Electrode and production method thereof

a production method and technology of electrodes, applied in the direction of sustainable manufacturing/processing, secondary cell details, paper/cardboard containers, etc., can solve the problems of high contact resistance between electrodes, achieve the effect of preventing separation of active material layers, reducing contact resistance, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

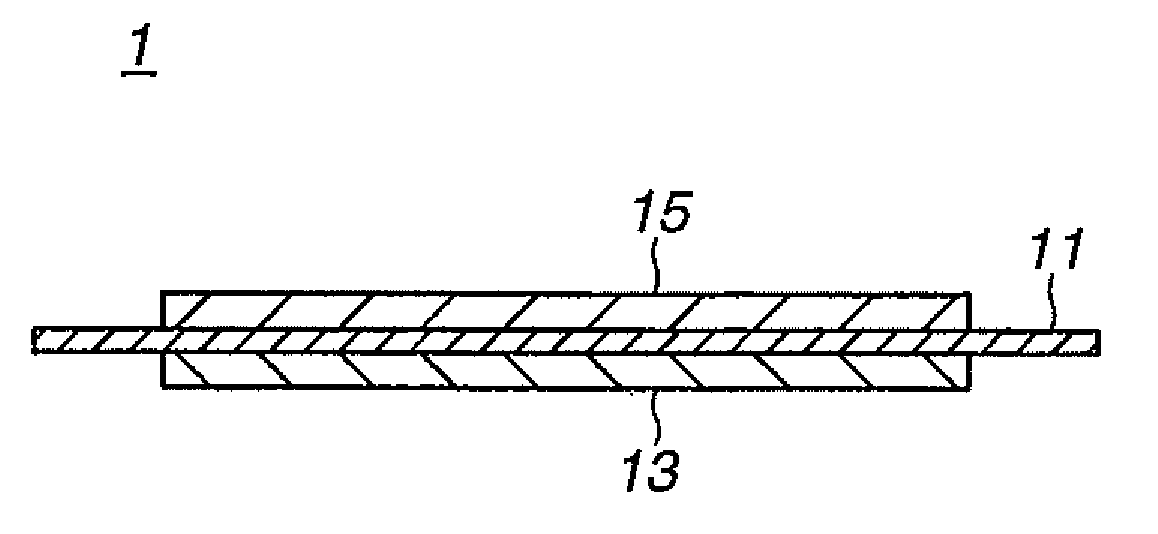

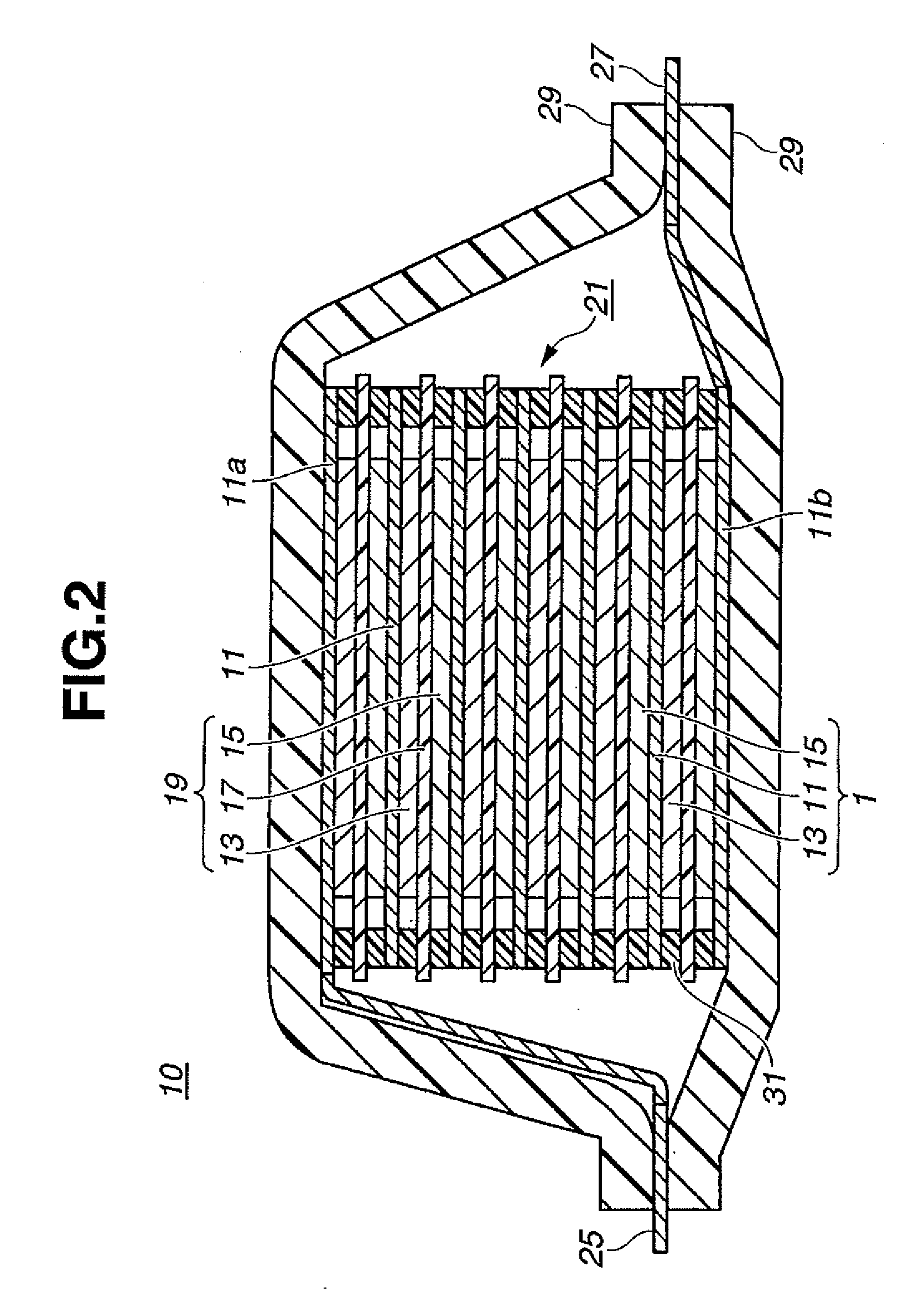

Image

Examples

example 1

1. Preparation of Positive Electrode Slurry

[0112]A positive electrode slurry (viscosity: 2000 cps) was prepared by adding an appropriate amount of N-methyl-2-pyrrolidone (NMP) as slurry viscosity adjusting solvent to a solid content of LiMn2O4 (average particle size: 5 μm) (85 mass %) as positive electrode active material, acetylene black (5 mass %) as conductive aid and polyvinylidene fluoride (PVdF) (10 mass %) as binder polymer. The softening point and melting point of PVdF are 134° C. and 169° C., respectively.

2. Preparation of Negative Electrode Slurry

[0113]A negative electrode slurry (viscosity: 2000 cps) was prepared by adding an appropriate amount of N-methyl-2-pyrrolidone (NMP) as slurry viscosity adjusting solvent to a solid content of hard carbon (average particle size: 5 μm) (85 mass %) as negative electrode active material, acetylene black (5 mass %) as conductive aid and polyvinylidene fluoride (PVdF) (10 mass %) as binder polymer. The softening point and melting point...

example 2

[0126]A bipolar battery was produced in the same manner as in Example 1, except that collectors (thickness: 50 μm) were formed using polypropylene (softening point: 140° C., melting point: 155° C.) (70 mass %) as the polymer material and fine carbon particles (30 mass %) as the conductive filler.

example 3

[0127]A bipolar battery was produced in the same manner as in Example 1, except that collectors (thickness: 50 μm) were formed using polypropylene (softening point: 140° C., melting point: 155° C.) (90 mass %) as the polymer material and fine Au particles (average particle size: 10 nm) (10 mass %) as the conductive filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com