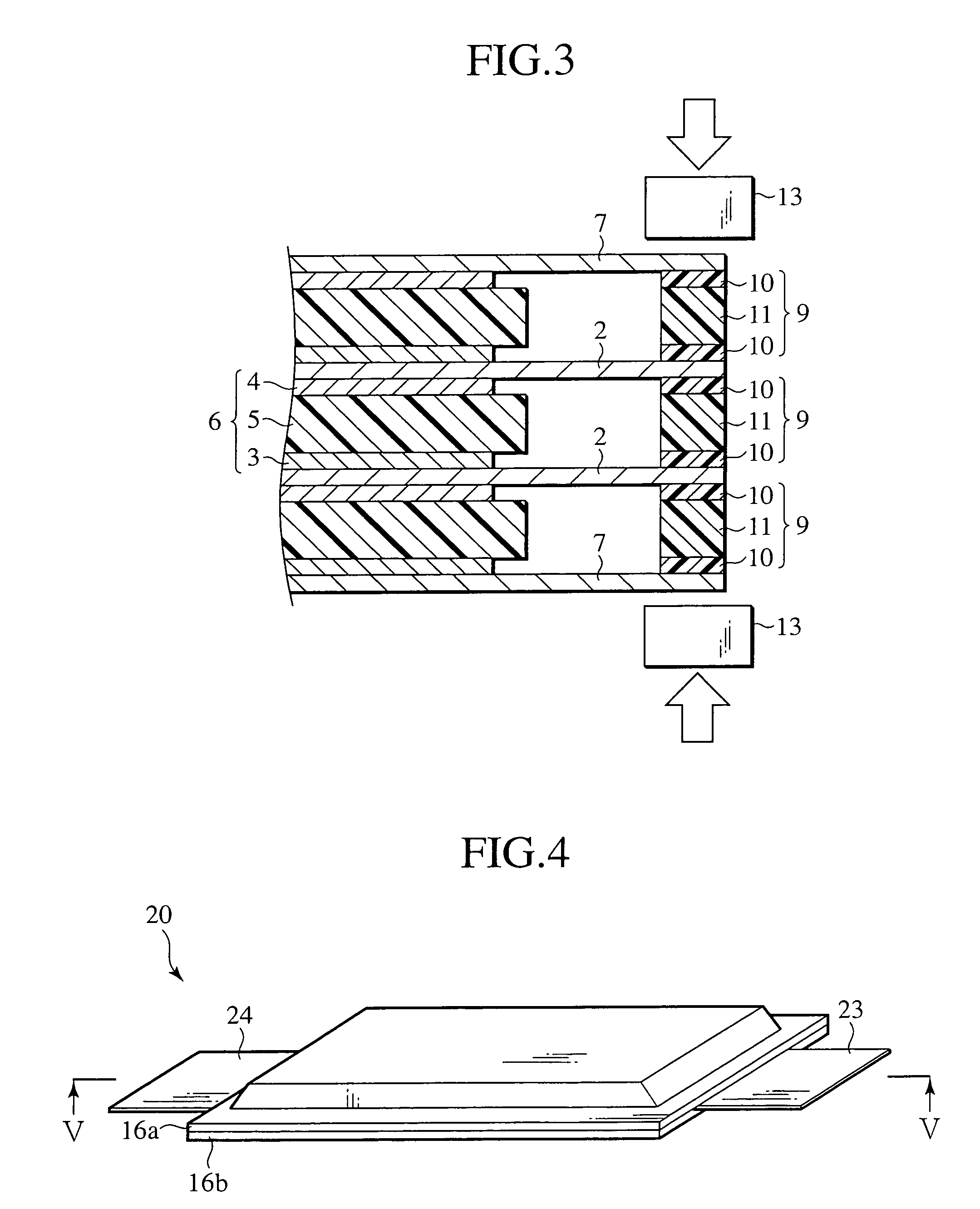

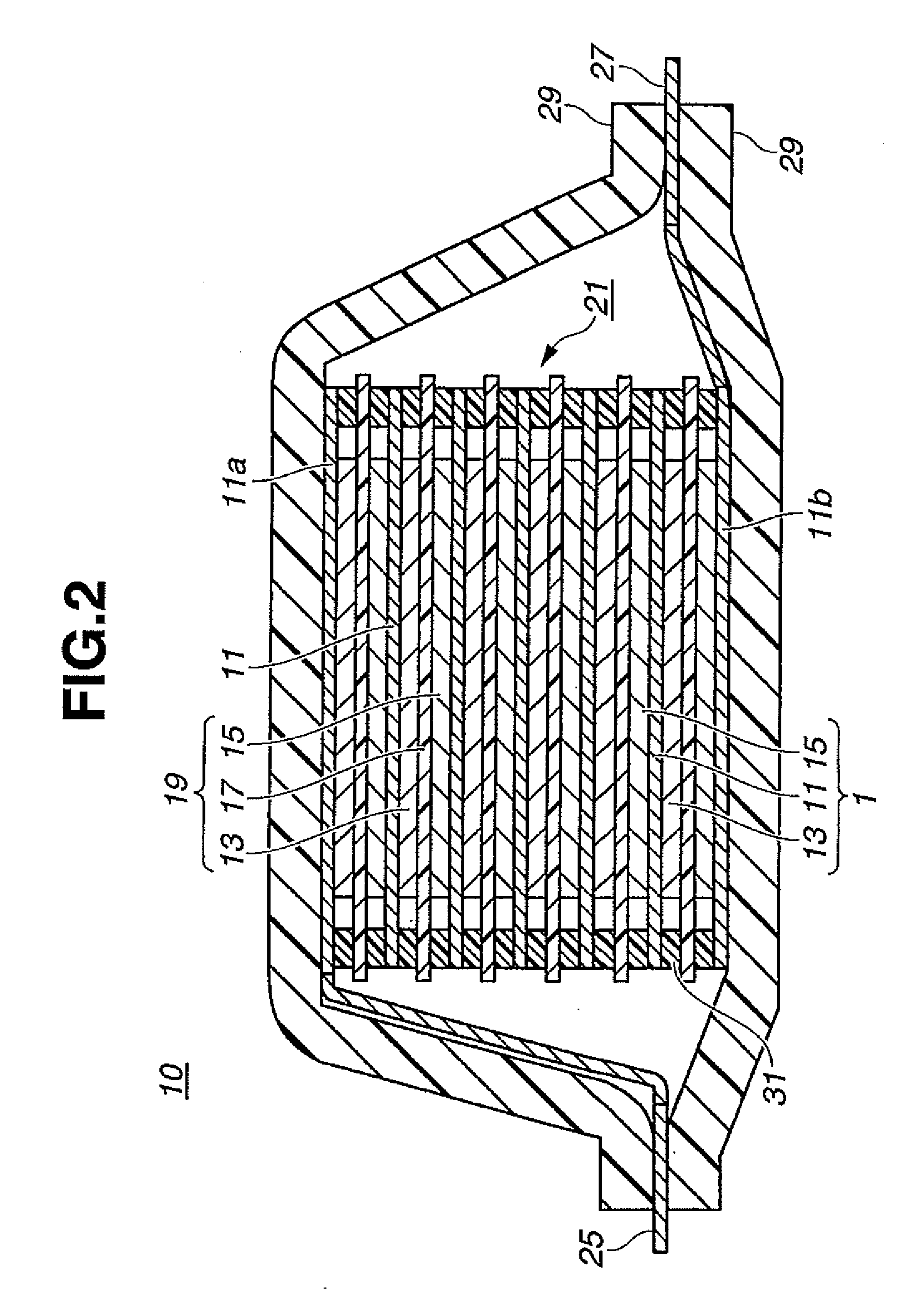

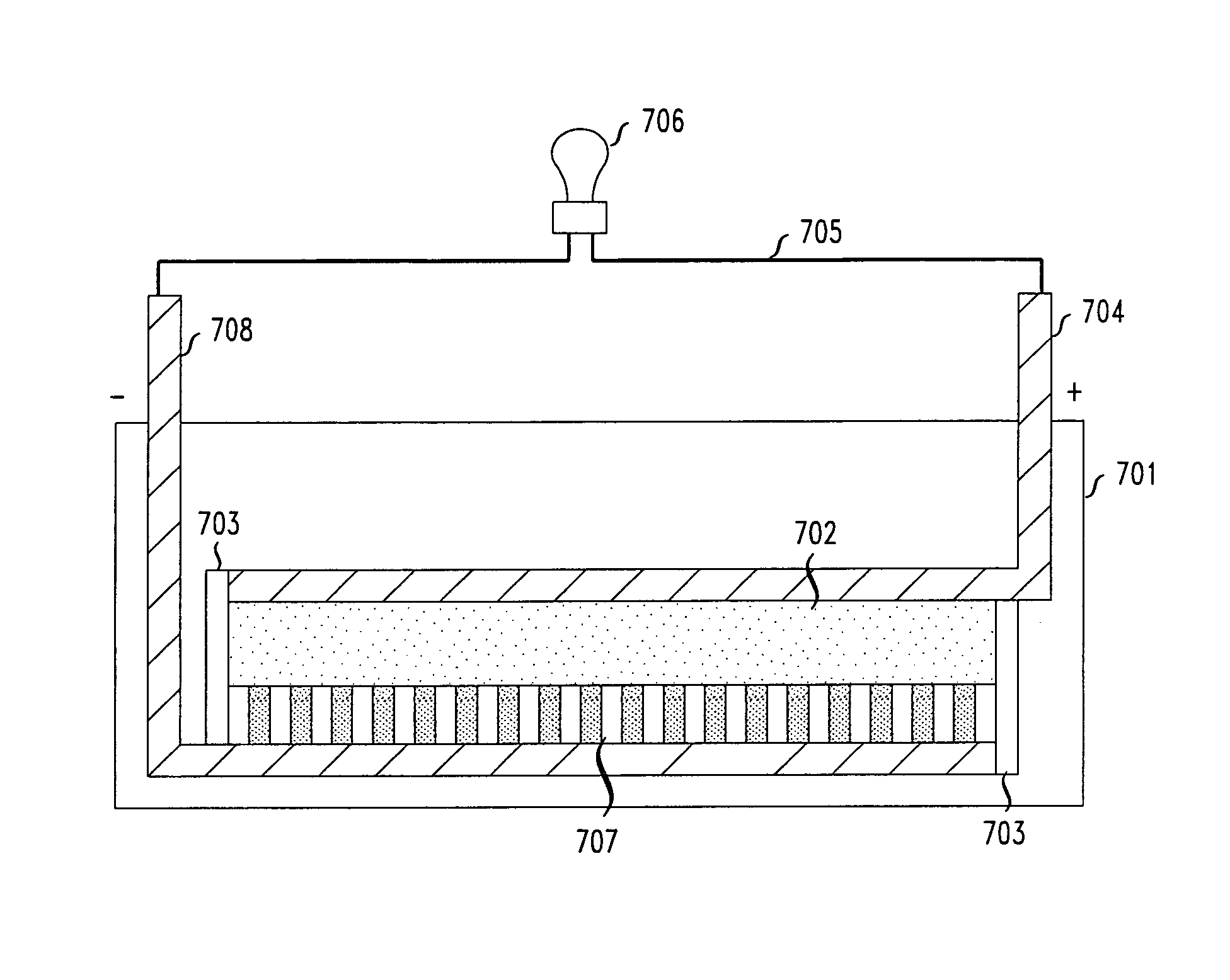

Membrane-separated, bipolar multicell electrochemical reactor

InactiveUS6555267B1Improve electrochemical performanceLower overall pressure dropFuel cells groupingFuel cell auxillariesPlastic materialsIon-exchange membranes

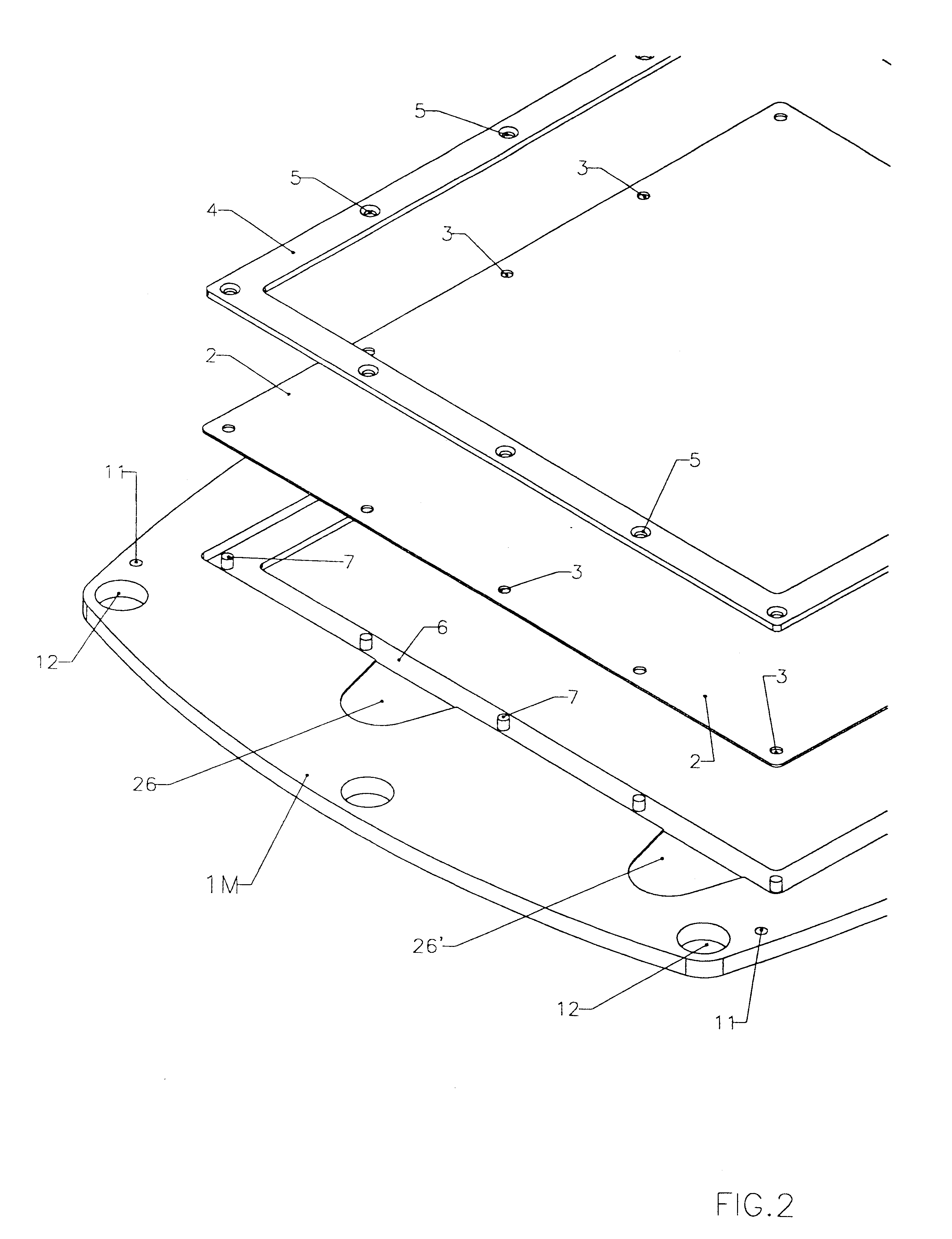

A multicell assembly is constituted by alternately stacking two types of pre-assembled elements: a bipolar electrode holding subassembly and a membrane holding subassembly. The alternate stack of elements is piled over a bottom end element and the stack is terminated by placing over the last membrane holding element a top end electrode element. Each bipolar plate electrode holding element and each ion exchange membrane separator holding element includes a substantially similar rectangular frame piece, made of an electrically nonconductive and chemically resistant material, typically of molded plastic material, having on its upper (assembly) face grooves for receiving O-ring type gasket means, and having through holes and recesses in coordinated locations disposed along two opposite sides of the rectangular frame forming, upon completion of the assembling, ducts for the separate circulation of the negative electrolyte and of the positive electrolyte through all the negative electrolyte flow chambers and all positive electrolyte flow chambers, respectively, in cascade.

