Production method of novel slow release urea-formaldehyde compound fertilizer

A production method, urea-formaldehyde technology, applied in urea compound fertilizer, nitrogen fertilizer, fertilization equipment, etc., to achieve the effect of improving utilization rate, not easy to agglomerate, and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

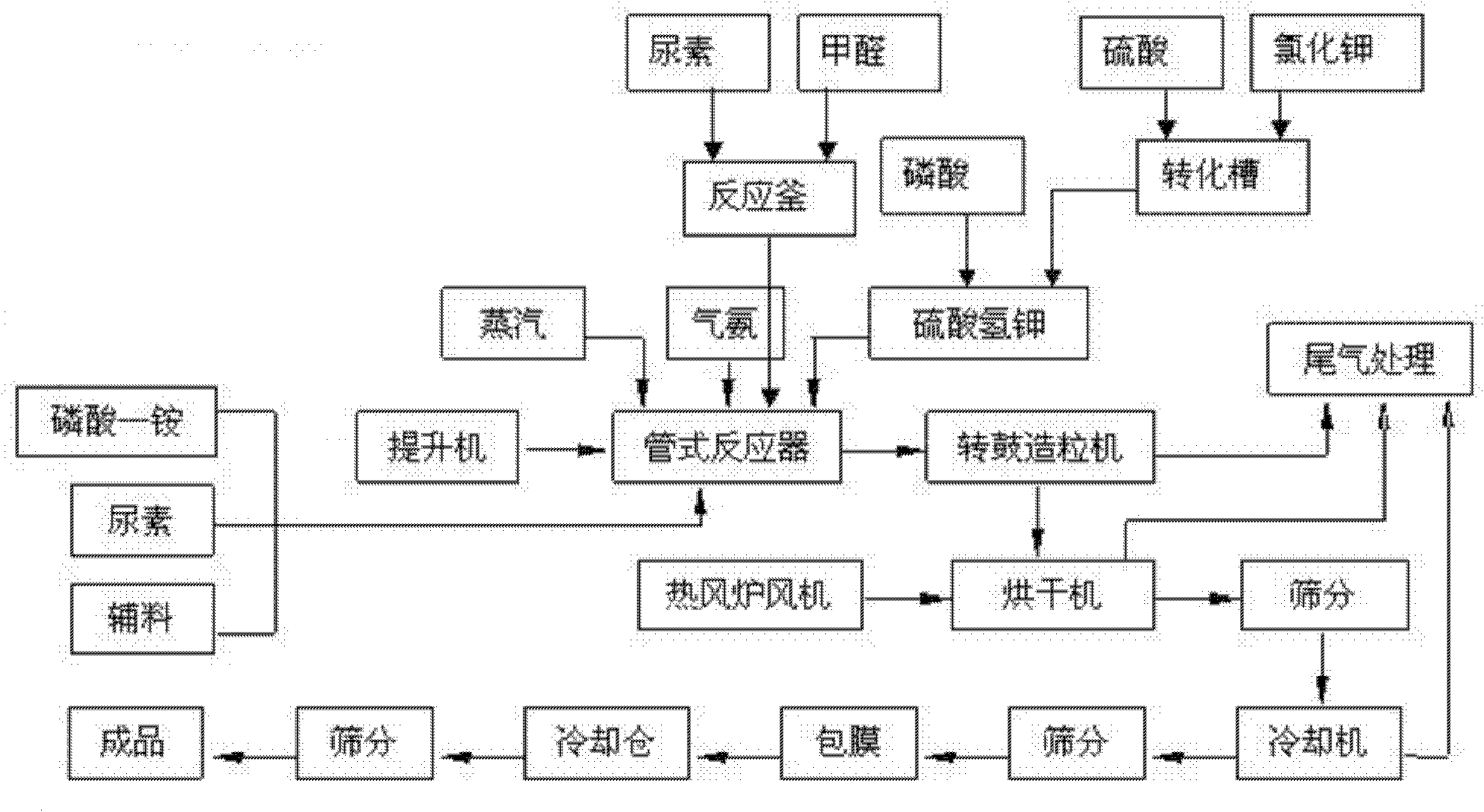

Image

Examples

Embodiment 1

[0034] The production method of the novel granular urea-formaldehyde sulfur-based compound fertilizer of the present embodiment is as follows:

[0035] (1) Potassium bisulfate solution is made by the reaction of 98% concentrated sulfuric acid and Repone K: 98% concentrated sulfuric acid refers to the concentrated sulfuric acid that mass concentration is 98%, 120 ℃ of concentrated sulfuric acid temperature, adding speed is 2.34 cubic / hours; Potassium chloride contains around 61% K 2 O, adding speed is 5 tons / hour. The mass-to-volume ratio of the potassium chloride added and the 98% concentrated sulfuric acid of reaction is potassium chloride: concentrated sulfuric acid=1000: 0.85 (kg: m 3 ).

[0036] (2) Potassium hydrogen sulfate solution is mixed with phosphoric acid to generate mixed acid slurry: the concentration of described phosphoric acid is 19.5%, and the density of potassium hydrogen sulfate solution is 1.70 g / ml, and potassium hydrogen sulfate solution is mixed wi...

Embodiment 2

[0049] The production method of the novel granular urea-formaldehyde sulfur-based compound fertilizer of the present embodiment is as follows:

[0050] (1) Potassium bisulfate solution is made by the reaction of 98% concentrated sulfuric acid and potassium chloride: the concentration of concentrated sulfuric acid is 98%, the temperature of concentrated sulfuric acid is 120 ° C, and the addition speed is 4.75 cubic / hour; potassium chloride contains about 61% K 2 O, adding speed is 10 tons / hour. The mass ratio of the added potassium chloride and 98% concentrated sulfuric acid is 1 ton of potassium chloride: 0.87 cubic concentrated sulfuric acid. (i.e. potassium chloride: concentrated sulfuric acid = 1000: 0.87 (kg: m 3 ))

[0051] (2) Potassium hydrogen sulfate solution is mixed with phosphoric acid to generate mixed acid slurry: the concentration of described phosphoric acid is 22%, and the density of potassium hydrogen sulfate solution is 1.50 g / ml, and potassium hydrogen su...

Embodiment 3

[0060] The production method of the novel granular urea-formaldehyde-based compound fertilizer of the present embodiment is as follows:

[0061] (1) Potassium bisulfate solution is made by the reaction of 98% concentrated sulfuric acid and potassium chloride: concentrated sulfuric acid concentration 98%, concentrated sulfuric acid temperature 120 ℃, adding speed is 2.74 cubic / hour; Potassium chloride contains about 61% K 2 O, adding speed is 6 tons / hour. The volume mass ratio of the potassium chloride added and the 98% vitriol oil of reaction is 1000: 0.83 (kg: m 3 ).

[0062] (2) Potassium hydrogen sulfate solution is mixed with phosphoric acid to generate mixed acid slurry: the concentration of described phosphoric acid is 20.0, and the density of potassium hydrogen sulfate solution is 1.50 g / ml, and potassium hydrogen sulfate solution is mixed with phosphoric acid to generate the density of mixed acid slurry was 1.39 g / ml.

[0063] (3) After pre-neutralizing the mixed ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com