Preparation of ammonium potassium dihydrogen phosphate

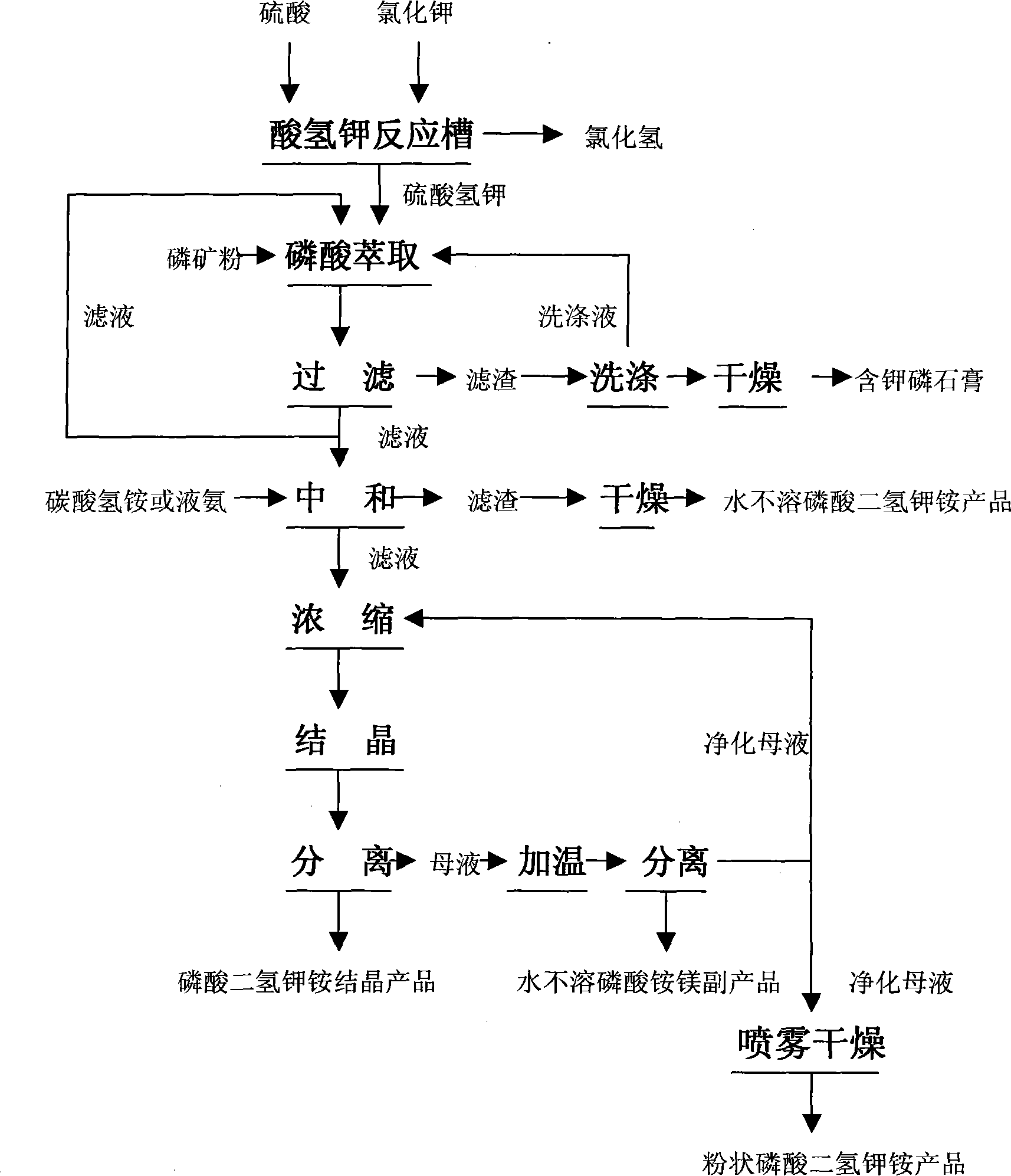

A technology of potassium ammonium dihydrogen phosphate and potassium hydrogen sulfate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of inability to popularize potassium ammonium dihydrogen phosphate on a large scale, high production cost, complicated process, and the like, Achieve the effect of reducing equipment investment and energy consumption, low production cost and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A, the concentration is 97.5% sulfuric acid and K 2 Potassium chloride with an O content of 59.8%, by H 2 SO 4 : After the mol ratio of KCl=3.5: 1 mixes, react at 110 ℃ of temperature for 60 minutes, obtain the mixed solution of potassium bisulfate and sulfuric acid, and the hydrogen chloride gas that reaction produces sends hydrochloric acid operation production hydrochloric acid;

[0024] B. Add phosphoric acid back into the phosphoric acid extraction tank of the common sulfuric acid wet phosphoric acid process in advance, and the P in the phosphoric acid back 2 o 5 Not less than 15%, K 2 Under the condition that O is not less than 4%, the mixed solution obtained in step A and the phosphate rock powder crossing 100 mesh sieves are added respectively in the phosphoric acid extraction tank by the mass ratio of mixed solution: phosphate rock powder=0.8:1, and The liquid-solid ratio of the slurry is 2.8:1, and the liquid phase SO 3 The concentration is 30-50 g / L, the...

Embodiment 2

[0033] A, the concentration is 97.5% sulfuric acid and K 2 O content is the agricultural grade potassium sulfate of 49.41%, after mixing by sulfuric acid: the mol ratio of potassium sulfate=5.4:1, obtains the mixed solution of potassium bisulfate and sulfuric acid;

[0034] B. Add phosphoric acid back into the phosphoric acid extraction tank of the common sulfuric acid wet phosphoric acid process in advance, and the P in the phosphoric acid back 2 o 5 Not less than 15%, K 2 Under the condition that O is not less than 4%, the mixed solution obtained in step A and the phosphate rock powder crossing 100 mesh sieves are added respectively in the phosphoric acid extraction tank by the mass ratio of mixed solution: phosphate rock powder=0.9:1, and The liquid-solid ratio of the slurry is 2.6:1, and the liquid phase SO 3 The concentration is 30-50 g / L, the reaction temperature is 75°C, and the reaction is carried out for 6 hours; the slurry after the reaction is filtered, the filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com