Owner:SQUIRREL HLDG

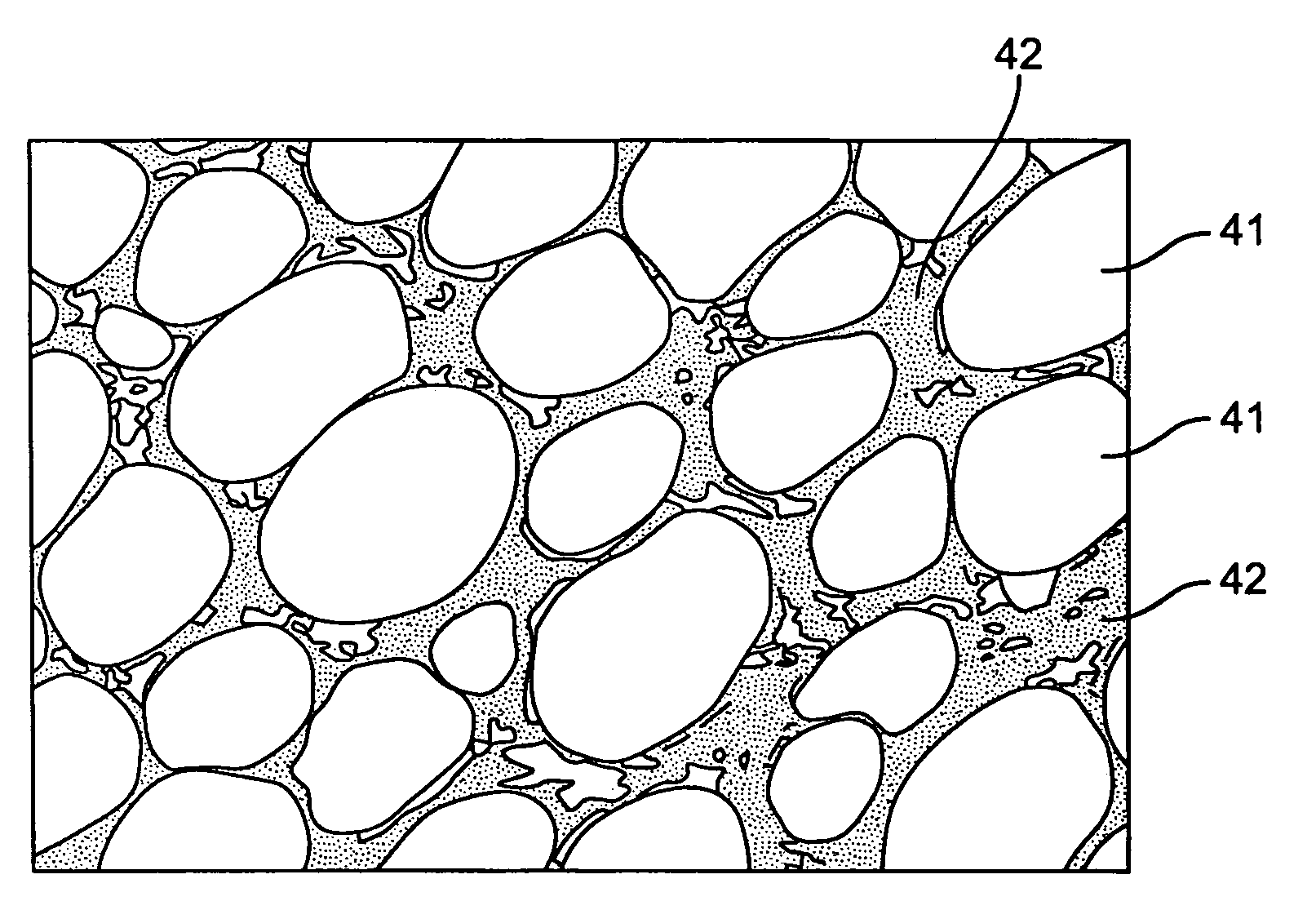

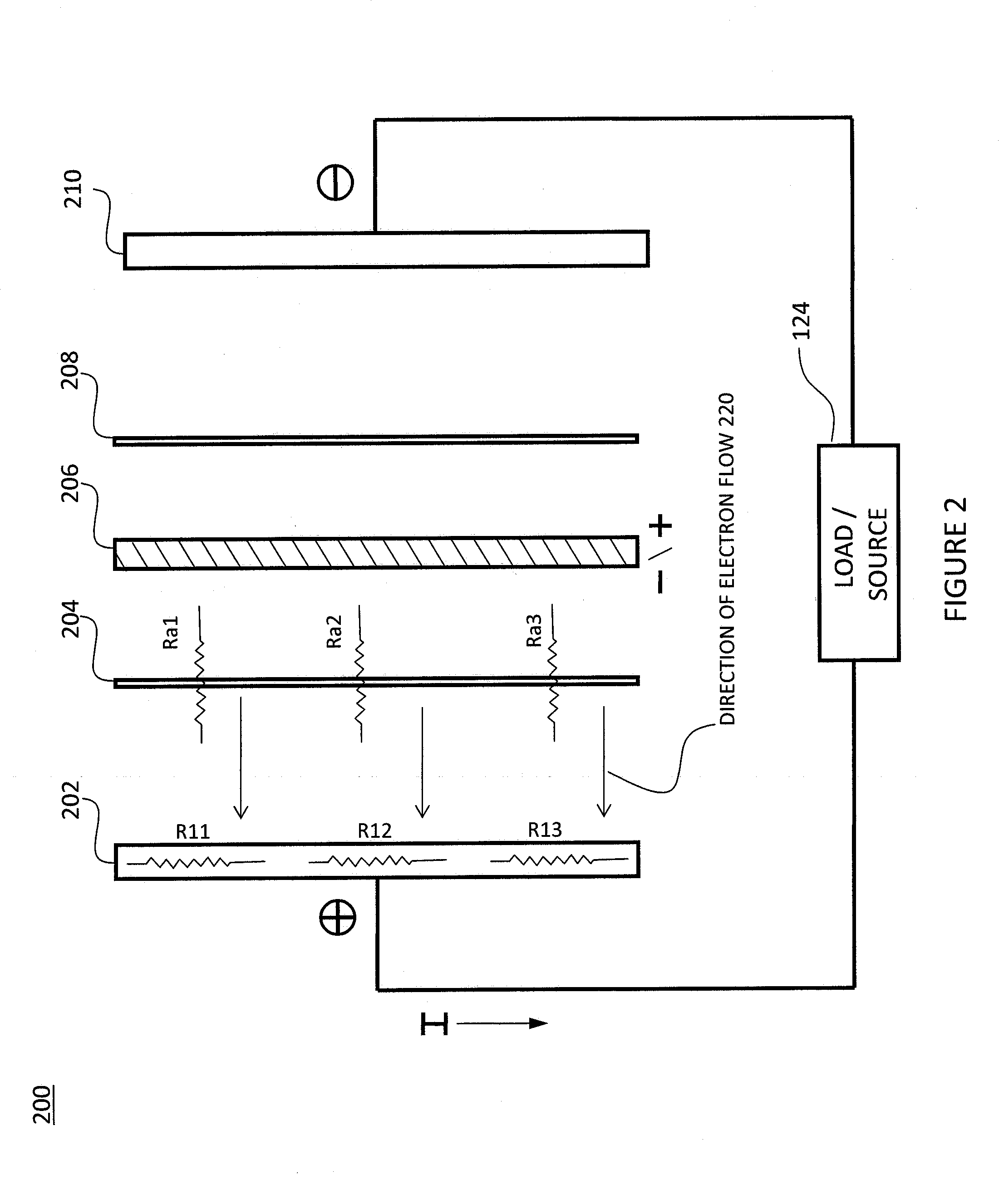

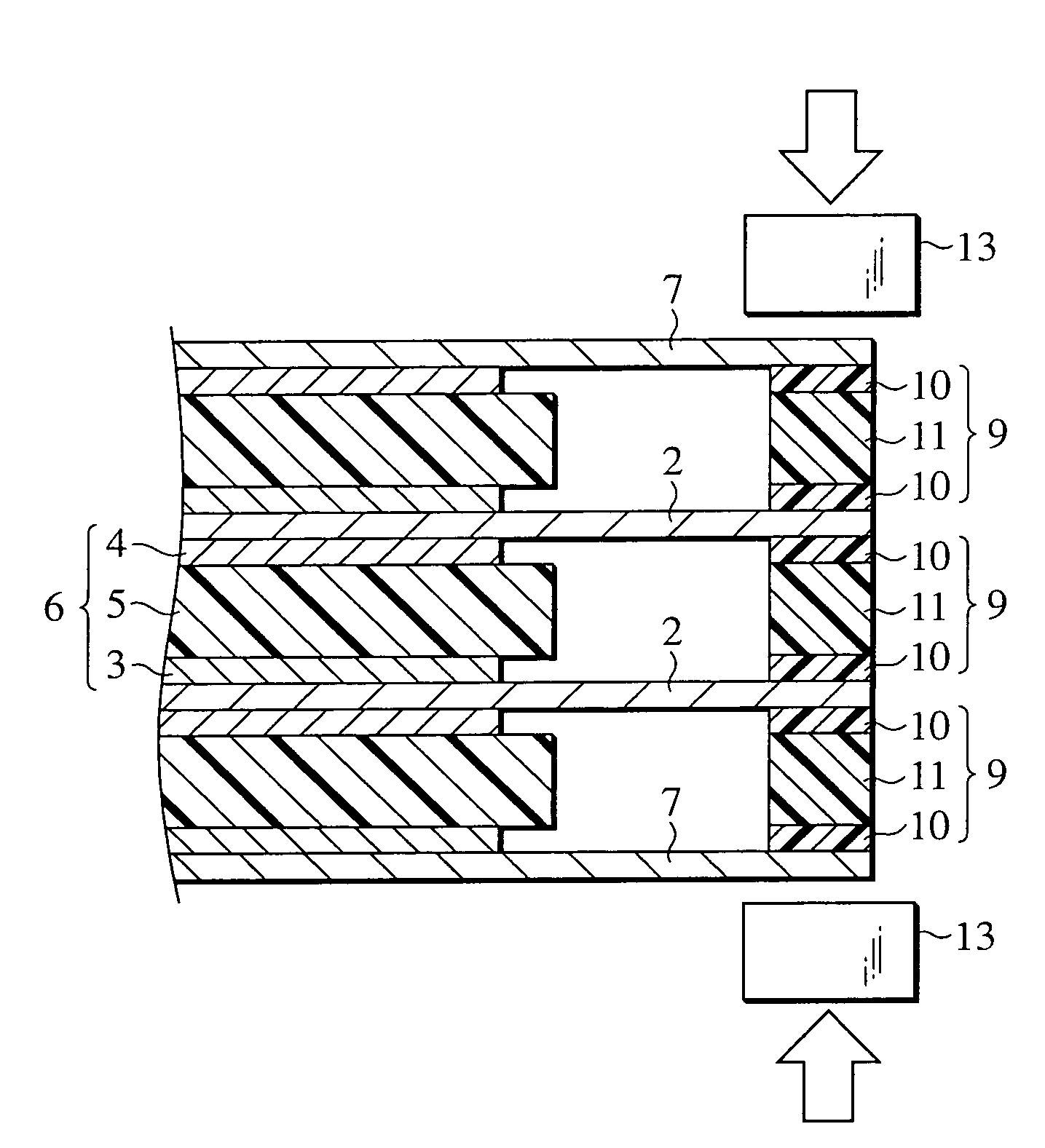

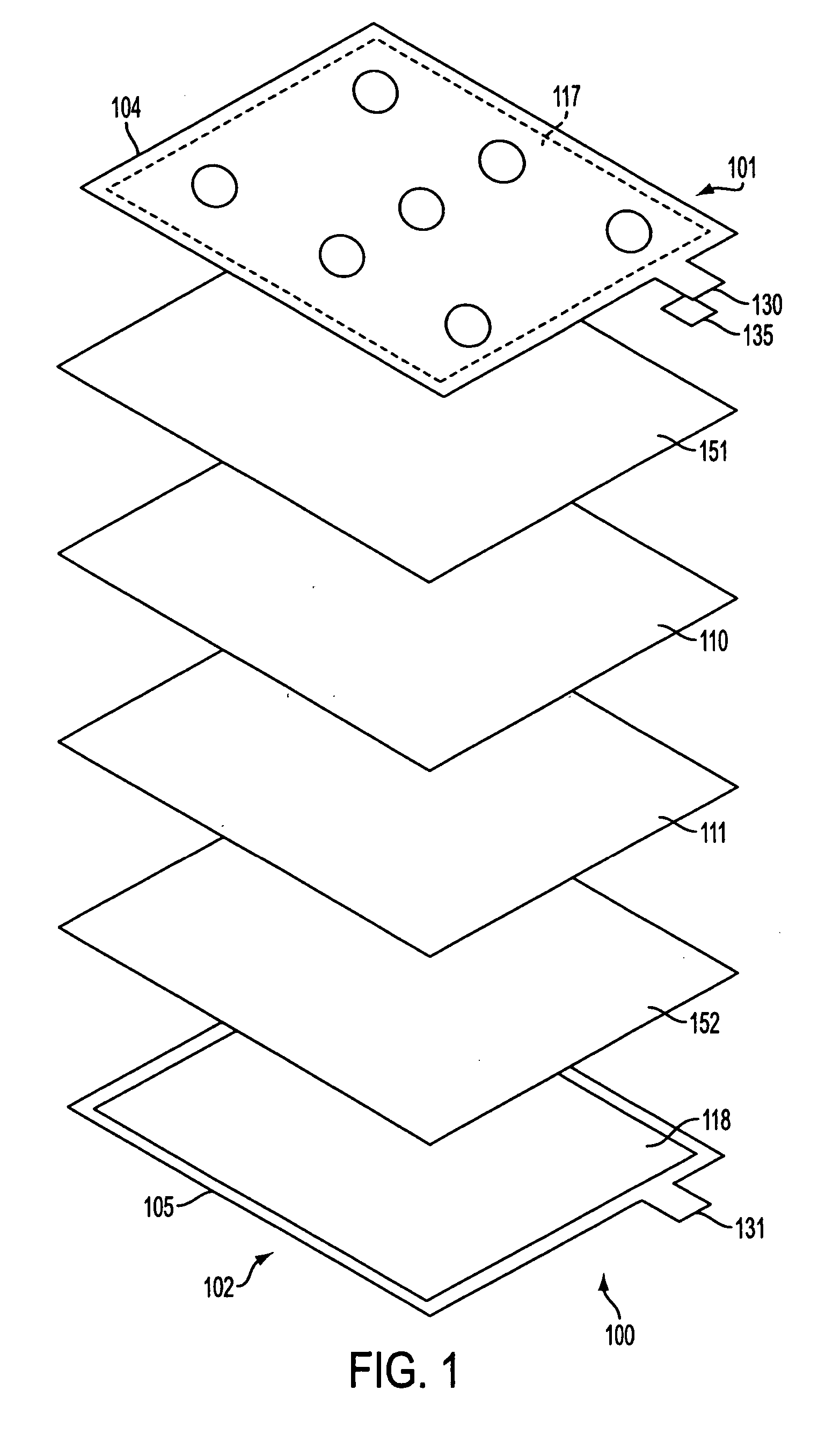

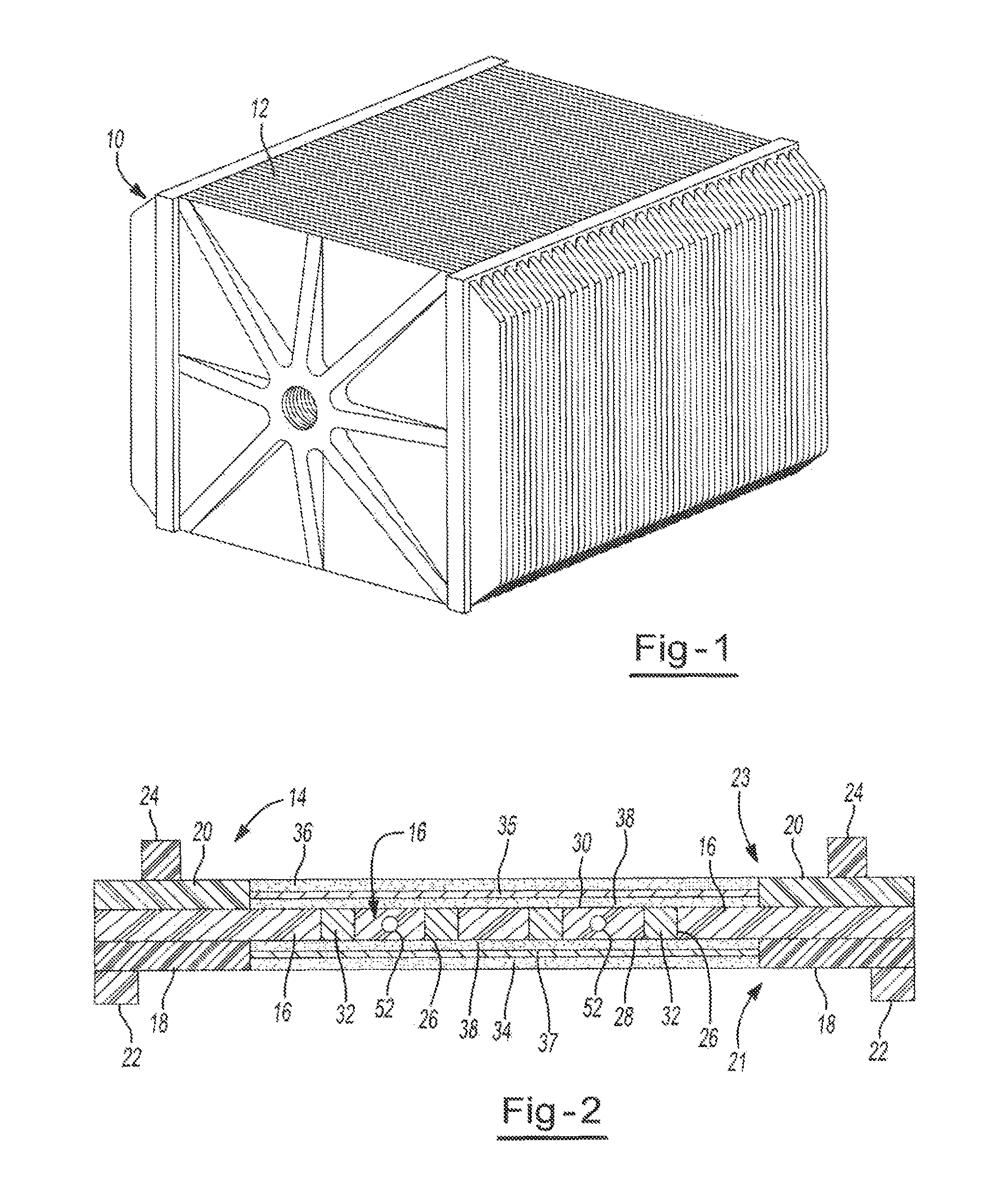

Reticulated and controlled porosity battery structures

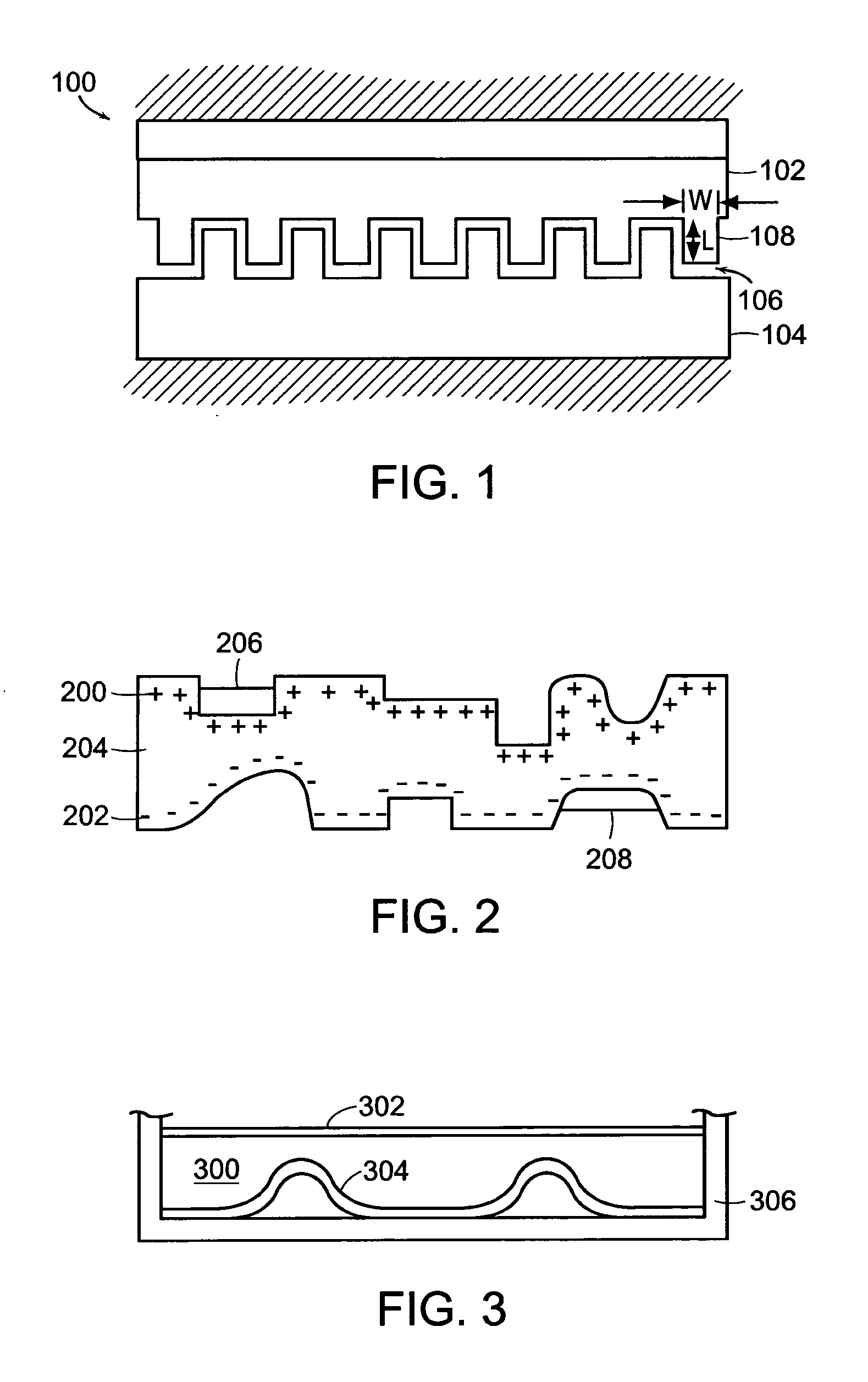

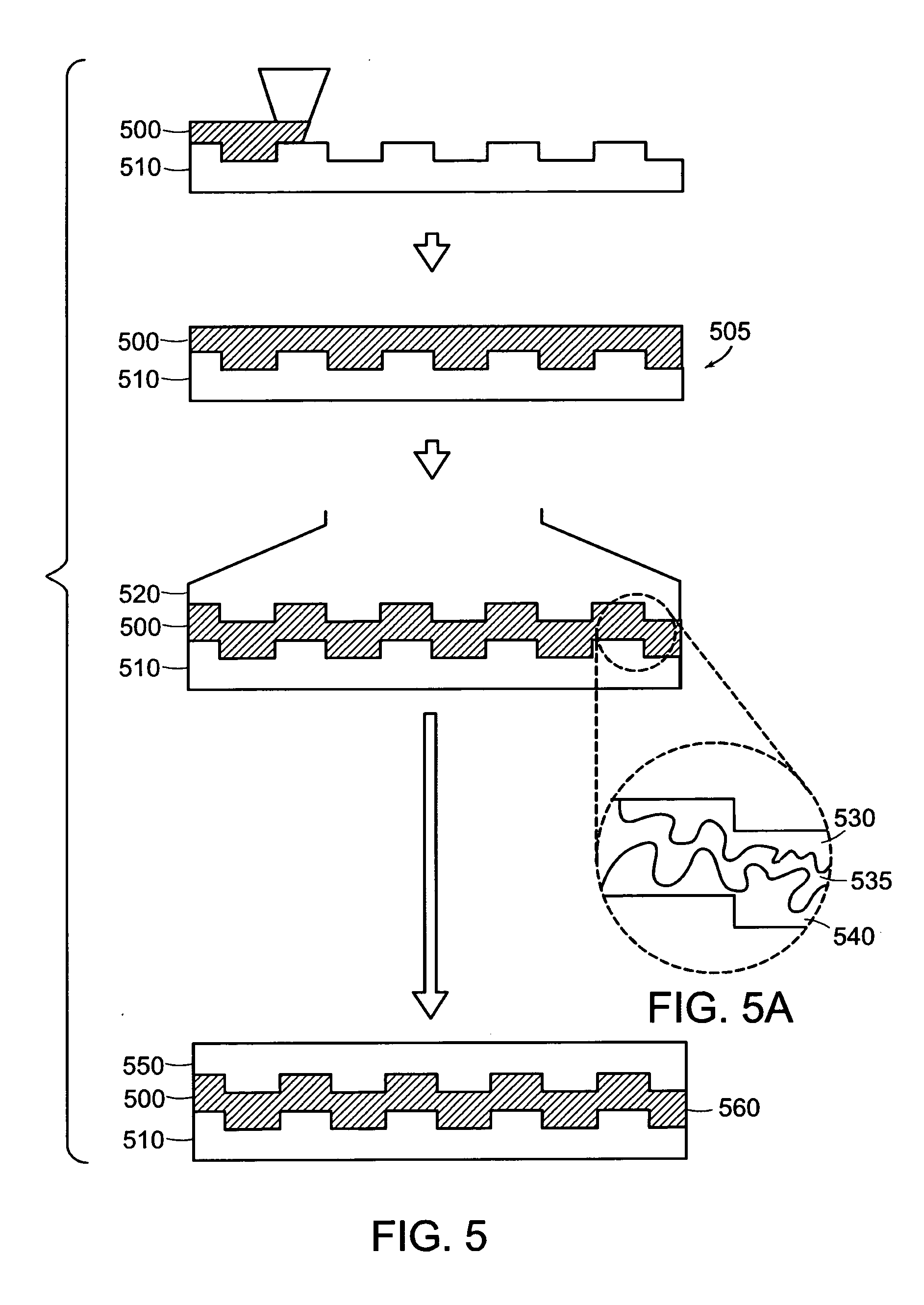

InactiveUS7553584B2Boost energyHigh porosityElectrode thermal treatmentElectrolytic capacitorsEngineeringTortuous retinal vessels

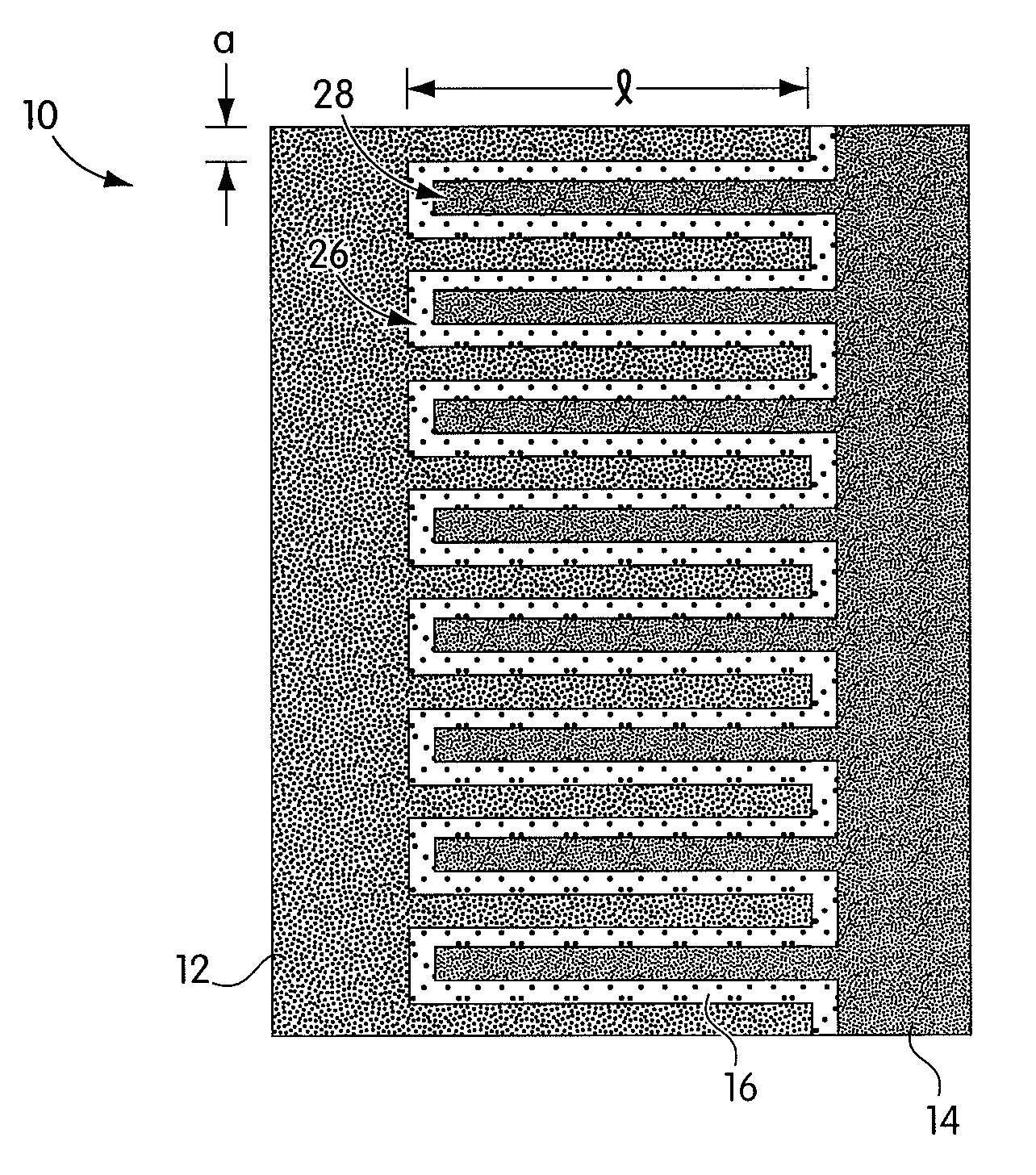

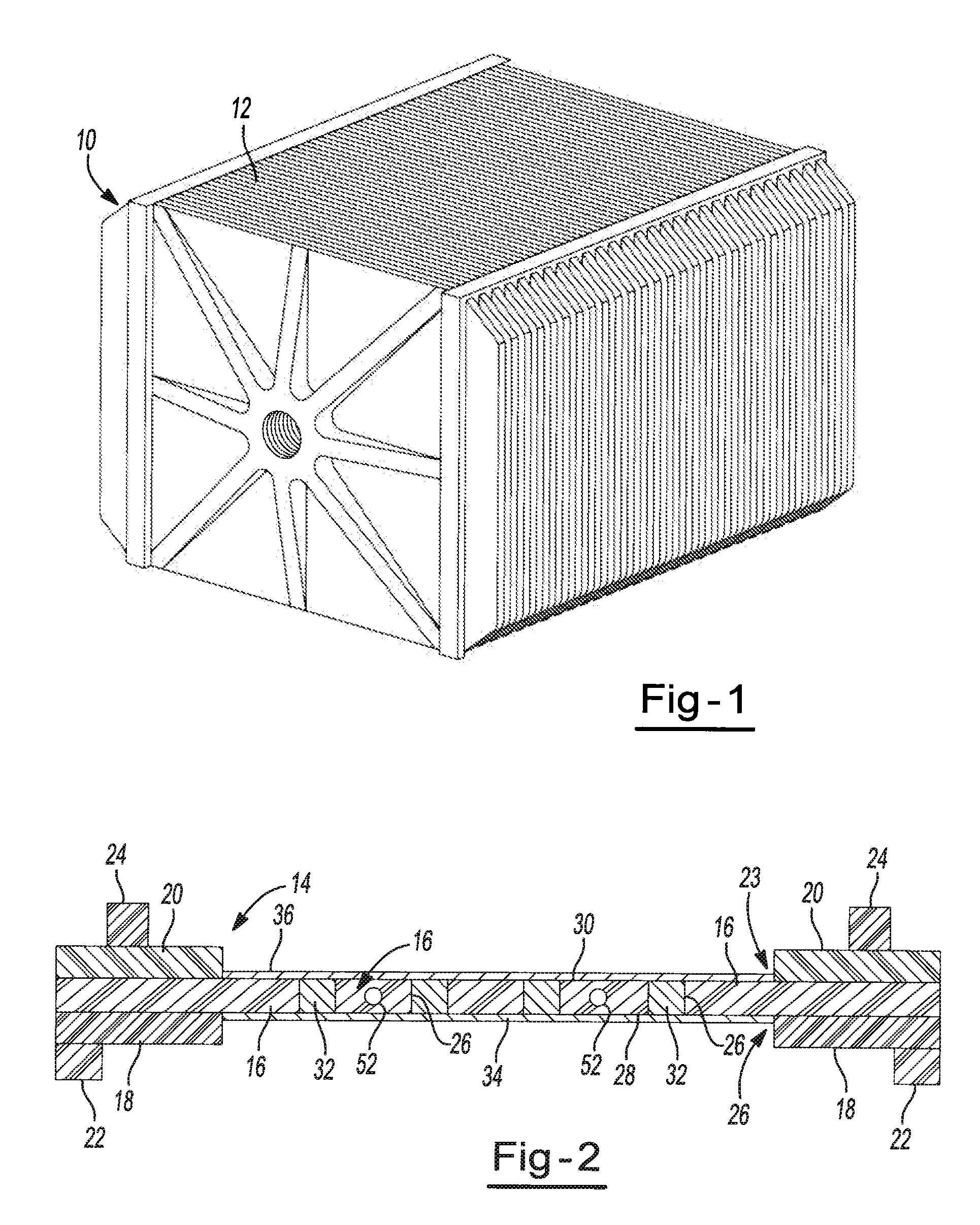

The effective ionic conductivity in a composite structure is believed to decrease rapidly with volume fraction. A system, such as a bipolar device or energy storage device, has structures or components in which the diffusion length or path that electrodes or ions must traverse is minimized and the interfacial area exposed to the ions or electrons is maximized. The device includes components that can be reticulated or has a reticulated interface so that an interface area can be increased. The increased interfacial perimeter increases the available sites for reaction of ionic species. Many different reticulation patterns can be used. The aspect ratio of the reticulated features can be varied. Such bipolar devices can be fabricated by a variety of methods or procedures. A bipolar device having structures of reticulated interface can be tailored for the purposes of controlling and optimizing charge and discharge kinetics. A bipolar device having graded porosity structures can have improved transport properties because the diffusion controlling reaction kinetics can be modified. Graded porosity electrodes can be linearly or nonlinearly graded. A bipolar device having perforated structures also provides improved transport properties by removing tortuosity and reducing diffusion distance.

Owner:MASSACHUSETTS INST OF TECH

Battery including carbon foam current collectors

InactiveUS6979513B2Electrode manufacturing processesSemi-lead accumulatorsElectrical batteryNanotechnology

