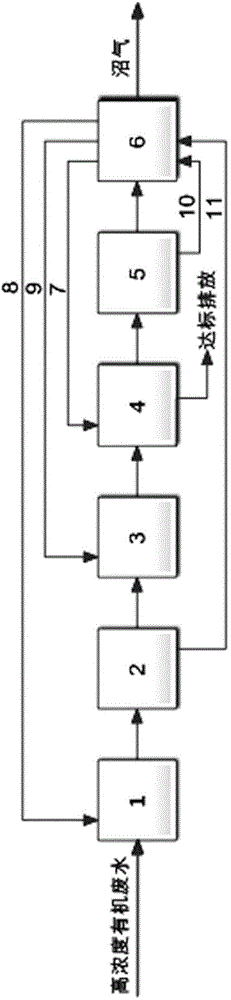

Inner-loop anaerobic membrane bioreactor treatment method and equipment for high-concentration organic wastewater

An anaerobic membrane biology and internal circulation technology, which is applied in anaerobic digestion treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of urgent short-process demand, complex factory management, and large land occupation. Achieve the effect of improving COD methanation rate, simplifying treatment process and high volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

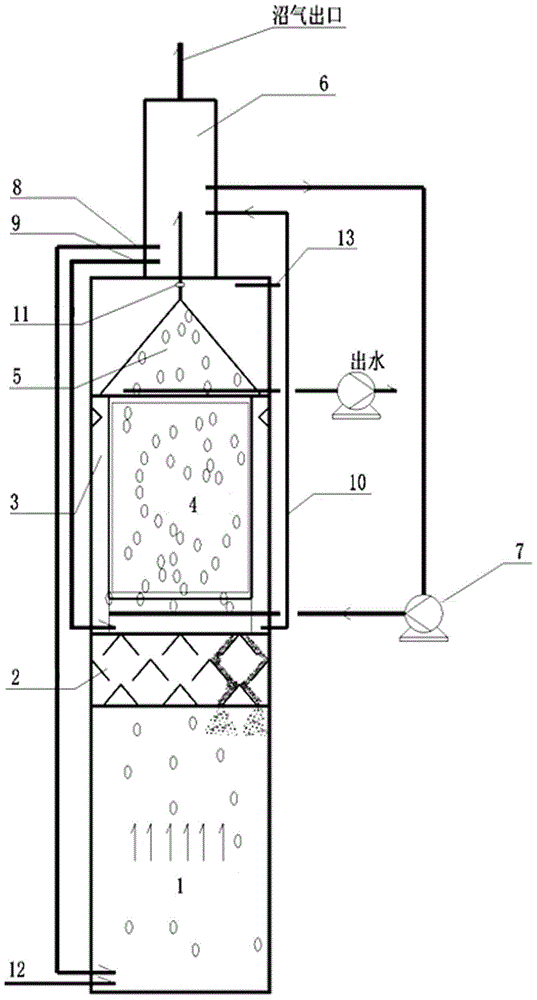

[0059] The internal circulation anaerobic membrane bioreactor in this embodiment is cylindrical, with a height-to-diameter ratio of 4-9.

[0060] The anaerobic sludge was inoculated according to the different sludge concentrations in the first reaction chamber 1 and the second reaction chamber 3 . The wastewater from the agricultural and sideline food processing industry pumped in from the water inlet pipe is transported to the first reaction chamber, and then passes through the three-phase separator in the first reaction chamber, the second reaction chamber, the three-phase separator in the second reaction chamber, the gas-water Separator, and then back to the first reaction chamber to form an internal reflux. During the whole operation process, keep the water temperature of the internal circulation anaerobic membrane bioreactor at 35-37°C, the first reaction chamber is high-concentration (10.0-30.0g / L) granular sludge, and the second reaction chamber has a sludge concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com