A bipolar battery and a biplate assembly

A bipolar battery and bipolar plate technology, which is applied to battery pack components, batteries with bipolar electrodes, large-sized batteries/battery packs, etc., can solve problems such as pressure difference, achieve cost reduction, and be easy to manufacture , the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

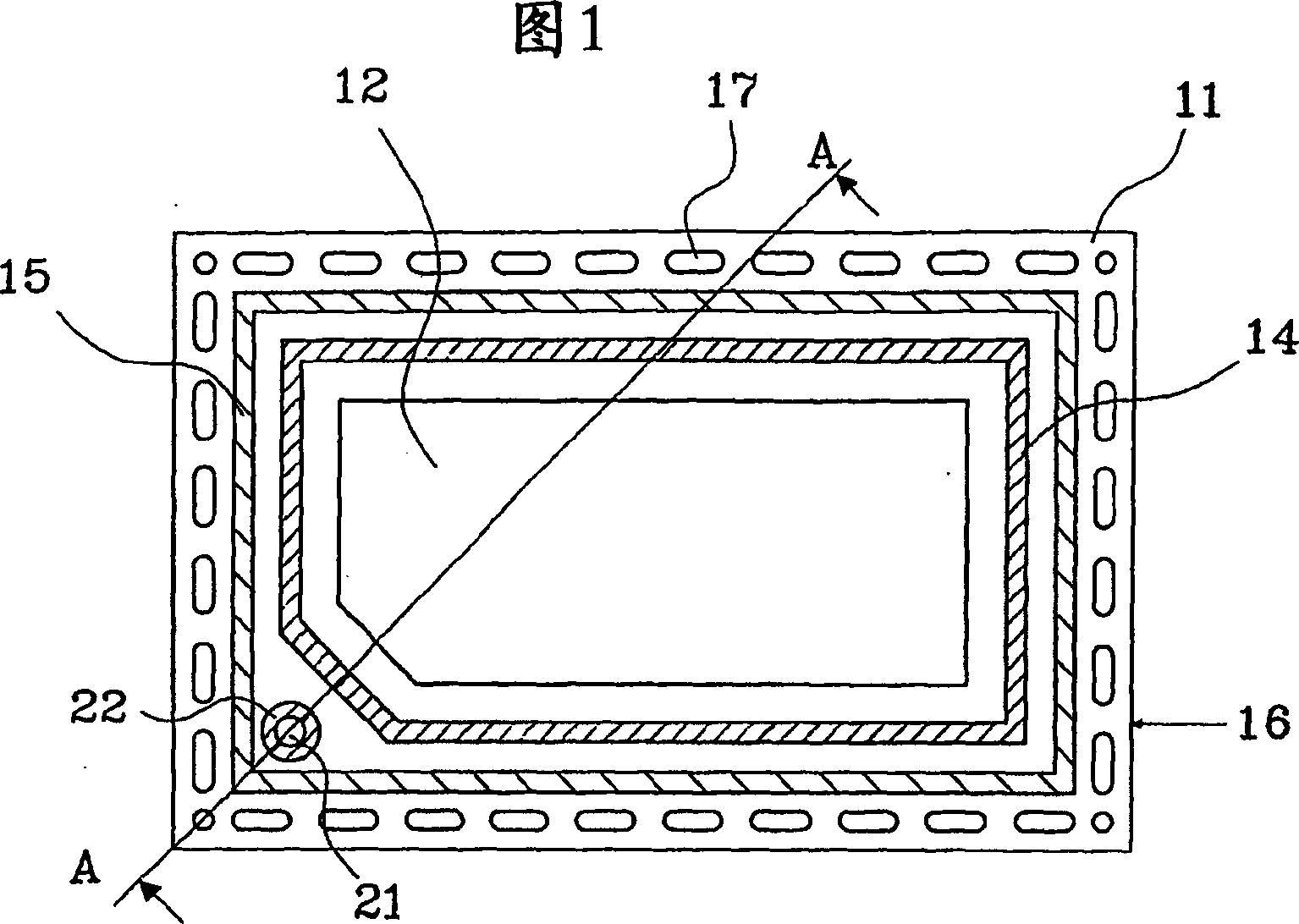

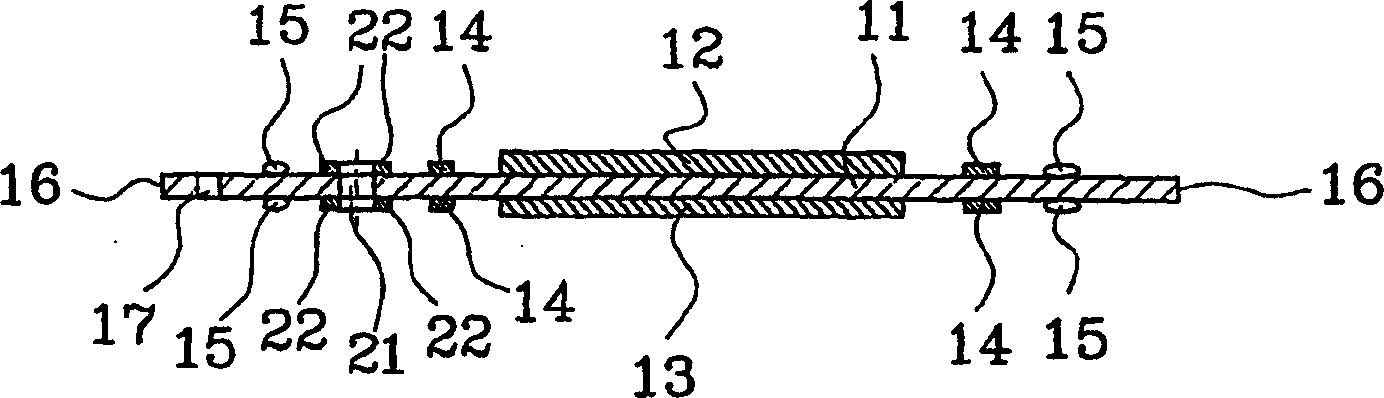

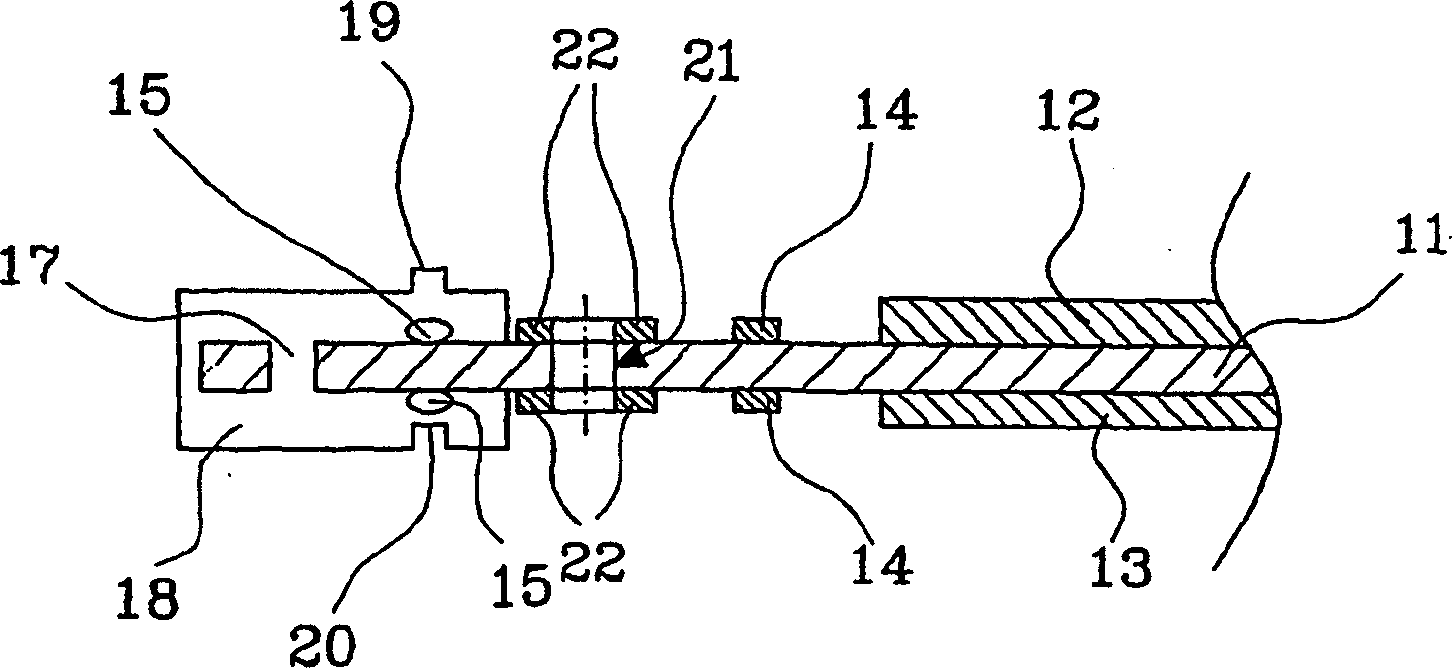

[0026] The main advantages of the bipolar battery design are simplicity and low resistive losses. The battery has a relatively low part count consisting only of end plates and bipolar plates with appropriate components and sealing elements. By laminating a required number of bipolar plates, a battery pack with a desired voltage is constructed. Since the bipolar plates are electrically conductive and impermeable to electrolyte, the electrical connections between the cells are formed when the cells are stacked.

[0027] With terminals at each end, current flows perpendicular to the plates, which ensures uniform current and voltage distribution. Since the current path is very short, the voltage drop is significantly reduced.

[0028] Bipolar plates also have significantly reduced weight, volume, and manufacturing costs due to the elimination of components and manufacturing methods.

[0029] Bipolar Batteries The main problem that has not been solved commercially until now is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com