Owner:FIREFLY ENERGY INC

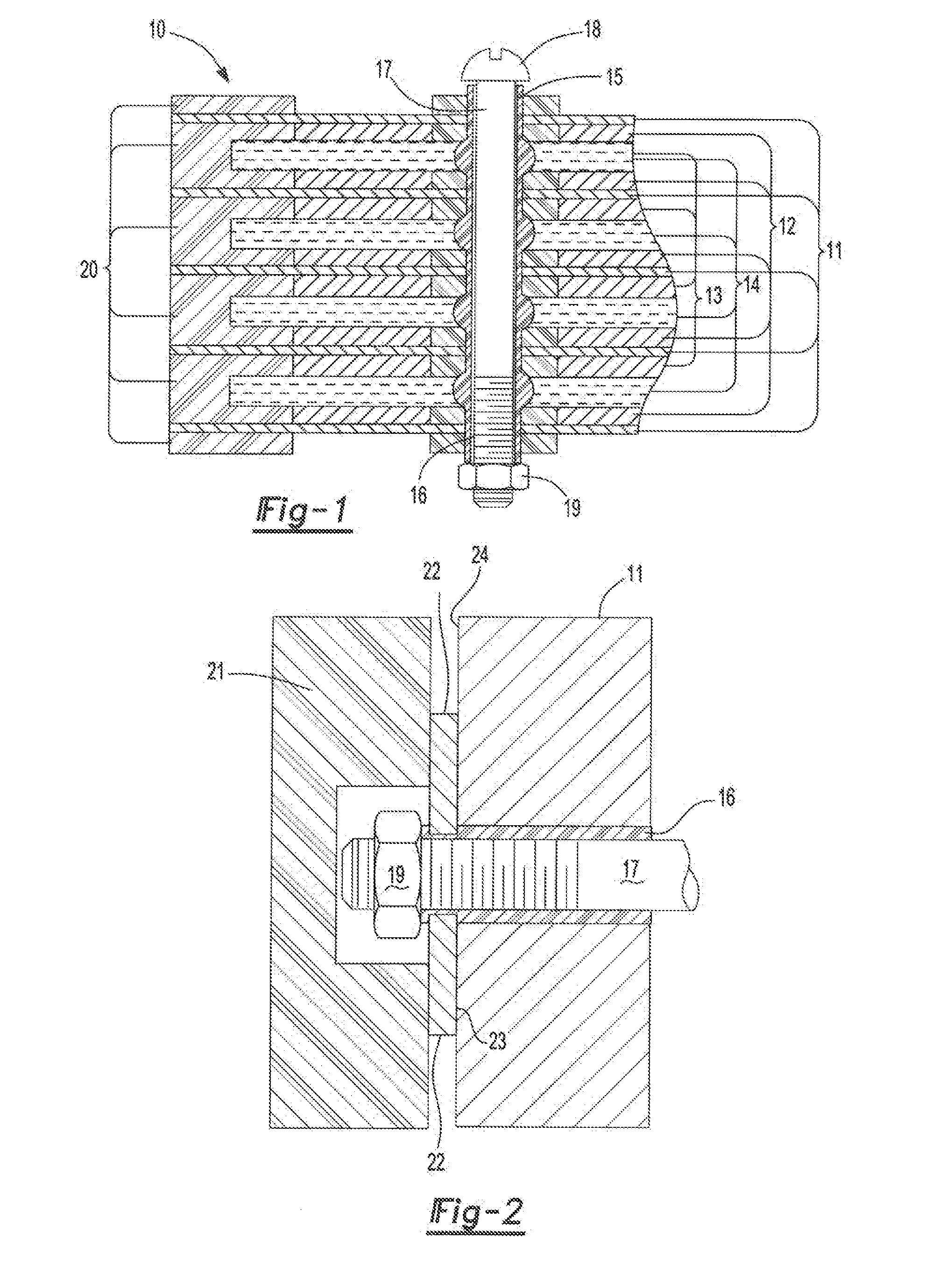

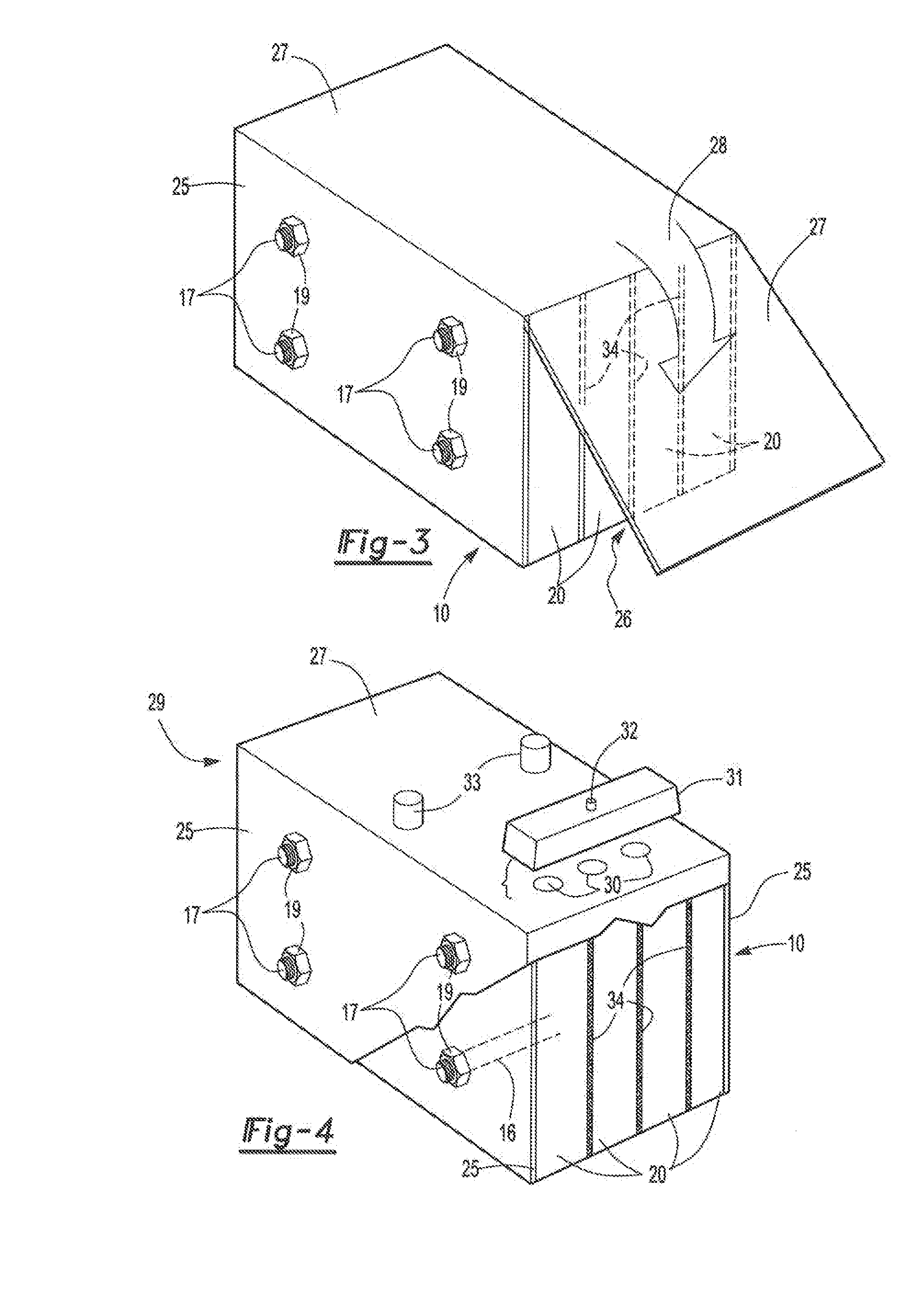

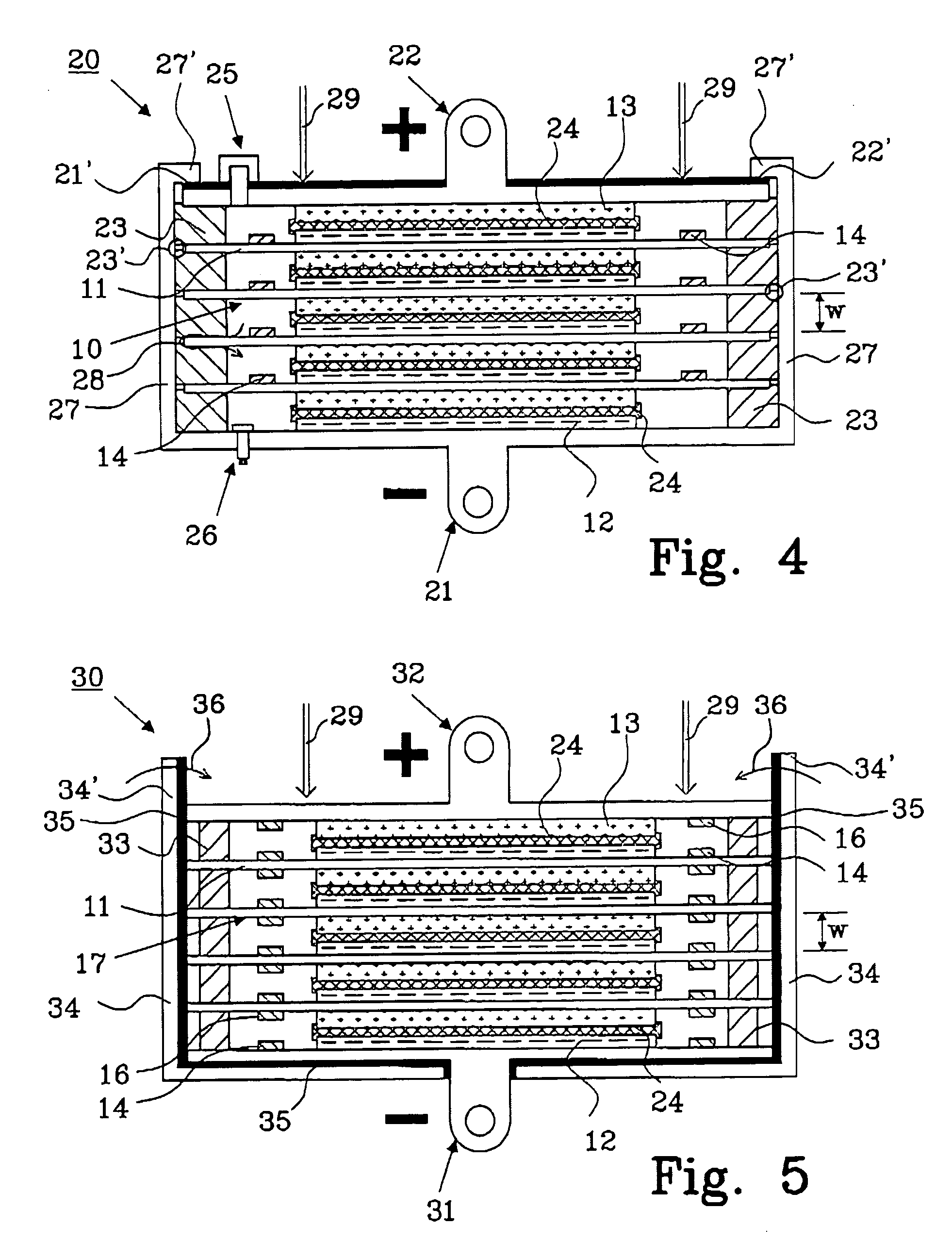

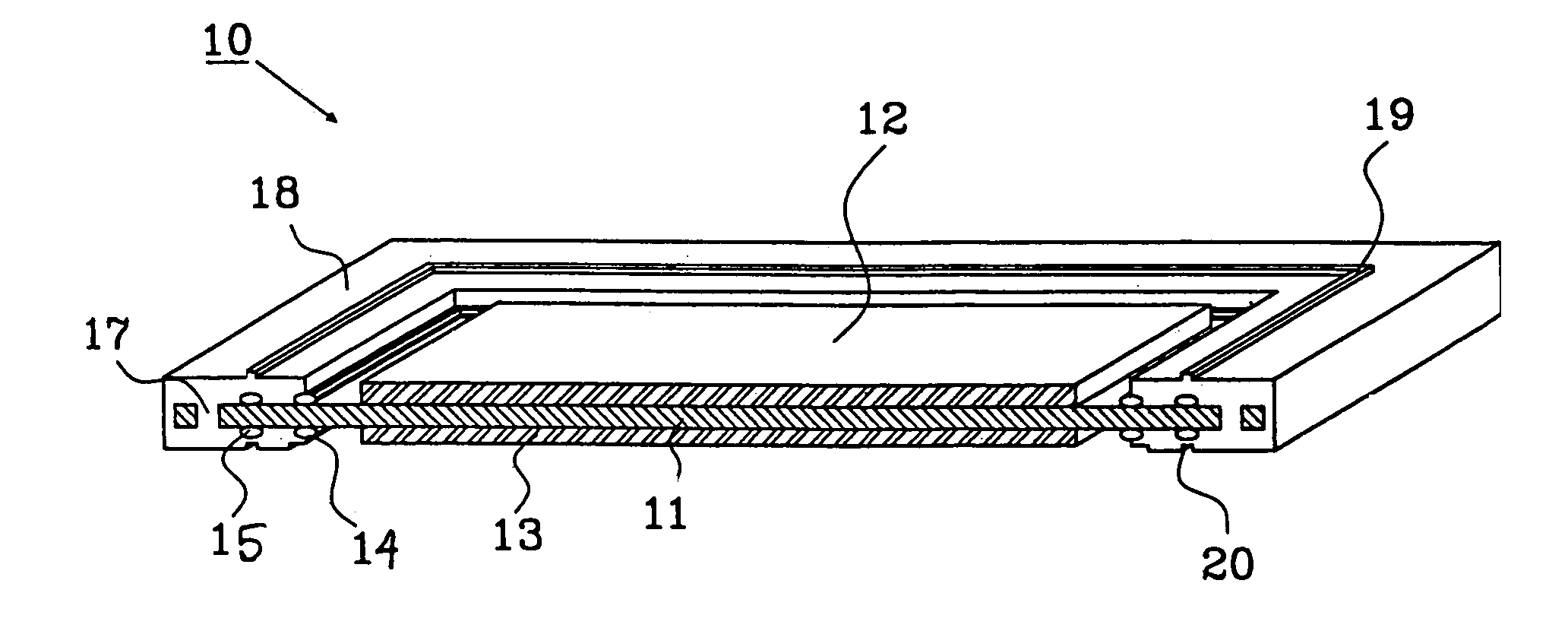

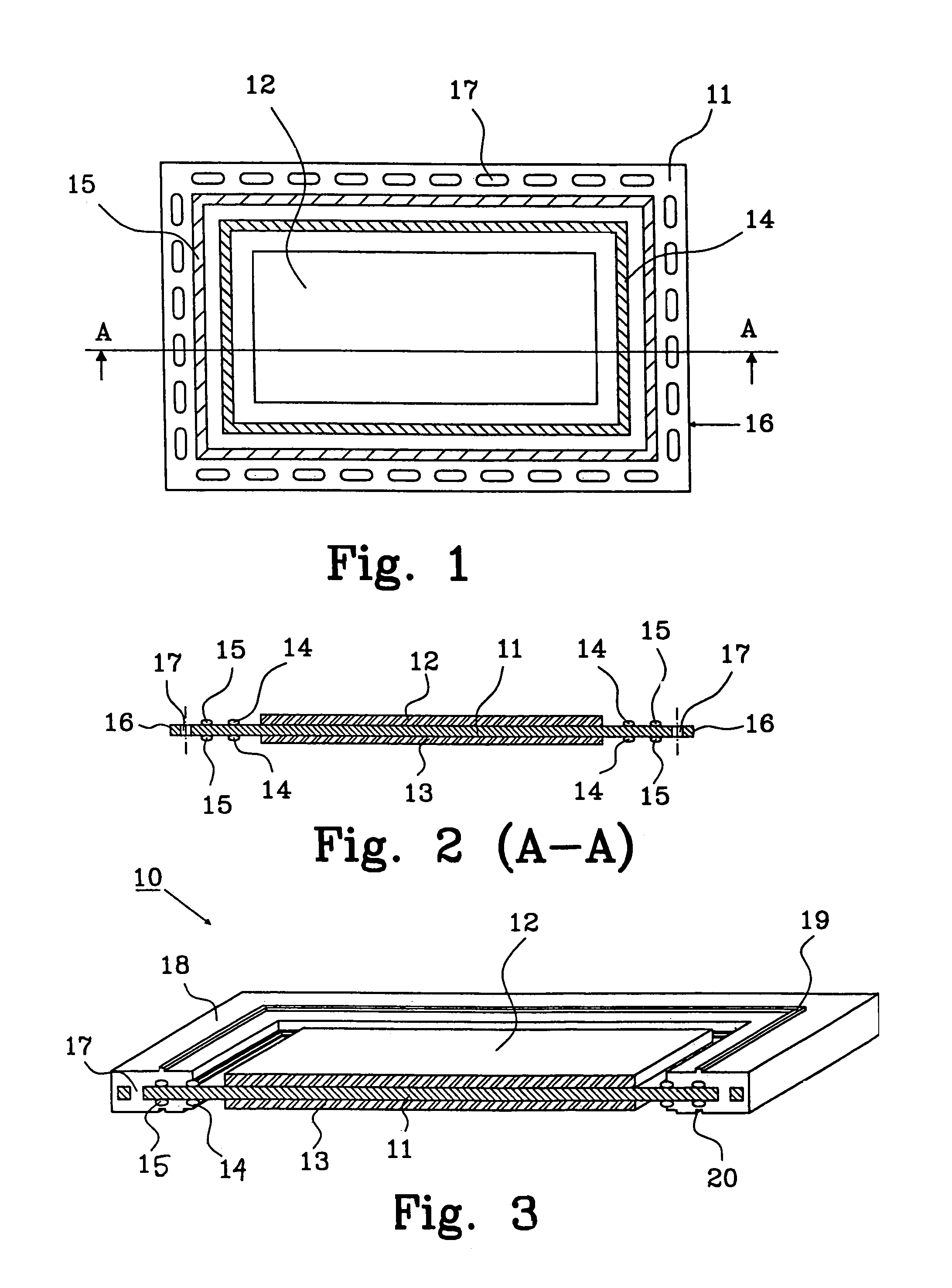

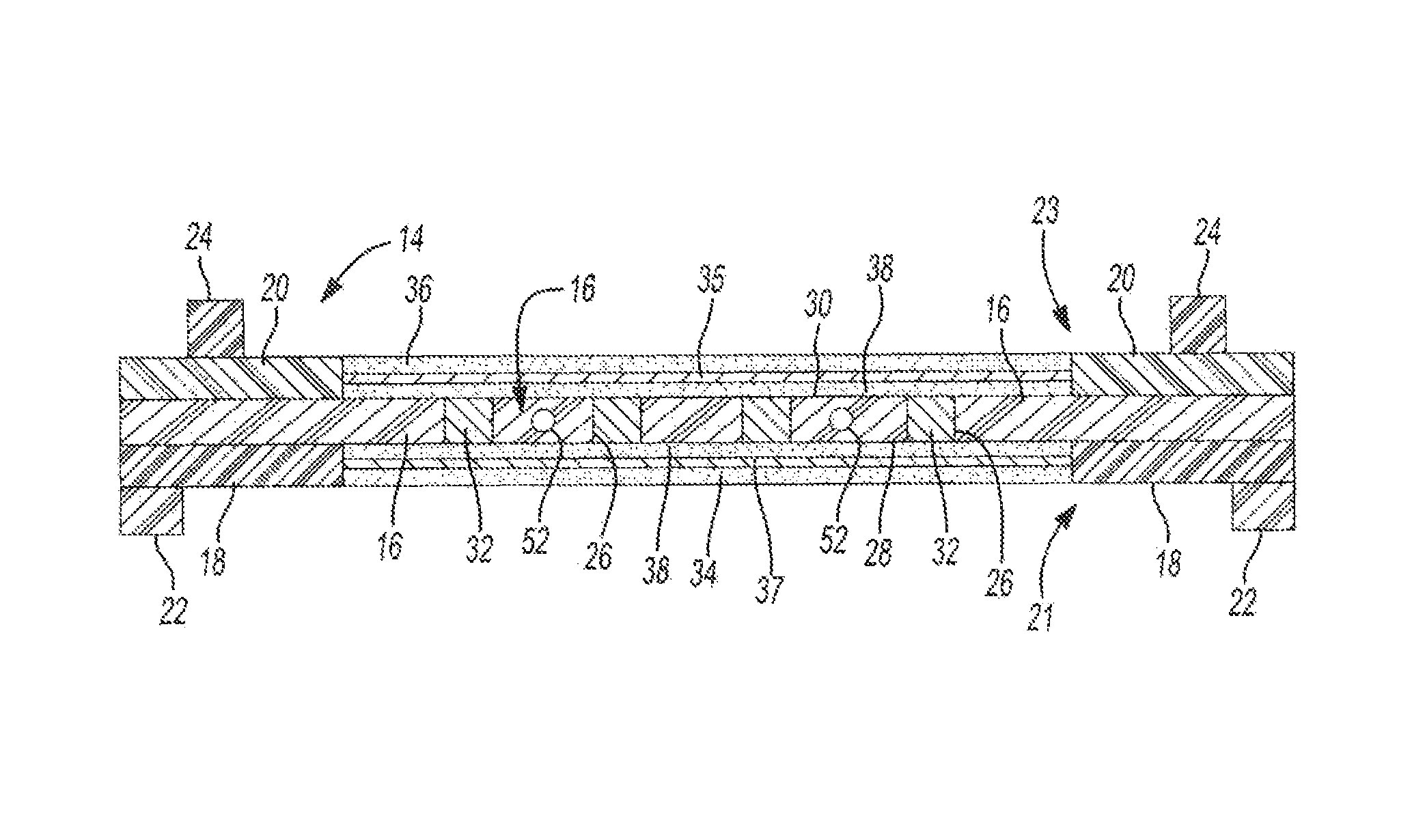

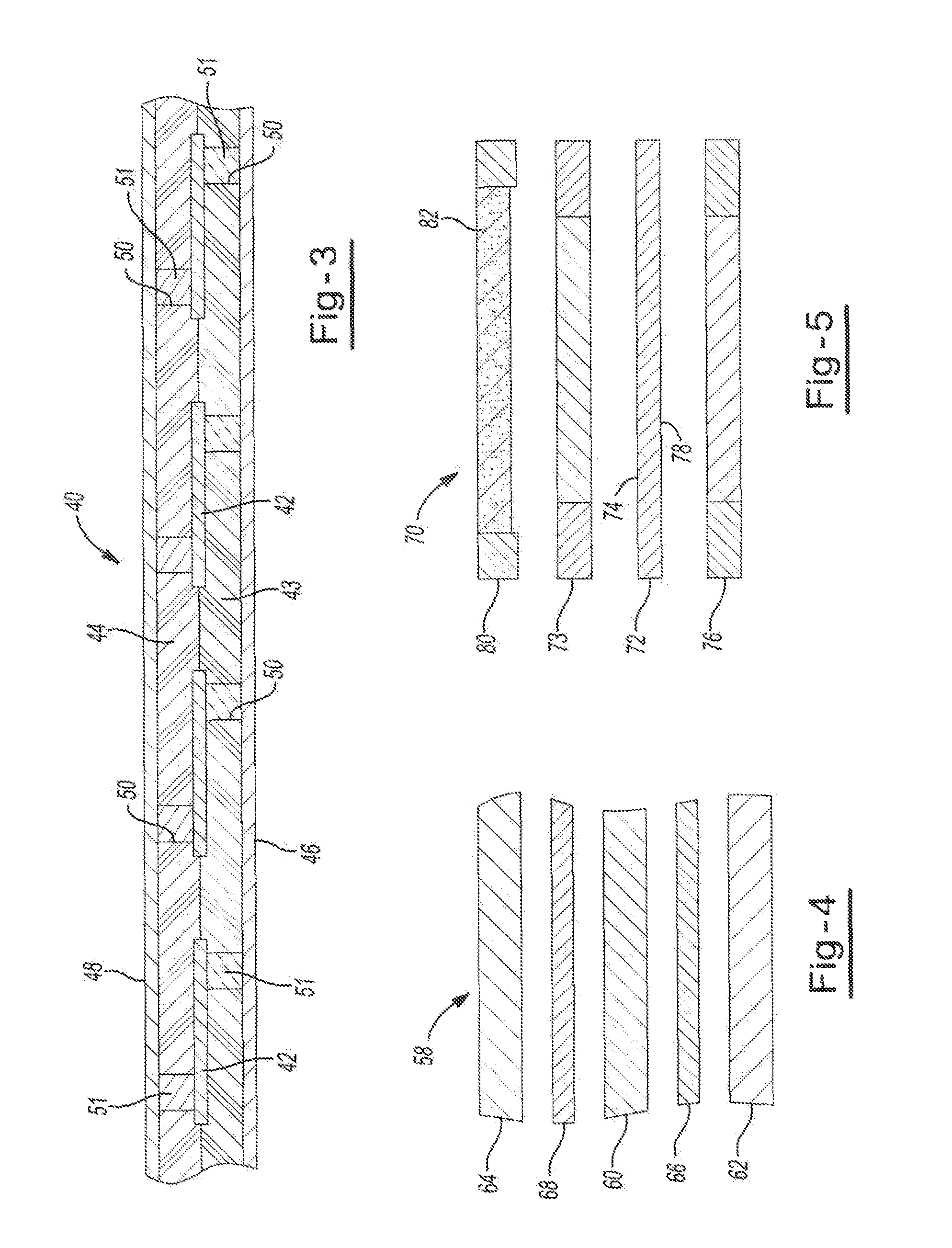

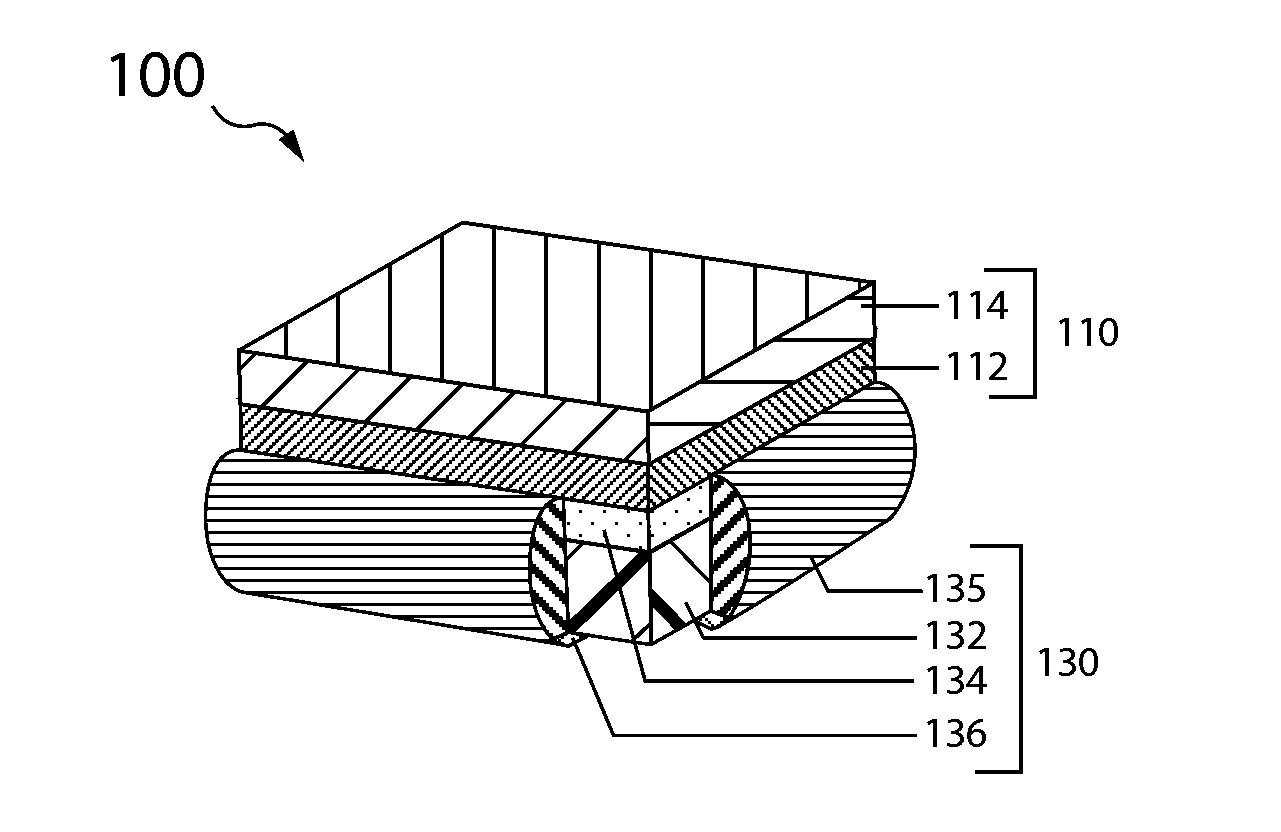

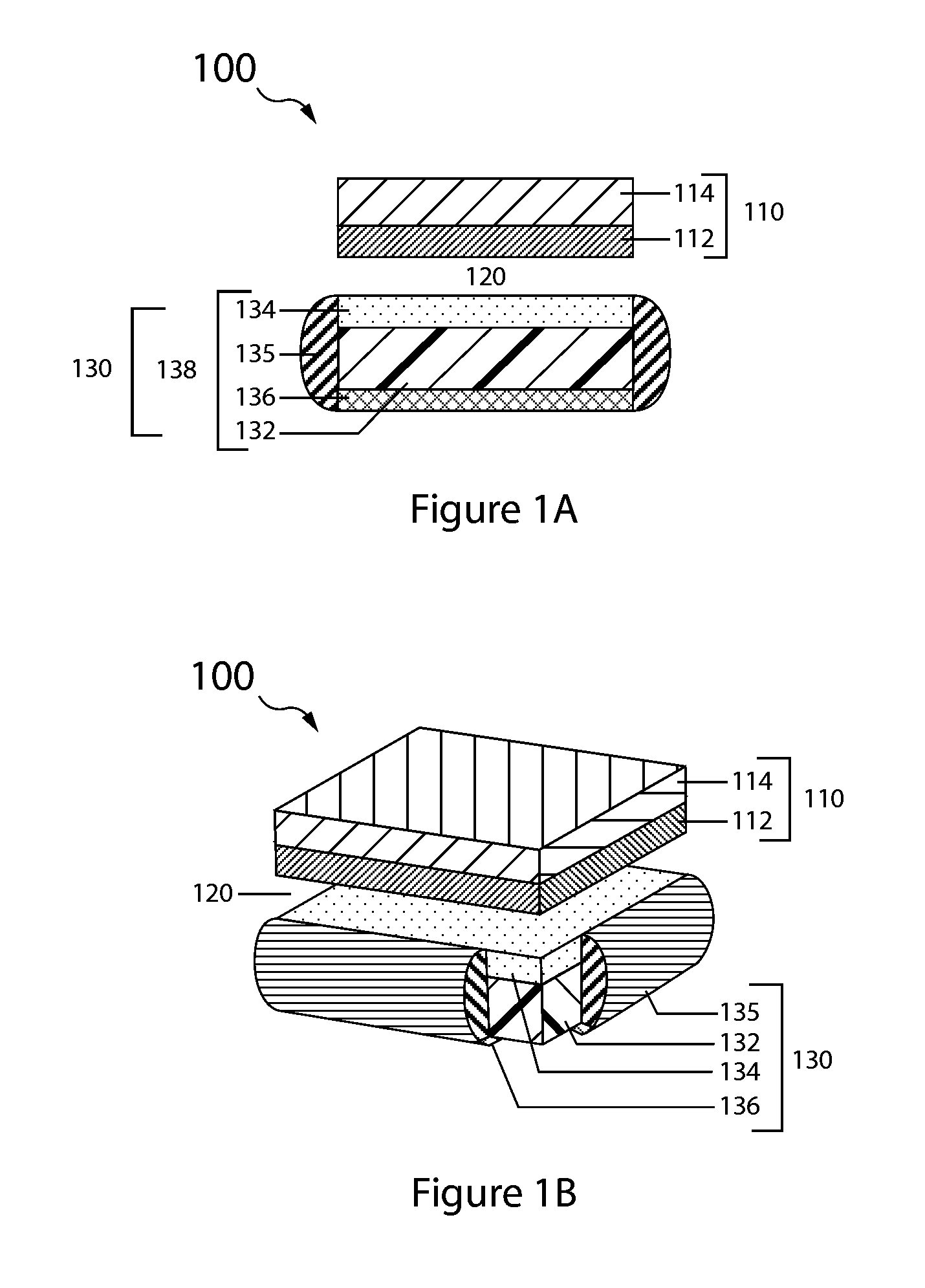

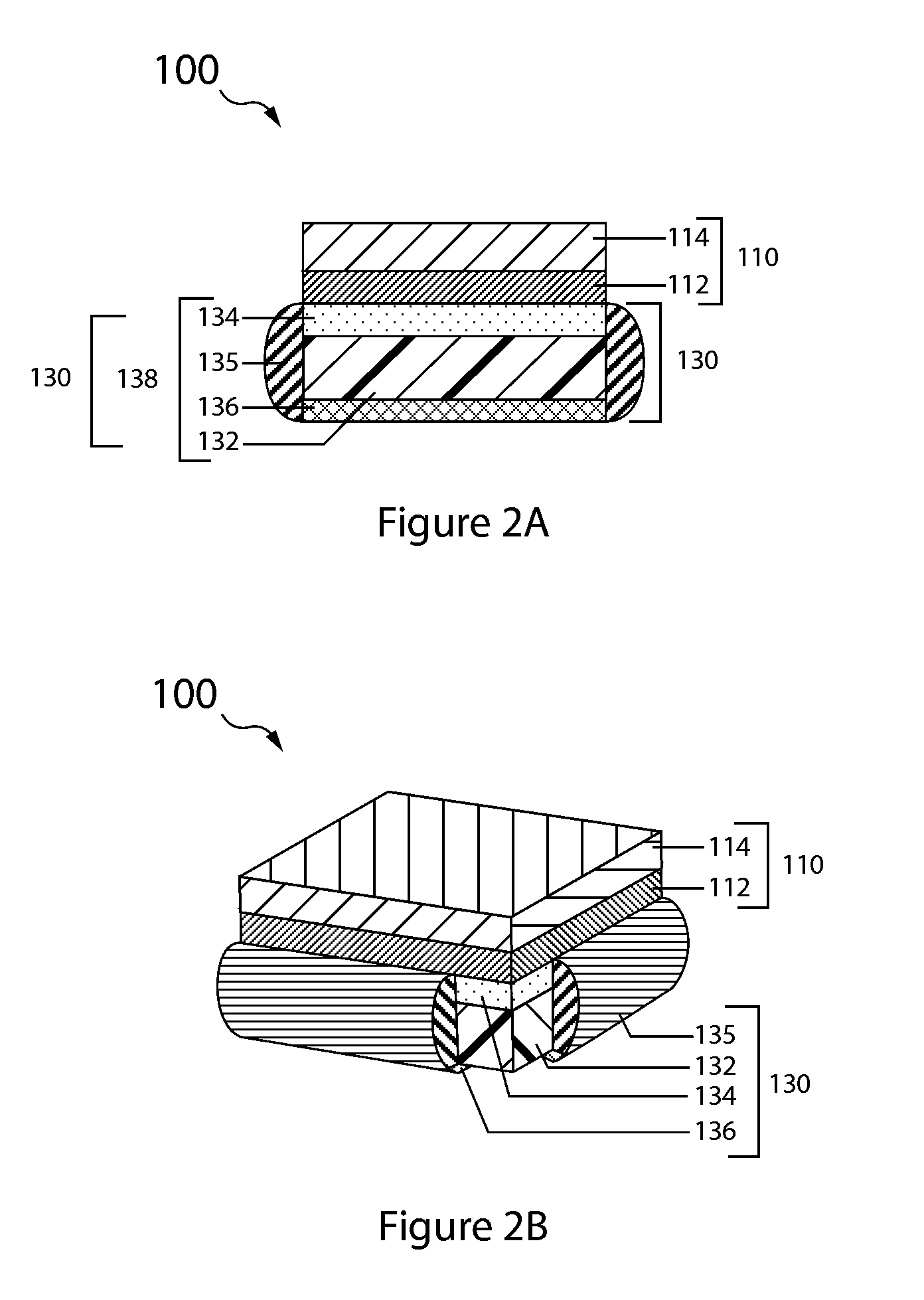

Bipolar battery assembly

ActiveUS20100183920A1Easy constructionEffective distanceCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesConductive materialsPositive current

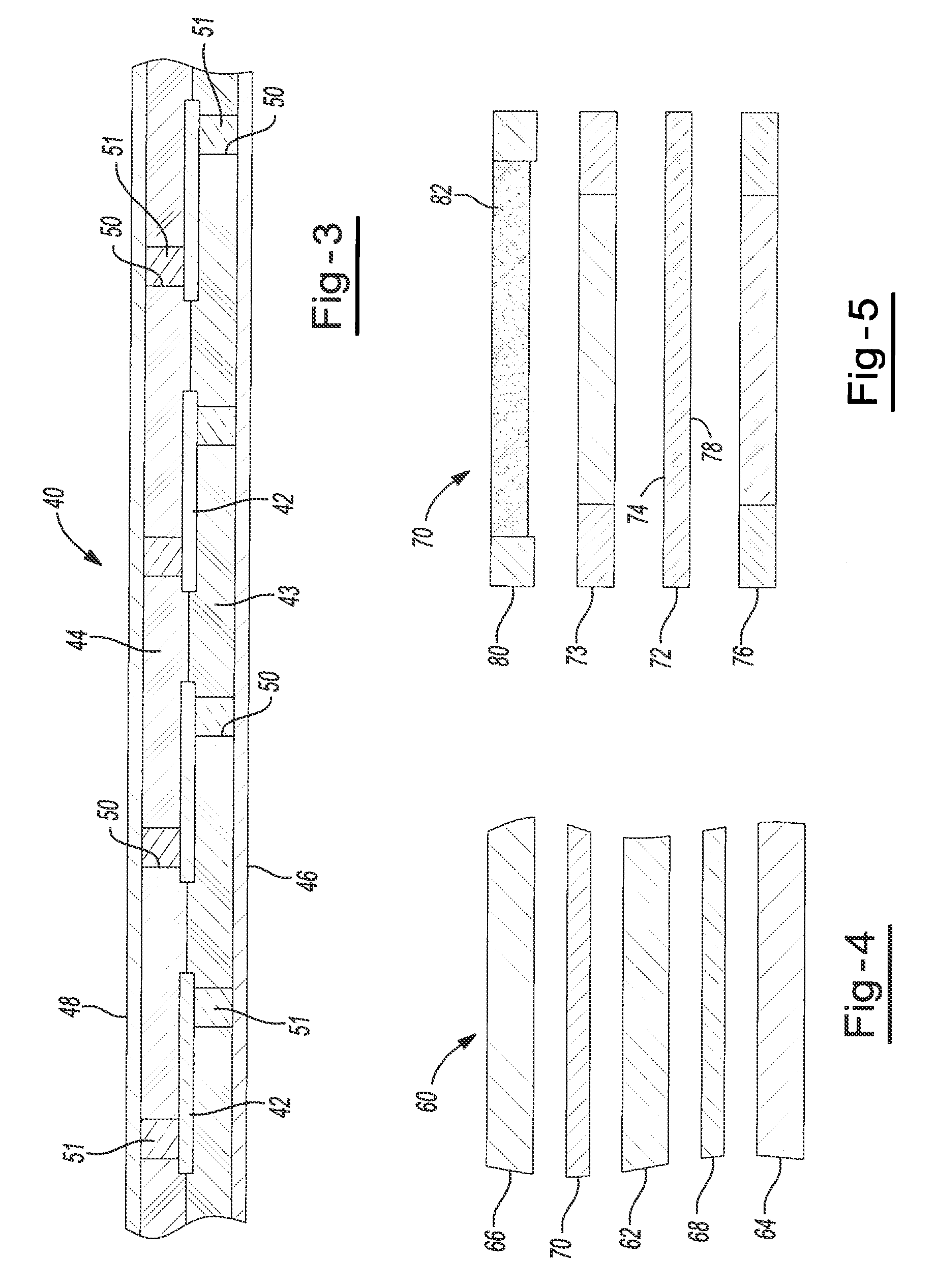

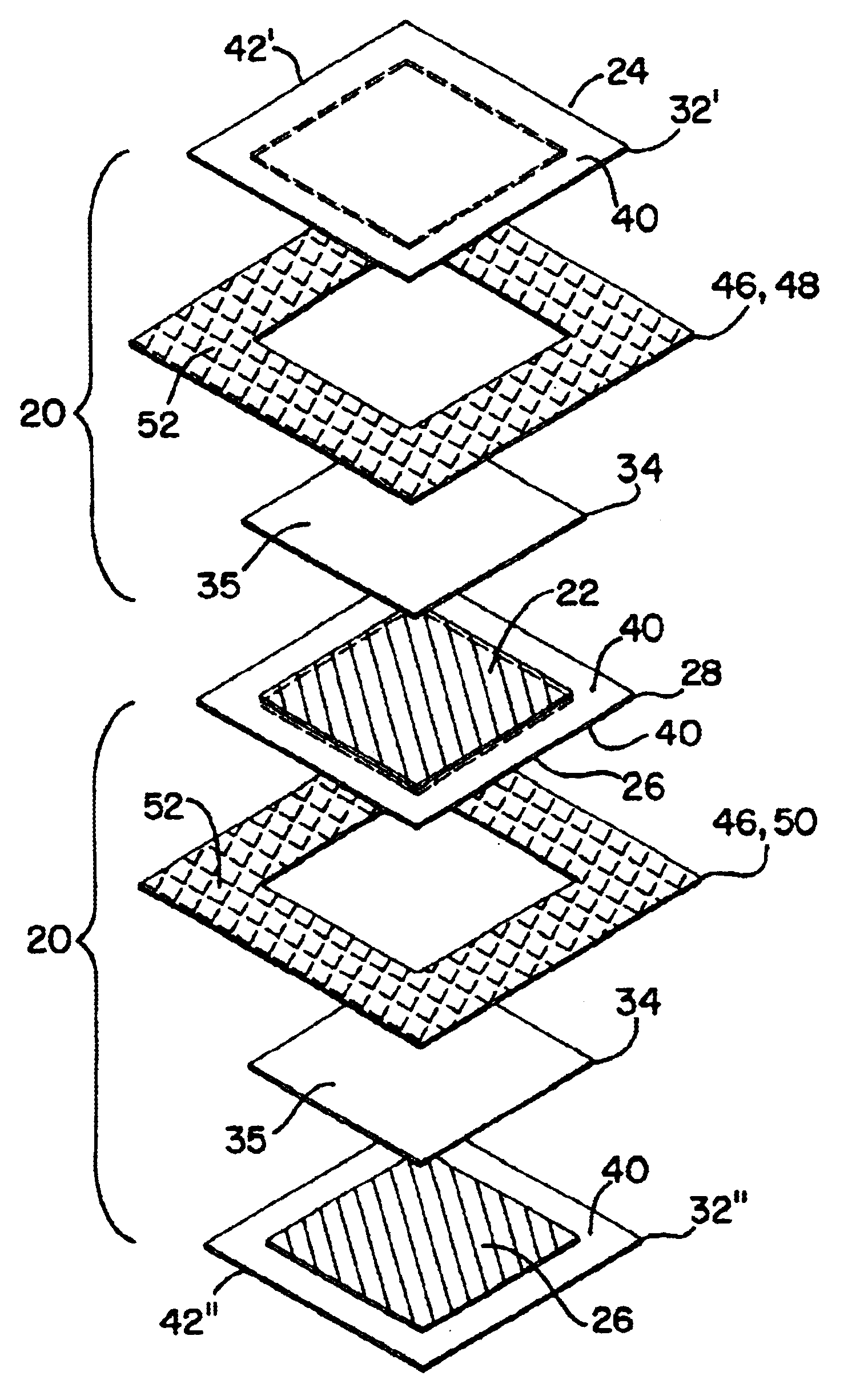

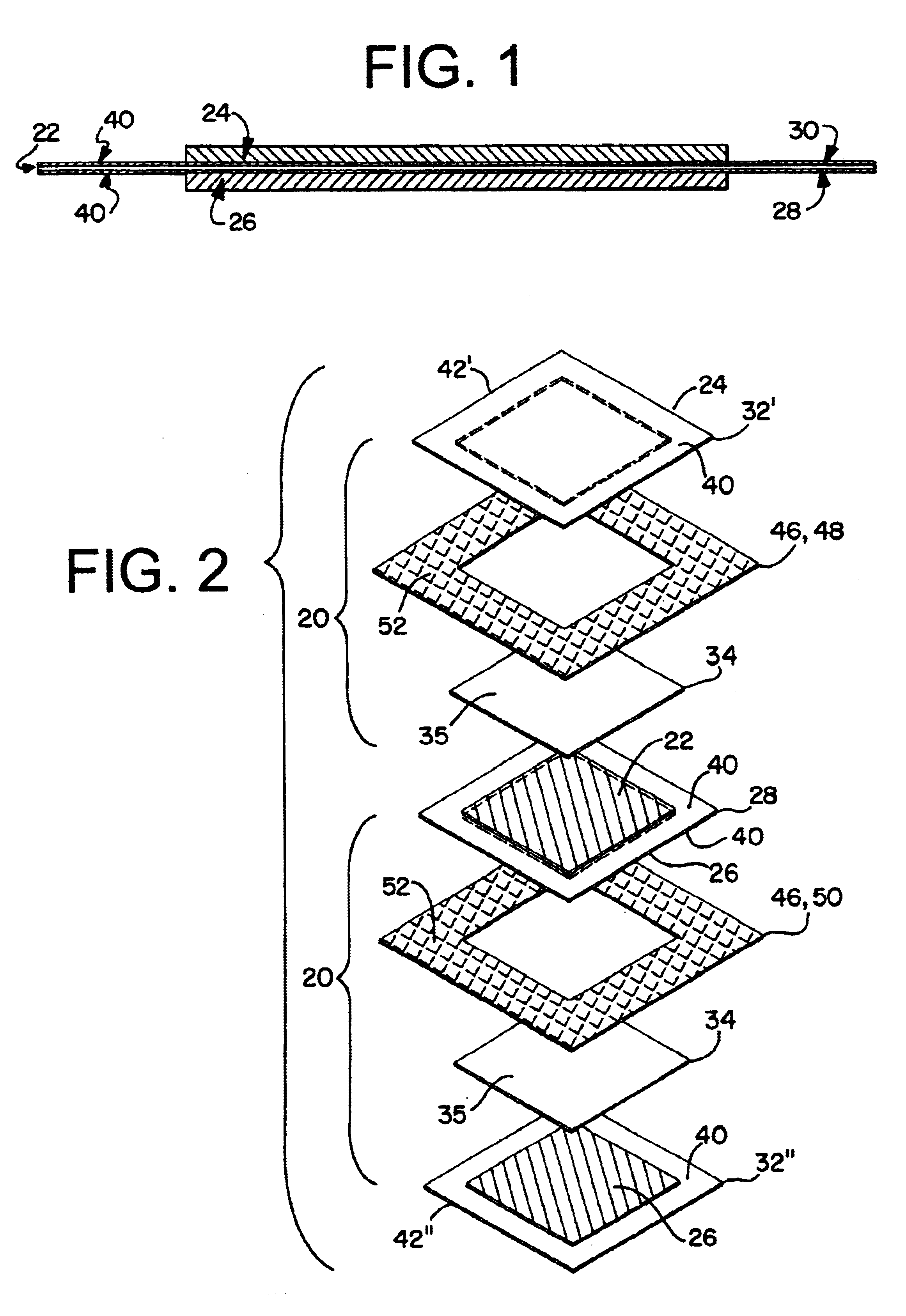

A bipolar battery construction is disclosed comprising a substrate, openings in the substrate, an electrically conductive material placed within the openings, a negative and positive current collector foil placed on opposing sides of the substrate and negative and positive pasting frame members. The electrically conductive material may have a melting point below the thermal degradation temperature of the substrate.

Owner:ADVANCED BATTERY CONCEPTS

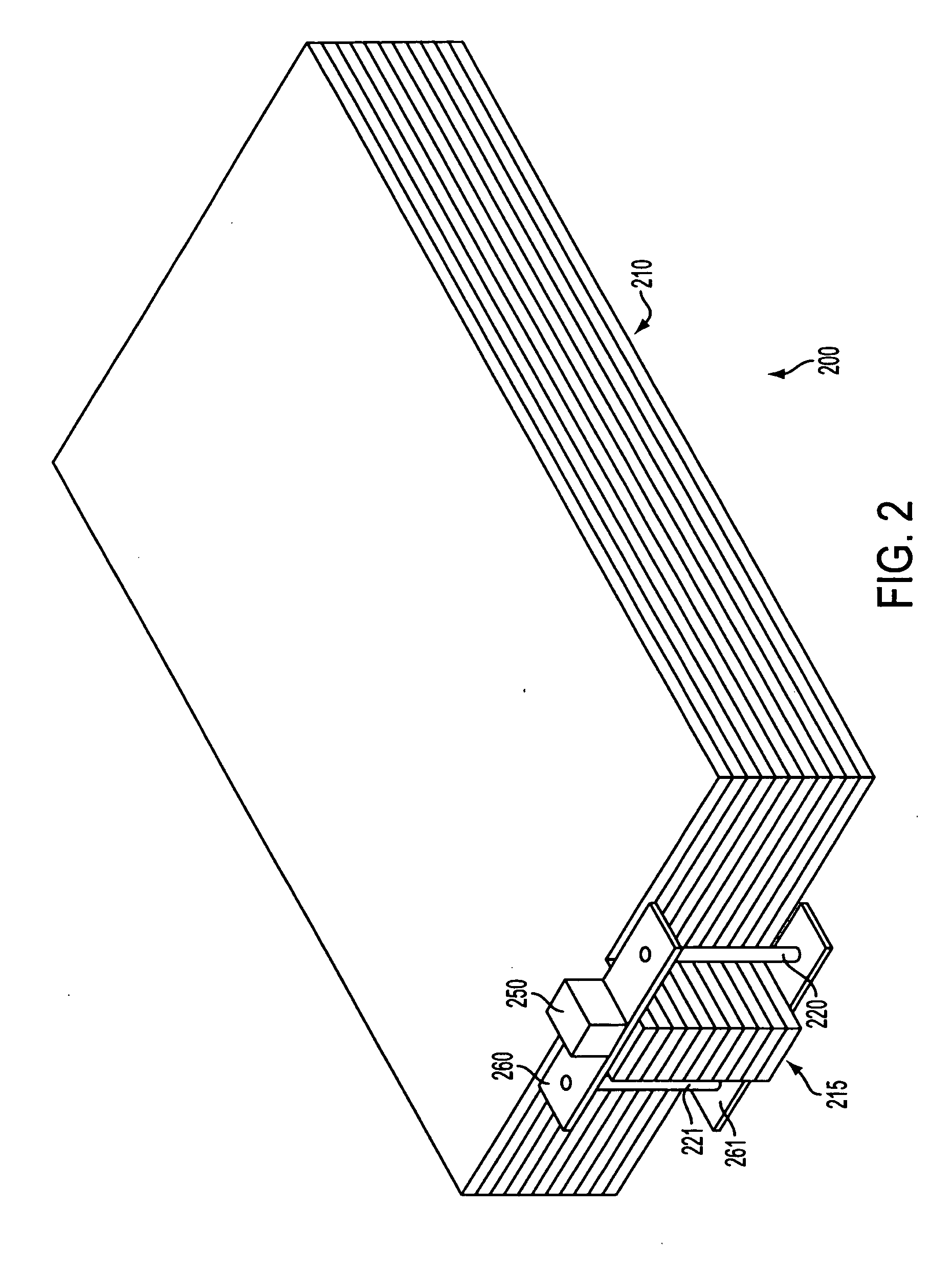

Rechargeable high power electrochemical device

InactiveUS6908711B2Increase powerLarge-sized flat cells/batteriesFinal product manufactureEngineeringElectrochemistry

The present invention is drawn to a high power electrochemical energy storage device, comprising at least one stackable, monolithic battery unit. The monolithic battery unit includes at least two electrochemical energy storage cells. The cells have a lithium ion insertion anode and a lithium ion insertion cathode, a bipolar current collector between cells and end plate current collectors at the opposing ends of each battery unit. A frame may be associated with the perimeter of the current collector. The current collector comprises a high-conductivity metal. The device also has the at least two storage cells substantially aligned adjacent one another, a separator material associated between the anode and the cathode within each cell; and an electrolyte within each cell.Additionally, the present invention is drawn to a device combining two or more of the monolithic units, either in series or in parallel or any combination thereof, so as to create a high power, high voltage energy storage device.

Owner:PACIFIC LITHIUM NEW ZEALAND

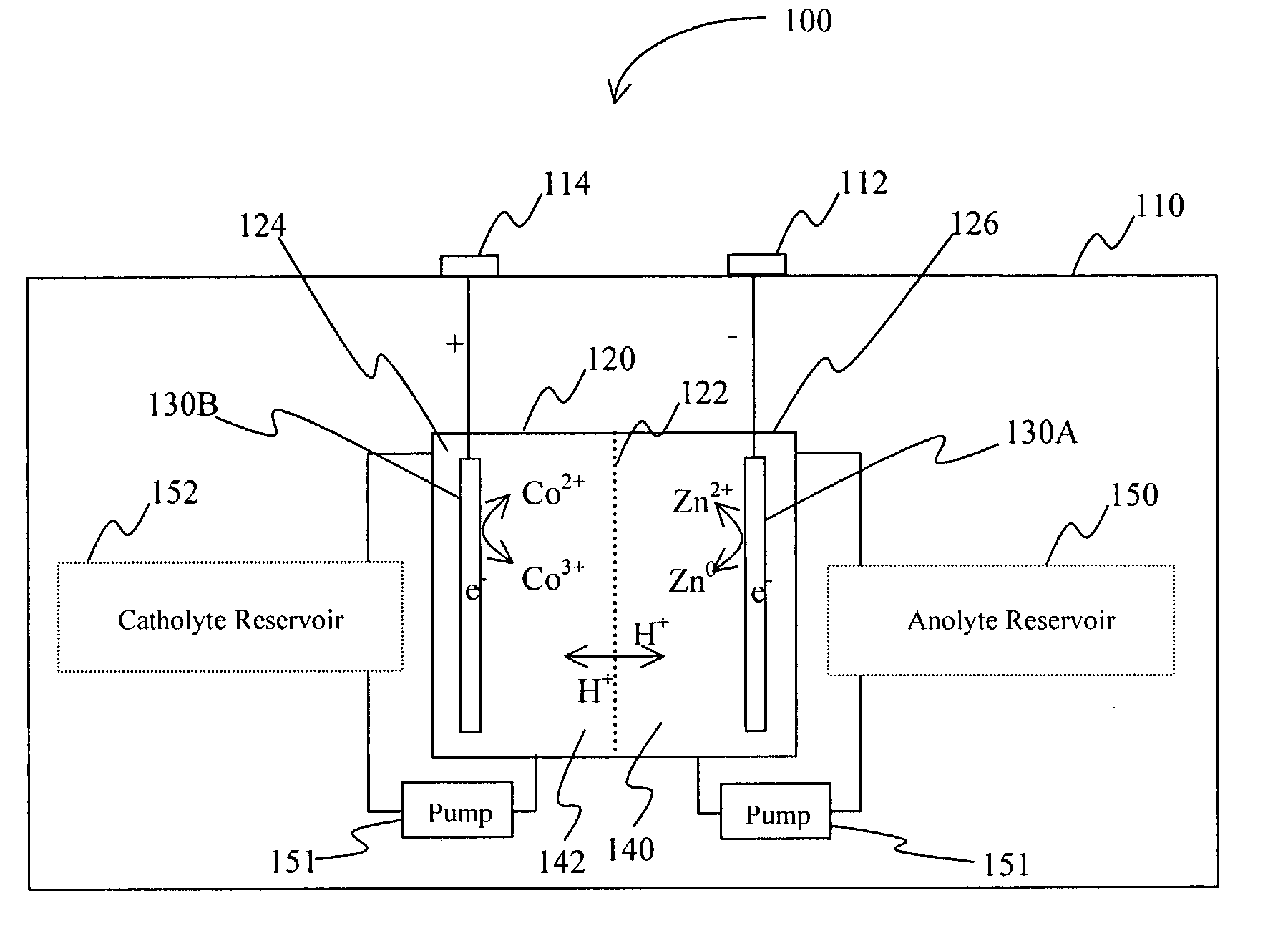

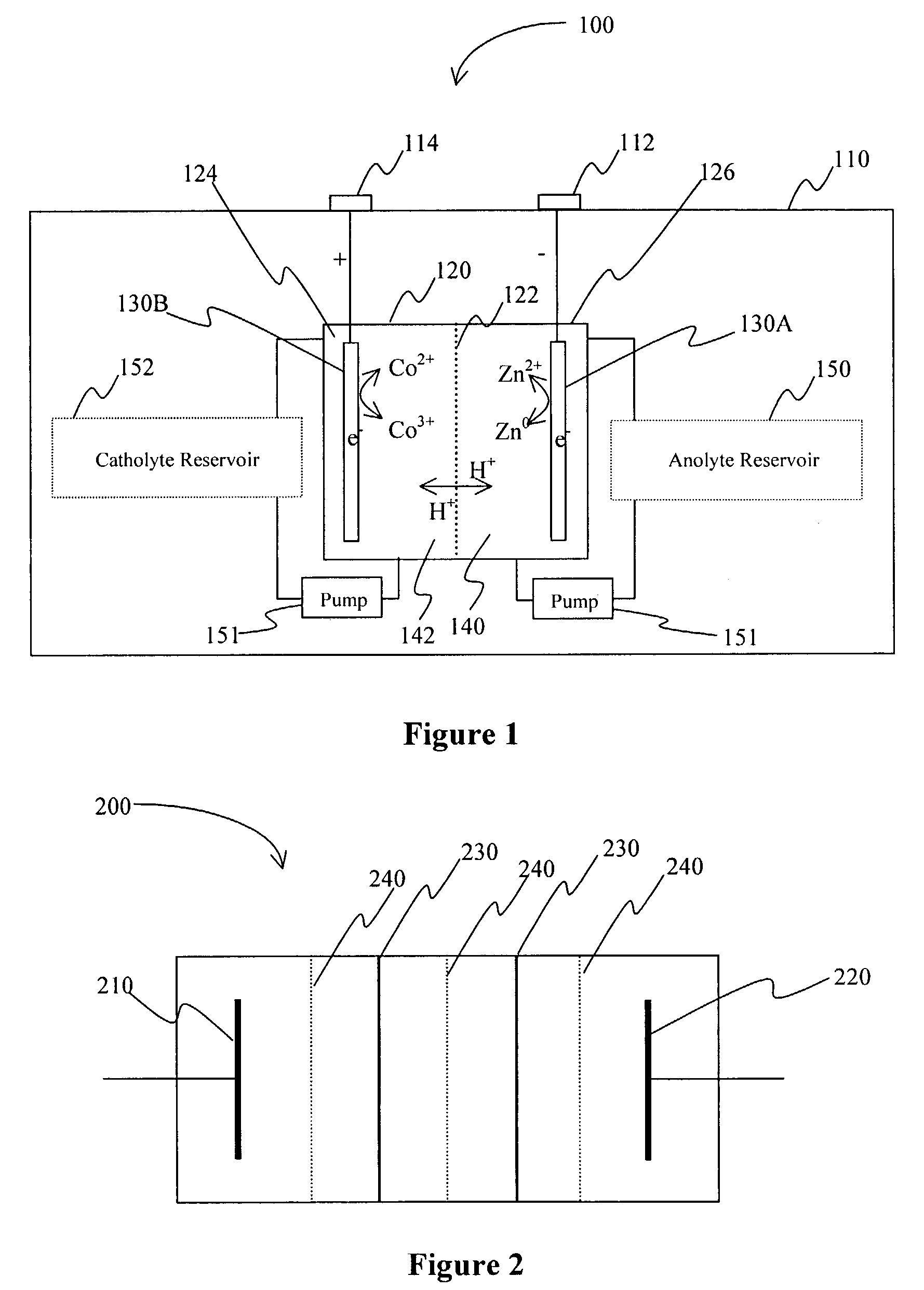

Battery with bifunctional electrolyte

A battery comprises an acid electrolyte in which a compound provides acidity to the electrolyte and further increases solubility of at least one metal in the redox pair. Especially preferred compounds include alkyl sulfonic acids and alkyl phosphonic acids, and particularly preferred redox coupled include Co3+ / Zn0, Mn3+ / Zn0, Ce4+ / V2+, Ce4+ / Ti3+, Ce4+ / Zn0, and Pb4+ / Pb0.

Owner:ITI SCOTLAND +1

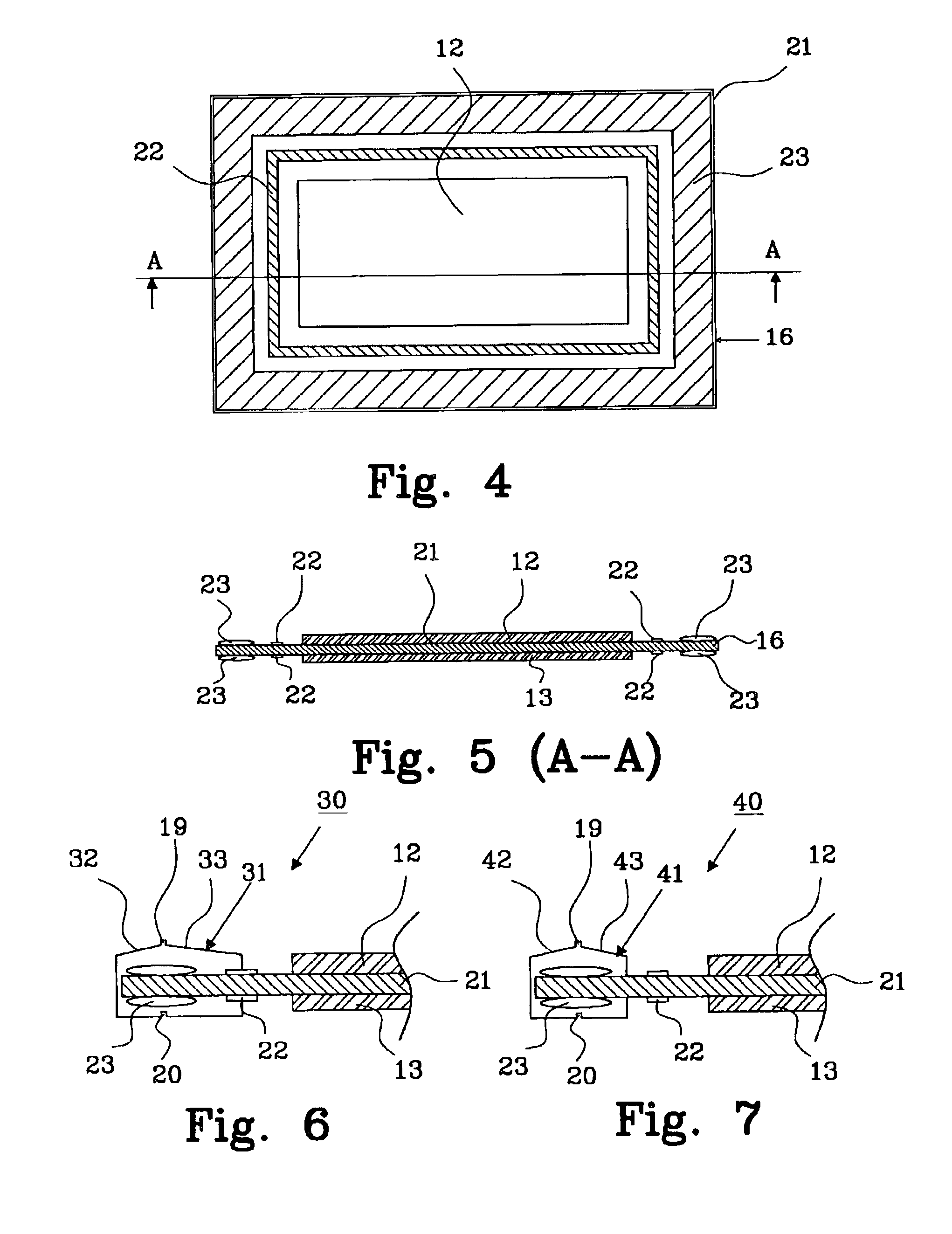

Bipolar battery assembly

ActiveUS20140349147A1Sufficient structural integrityPreventing electrical shortingFinal product manufactureLead-acid accumulator electrodesElectrical batteryFluid electrolytes

The invention relates to an article comprising: a) one or more stacks of battery plates comprising one or more bipolar plates; b) located between each plate is a separator and a liquid electrolyte; further comprising one of more of the features: 1) c) the one or more stacks of battery plates having a plurality of channels passing transversely though the portion of the plates having the cathode and / or the anode deposited thereon; and d) i) one or more seals about the periphery of the channels which prevent the leakage of the liquid electrolyte into the channels, and / or posts located in one or more of the channels having on each end an overlapping portion that covers the channel and sealing surface on the outside of the monopolar plates adjacent to the holes for the transverse channels and applies pressure on the sealing surface of the monopolar plates wherein the pressure is sufficient to withstand pressures created during assembly and operation of electrochemical cells created by the stacks of battery plates; 2) c) a membrane comprising a thermoplastic polymer is disposed about the entire periphery of the edges of the stack of plates; 3) wherein the separator is in the form of a sheet having adhered to its periphery a frame; and 4) c) an integrated valve and integrated channel communicating with the valve.

Owner:ADVANCED BATTERY CONCEPTS

Bipolar battery and related method

ActiveUS7279248B2Improve reliabilityKeep gapNon-aqueous electrolyte accumulatorsLarge-sized flat cells/batteriesEngineeringElectrolyte

A bipolar battery comprises: a plurality of bipolar electrodes; electrolyte layers formed between adjacent ones of the plurality of bipolar electrodes, respectively; sealing portions surrounding and sealing the electrolyte layers, respectively; and contributing members contributing to keeping gaps between the adjacent ones of the plurality of bipolar electrodes, respectively. The contributing members are disposed within areas of the sealing portions, respectively.

Owner:NISSAN MOTOR CO LTD

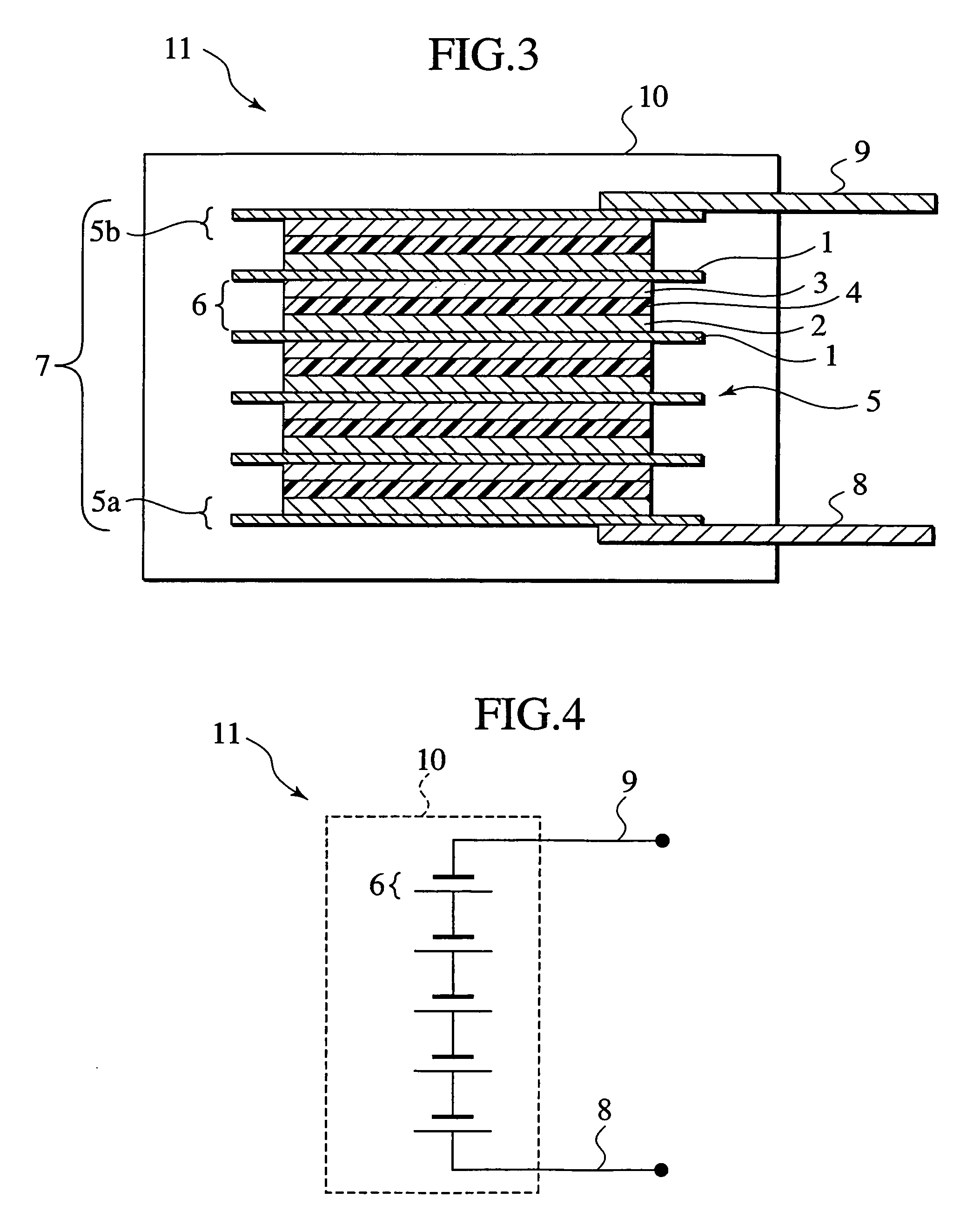

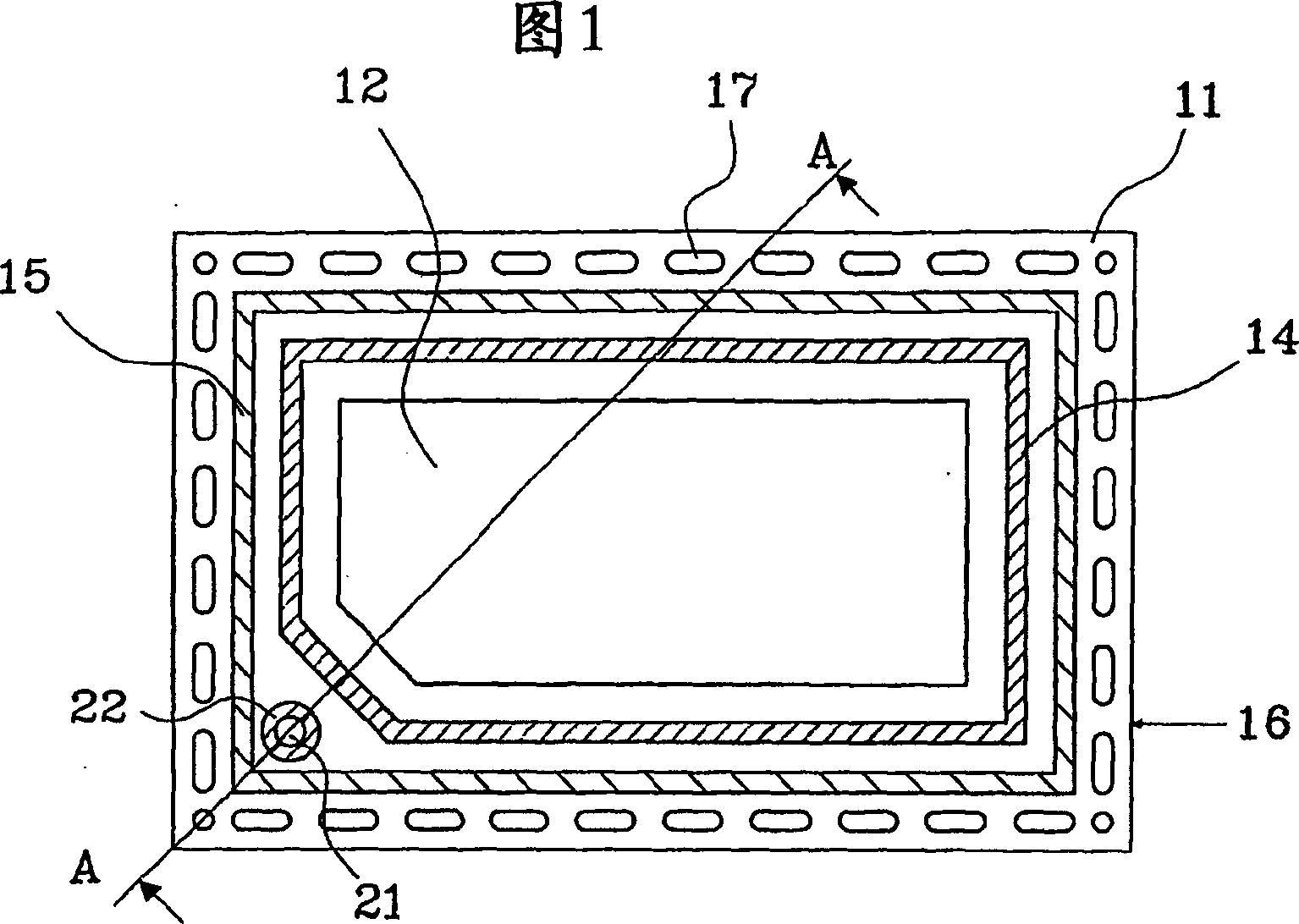

Bipolar battery and a method for manufacturing a bipolar battery

ActiveUS20050260493A1Easy to manufactureLow costLarge-sized flat cells/batteriesFinal product manufactureMechanical engineeringBattery cell

The present invention relates to a bipolar battery, especially a NiMH battery, having: a sealed housing, a negative end terminal, a positive end terminal, and at least one biplate assembly comprising a biplate, a positive and a negative electrode. A separator is arranged between each negative and positive electrode forming a battery cell, said separator includes an electrolyte. An inner barrier of a hydrophobic material is arranged around at least one electrode, whereby said inner barrier prevents an electrolyte path from one cell to another cell, and a frame is present to provide predetermined cell spacing between each biplate and / or biplate and end terminal. The frame is attached in such a way to each biplate to permit ambient gas to pass between adjacent cells, thereby creating a common gas space for all cells in the battery. The invention also relates to a method for manufacturing a bipolar battery.

Owner:NILAR INT AB

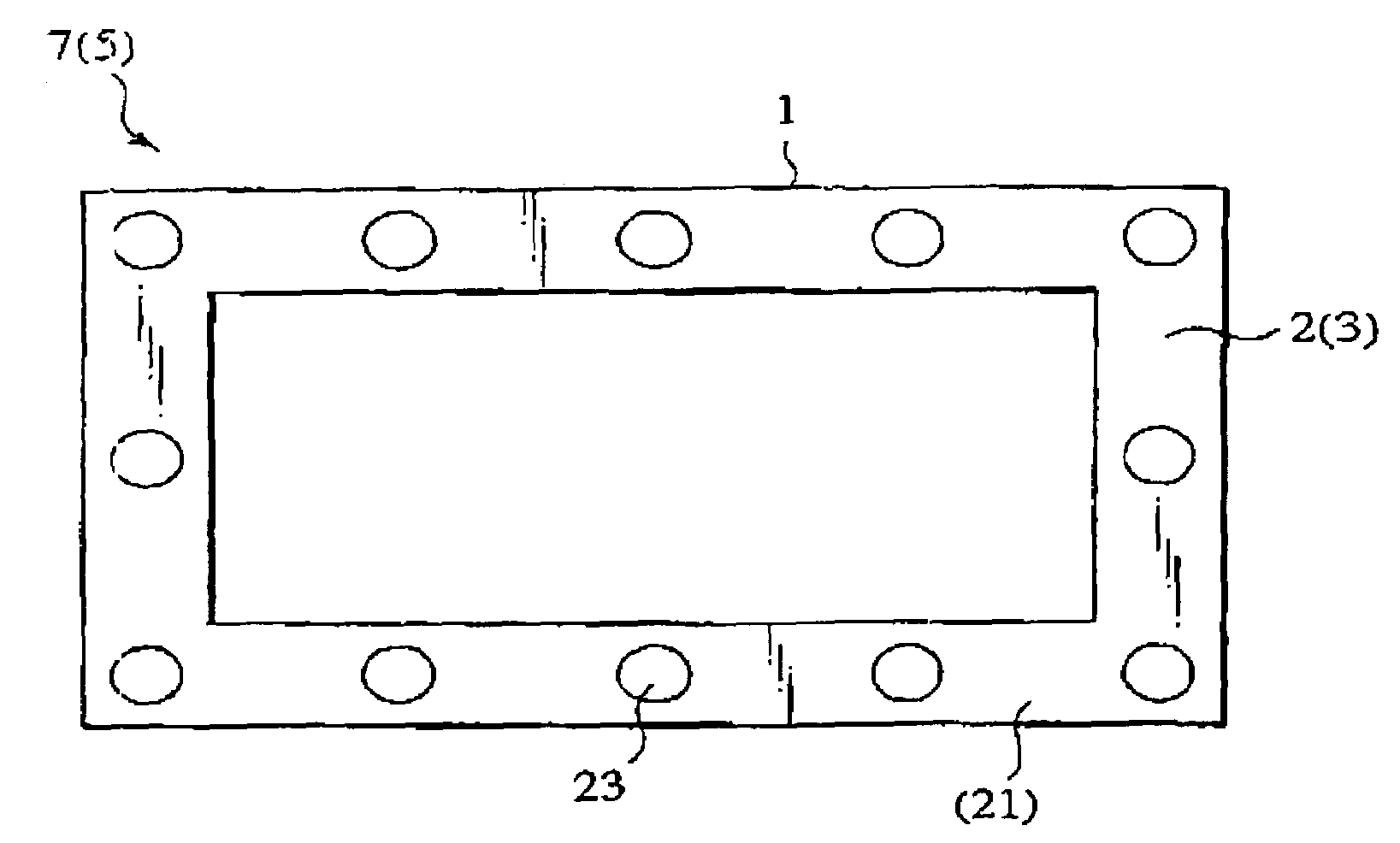

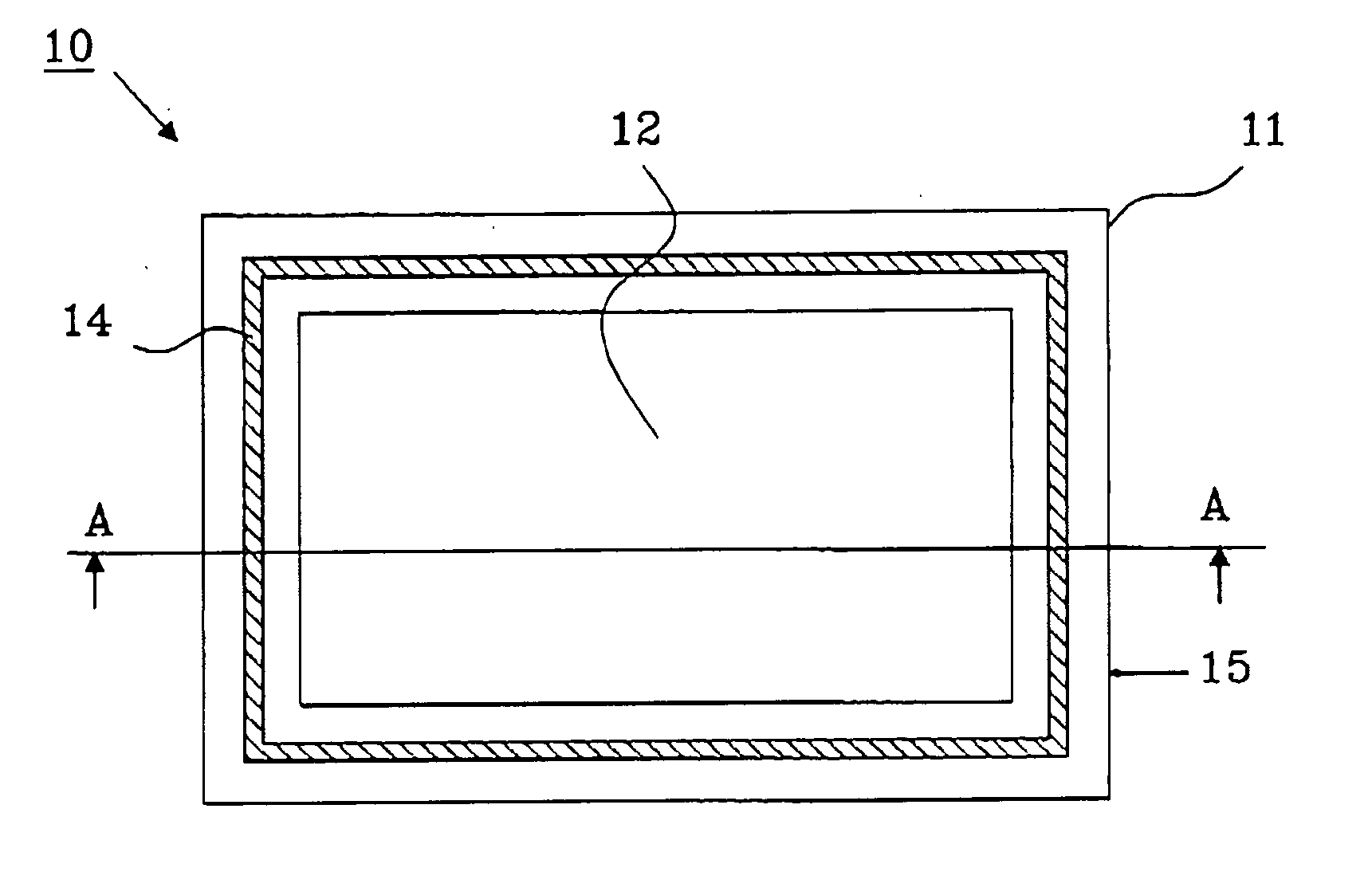

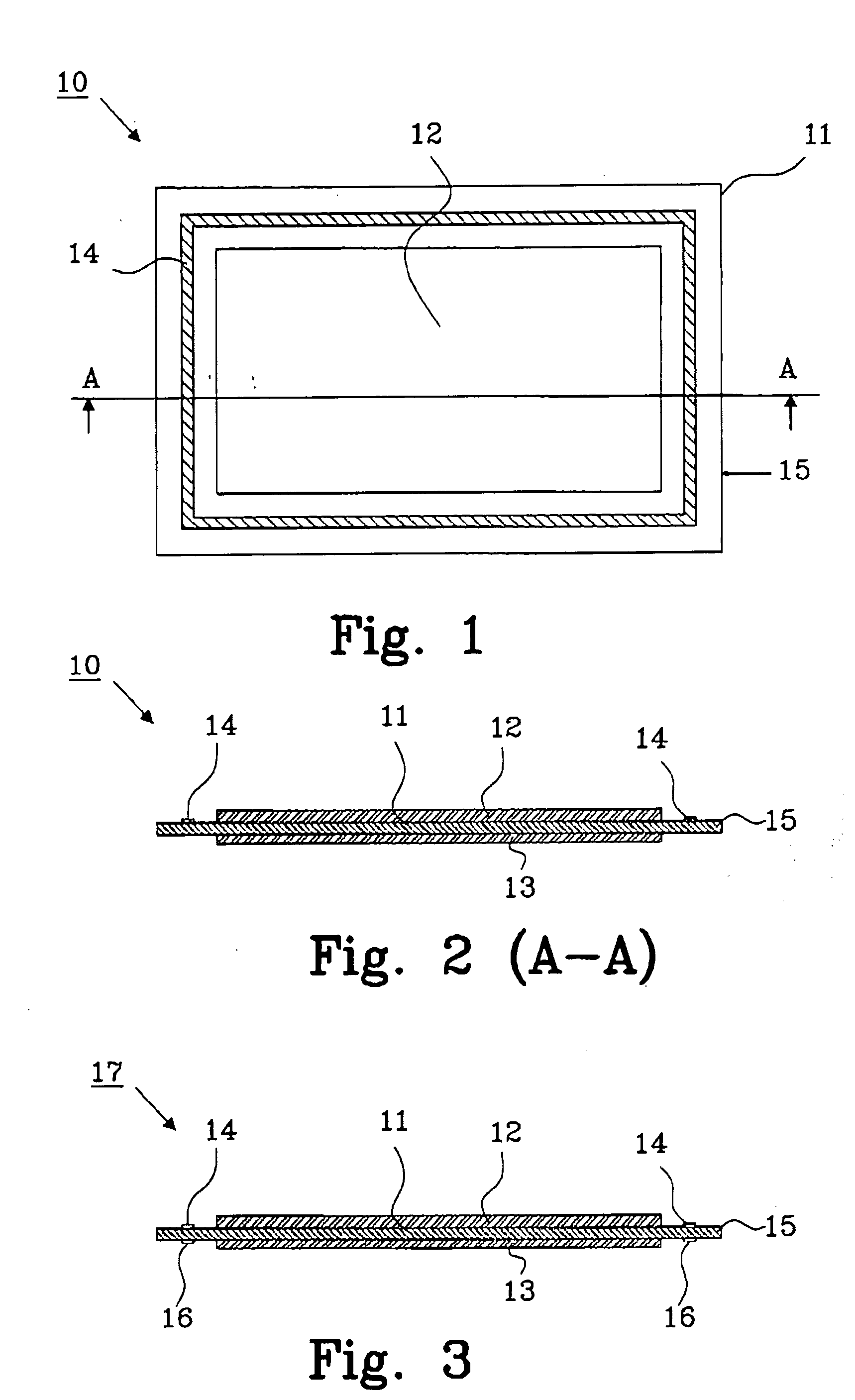

Bipolar battery and biplate assembly

ActiveUS7097937B2Improve sealingPrevent electrolyte leakage pathLarge-sized flat cells/batteriesFinal product manufactureEngineeringBattery cell

The present invention relates to a bipolar battery having at least two battery cells comprising: a sealed housing, a negative end terminal, a positive end terminal, at least one biplate assembly arranged in a sandwich structure between said negative and positive end terminals, and a separator, including an electrolyte, arranged between each negative and positive electrode forming a battery cell. The biplate assembly is provided with an inner barrier of a hydrophobic material around the negative and the positive electrode, respectively, and an outer seal around the edge of each biplate. Each end terminal is provided with a terminal seal. The edge of each biplate is positioned close to the sealed housing to provide means to conduct heat from each biplate assembly to the ambient environment. The invention also relates to a method for manufacturing a bipolar battery and a biplate assembly.

Owner:NILAR INT AB

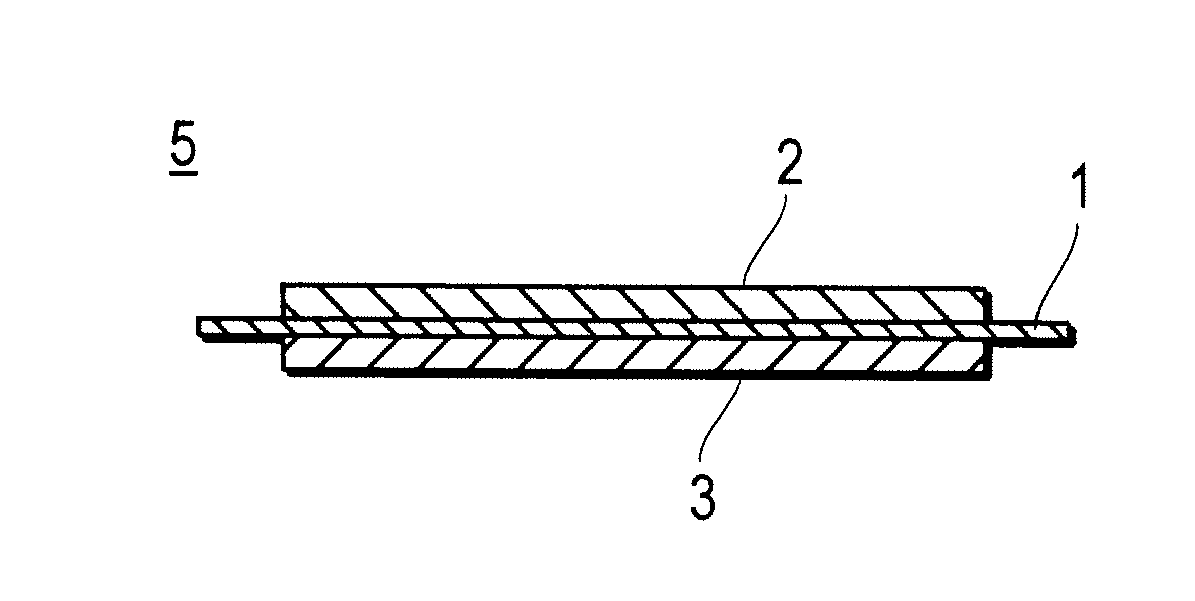

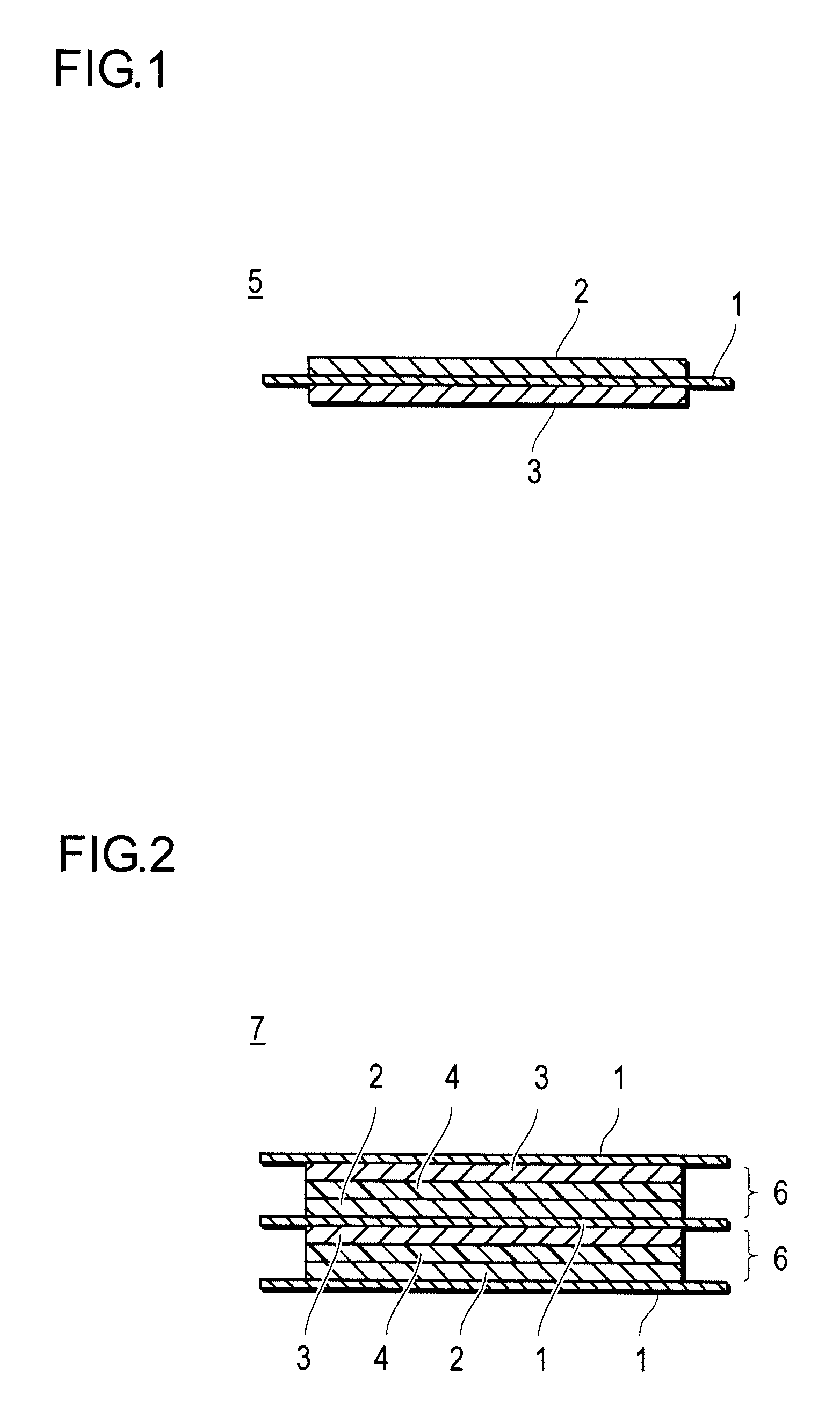

Bipolar battery

ActiveUS7163765B2Liquid junctionFinal product manufactureElectrode carriers/collectorsEngineeringCurrent collector

A bipolar battery comprises a bipolar electrode in which a positive electrode is provided on one surface of a collector and a negative electrode is provided on the other surface of the collector, a gel electrolyte sandwiched between the positive electrode and the negative electrode, and a sealing layer which is provided between the collectors and surrounds a periphery of a single cell including the positive electrode, the negative electrode, and the gel electrolyte.

Owner:NISSAN MOTOR CO LTD

Negative Electrode Material For Lithium Secondary Battery, Method For Producing Same, Negative Electrode For Lithium Secondary Battery Using Same And Lithium Secondary Battery

InactiveUS20080032192A1High electrode-mechanical strengthImprove immersion effectNegative electrodesNon-aqueous electrolyte accumulator electrodesHigh current densityMetal particle

A negative-electrode material for a lithium secondary battery is provided that can be produced through a simple procedure and can yield a lithium secondary battery having a high electrode-mechanical strength, being excellent in immersibility, involving a small initial irreversible capacity, being excellent in charge-discharge characteristic under high current densities, and having a high cycle retention ratio, i.e. having an excellent balance of various battery characteristics. The material includes particles (A), which are selected from the group consisting of carbon-material particles, metal particles, and metal-oxide particles, and two or more different polymeric materials each attached to different sites of the particles.

Owner:MITSUBISHI CHEM CORP

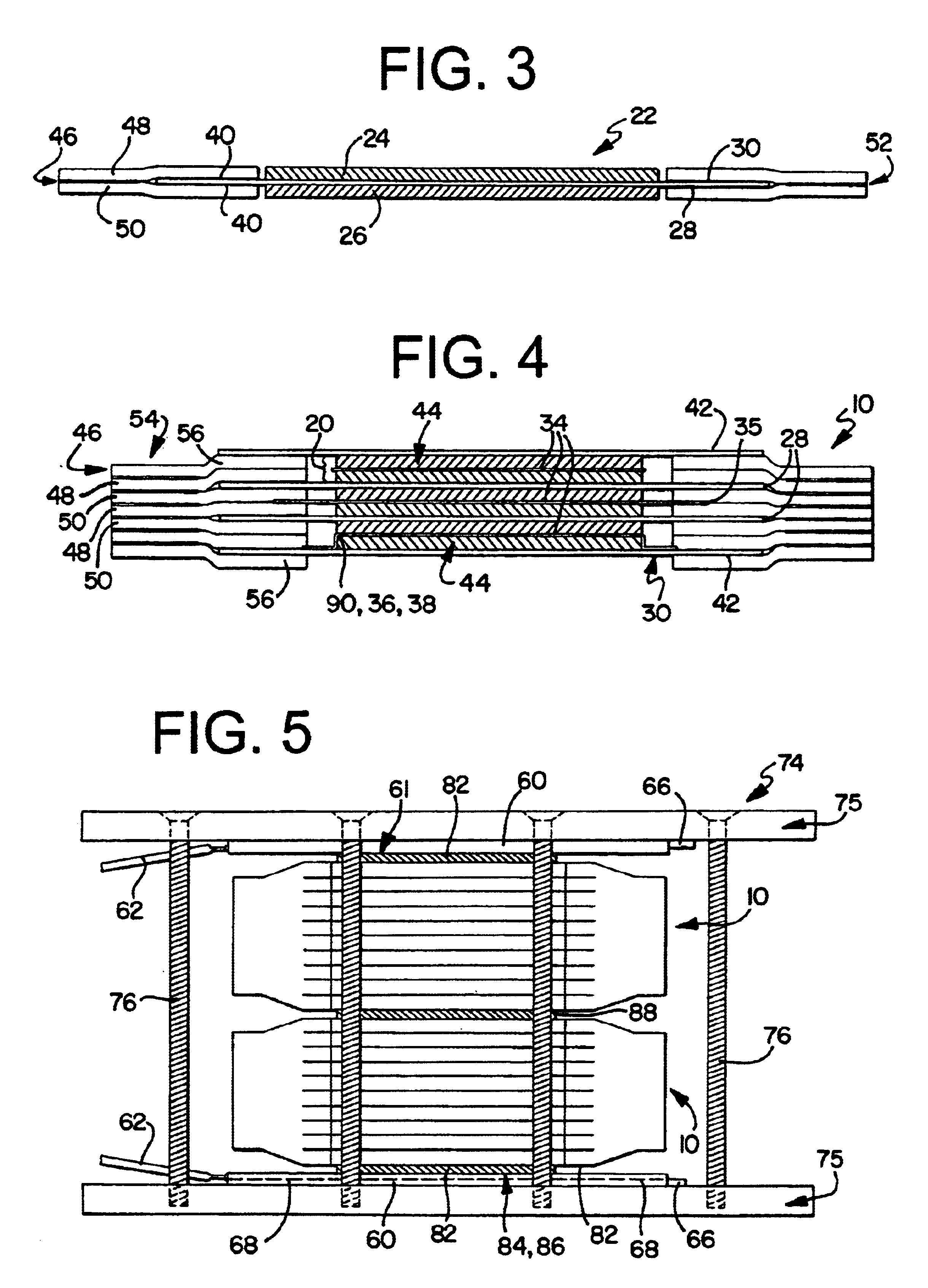

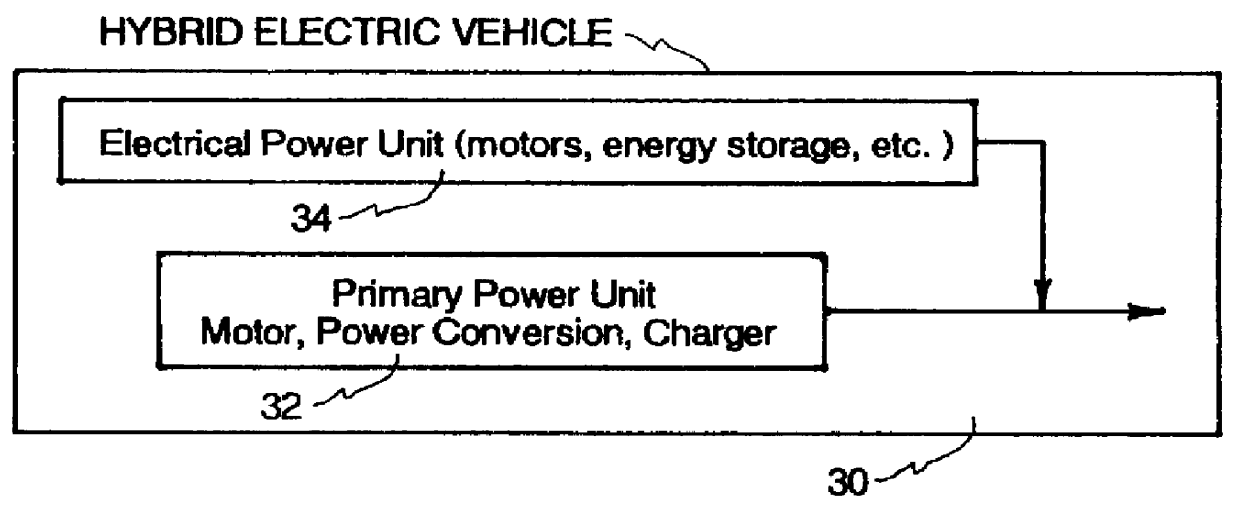

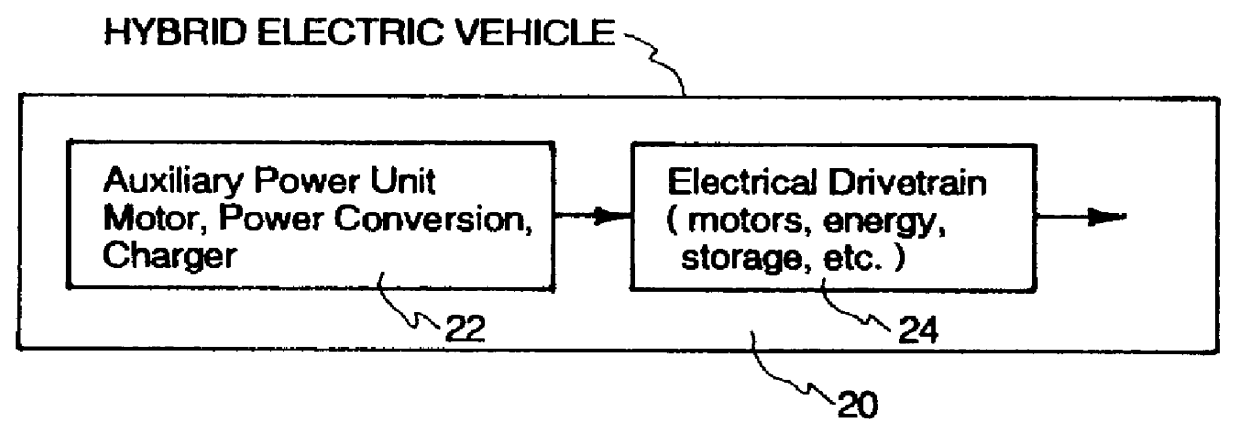

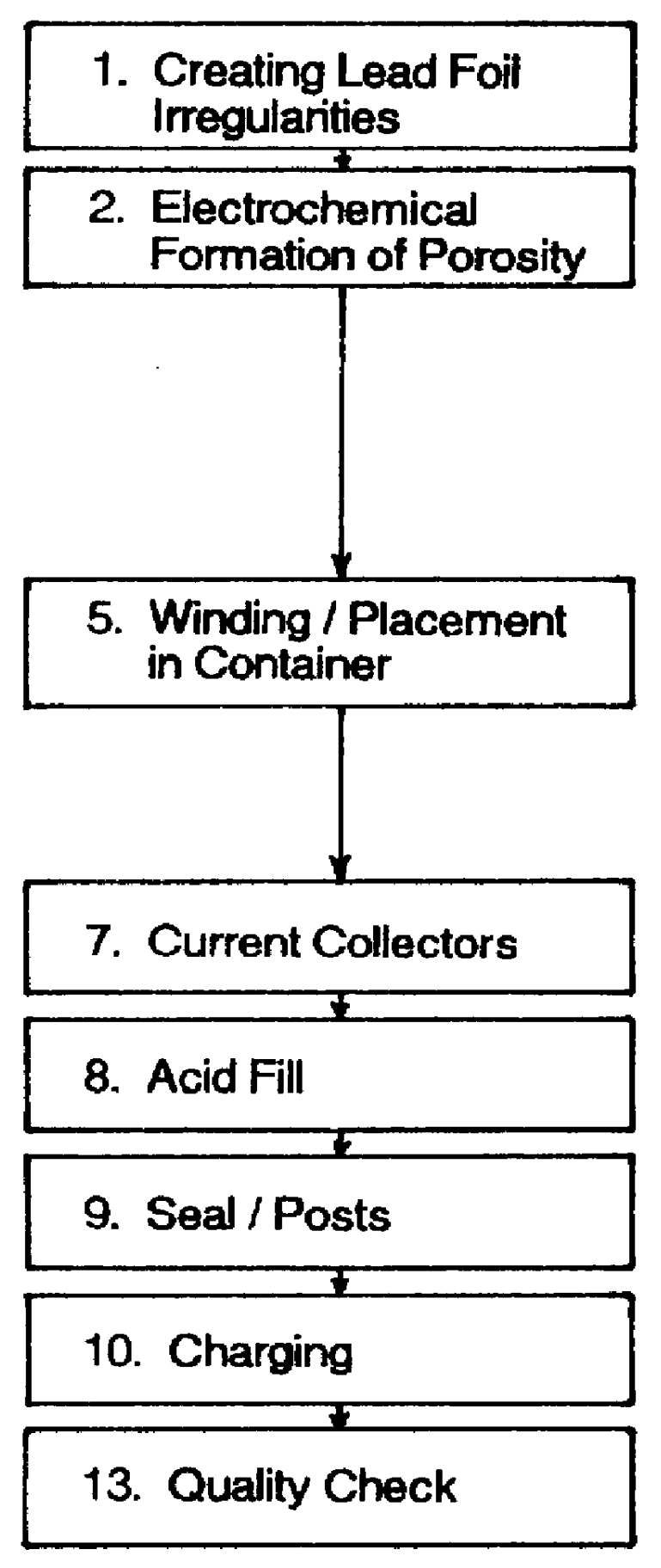

Source of electrical power for an electric vehicle and other purposes, and related methods

InactiveUS6063525AIncrease capacityIncrease powerSilver accumulatorsElectrode manufacturing processesCapacitancePorosity

Microthin sheet technology is disclosed by which superior batteries are constructed which, among other things, accommodate the requirements for high load rapid discharge and recharge, mandated by electric vehicle criteria. The microthin sheet technology has process and article overtones and can be used to form thin electrodes used in batteries of various kinds and types, such as spirally-wound batteries, bipolar batteries, lead acid batteries, silver / zinc batteries, and others. Superior high performance battery features include: (a) minimal ionic resistance; (b) minimal electronic resistance; (c) minimal polarization resistance to both charging and discharging; (d) improved current accessibility to active material of the electrodes; (e) a high surface area to volume ratio; (f) high electrode porosity (microporosity); (g) longer life cycle; (h) superior discharge / recharge characteristics; (j) higher capacities (Axhr); and k) high specific capacitance.

Owner:BIPOLAR TECH

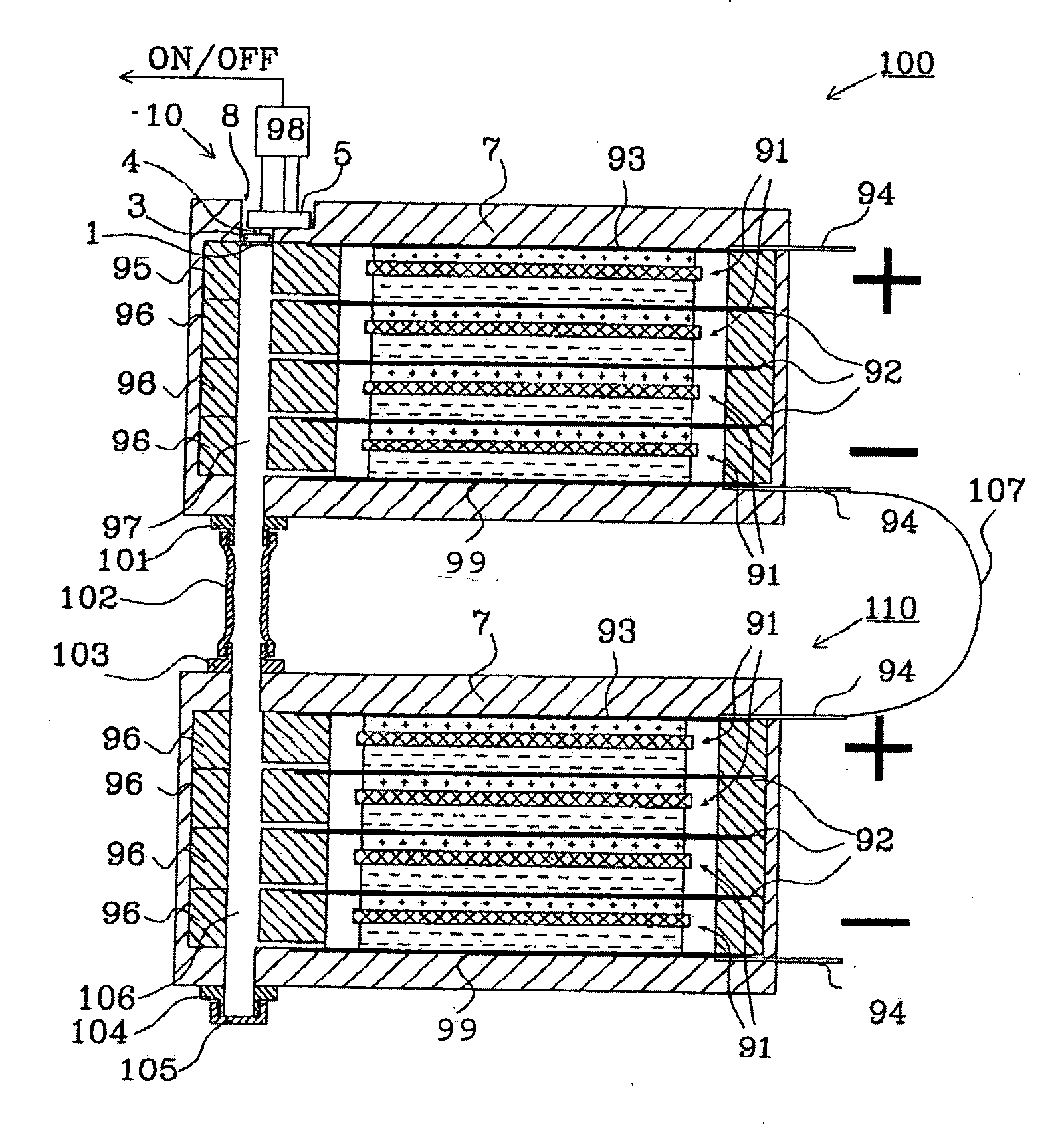

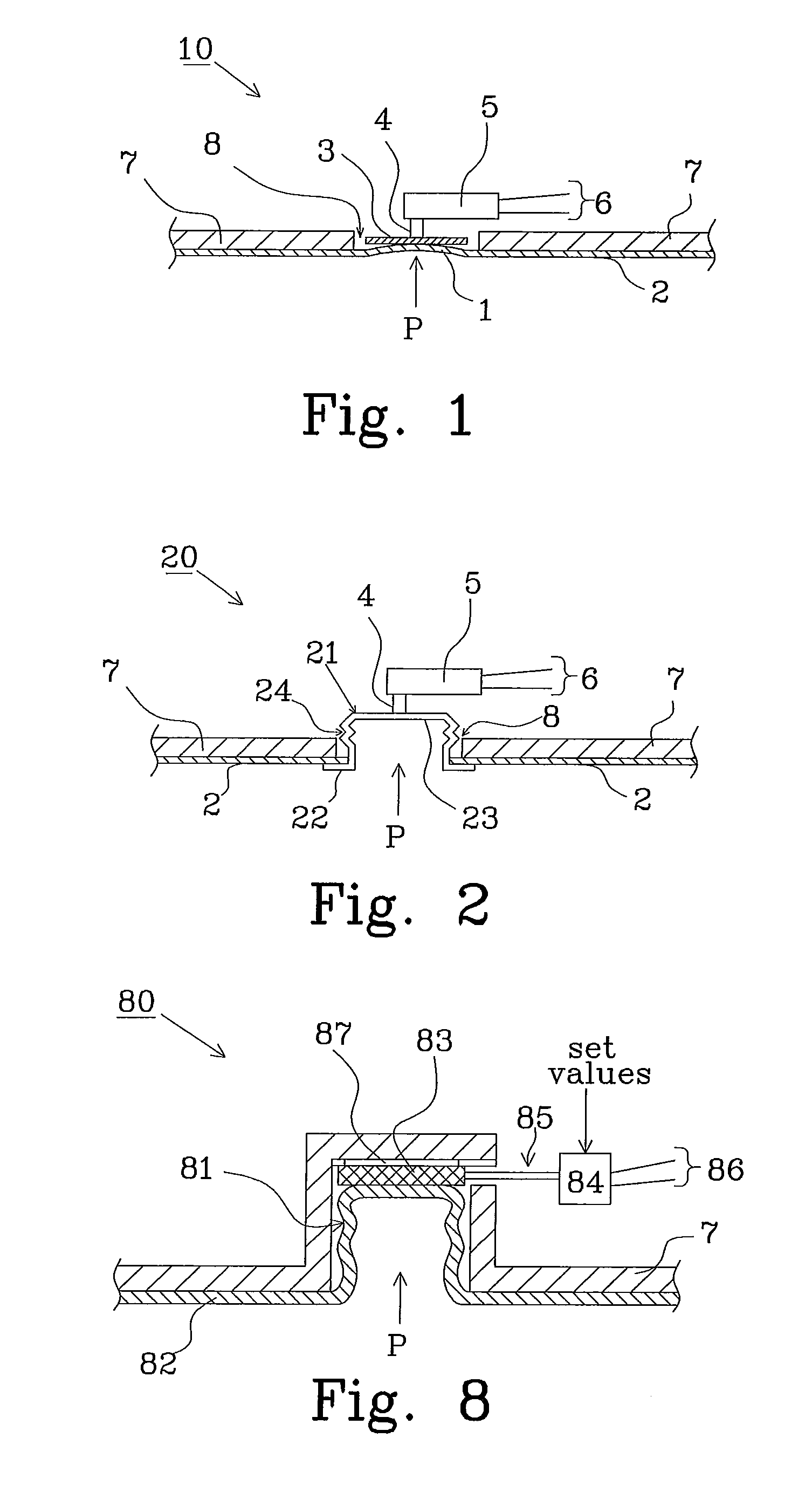

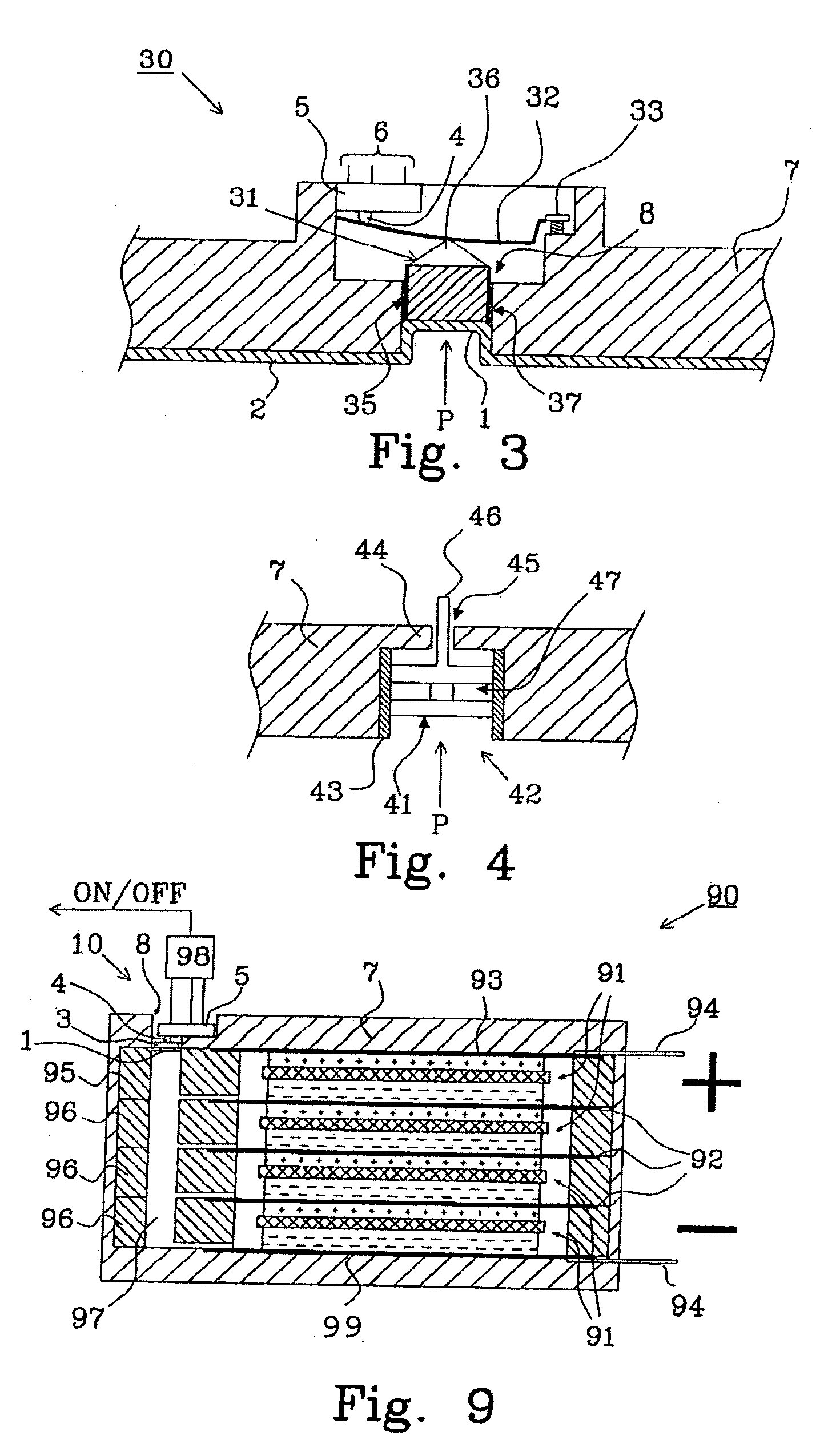

Bipolar battery including a pressure sensor

InactiveUS20090053586A1Reduce the impactLow constantBatteries circuit arrangementsCell seperators/membranes/diaphragms/spacersInternal pressureReciprocating motion

The present invention relates to a bipolar battery provided with a pressure sensor. The battery is provided with a housing 7 containing common gas space 97. The pressure sensor 10; 20; 50; 63; 80; 111 comprises: an actuator 3, 21; 31; 41; 48; 81 configured to transfer an internal pressure P within the common gas space to a reciprocal movement, and a switching device 5; 83 configured to generate a control signal indicative of changes in relation to an initial switching state generated by said reciprocal movement when the internal pressure exceeds a predetermined upper level. The pressure sensor further comprises a reset means 4; 32; 81 to automatically reset the switching device to the initial switch state when the internal pressure goes below a predetermined lower level, whereby said control signal is based on the internal pressure (P) within said sealed common gas space. The present invention also relates to a method for charging bipolar batteries.

Owner:NILAR INT AB

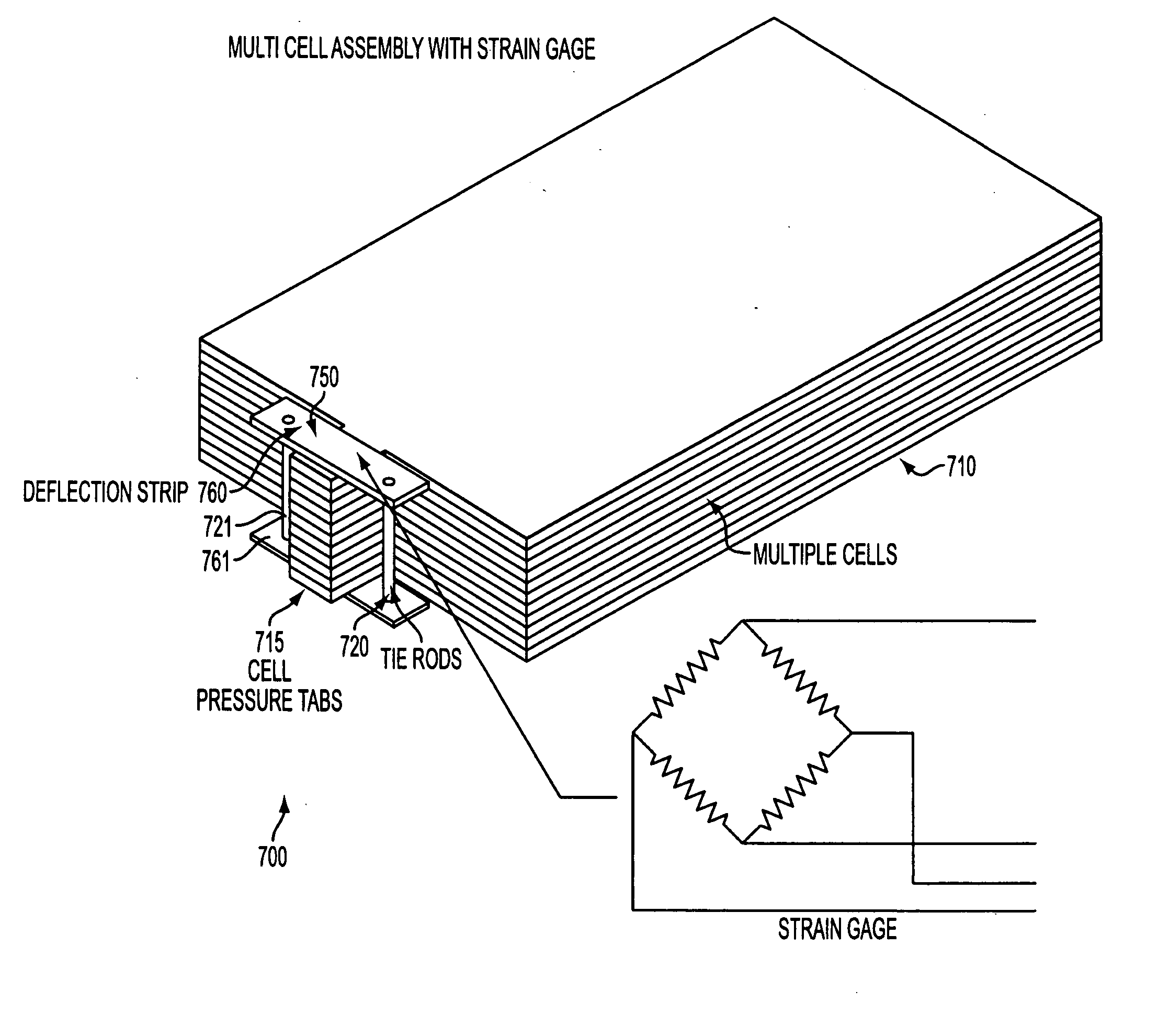

Multi-cell battery charge control

InactiveUS20050084754A1Secondary cells charging/dischargingNon-aqueous electrolyte accumulator electrodesPressure generationBattery charge

Embodiments of the present invention provide a method and system for controlling a multi-cell battery. In one embodiment of the present invention, a stack of bipolar wafer cells may be connected in series. Each cell may have an area that may be expandable in response to pressure. Such an area may be aligned with a corresponding area of at least one adjacent cell. The invention further includes a trigger mechanism that may be responsive to a force created by pressure generated in a cell in the stack of bipolar cells.

Owner:ELECTRO ENERGY

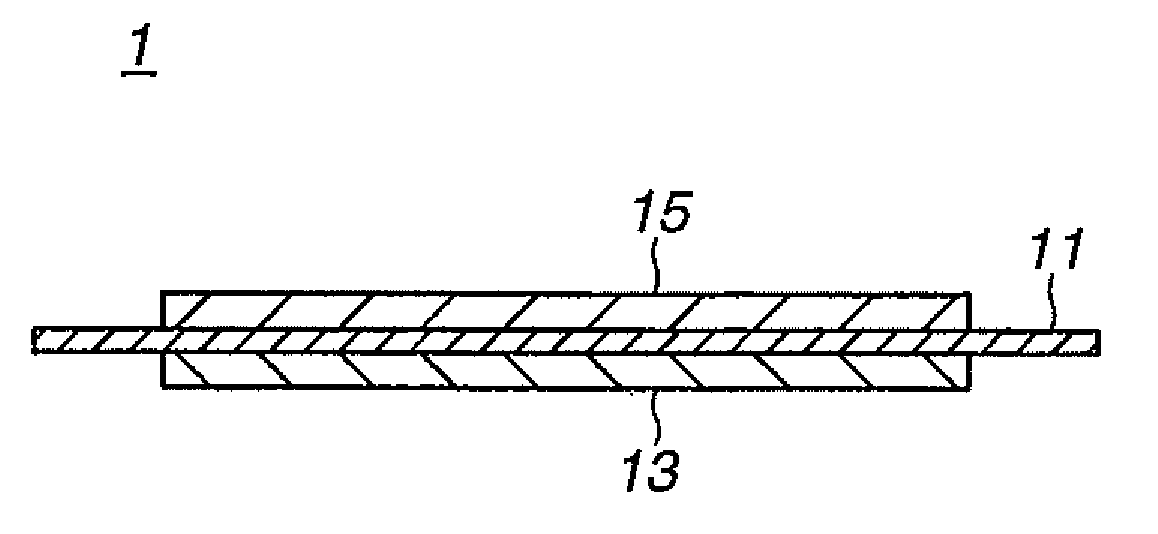

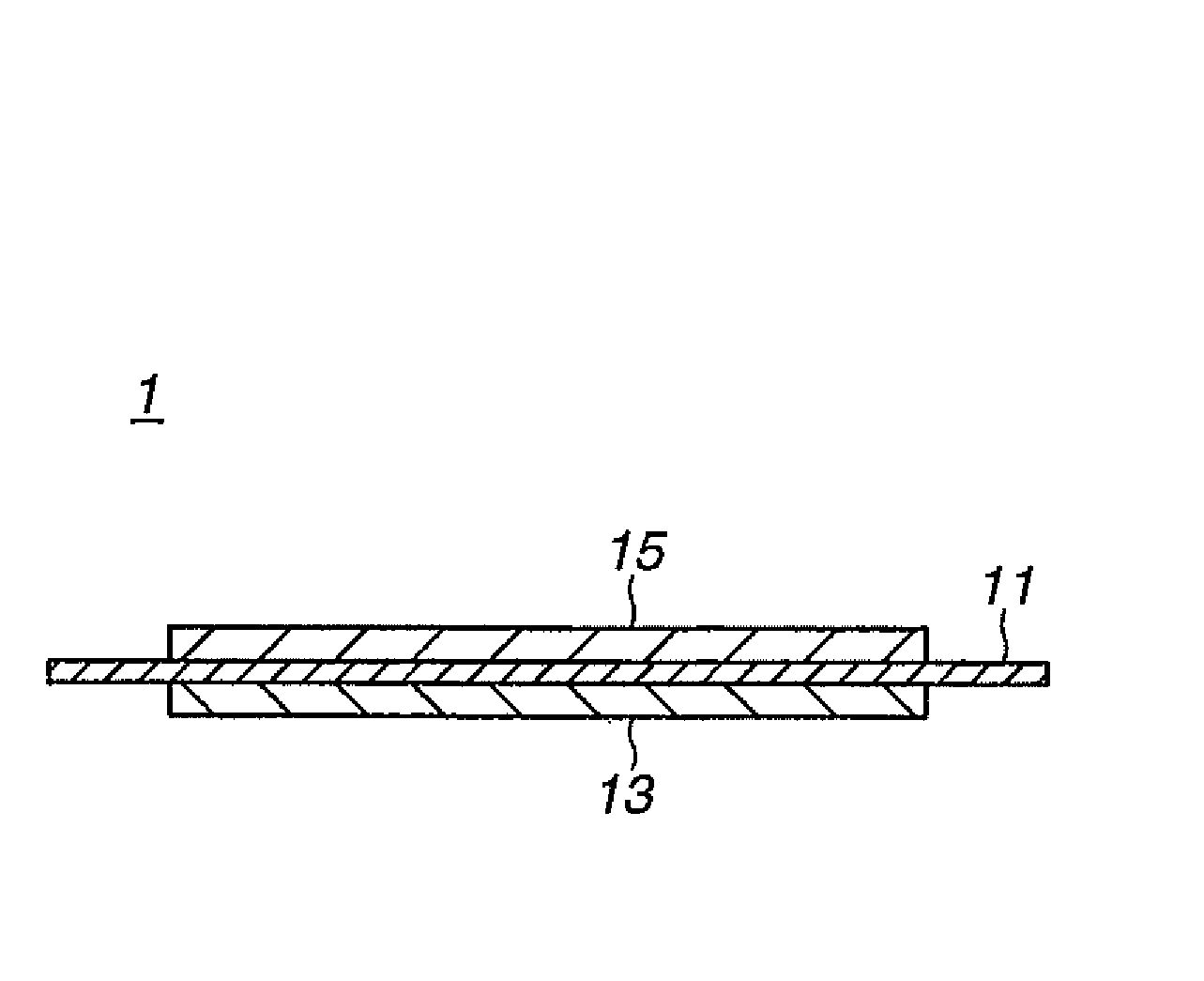

Electrode and production method thereof

ActiveUS20110206974A1Improve adhesionAvoid separationFinal product manufactureElectrode carriers/collectorsMethods of productionPolymer

An electrode includes a collector formed with a conductive resin layer and an active material layer formed on the conductive resin layer. The active material layer comprises an active material and a binder polymer, and the conductive resin layer is bonded by thermal fusion bonding to the active material layer.

Owner:ENVISION AESC JAPAN LTD

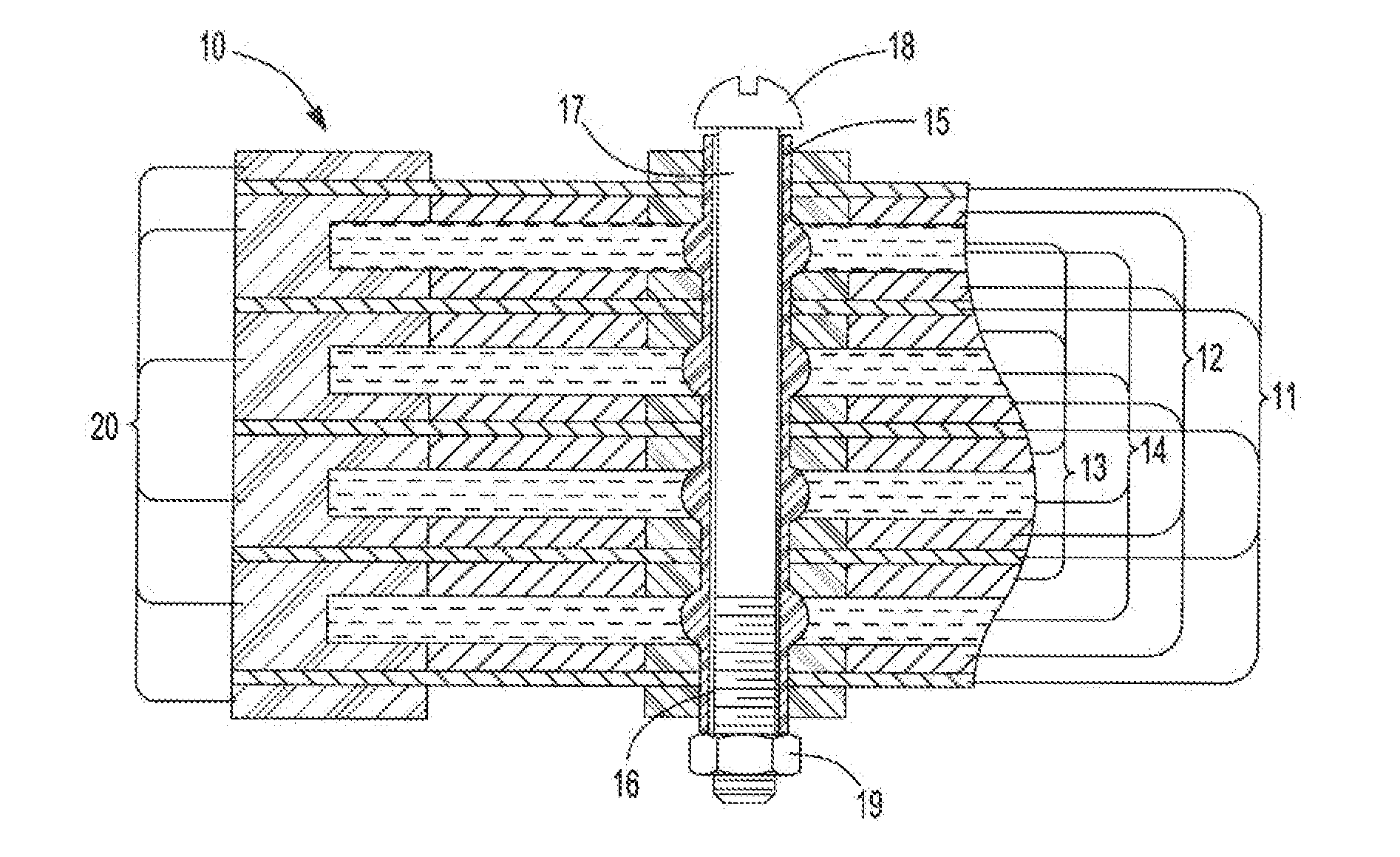

Bipolar battery assembly

ActiveUS8357469B2Easy constructionEffective distanceCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesPositive currentEngineering

A bipolar battery construction is disclosed comprising a substrate, openings in the substrate, an electrically conductive material placed within the openings, a negative and positive current collector foil placed on opposing sides of the substrate and negative and positive pasting frame members. The electrically conductive material may have a melting point below the thermal degradation temperature of the substrate.

Owner:ADVANCED BATTERY CONCEPTS

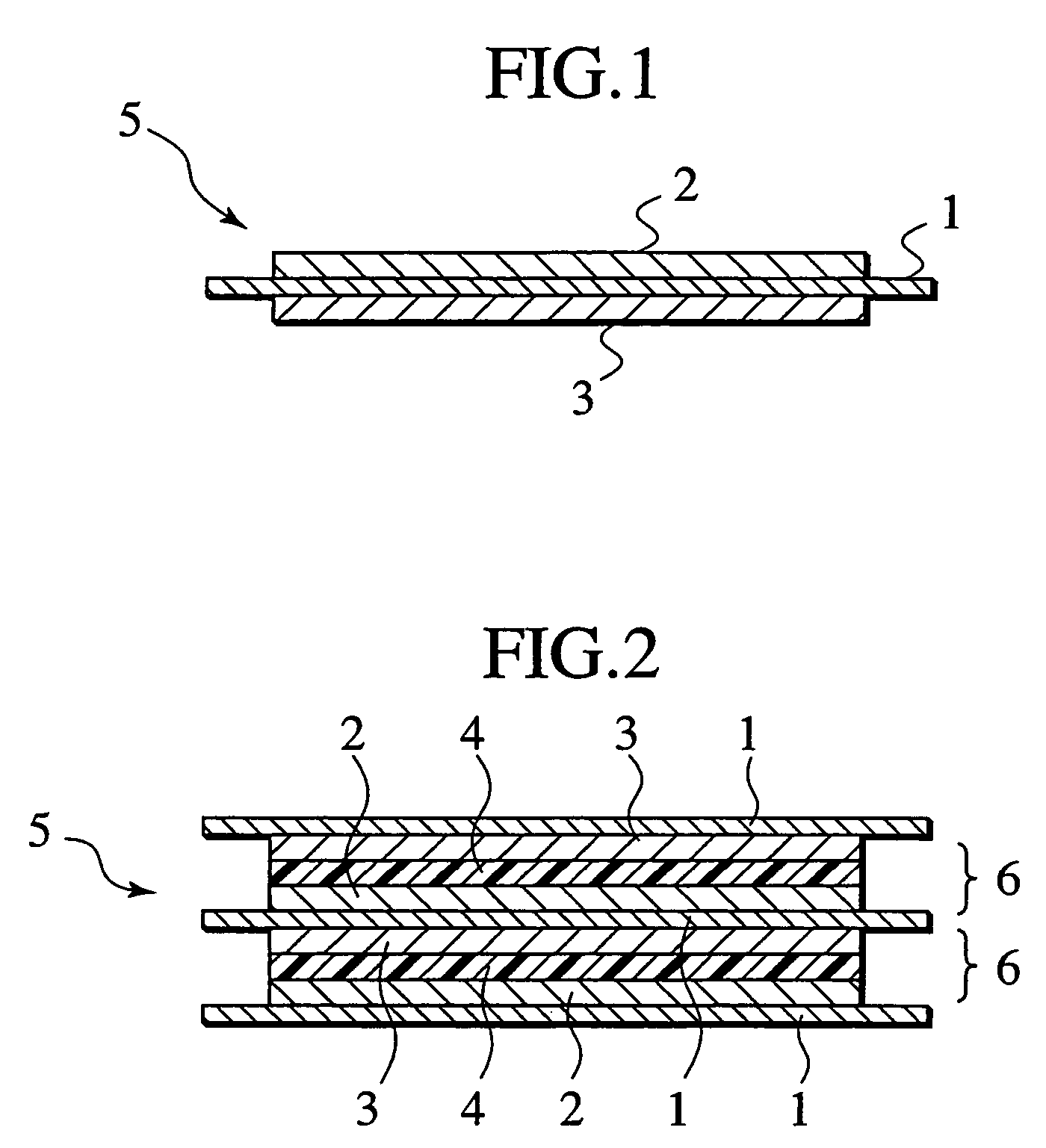

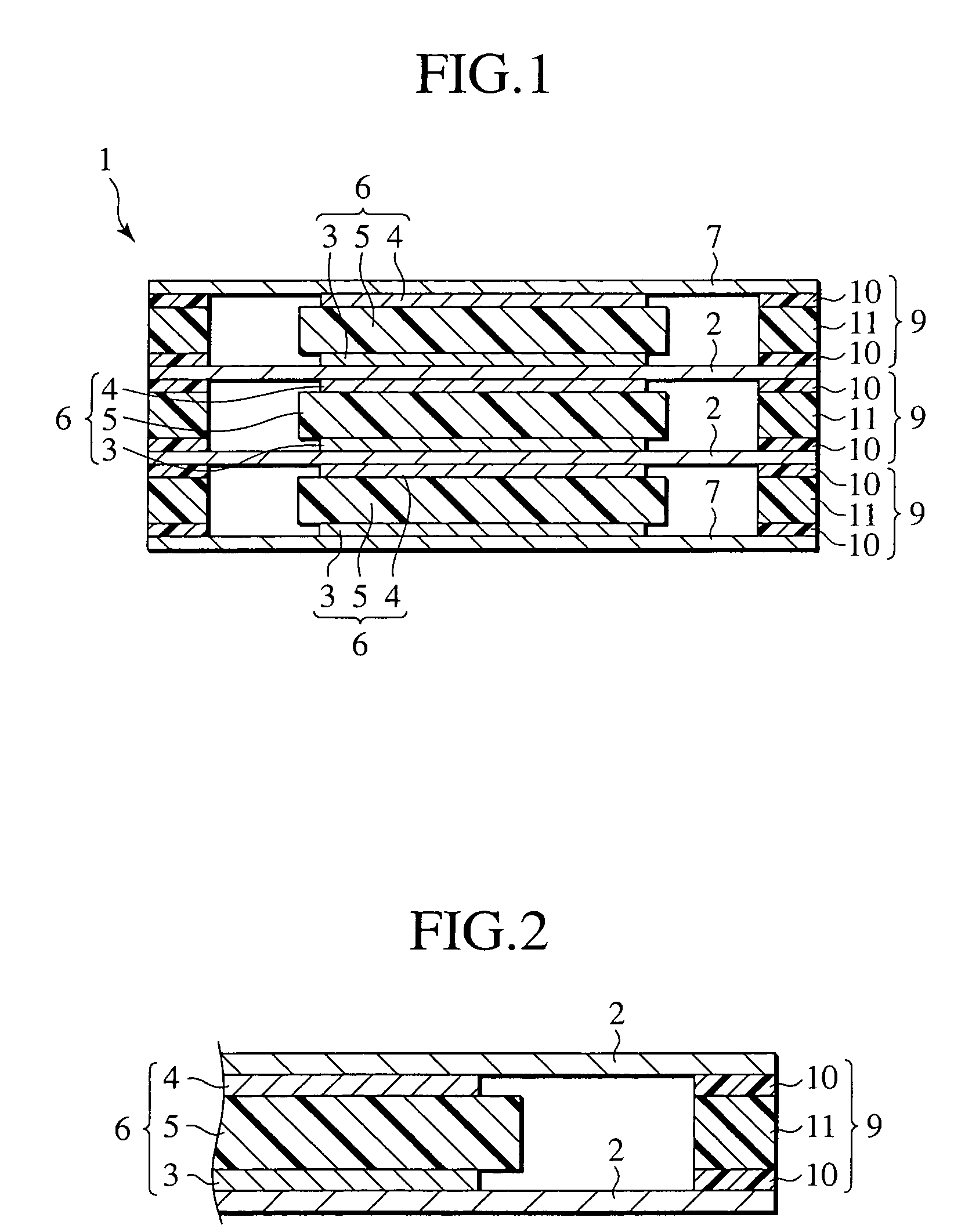

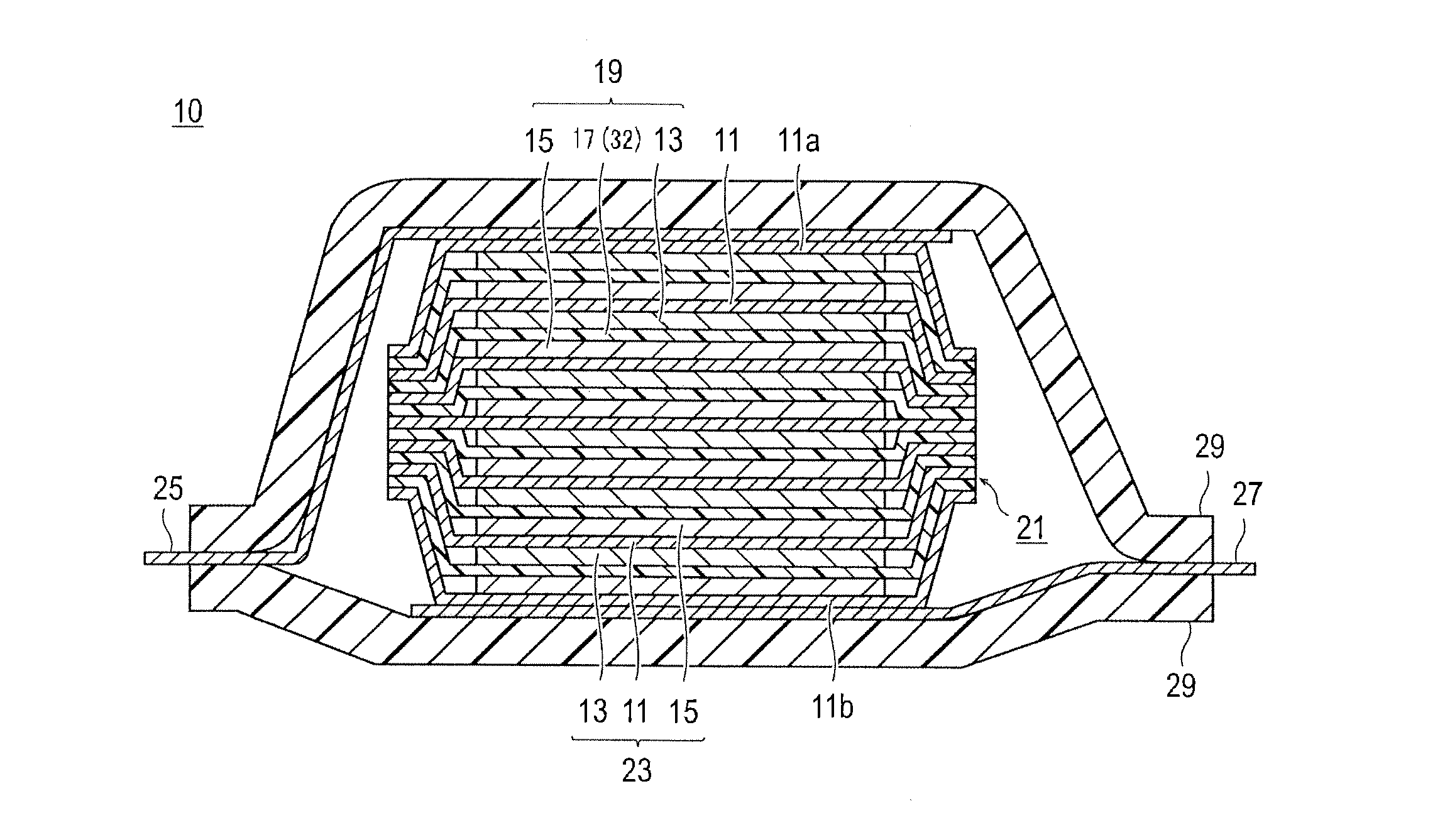

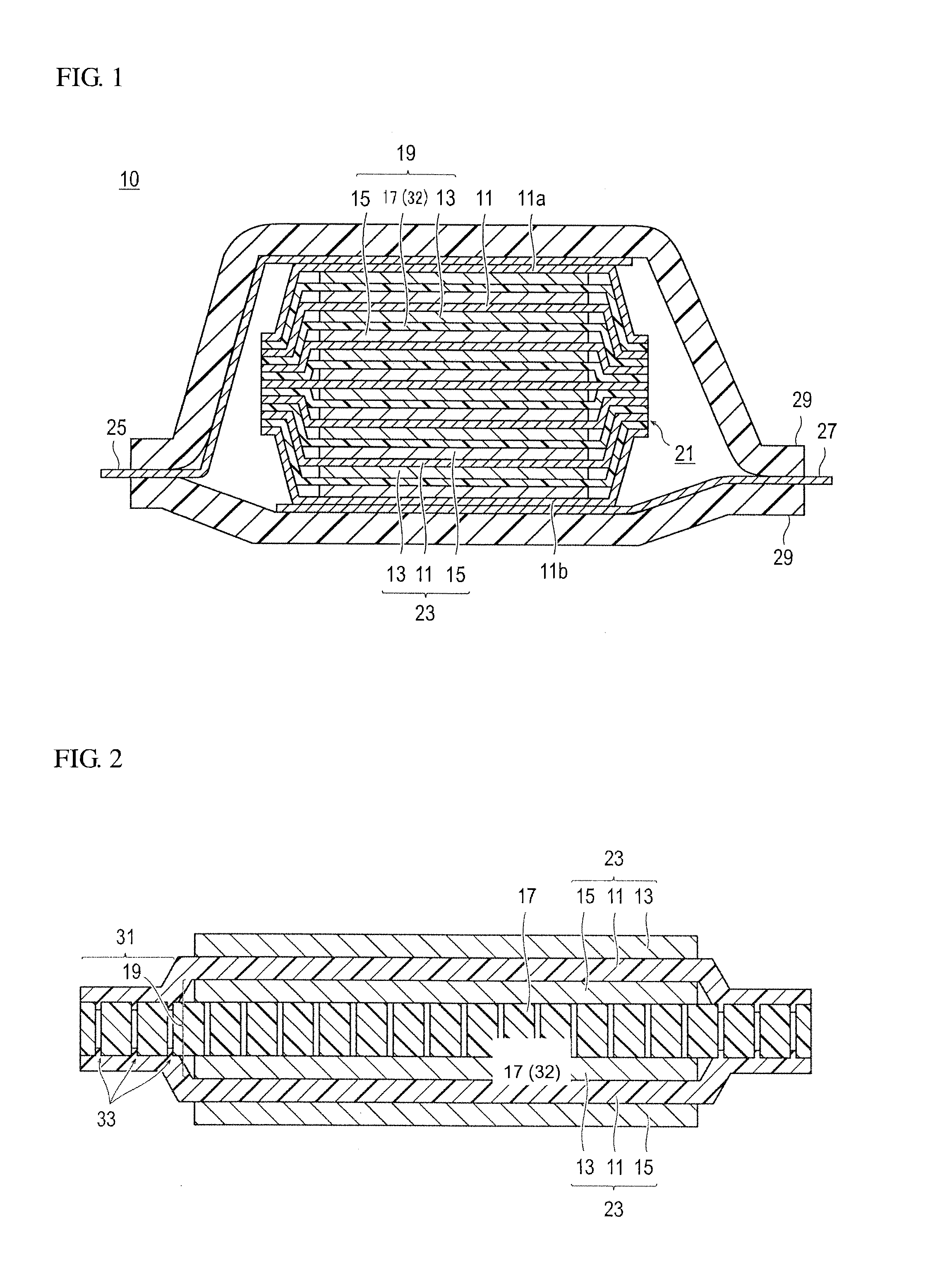

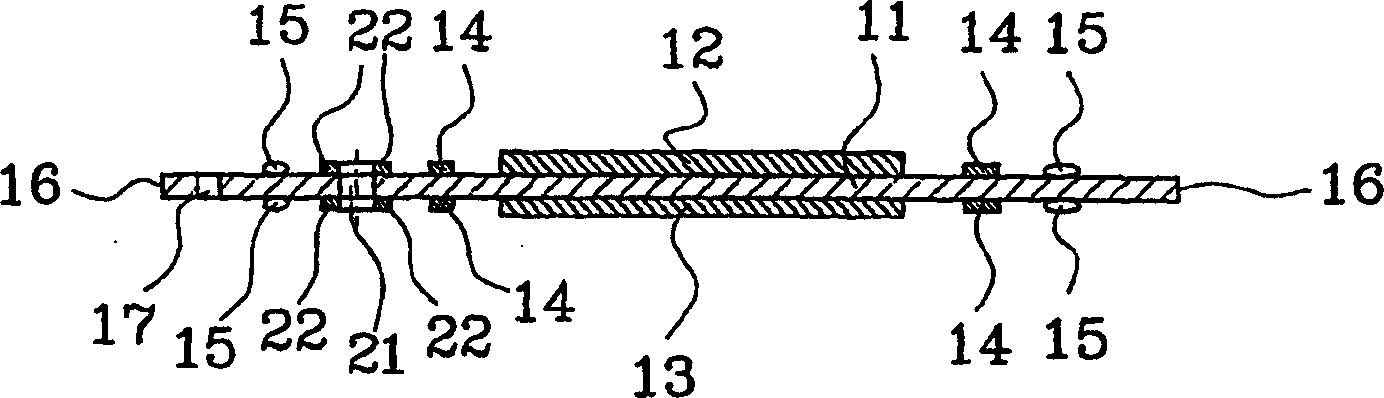

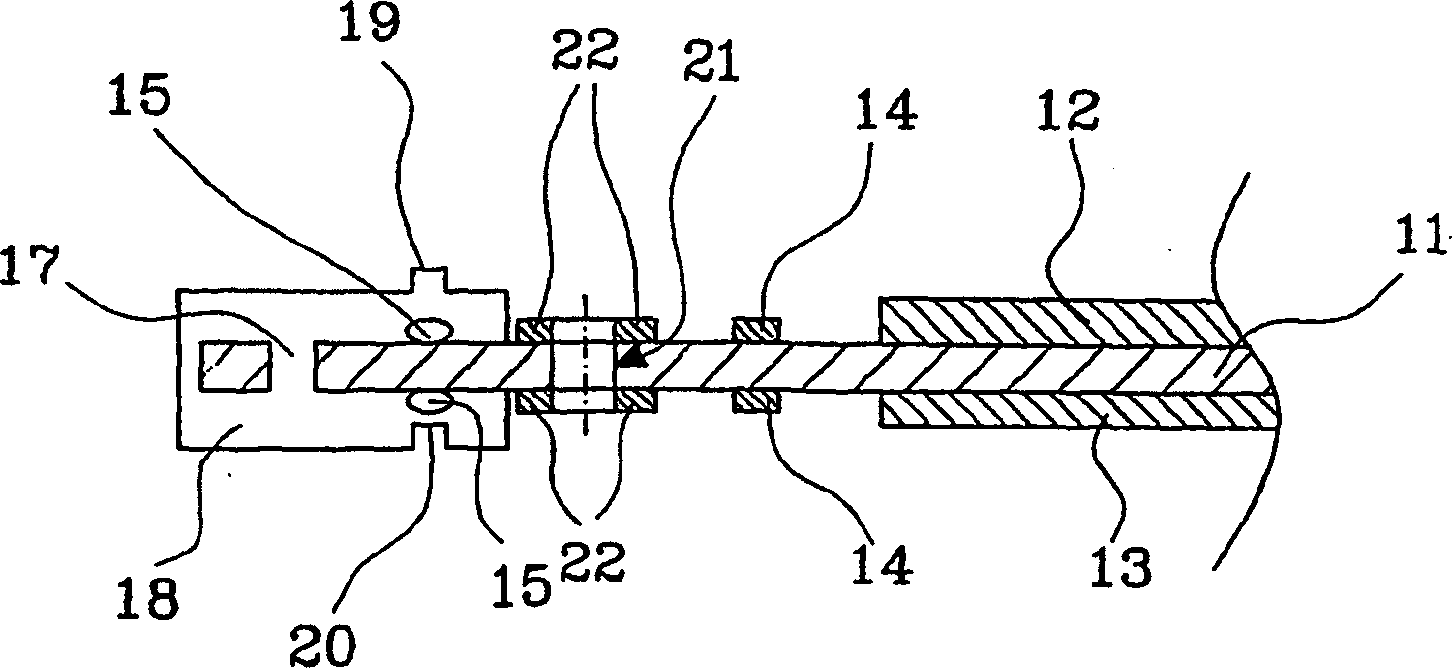

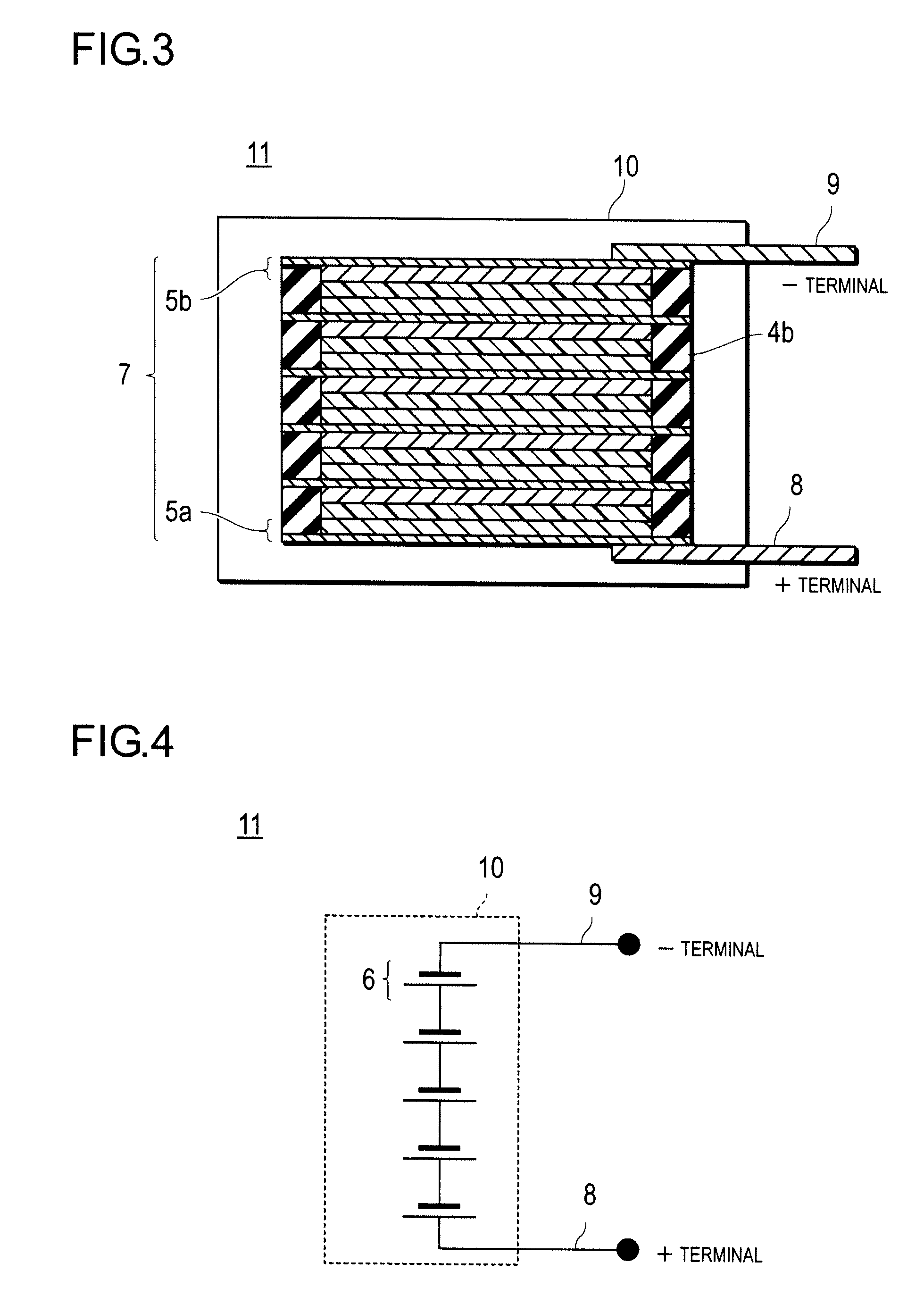

Bipolar secondary battery and method for producing the same

ActiveUS20110294007A1Improved seal durabilityImprove sealingLarge-sized flat cells/batteriesFinal product manufactureElectrical and Electronics engineeringMelting point

A bipolar secondary battery has a battery element that includes first and second bipolar electrodes each having a collector disposed with a conductive resin layer containing a first resin as a base material and positive and negative electrode active material layers formed on opposite sides of the collector and a separator containing a second resin as a base material, arranged between the first and second bipolar electrodes and retaining an electrolyte material to form an electrolyte layer. The positive electrode active material layer of the first bipolar electrode, the electrolyte layer and the negative electrode active material layer of the second bipolar electrode constitute a unit cell. A melting point of the first resin is lower than or equal to a melting point of the second resin. Outer peripheries of the collectors of the first and second bipolar electrodes and an outer periphery of the separator are fused together to thereby seal an outer peripheral portion of the unit cell.

Owner:NISSAN MOTOR CO LTD

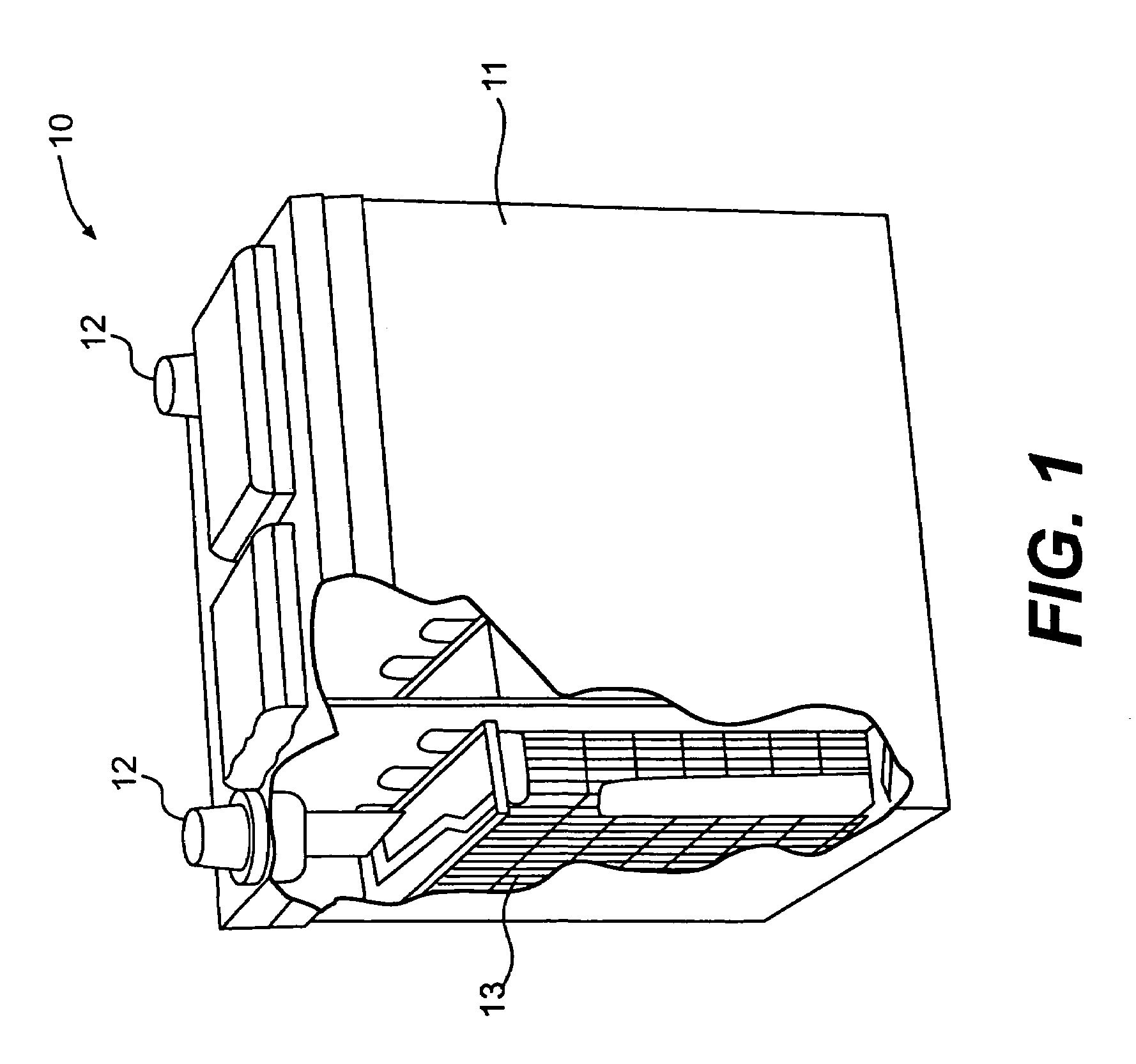

Electrowetting battery having a nanostructured electrode surface

InactiveUS7227235B2Avoid dischargeCell temperature controlElectrode carriers/collectorsElectricityElectrical battery

A method and apparatus are disclosed wherein a battery comprises an electrode having at least one nanostructured surface. The nanostructured surface is disposed in a way such that an electrolyte fluid of the battery is prevented from contacting the electrode, thus preventing discharge of the battery when the battery is not in use. When a voltage is passed over the nanostructured surface, the electrolyte fluid is caused to penetrate the nanostructured surface and to contact the electrode, thus activating the battery. In one illustrative embodiment, the battery is an integrated part of an electronics package. In another embodiment, the battery is manufactured as a separate device and is then brought into contact with the electronics package. In yet another embodiment, the electronics package and an attached battery are disposed in a projectile that is used as a military targeting device.

Owner:ALCATEL-LUCENT USA INC

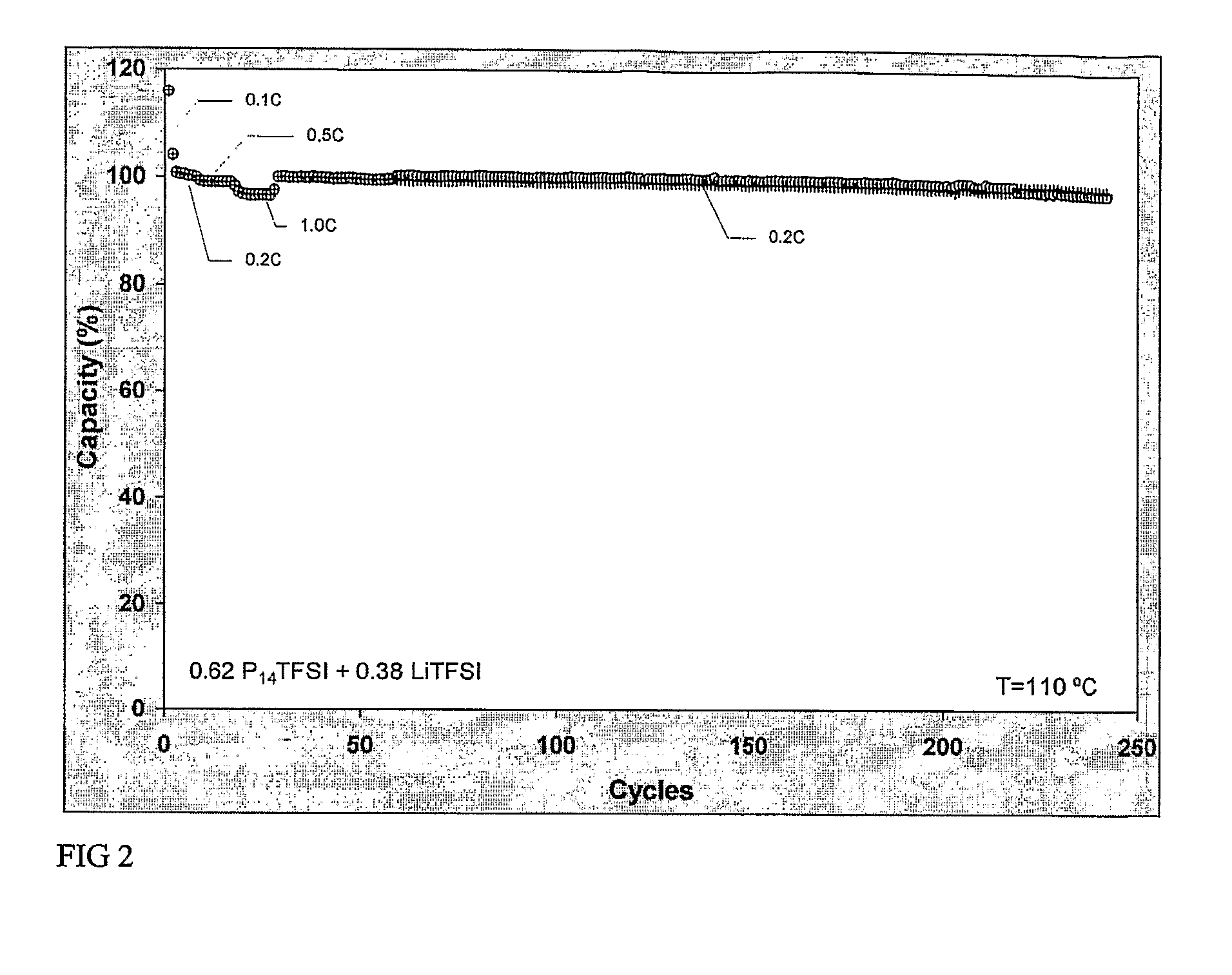

Electrochemical Element for Use at High Temperatures

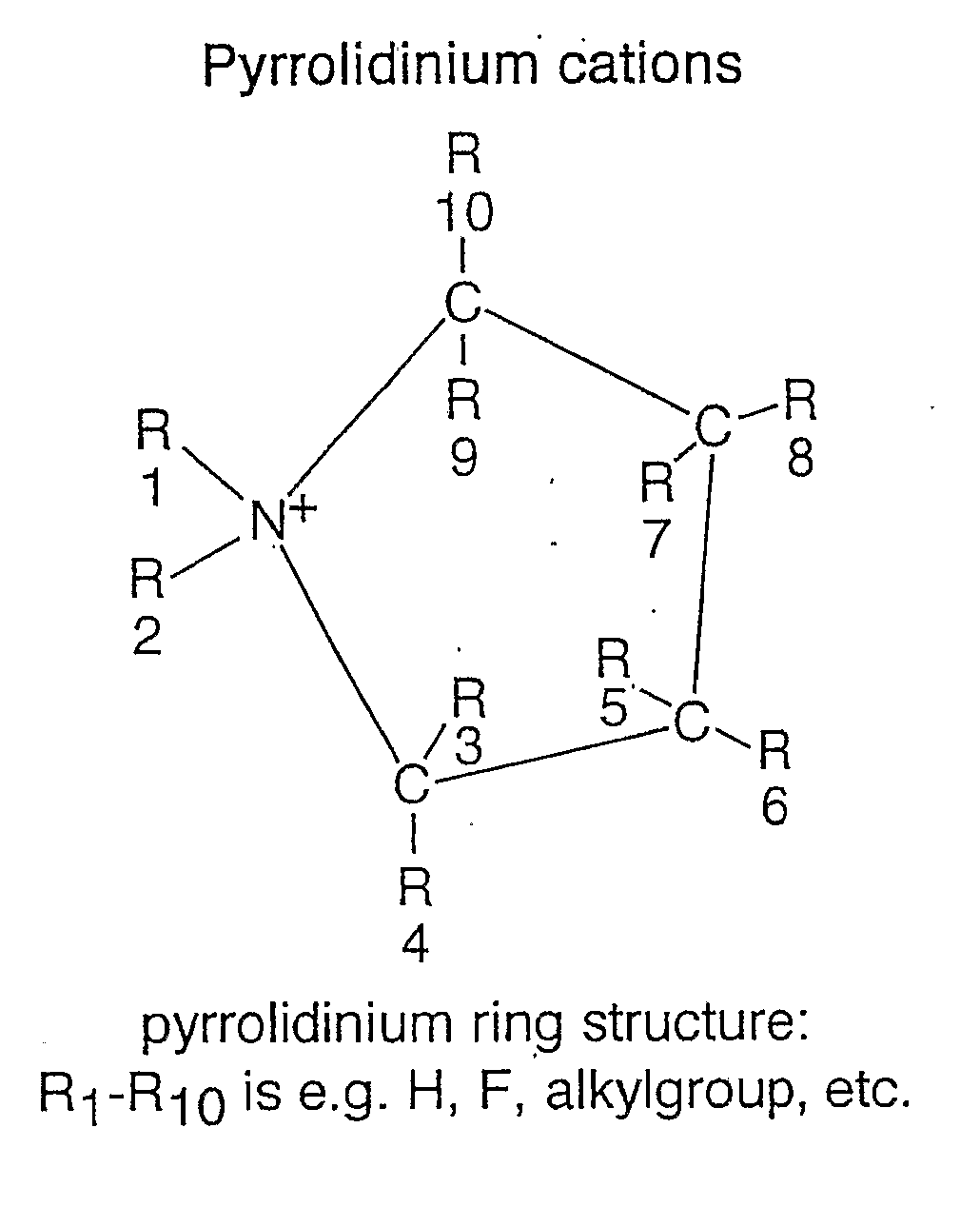

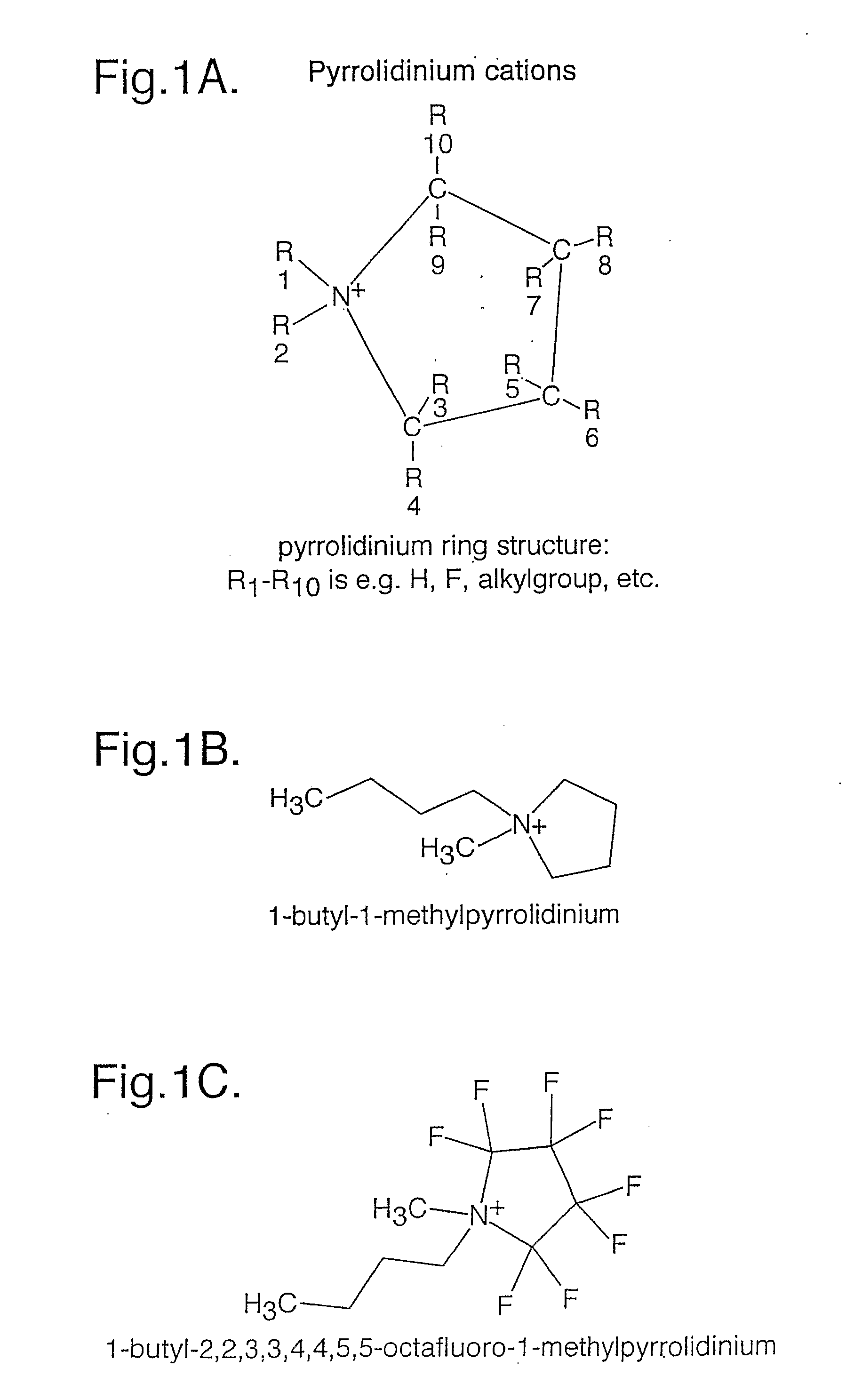

ActiveUS20070254213A1Reduces ionic conductivityImprove power densityOrganic electrolyte cellsCapacitor electrolytes/absorbentsCelsius DegreeRechargeable cell

An electrochemical element for use at a high temperature has a cathode comprising an intercalation material as active material, an anode and an electrolyte arranged between the cathode and anode, which electrolyte comprises an ionic liquid with an anion and a cation, which cation comprises a pyrrolidinium ring structure comprising four Carbon atoms and one Nitrogen atom. Experiments revealed that rechargeable batteries comprising N—R1—N—R2-pyrrolidinium, wherein R1 and R2 are alkyl groups and R1 may be methyl and R2 may be butyl or hexyl, are particularly suitable for use at a temperature of up to about 150 degrees Celsius and may be used in oil and / or gas production wells.

Owner:SHELL USA INC

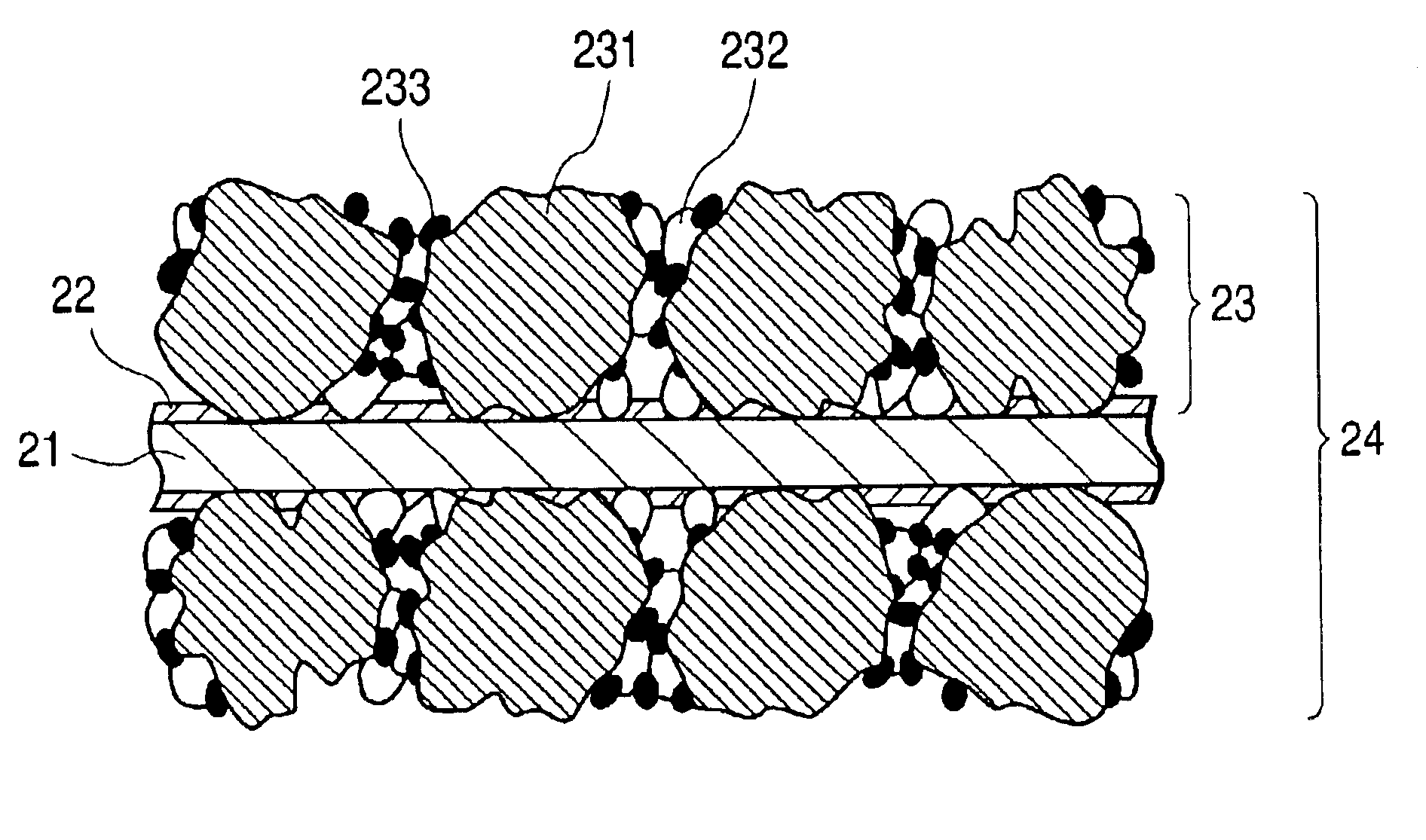

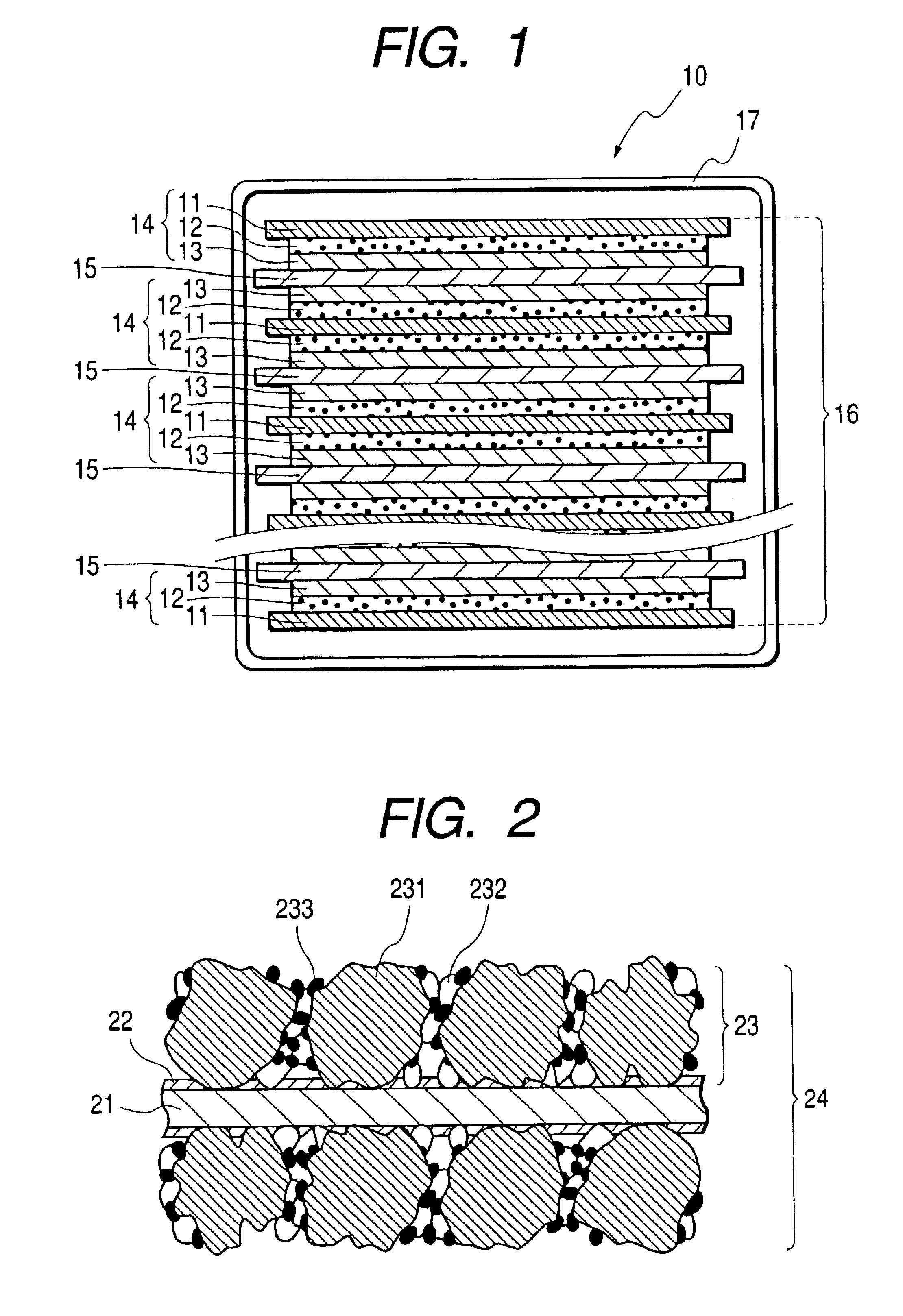

Electrochemical device and process for producing same

InactiveUS6912116B2Improve cycle performanceLower internal resistanceBatteries circuit arrangementsFinal product manufactureElectrical connectionElectrochemistry

An electrochemical device includes electrodes stacked one on the other with a separator intervening between the adjacent electrodes. The electrode includes a current collector and an electrode layer stacked on the current collector via an adhesive resin layer. The electrode layer contains an active material, an electrically conductive auxiliary and a binder resin. At least part of the electrically conductive auxiliary or the active material penetrates the adhesive resin layer to establish an electrical connection with the current collector.

Owner:TDK CORPARATION

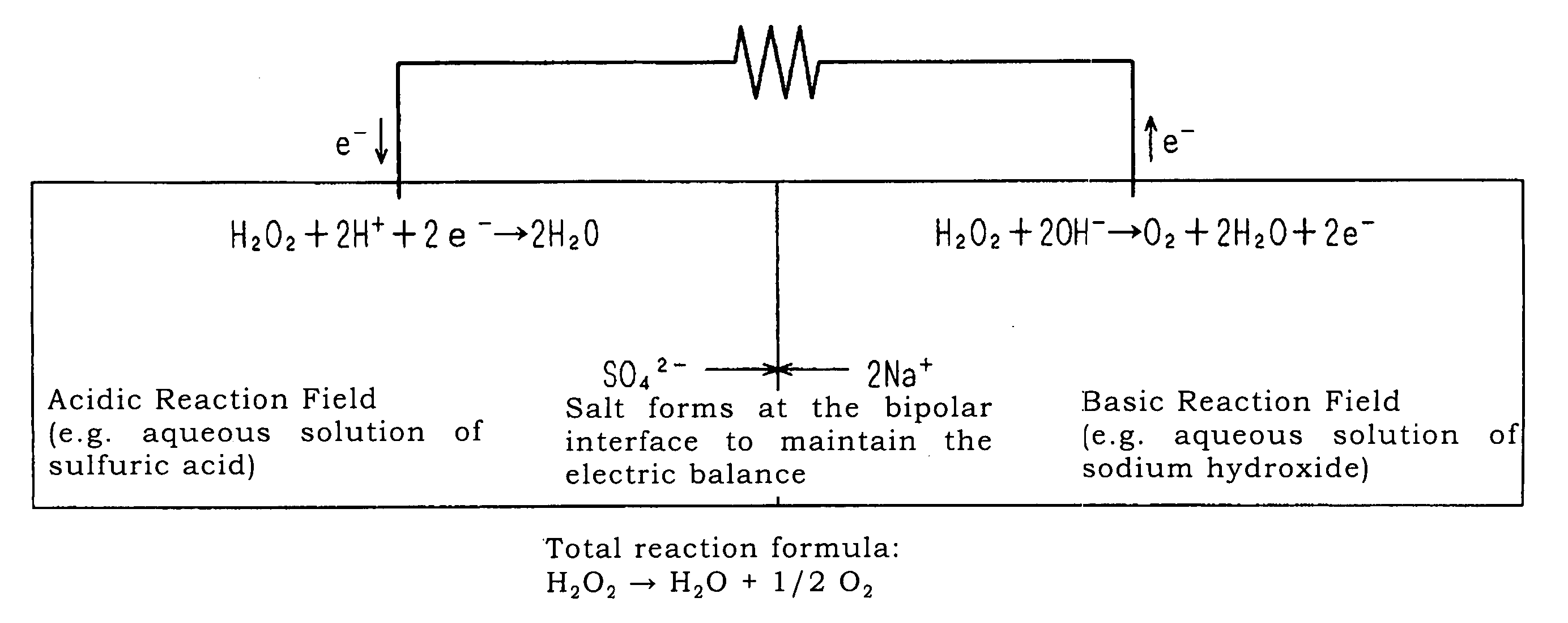

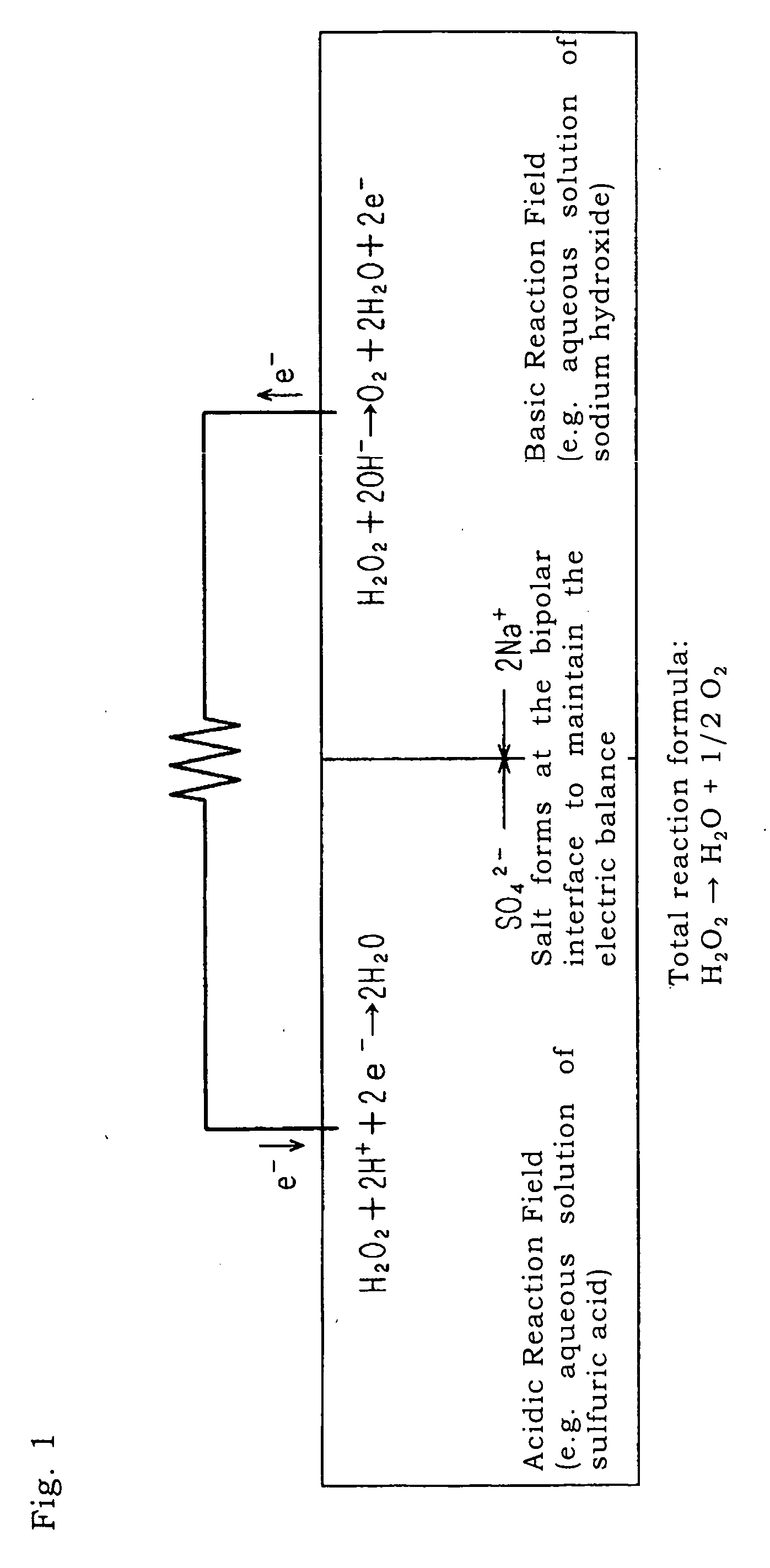

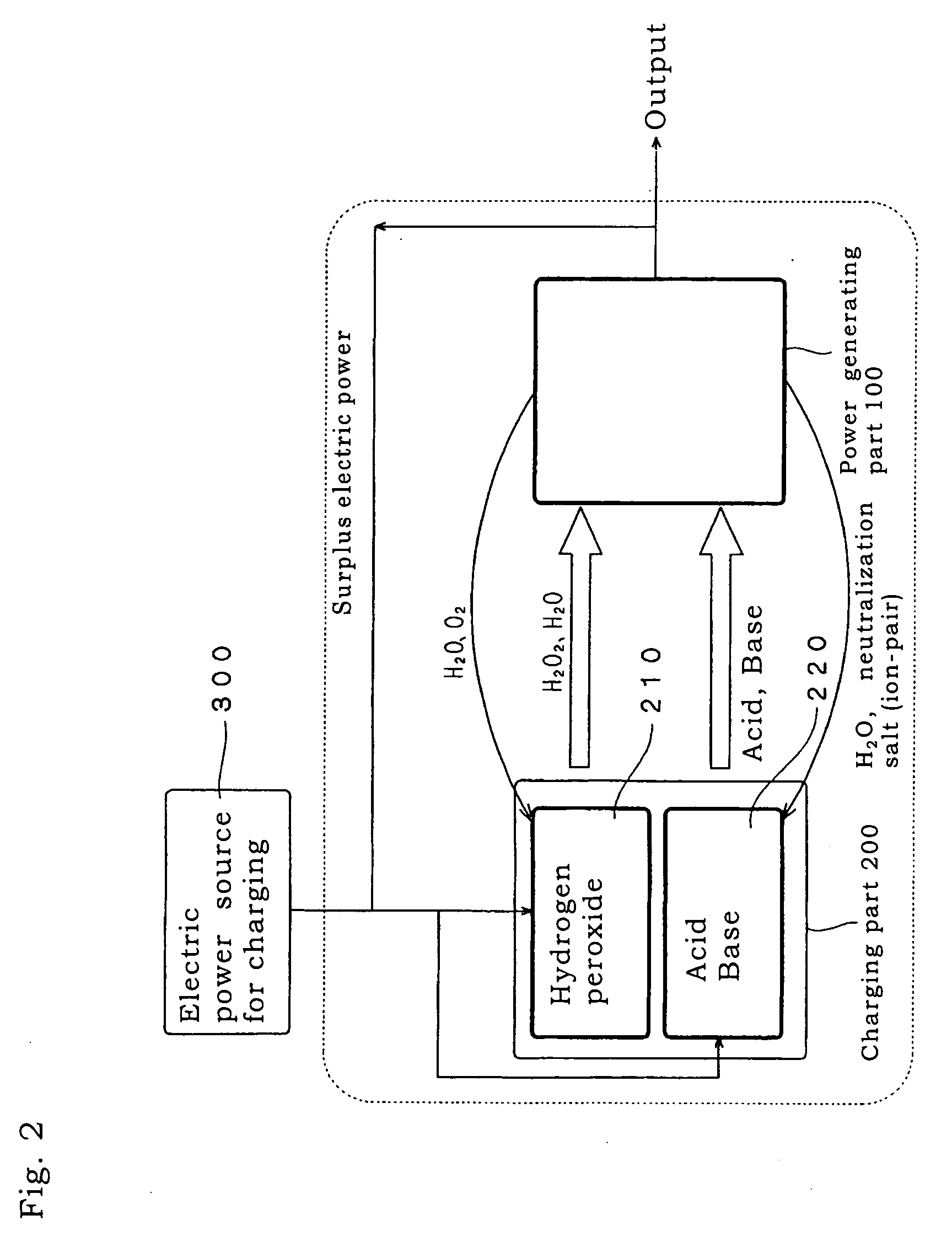

Secondary battery and method of generating electric power

InactiveUS20050260460A1Electrolysis componentsElectrode manufacturing processesElectrical batteryEngineering

A secondary battery comprising a power generating part and a charging part, wherein the power generating part comprises an acidic medium in which a first electrode is disposed and a basic medium in which a second electrode is disposed; the acidic medium and the basic medium are disposed adjacent to each other; at least one of the acidic medium or the basic medium includes at least one reactive substance; and the charging part comprises a reactive substance regenerating device which regenerates the reactive substance from power-generation products produced by electric power generation in the power generating part.

Owner:FUJIFILM BUSINESS INNOVATION CORP

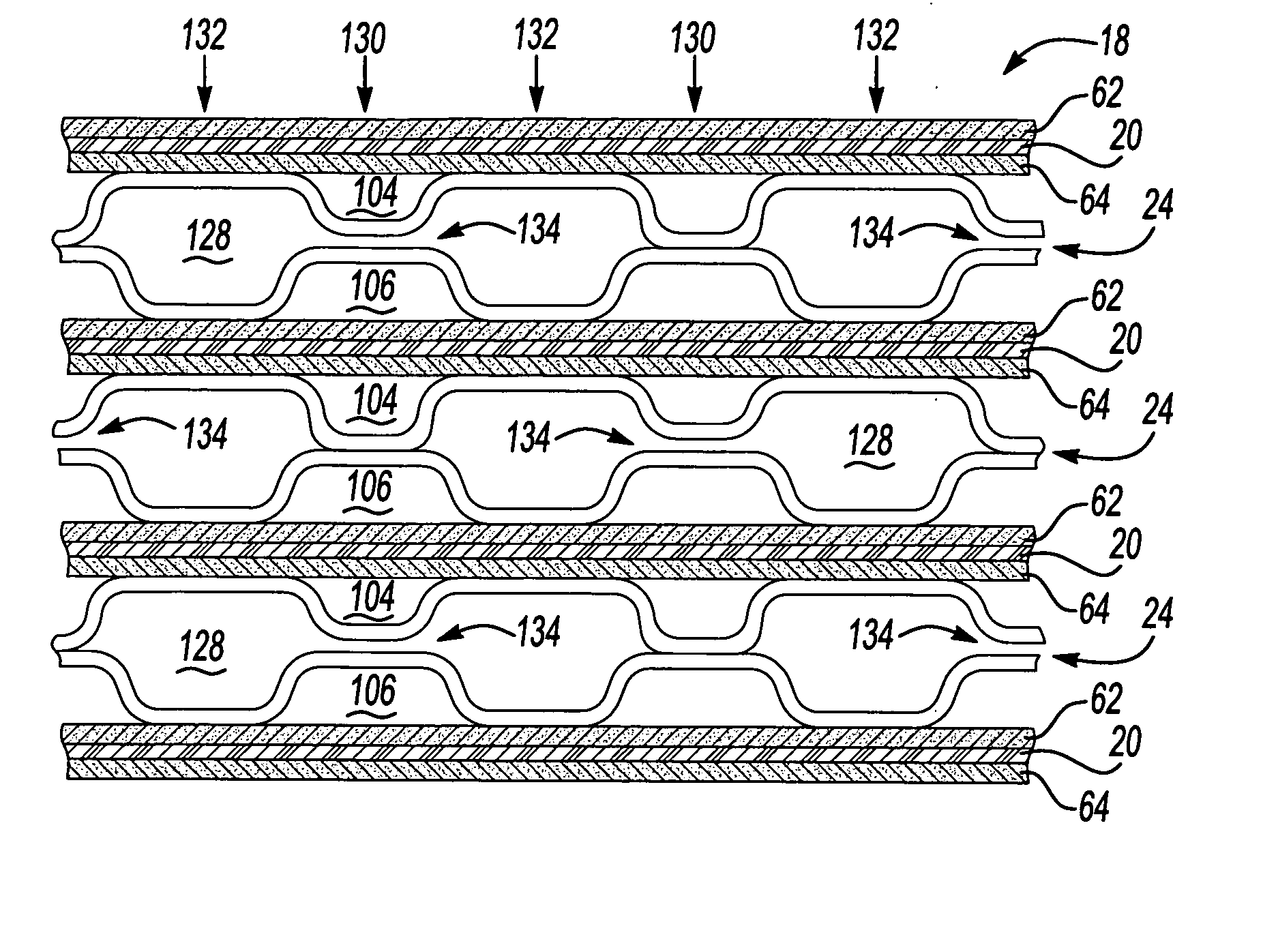

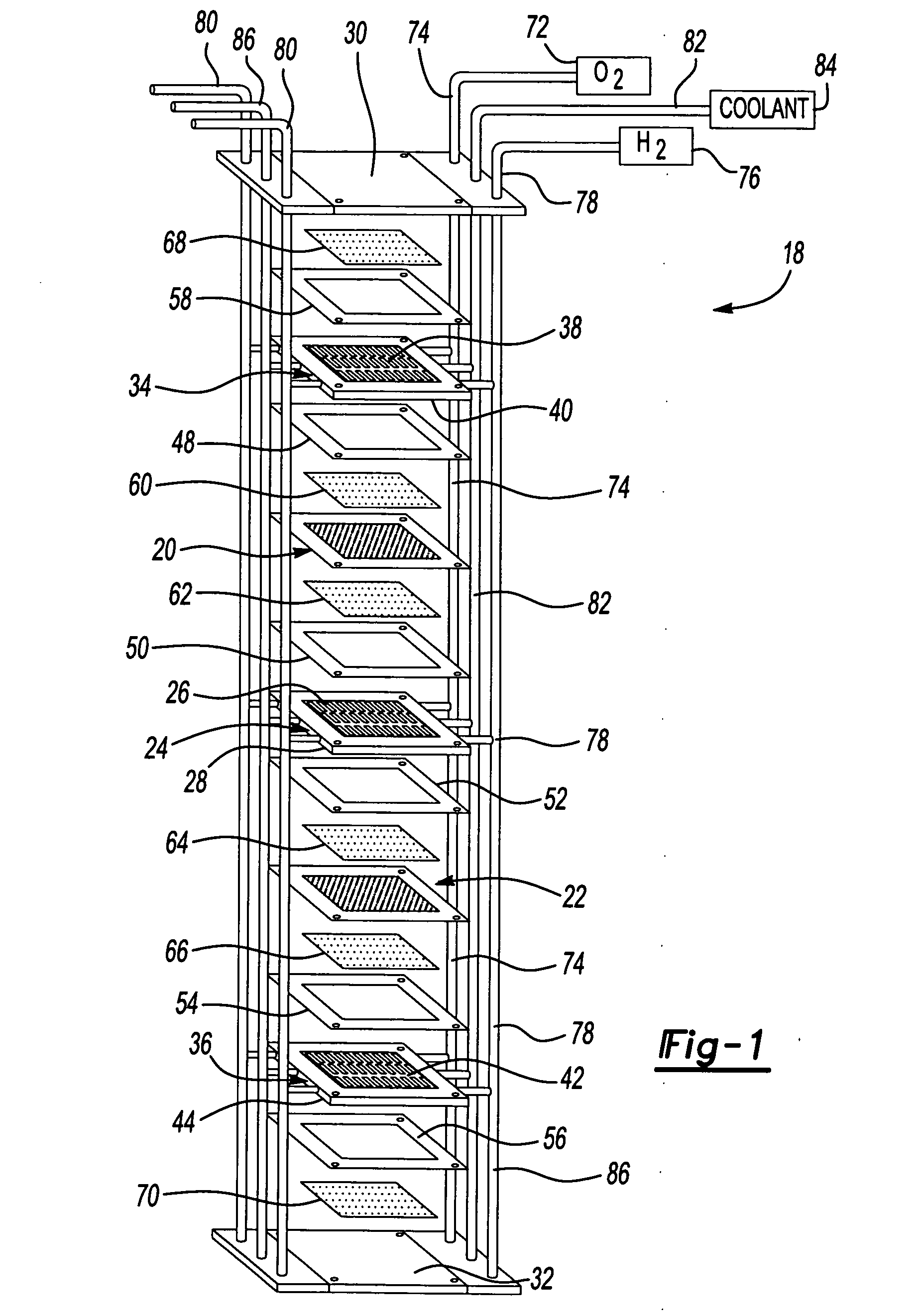

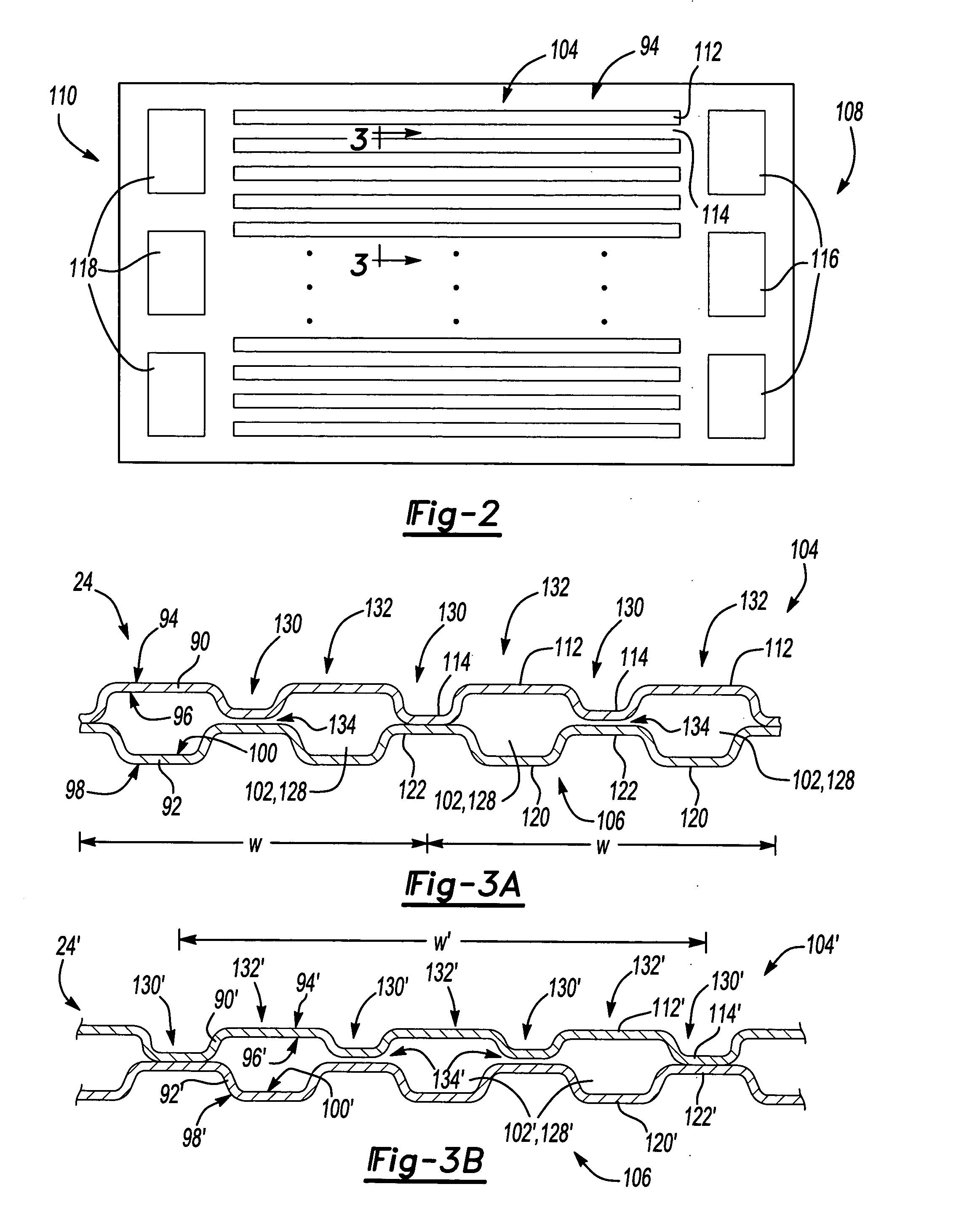

Flexible bipolar plate

ActiveUS20060046130A1Maintaining compressionFuel cells groupingFuel cell auxillariesFuel cellsCoolant flow

The present invention provides for a construction for a bipolar plate for a fuel cell stack that enables the bipolar plate to be a more compliant member in the fuel cell stack. The bipolar plate can be configured to provide varying levels of compliance, as demanded by the design of the fuel cell stack. The bipolar plate can be more compliant than the diffusion media members and the active elements used to form the individual fuel cells. The compliant nature of the individual bipolar plates enables localized dimensional changes that occur within the fuel cell stack to be compensated by a localized deformation of the portions of the bipolar plate within that region. The bipolar plate has an internal coolant flow field where some opposing pairs of lands are spaced apart with a gap therebetween while other opposing pairs of lands are in contact with one another.

Owner:GM GLOBAL TECH OPERATIONS LLC

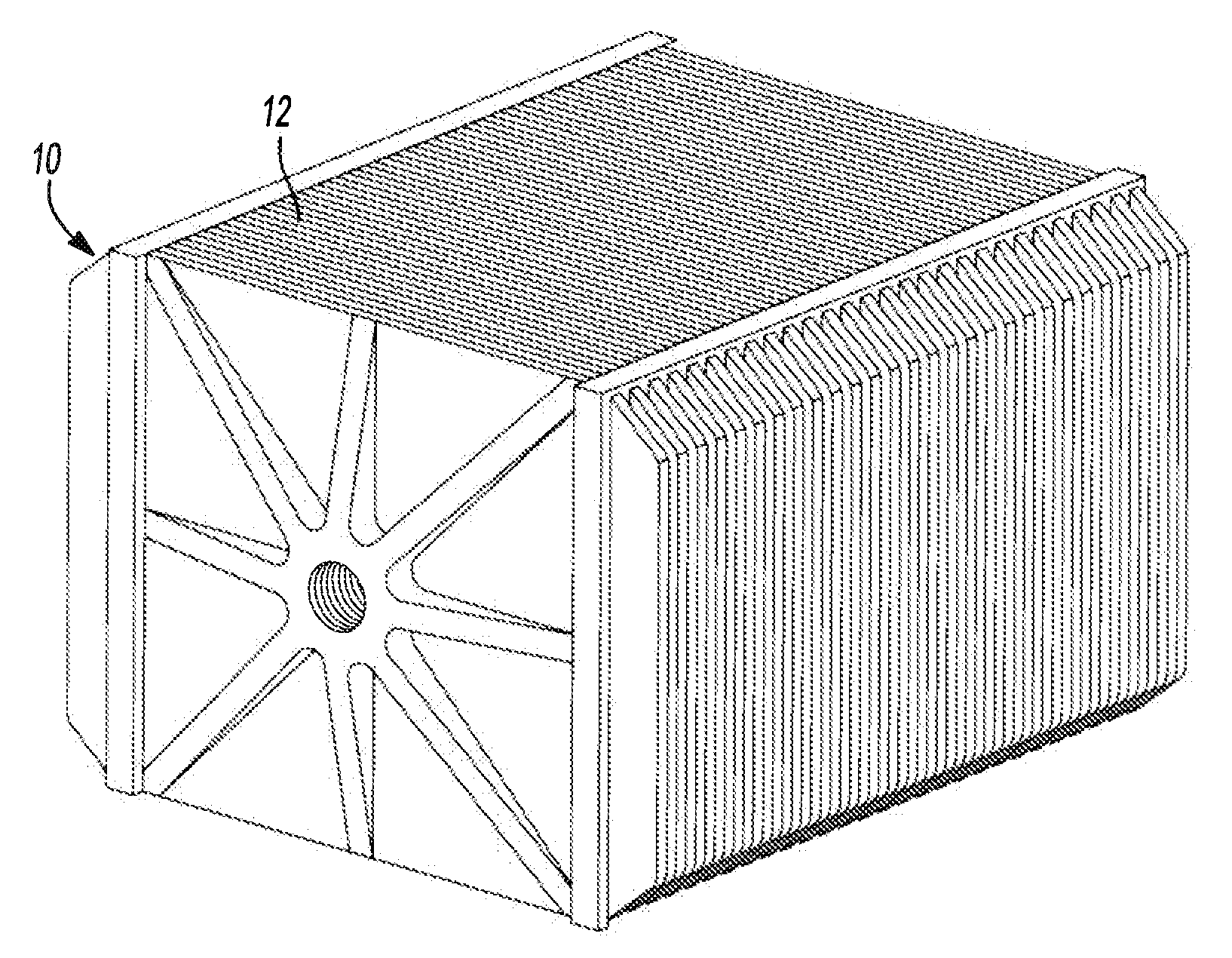

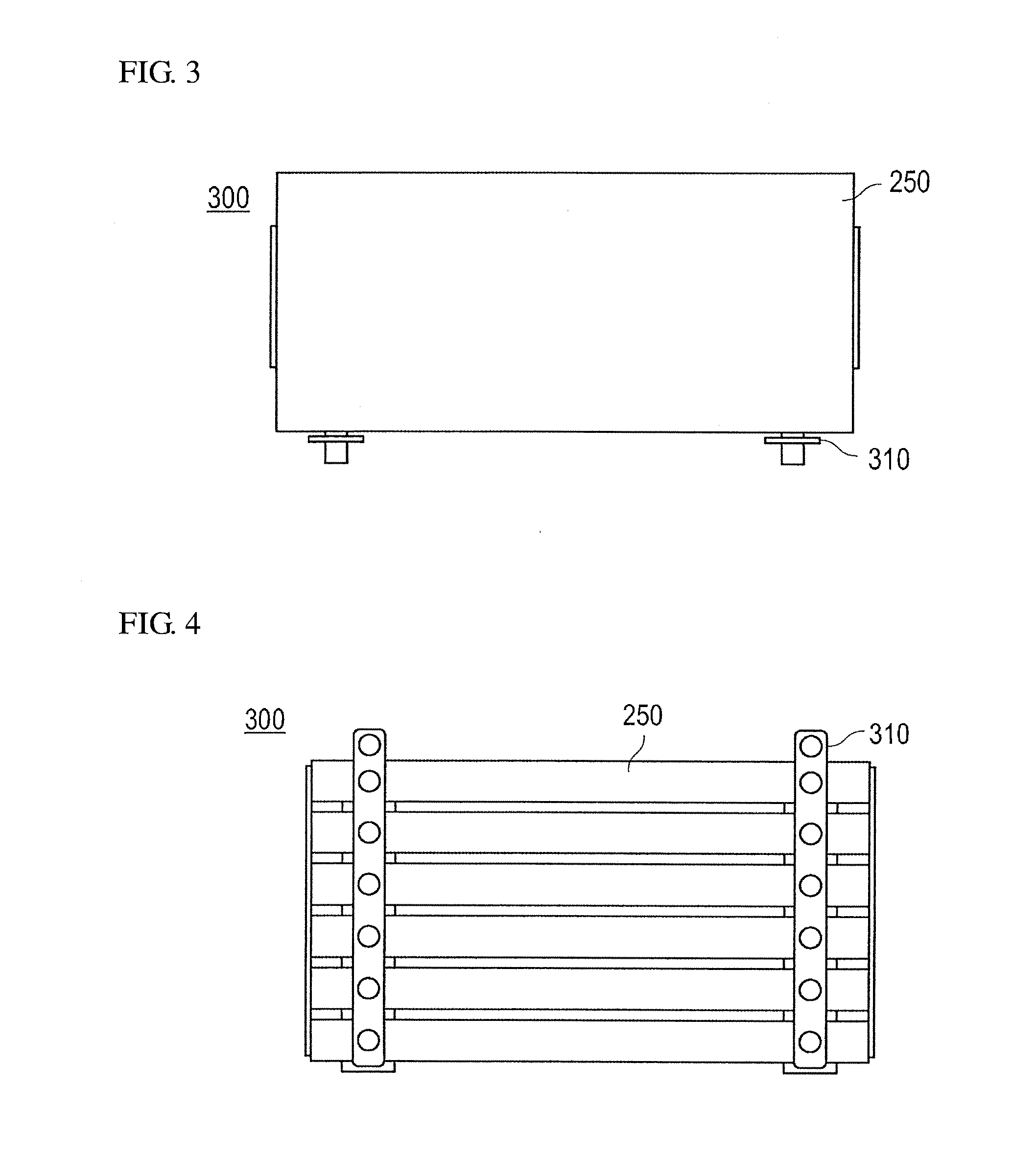

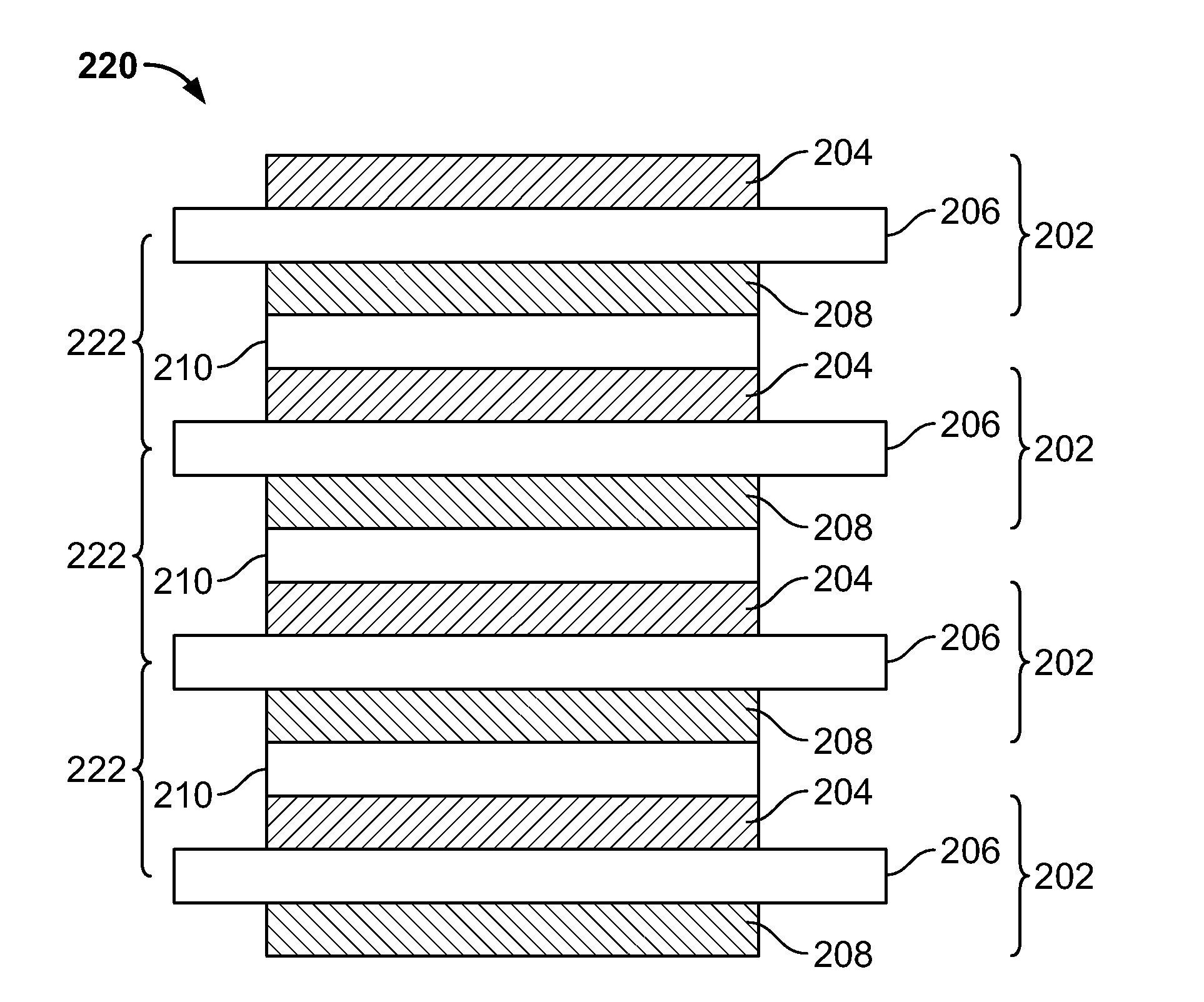

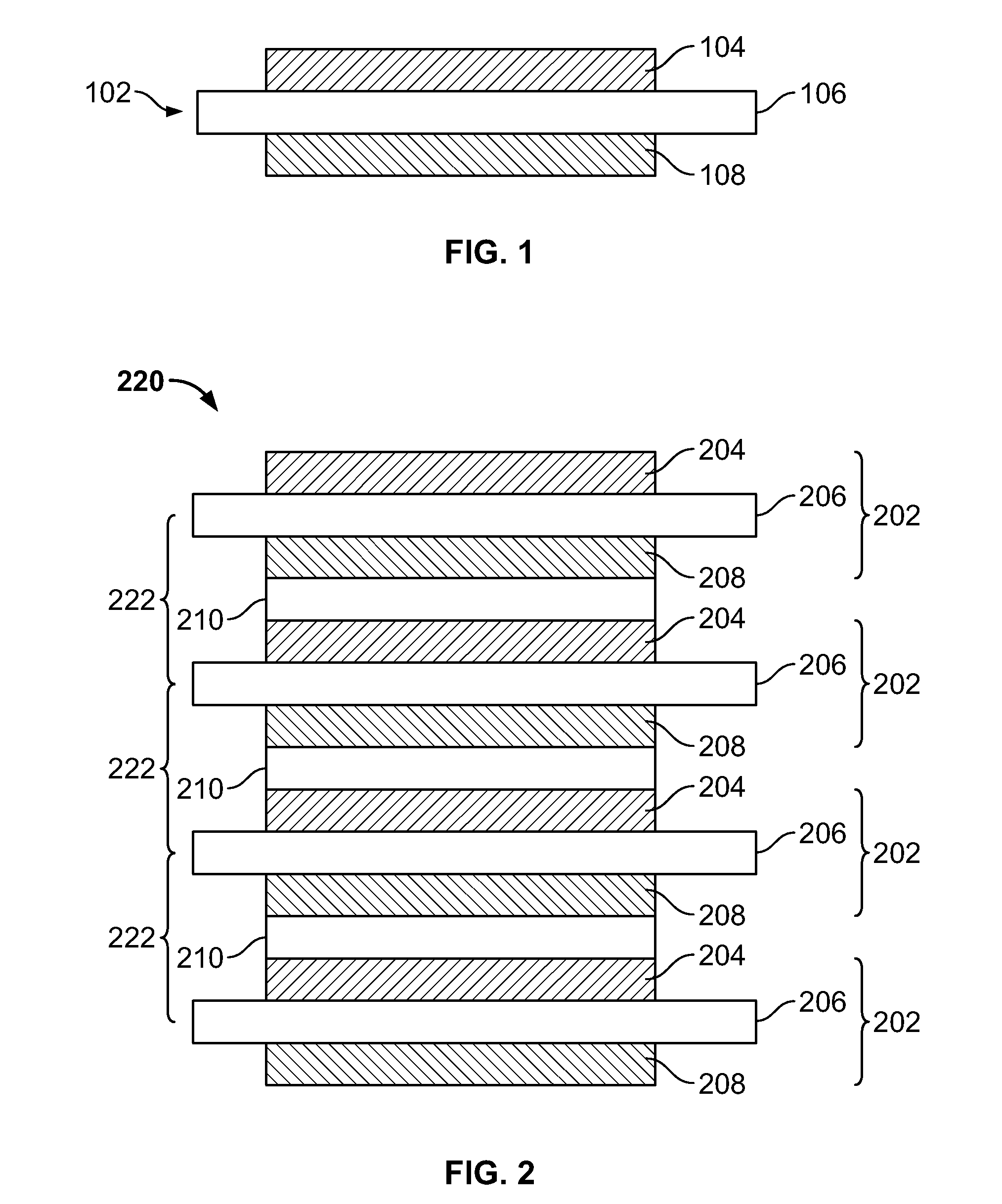

Variable volume containment for energy storage devices

A stacked energy storage device (ESD) has at least two cell segments arranged in a stack. Each cell segment may have a first electrode unit having a first active material electrode, a second electrode unit having a second active material electrode, and an electrolyte layer between the active material electrodes. Variable volume containment may be used to control the inter-electrode spacing within each cell segment. In some embodiments, one or more dynamic flexible gaskets may be included in each cell segment to seal the electrolyte within the cell segment and to deform in preferred directions. In some embodiments, hard stops may set the inter-electrode spacing of the ESD.

Owner:G4 SYNERGETICS INC

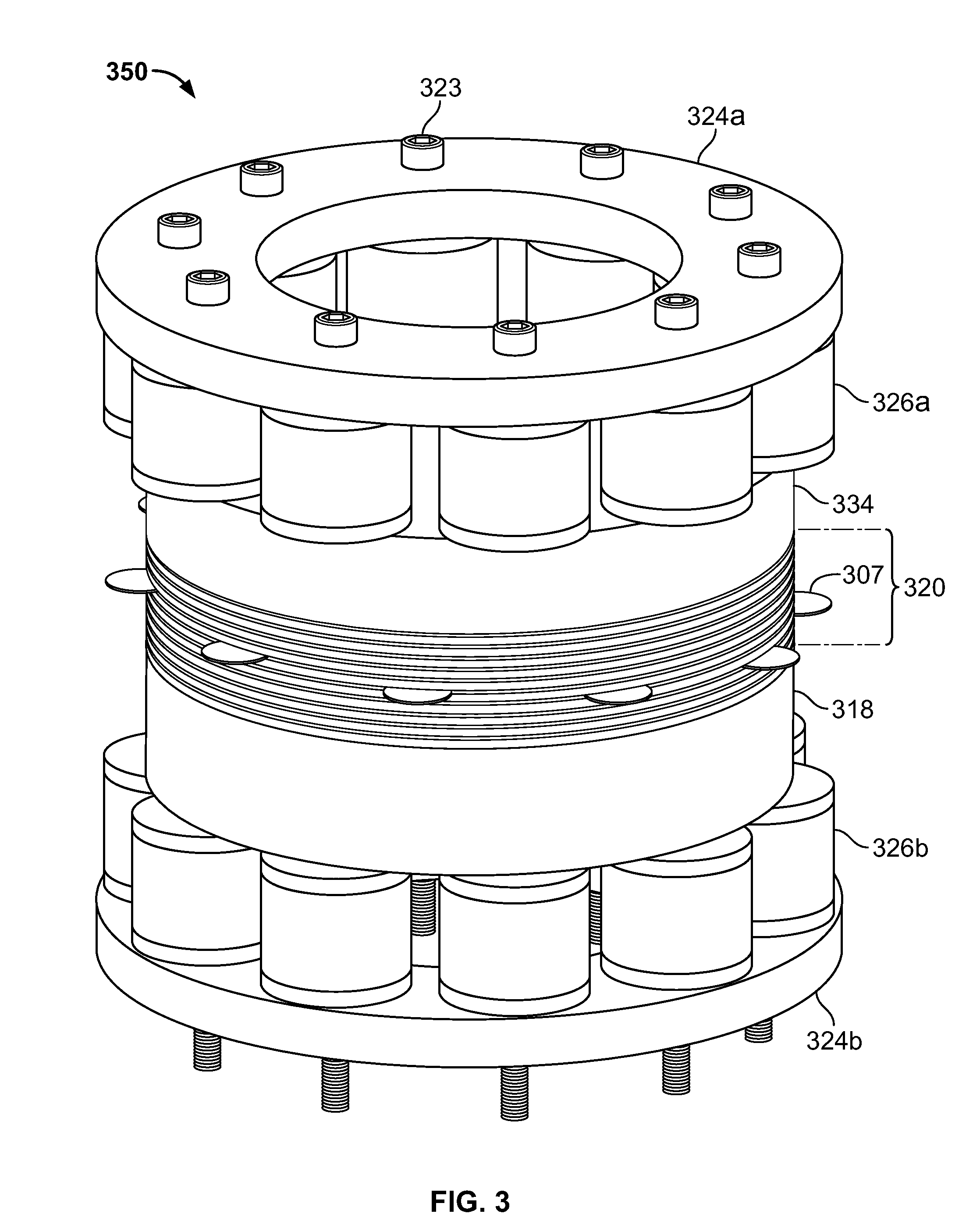

High rate seawater activated lithium battery cells bi-polar protected electrodes and multi-cell stacks

InactiveUS20110269007A1Significant motionReduce probabilityFinal product manufactureNegative electrodesHigh rateHigh energy

Water activated alkali metal battery cells, protected anode bi-polar electrodes and multi-cell stacks are configurable to achieve very high energy density. The cells, bi-polar electrode and multi-cell stacks include a protected anode and a cathode having a solid phase electro-active component material that is reduced during cell discharge.

Owner:POLYPLUS BATTERY CO INC

A bipolar battery and a biplate assembly

The present invention relates to a bipolar battery having at least two battery cells comprising: a negative end terminal, a positive end terminal and at least one biplate assembly arranged in a sandwich structure between the negative and positive end terminals. The battery also comprises a separator, with electrolyte, arranged between each negative and positive electrode forming a cell. An inner barrier of a hydrophobic material is arranged at least around one electrode on a first side of the biplate. An outer sealing, e.g. a frame, is provided around the edge of each biplate assembly and each end terminal and a hole is arranged through each biplate interconnecting each cell with adjacent cell(s) to create a common gas space for all cells in the battery. The invention also relates to a biplate assembly.

Owner:NILAR INT AB

Bipolar battery

ActiveUS20090233164A1Prevents liquid junction (short circuit)Improve reliabilityLarge-sized flat cells/batteriesFinal product manufactureFluid electrolytesPolymer gel

The present invention provides a bipolar battery made by using a polymer gel electrolyte or a liquid electrolyte in an electrolyte layer, which is highly reliable and prevents liquid junction (short circuit) caused by leak out of an electrolyte solution from the electrolyte part. The present invention provides a bipolar battery laminated, in series, with a plurality pieces of bipolar electrodes which is formed with a positive electrode on one surface of a collector, and a negative electrode on the other surface, so as to sandwich an electrolyte layer, characterized by being provided with a separator which retains the electrolyte later, and a seal resin which is formed and arranged at the outer circumference part of a part of the separator where the electrolyte is retained.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com